Preparation method for NiZn ferrite film

A ferrite film and ferrite technology, which is applied in the field of low-temperature deposition of NiZn ferrite film preparation, can solve the problems of incompatibility of semiconductor processes, achieve good crystallization performance, increase the cut-off frequency, and improve the effect of fr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

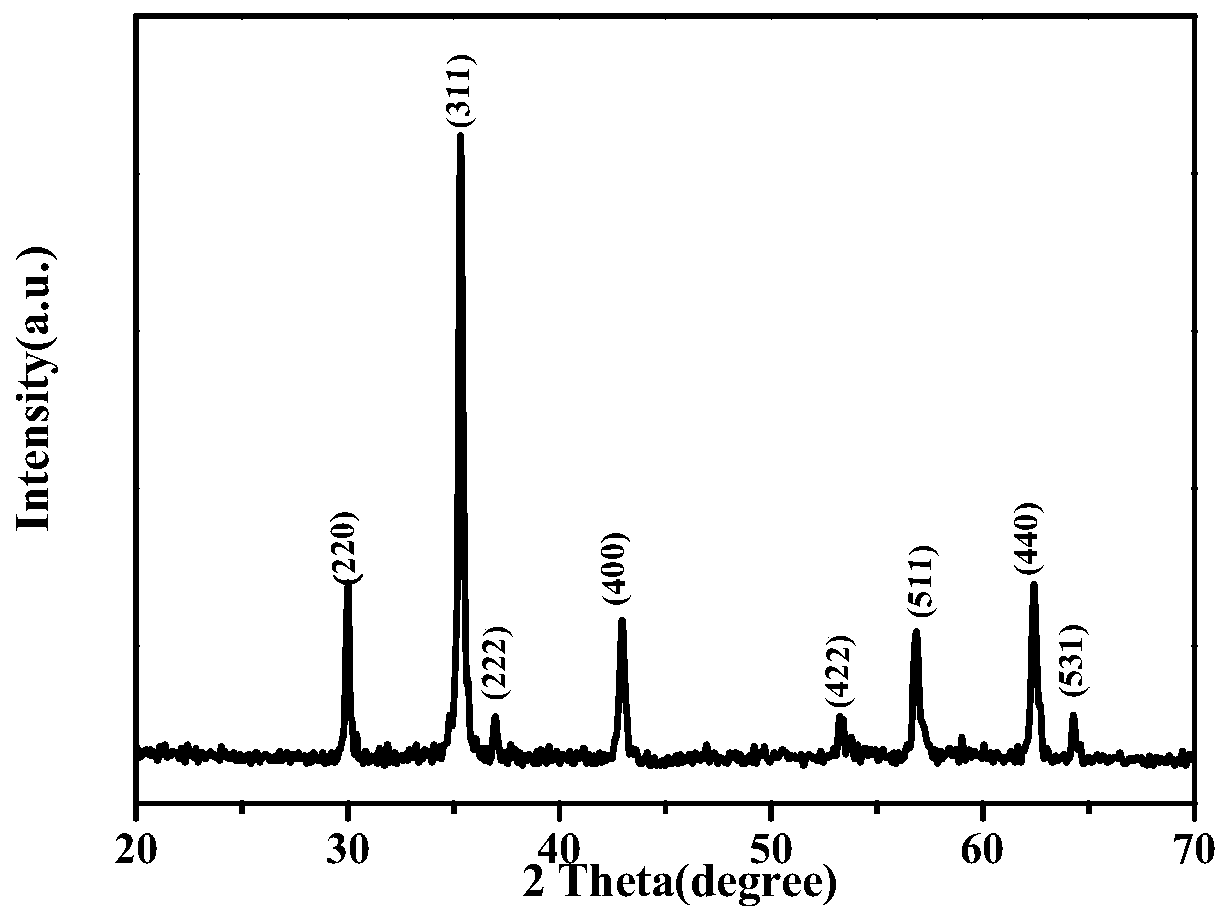

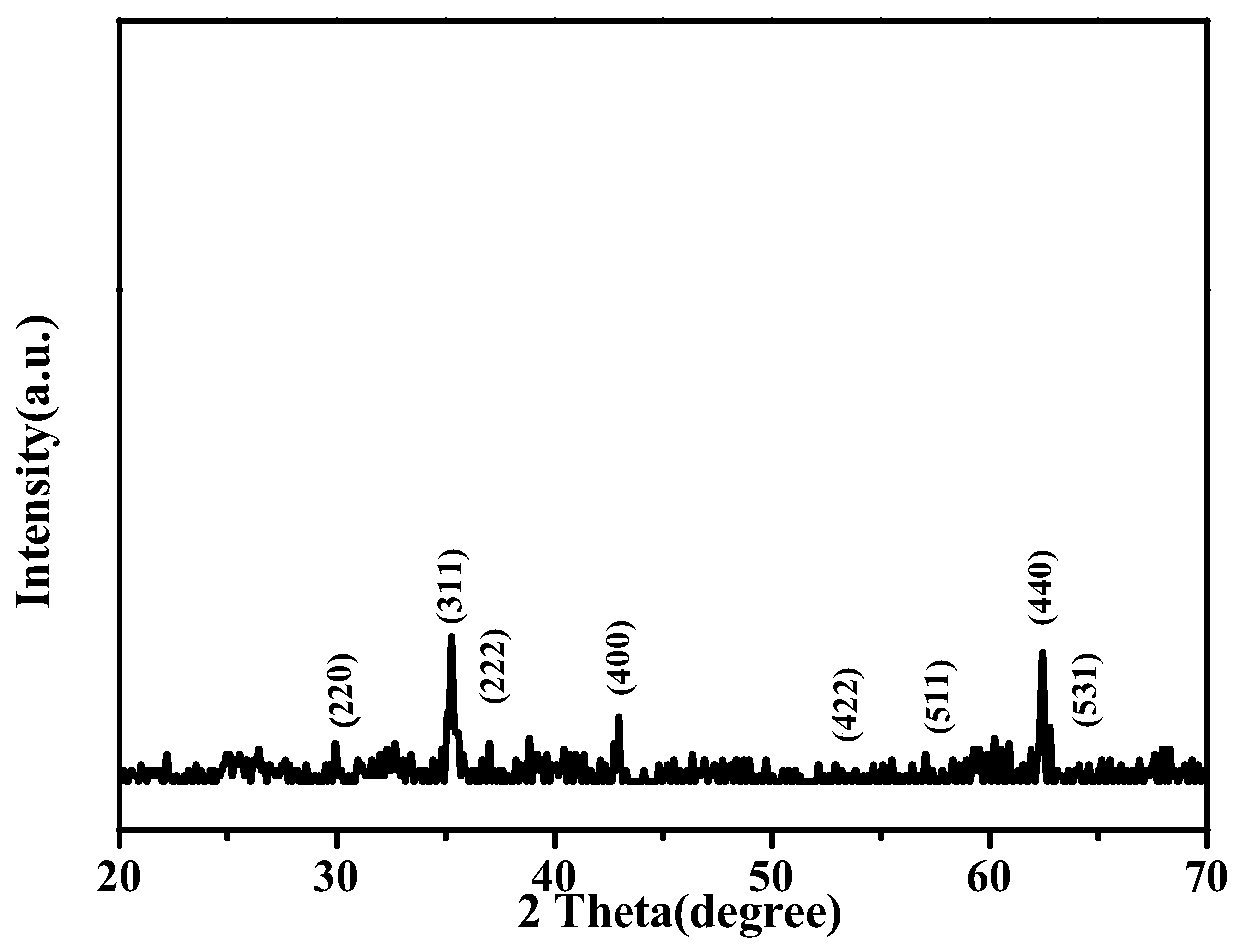

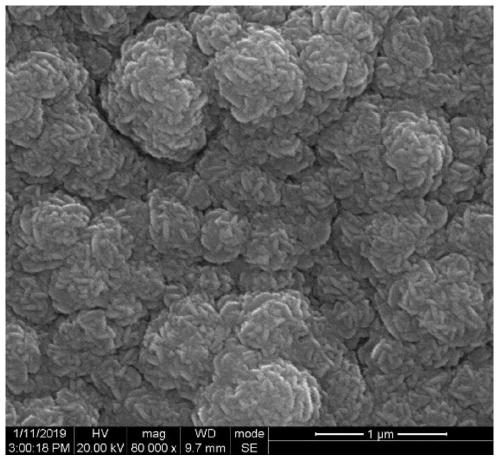

Image

Examples

Embodiment 1~4

[0037] A kind of preparation method of NiZn ferrite film, specifically comprises the following steps:

[0038] Step 1, depositing a NiZn ferrite seed layer on the substrate by a spin spraying method;

[0039] 1.1 FeCl 2 、NiCl 2 and ZnCl 2 Add 100mL deionized water to prepare a reducing solution; wherein, FeCl 2 The concentration is 1.51g / L, NiCl 2 The concentration is 0.26g / L, ZnCl 2 The concentration is 0.09g / L;

[0040] 1.2 Add sodium nitrite and sodium acetate into 100mL of deionized water, and mix well to obtain an oxidizing solution; wherein, the concentration of sodium nitrite is 0.15g / L, and the concentration of sodium acetate is 1.34g / L;

[0041] 1.3 Using an ultrasonic atomization system, deposit a NiZn ferrite seed layer on a glass substrate: first, atomize the reducing solution obtained in step 1.1 and the oxidizing solution obtained in step 1.2 into droplets with a particle size of 38 μm; then, The reducing solution and the oxidizing solution are respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com