Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Crystal oven" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crystal oven is a temperature-controlled chamber used to maintain the quartz crystal in electronic crystal oscillators at a constant temperature, in order to prevent changes in the frequency due to variations in ambient temperature. An oscillator of this type is known as an oven-controlled crystal oscillator (OCXO, where "XO" is an old abbreviation for "crystal oscillator".) This type of oscillator achieves the highest frequency stability possible with a crystal. They are typically used to control the frequency of radio transmitters, cellular base stations, military communications equipment, and for precision frequency measurement.

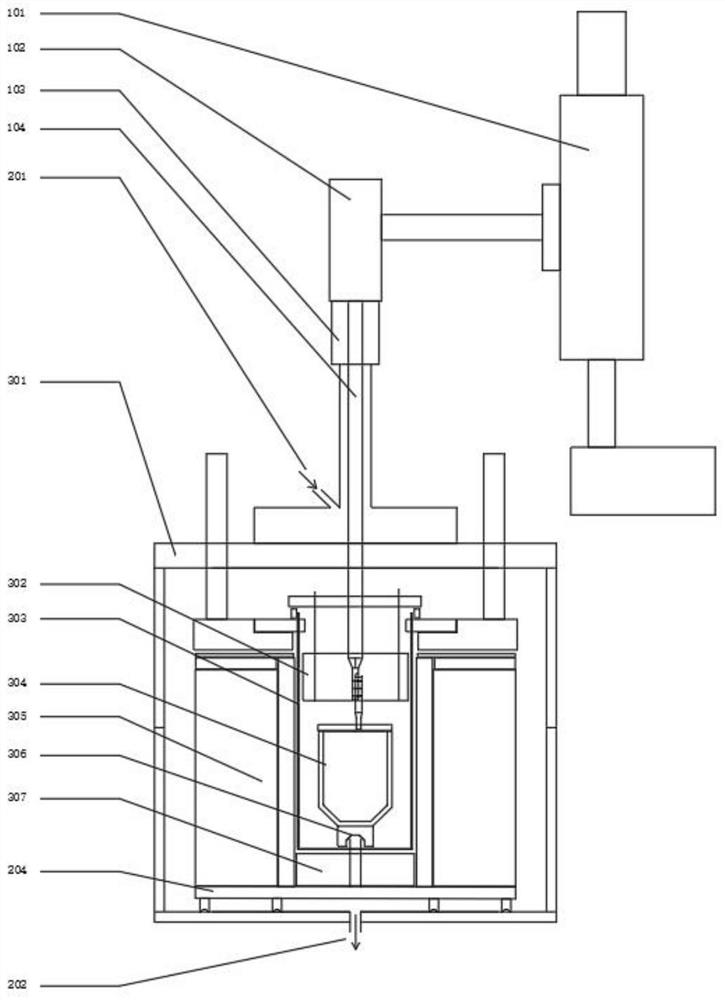

Growth early-stage control method of automatic photoelectric crystal furnace

InactiveCN101824649AFully automatedAvoid interferencePolycrystalline material growthTemperature controlControl system

The invention relates to a growth early-stage control method of an automatic photoelectric crystal furnace. The automatic photoelectric crystal furnace comprises a furnace body, a lifting rod, a heating module, a temperature measuring module, a temperature control module, a lifting module, a rotating module, a monitoring module and a control system. The method comprises the following steps: heating and smelting furnace body crystal materials; using the lifting rod for feeding crystals so that seed crystals on the lifting rod can go under the liquid level of the furnace body; entering a next step when the liquid absorbs the seed crystals; lifting and rotating the lifting rod to enter the neck reduction process; using the monitoring module for reading the weight of the rest seed crystals in the furnace body; lowering the heating temperature when the monitored crystal growth speed rate is a negative value; raising the heating temperature when the monitored crystal growth speed rate is a great positive value; completing the neck reduction process when a neck reduction part reaches the preset length; improving the growth speed rate of the crystals so that the diameter of the crystals becomes larger from a small value until the preset crystal diameter is reached; and completing the growth early stage.

Owner:SUN YAT SEN UNIV

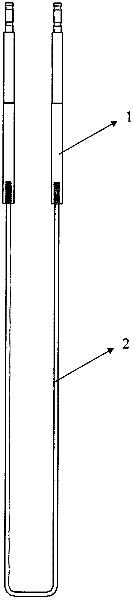

Optical fiber radiation thermometer based on colorimetric method

InactiveCN104330170AImprove the problem of easy foldingHigh precisionPyrometry using electric radation detectorsCamera lensRadiation thermometer

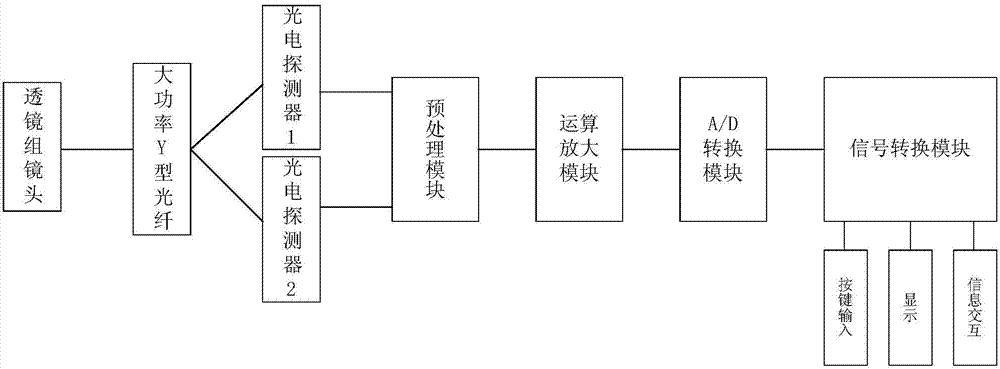

The invention discloses an optical fiber radiation thermometer based on a colorimetric method, and belongs to the field of high temperature measurement. The thermometer comprises an optical system and a circuit system, wherein lenses of a lens group are connected with a high-power Y-type power transmission optical fiber to form the optical system; the circuit system adopts signal dual-channel processing and comprises photoelectric detectors, a preprocessing module, a preamplifier, an AD sampling module, a signal processing module, a display module, a keyboard input module and an information interaction module. Signals are divided into two paths via the power transmission optical fiber and transmitted to the corresponding photoelectric detectors, optical signals are converted into current signals, the current signals are converted into voltage signals via the preprocessing module and the pre-amplification module, the signal processing module adopts a curve fitting algorithm for analysis, sampling signals are obtained, a corresponding temperature value is calculated through calibration, and difference setting is further improved through the interaction module. The optical fiber radiation thermometer structure based on the colorimetric method can be applied to measurement of a crystal furnace thermal field.

