Ferrite material, ferrite film formed thereof, and radio frequency identification tag with ferrite film

A ferrite material and ferrite film technology, applied in the field of radio frequency identification tags, can solve the problem that composite materials are not effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

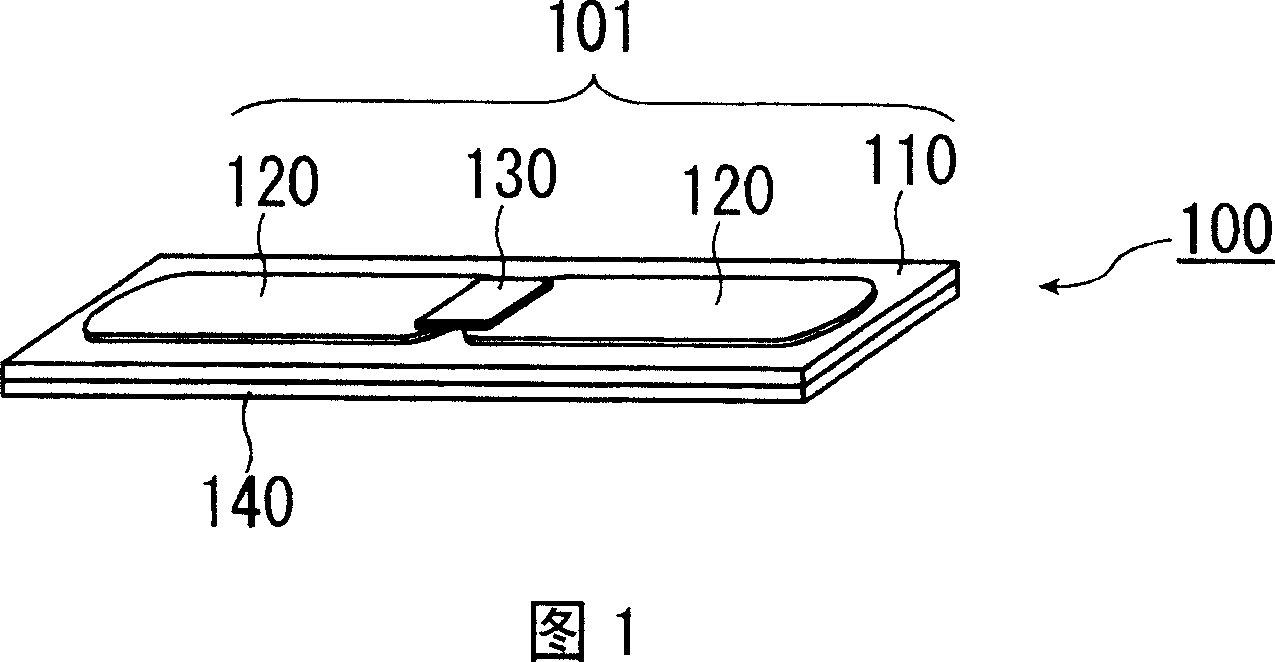

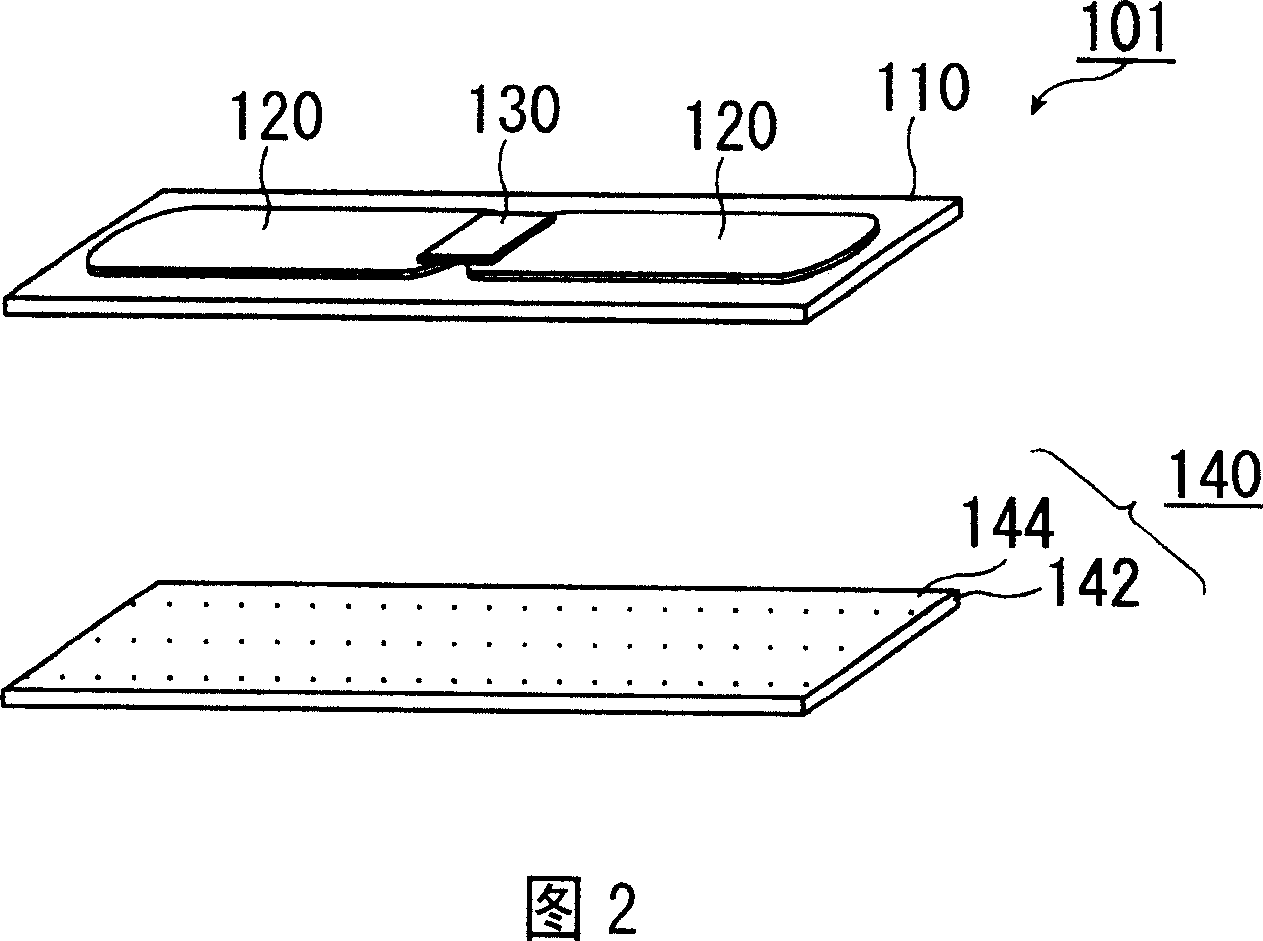

[0021] Referring to FIGS. 1 and 2 , an RFID tag 100 according to an embodiment of the present invention includes a main member 101 and a ferrite sheet 140 glued to the bottom surface of the main member 101 . The illustrated main member 101 includes a label base 110 . In this embodiment, the label substrate 110 is made of polyethylene terephthalate (PET). On the top surface of the label substrate 110, a plane antenna conductor 120 is formed by printing. On the center of the antenna wire 120, an integrated circuit (IC) chip is mounted.