Owner:NANJING NORMAL UNIVERSITY

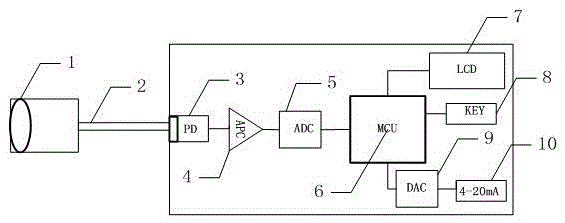

Portable optical fiber radiation thermodetector and measuring method thereof

InactiveCN103616080AWide coupling wavelength rangeImprove coupling efficiencyPyrometry using electric radation detectorsElectricityPhotovoltaic detectors

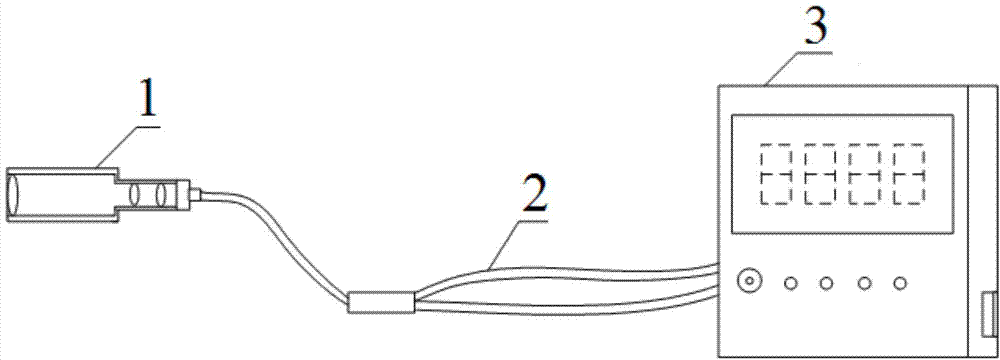

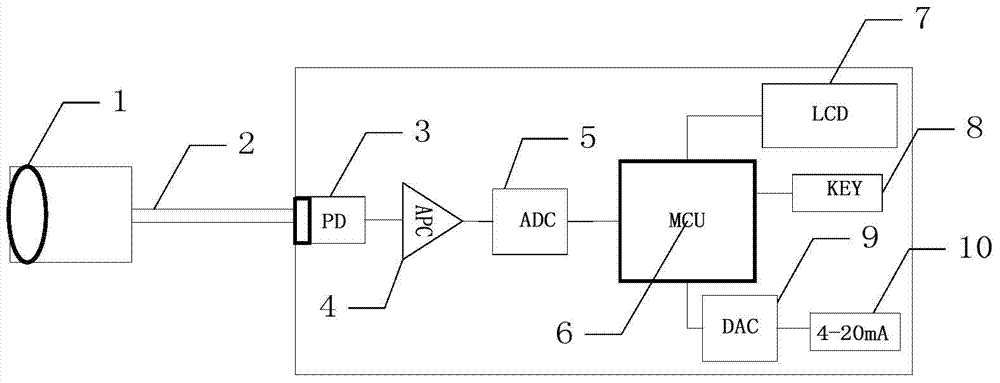

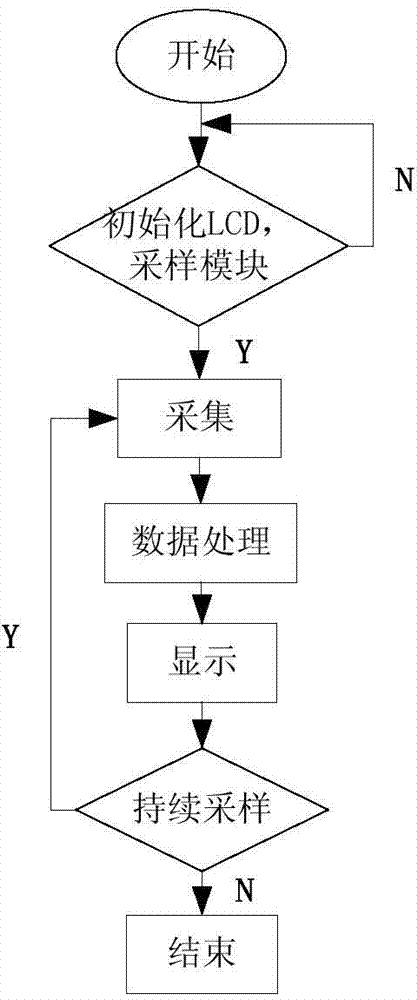

The invention discloses a portable optical fiber radiation thermodetector and a measuring method of the portable optical fiber radiation thermodetector, and belongs to the field of pyrometry. The thermodetector comprises a high-power optical fiber coupler, an energy transmitting optical fiber, a photoelectric detector, a pre-amplification module, an AD sampling module, a signal processing module, a display module, a keyboard input module, a digital-to-analog conversion module and a 4-20mA current loop. Thermal radiation energy at a broadband spectrum is coupled by the high-power optical fiber coupler and transmitted to the photoelectric detector by the energy transmitting optical fiber to convert optical signals into electrical signals, the electrical signals are sampled by the AD sampling module, obtained sampled signals are analyzed by the signal processing module through the curve-fitting algorithm, and a corresponding temperature value can be worked out finally through calibration. The portable optical fiber radiation thermodetector is very suitable for measuring crystal oven thermal fields due to the structure, easy and convenient to use and very practical.

Owner:NANJING NORMAL UNIVERSITY

Method for preparing special magnesium borate for oriented silicon steel

The invention relates to the field of oriented silicon steel plate manufacture, in particular to a method for preparing special magnesium borate for oriented silicon steel. The method solves the problems of poor adhesion, dispersibility and electromagnetic performance and the like of the conventional boron aid. The method comprises the following steps of: (1) pouring aqueous solution of magnesium bicarbonate and boric acid in a ratio into a reaction kettle; (2) performing sedimentation treatment on the mixed solution; (3) then conveying the sediment into a pyrolysis tank, adding finished magnesium borate crystal seeds and silane coupling agent into the pyrolysis tank, and producing a mixture of nano magnesium carbonate and metaboric acid by using a liquid phase precipitation method; (4) filter-pressing the pyrolysis product to obtain filter cakes; (5) treating the filter cakes in a high-temperature crystal oven to form nano magnesium borate powder with complete crystal; and (6) grading the material discharged out of the high-temperature crystal oven with jet milling to obtain a screened substance of less than or equal to 320 meshes. All indexes of the special magnesium borate are superior to that of the primary product, and in particular, the adhesion, dispersibility and electromagnetic performance are remarkably improved, and the quality of the oriented silicon steel plate is improved; and the method has the advantages of simple production process, lower cost and no three-waste pollution.