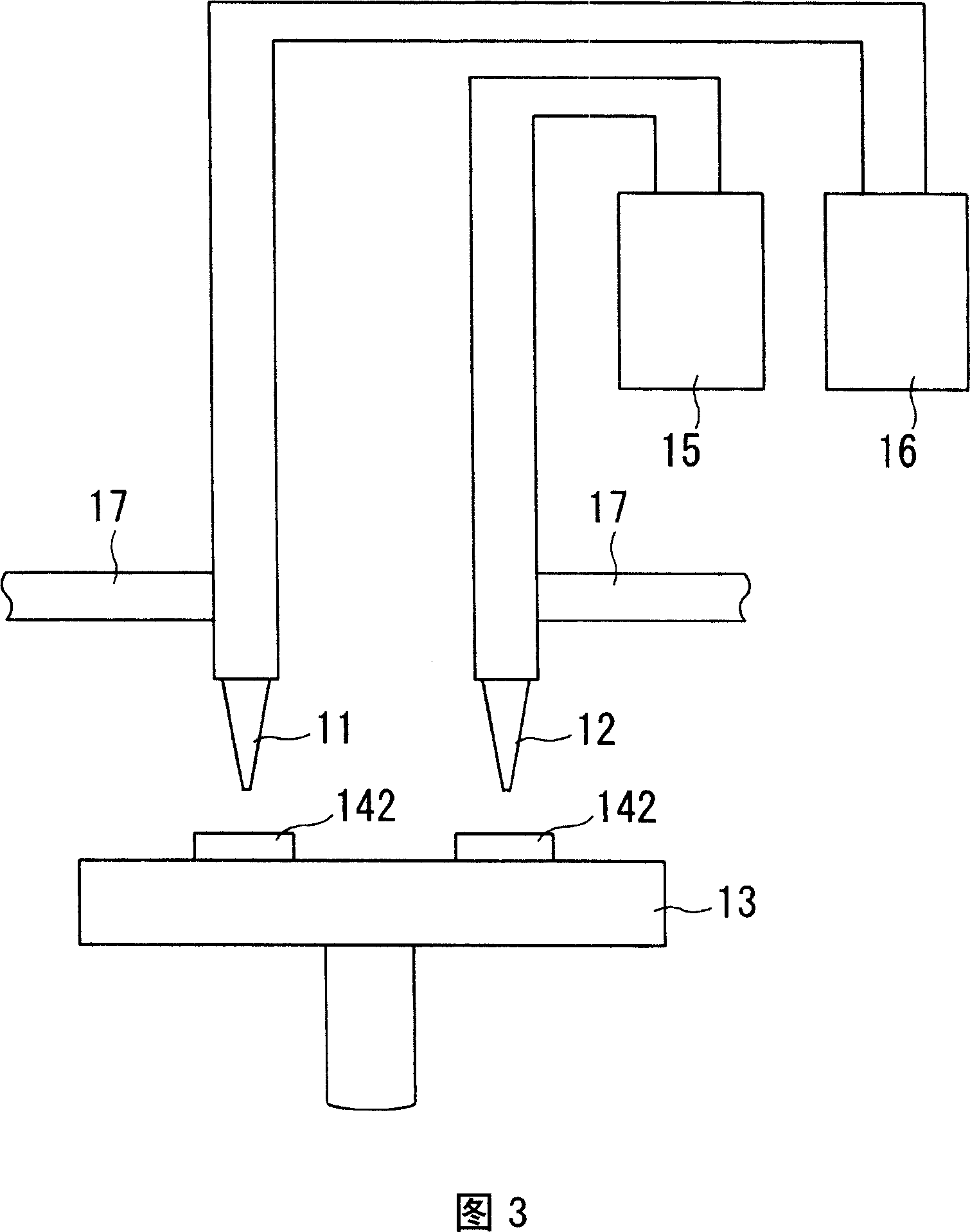

[0022] As shown in FIG. 2, the illustrated ferrite sheet 140 includes a supporter sheet made of polyimide on the surface on which a ferrite thin film 144 is directly formed by a ferrite plating method. 142. The ferrite plating method is as disclosed in USP 4,477,319, the contents of which are hereby incorporated by reference in their entirety. The ferrite electroplating method of the present embodiment comprises the steps of: preparing a spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com