Owner:山西银圣科技有限公司

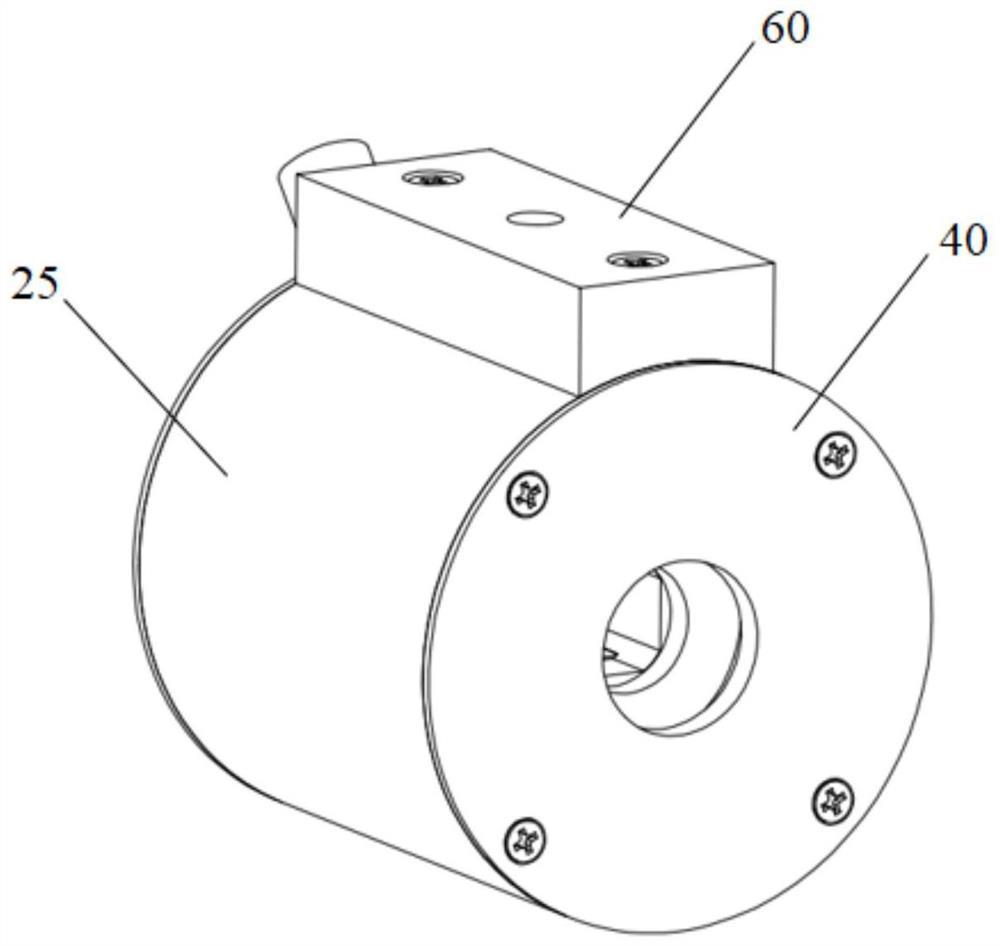

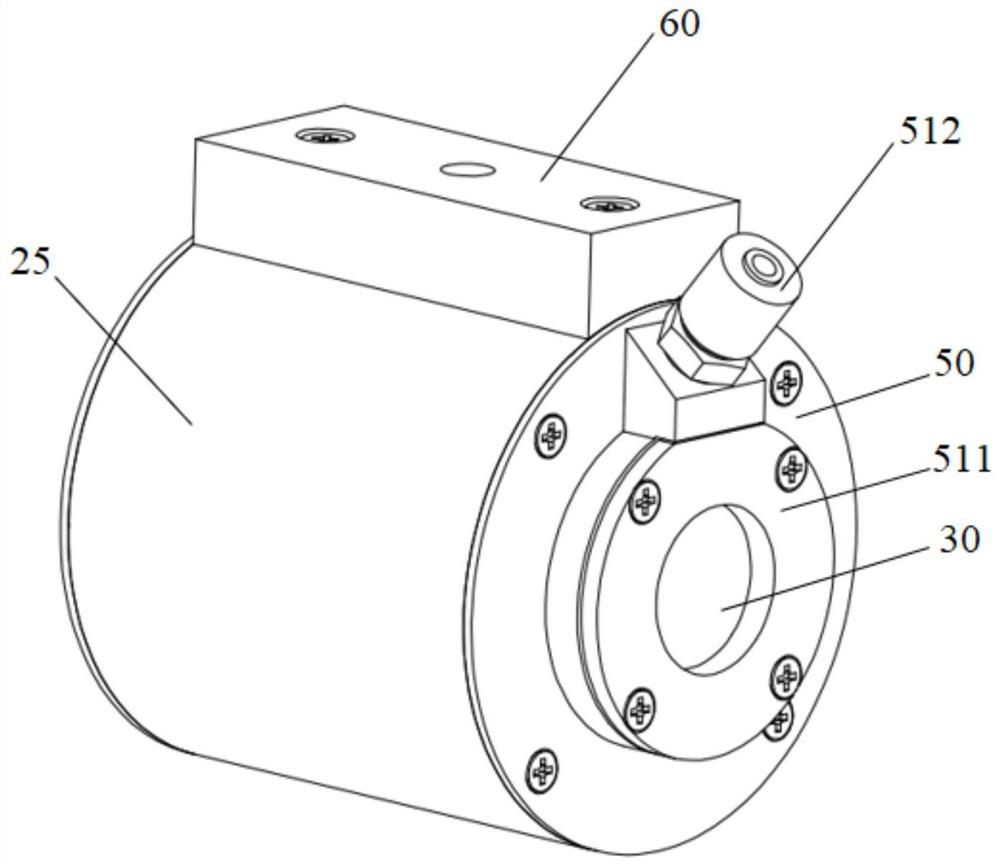

Optical resonator

ActiveCN108462029AGuaranteed connectivityReduce phase jitterOptical resonator shape and constructionNon-linear opticsEngineeringCrystal oven

The present invention provides an optical resonator. The optical resonator comprises a housing consisting of a main body portion and a rear end cover, wherein the main body portion has a cavity, and the rear end cover is arranged on the main body portion in a mode for sealing an opening at the rear side of the cavity; a red copper crystal oven with nonlinear crystal arranged in the cavity; and piezoelectric ceramics and an output mirror arranged in the rear end cover, wherein the nonlinear crystal, the piezoelectric ceramics and an optical path of the output mirror communicate in order and arearranged in the same straight line. The objective of the invention is to provide an optical resonator capable of reducing phase jittering and improving the phase stability.

Owner:SHANXI UNIV

Lining for polysilicon crystal oven wall protection and manufacturing method thereof

ActiveCN101775639AHighlight substantive featuresSignificant progressAfter-treatment apparatusPolycrystalline material growthIron oxideCrystal oven

The invention relates to a lining for polysilicon crystal oven wall protection and a manufacturing method thereof; the shape of the lining is in a regular hemispherical opaque three-dimensional structure, and the upper part thereof is open; the mass ratio of the components is as follows: silicon dioxide is more than 99.6 weight percent, alumina is less than 800ppm, and ferric oxide is less than 40ppm. The process comprises the following steps: raw material high-purity quartz is put into granulating equipment for wet granulation, grout is then taken out and fully stirred, placed and poured into a pressure device, and injected into a plaster mold; in pre-grouting, the plaster mold is slightly vibrated, and the grout is put into the mold and stays still so that the grout is fully dehydrated, and demolded; after demolding, the grout is dried in a dryer, an embryo prepared is put into a kiln to be sintered, and the opaque quartz lining is prepared after sintering; and finally a layer of silicon nitride is sprayed on the inner wall of the opaque quartz lining. The invention produces the matched oven wall protection quartz lining according to the technical requirements of a multicrystal furnace, effectively prevents the harm of silicon leakage in the crystallization process of the crystal oven to the multicrystal furnace, and is simple and practical.

Owner:常熟华融太阳能新型材料有限公司

83kg-grade sapphire crystal furnace crystal-growing structure and crystal-growing method

InactiveCN104499043AImprove sealingReasonable designPolycrystalline material growthBy pulling from meltFurnace temperatureNarrow range

The invention discloses an 83KG-grade sapphire crystal furnace crystal-growing method which comprises the following steps: S1, equipment checking and loading; S2, finding crystal pattern melting critical power; S3, performing amethyst preheating under the condition of the stable power of 80-84kW, controlling the furnace temperature at the stabilization stage to reach the seeding temperature, descending the seed rod to a safe position at a constant speed, and getting ready to enter into the crystal cleaning and trial temperature stage; S4, cleaning the crystal and seeding; S5, shouldering; S6, growing crystals; S7, annealing; and S8, cooling and taking out. The melting power, stabilizing power and seeding power are controlled by virtue of the crystal growing power, and the thermal insulation effect, the crystal quality and crystal yield are improved. The crystal pattern melting critical power is found, crystal growing is performed in a narrow range in the critical power range, the cost of the enterprise is saved, the production efficiency is improved, the product quality is improved, the design of the crystal growing structure is reasonable, the production method is optimized, the production efficiency is high, and the method is suitable for mass production.

Owner:JIANGSU SUBORUI PHOTOELECTRIC EQUIP TECH

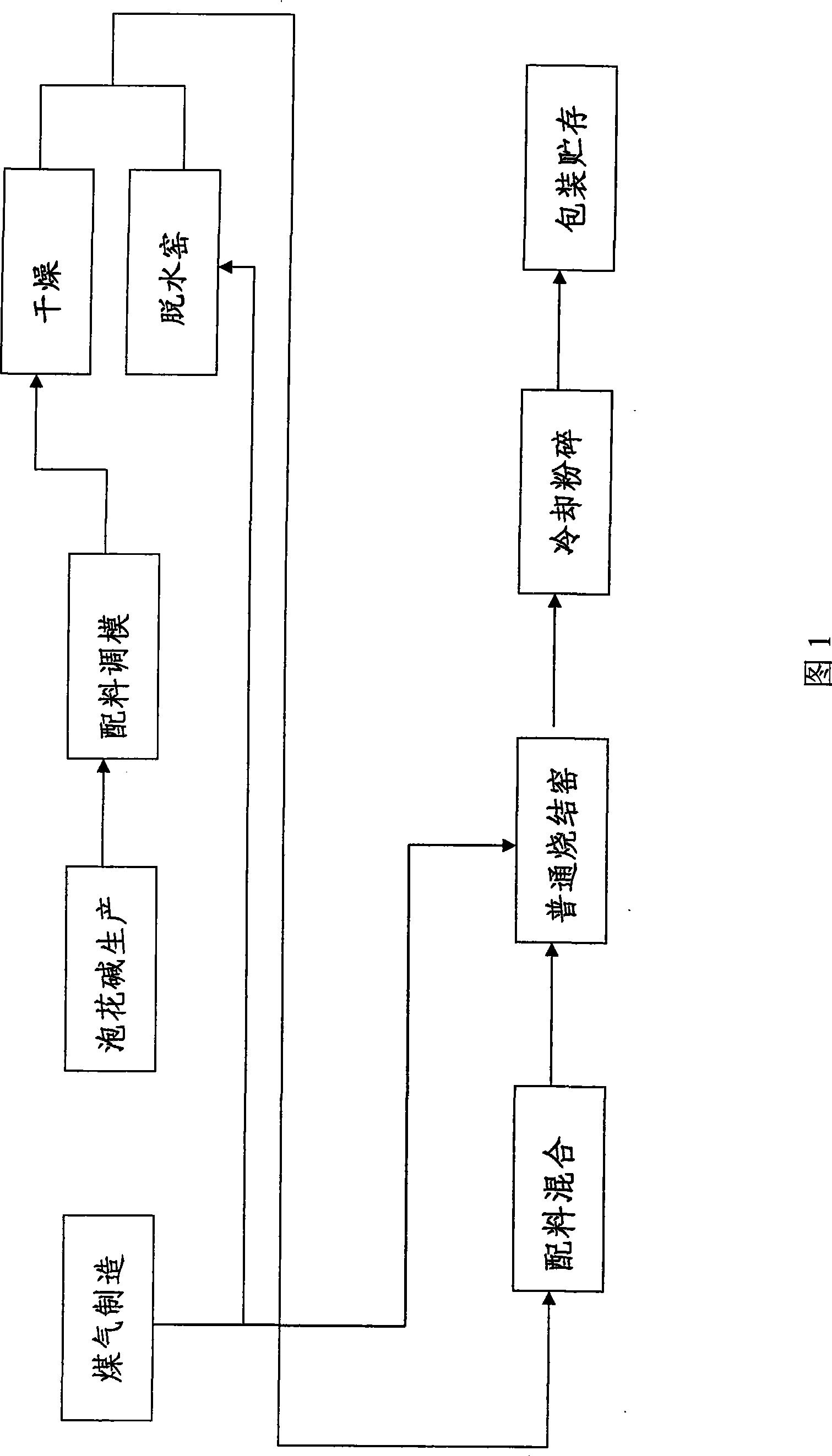

Energy-saving production method for layered crystal sodium disilicate

InactiveCN101412518AImprove efficiencyEmission reductionEnergy inputAlkali metal silicatesMass ratioDissolution

The invention relates to an energy-saving process for producing layered crystal sodium disilicate in the field of the process for producing a washing assistant. The process is as follows: (1) the dust content of coal gas is controlled to less than or equal to 50 mg / m<3>, the temperature is controlled to between 30 and 40 DEG C, and the pressure is controlled to between 0.2 and 0.3 MPa; (2) the concentration of a solution is controlled to between 40 and 45 percent, and settled dreg is filtered after dissolution is over; (3) a module adjusting agent is added into the mixture to adjust the mixture to the required module, the mixture is subjected to spray drying and dehydration, and the moisture mass ratio of the produced instant sodium silicate is between 9 and 12 percent; and (4) the temperature of a high-temperature crystal oven is between 600 and 900 DEG C, the gas exhaust temperature is between 500 and 600 DEG C, the crystallization time is kept to between 8 and 15 minutes, and high-temperature crystalline substances which are discharged from the crystal oven are crushed and cooled and the granularity of the high-temperature crystalline substances is controlled to less than 100 meshes. The process adopts the method of replacing high-cost fuel by low-cost fuel to reduce the production cost, utilizes recovery of waste heat of the crystal oven to save the energy and reduce exhaust emission and the cost, and technically reaches the domestic advanced level.

Owner:SHANDONG SNTON GROUP CO LTD

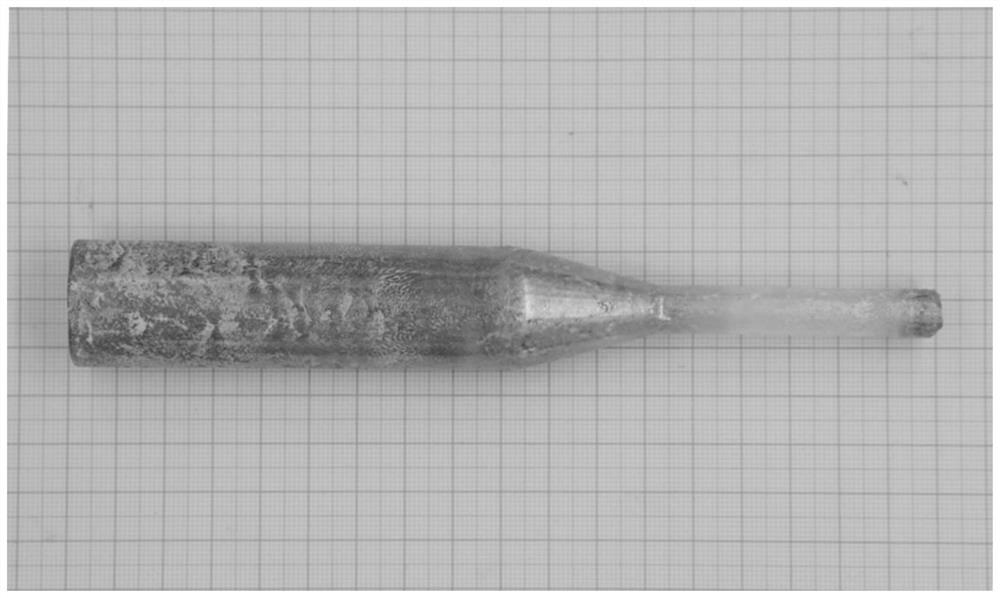

Transitional connection method for heating rod and water cooling electrode of crystal growing furnace

InactiveCN102404884AAvoid heat damageAvoid arcingOhmic-resistance heating detailsHeating element shapesLow voltageHeater Rod

The invention discloses a transitional connection method for a heating rod and a water cooling electrode of a crystal growing furnace. The transitional connection method is characterized in that two ends of the heating rod are respectively connected with a refractory metal rod with a larger cross section, and the refractory metal rods with the larger cross section are fixed with the water cooling electrode. When the transitional connection method is adopted, reliable contact can be ensured, electric clearance can be prevented from arc striking, and the thermal damage to the electrode caused by the direct contact of a thermal load of the high-temperature heating rod with the electrode can also be avoided; and the transitional connection method is applicable to various low-voltage high-power tungsten resistance furnaces, such as a sapphire crystal growing furnace and a monocrystalline silicon crystal growing furnace.

Owner:GUANGZHOU JINGLANDI CRYSTAL EQUIP CO LTD

Method for controlling kyropoulos sapphire molten crystal vaccination state based on random distribution

InactiveCN109487334AIncrease success rateImprove crystal qualityPolycrystalline material growthUsing seed in meltDistribution controlVaccination

The invention belongs to the field of sapphire preparation, and provides a method for controlling the kyropoulos sapphire molten crystal vaccination state based on random distribution. The method comprises the following steps: determining and controlling the sapphire molten crystal vaccination state by utilizing random distribution control; acquiring and processing the sapphire molten crystal surface image, establishing a model which takes the primary function approximate weight corresponding to the molten crystal surface image corrugated information distribution, input voltage change ratio, voltage tuning ratio, cooling water hydraulic pressure and cooling water temperature of a power supply cabinet as input; predicting errors by the model to constantly correct the input information; andtracking the molten crystal surface image corrugated information distribution when vaccination is expected regularly to control the sapphire molten crystal vaccination state. According to the method,after a crystal furnace is heated, the molten crystal in a proper vaccination state is determined and kept by utilizing the molten crystal image distribution information, the vaccination time determined by artificial observation and experience is not required, so that labor resource is reduced, and the vaccination success rate is improved. The method is applicable to large-scale production of sapphire crystal.

Owner:TAIYUAN UNIV OF TECH

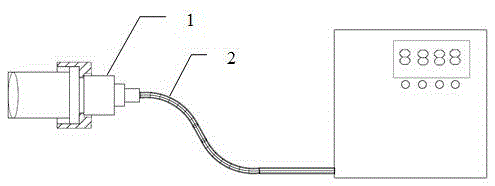

Portable fiber radiation thermometric indicator

InactiveCN105606226AWide coupling wavelength rangeImprove coupling efficiencyPyrometry using electric radation detectorsFiber couplerFiber

The invention discloses a portable fiber radiation thermometric indicator. The portable fiber radiation thermometric indicator is composed of an optical system and a circuit system, and is characterized in that the optical system is formed by connecting a large-power fiber coupler with an energy transfer fiber, and the circuit system comprises a photoelectric detector, a front amplifier, an AD sampling module, a signal processing module, a display module, a button input portion, a digital-to-analog conversion module and an electric current loop. The coupling wavelength scope of the large-power fiber coupler employed by the portable fiber radiation thermometric indicator is ultra-wide, and the portable fiber radiation thermometric indicator is suitable for measurement of a crystal furnace heat field and is simple, convenient and quite practical.

Owner:江苏浩瀚蓝宝石科技有限公司

Thulium-doped BGSO human eye safety laser crystal and preparation method thereof

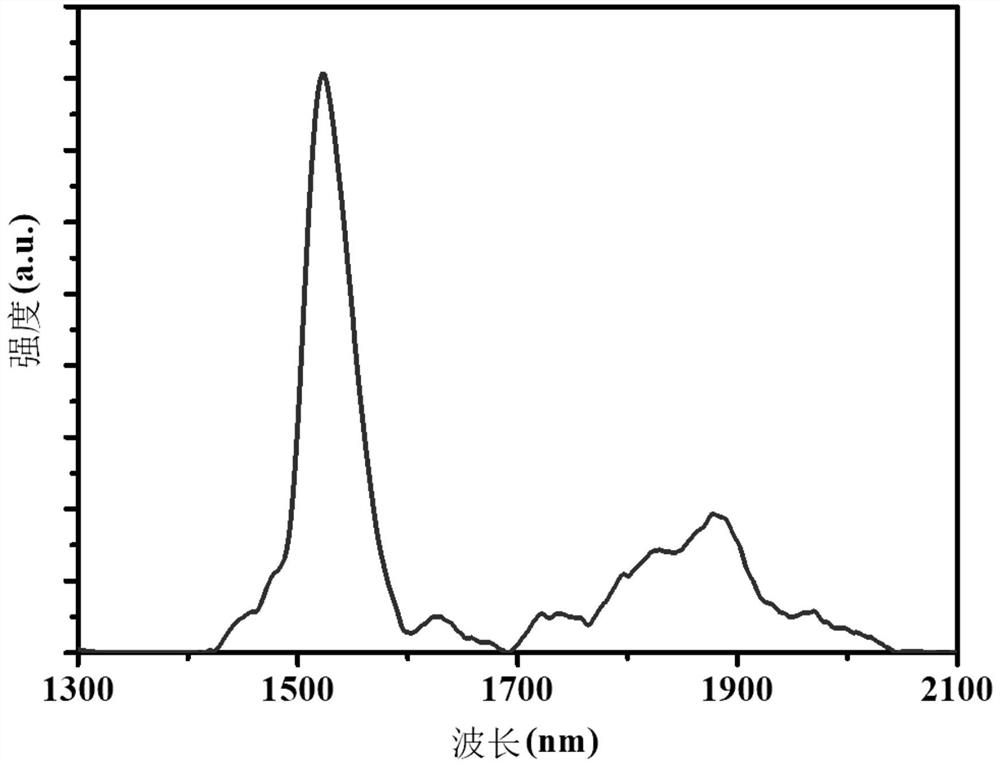

InactiveCN113699582APrevent volatilizationInhibition of segregationPolycrystalline material growthFrom frozen solutionsLuminescenceSeed crystal

The invention discloses a thulium-doped bismuth silicon germanate laser crystal and a preparation method thereof. The molecular formula of the material is (TmxBi1-x)4(GeySi1-y)3O12, the value range of x is 0.005-0.15, and the value range of y is 0.1-0.9. The method comprises the following steps: mixing the raw material powder in proportion, sintering, grinding, and sintering again to obtain a thulium-doped bismuth germanium silicate polycrystal material; putting a seed crystal into a seed trap part of the crucible and fixing the seed crystal, filling the thulium-doped bismuth germanate polycrystal material into the crucible and sealing the crucible, and moving the crucible into a down-leading pipe; placing the lead-down pipe in a crystal furnace, and after the polycrystal material in the crucible is completely melted, keeping the temperature for 2-4 hours; and descending the leading-down pipe at the speed of 0.2-0.5 mm / h, and carrying out crystal growth. The thulium-doped bismuth silicon germanate laser crystal prepared by the invention has high-intensity broadband luminescence in a range of 1.5-2.0 microns, can realize high-power laser output, and has a wide application prospect in the directions of laser ranging radars and space communication.

Owner:SHANGHAI INST OF TECH

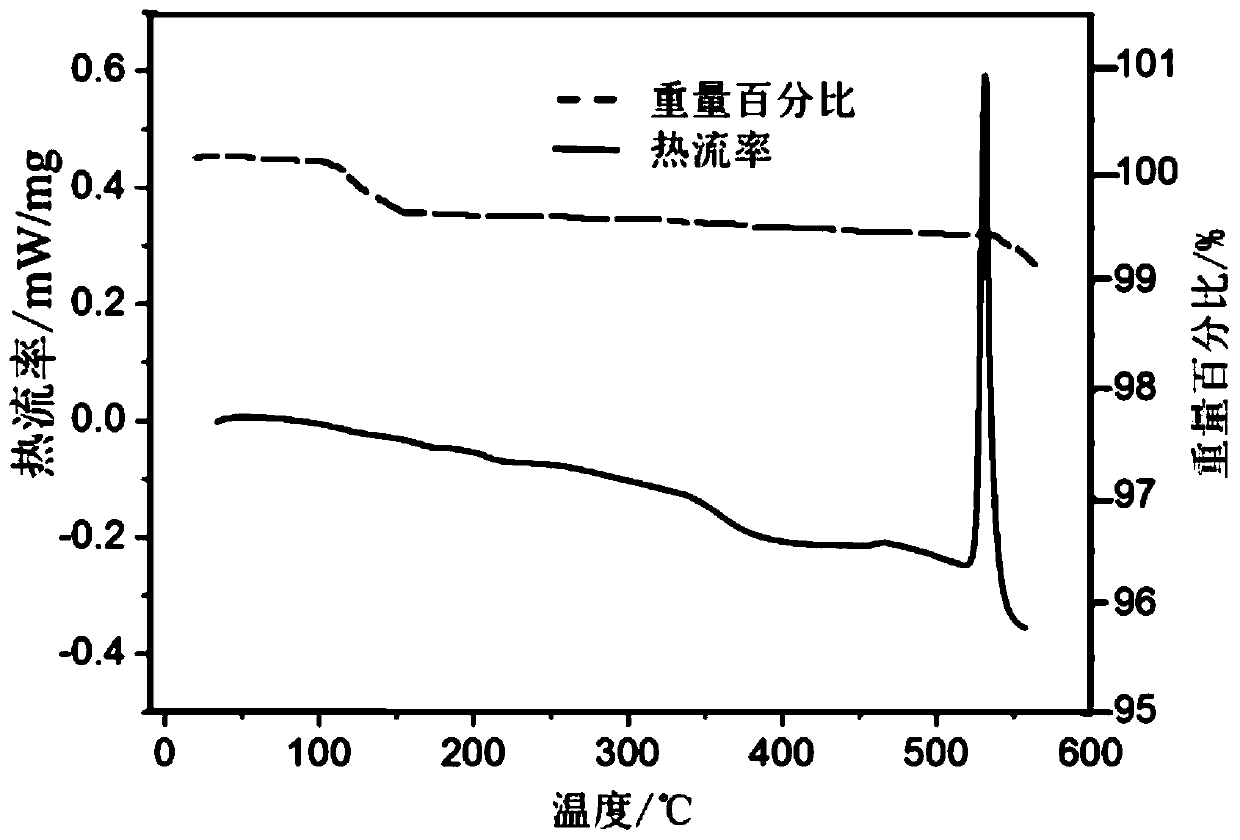

Intermediate infrared nonlinear optical crystal POC and preparation method thereof

InactiveCN110685006AReduce segregationImprove growth qualityPolycrystalline material growthFrom frozen solutionsNonlinear optical crystalCrystal system

The invention discloses an intermediate infrared nonlinear optical crystal POC and a preparation method thereof, wherein the crystal POC is a molten compound, has a melting point of 526 DEG C, and belongs to an orthorhombic system, the space group is Fmm2(42), and the cell parameters comprise that a is 35.4963(14)angstrom, b is 5.8320(2)angstrom, c is 16.0912(6)angstrom, V is 3331.11angstrom<3>, and Z is 3. The preparation method comprises: putting uniformly mixed powder of PbCl2 and PbO into a crucible, heating, naturally cooling to a room temperature, taking out, and fully grinding to obtaina POC crystal material; putting the POC crystal material into a crucible, putting the crucible into a furnace, and heating the crystal furnace; adjusting the position of the crucible, completely andfully melting the crystal material in the crucible, descending a leading-down pipe, and carrying out crystal growth; and carrying out annealing treatment. According to the method of the invention, thevolatilization of PbO and PbCl2 is reduced, and the yield of the POC single crystal is greatly increased.

Owner:SHANGHAI INST OF TECH

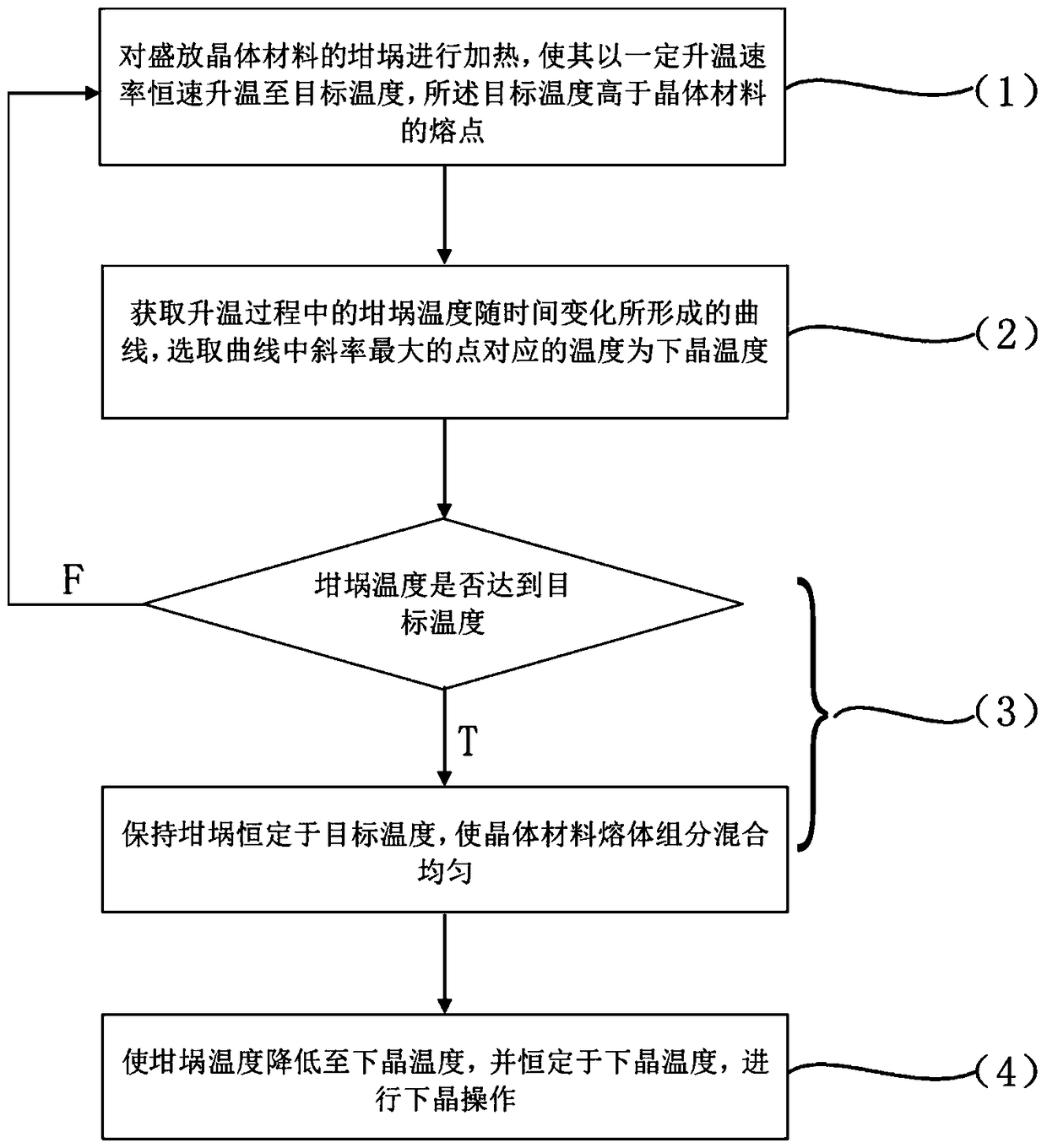

Seeding temperature capturing method for crystal growth adopting czochralski method and automatic capturing equipment

ActiveCN105603512AAccurate judgmentCrystal drop temperature is accurateBy pulling from meltCzochralski methodCrucible

The invention discloses a seeding temperature capturing method for crystal growth adopting a czochralski method. The method comprises the steps that a crucible for containing a crystal material in a crystal oven is heated at a constant speed with a certain heating rate to the target temperature, and the target temperature is higher than that of a melting point of the crystal material; a curve formed by crucible temperature changing along with time in the temperature rising process is obtained, and the temperature corresponding to a point with the maximum slope in the curve is selected as seeding temperature. According to the seeding temperature capturing method for crystal growth adopting the czochralski method, only by means of simple heating operation, the seeding temperature of a crystal can be selected by utilizing the curve of the temperature changing along with the time in the temperature rising process. The invention further provides automatic capturing equipment for the seeding temperature, a seeding temperature obtaining unit is used for obtaining the curve of the temperature changing along with the time in the temperature rising process, so that the seeding temperature of the crystal is selected and obtained, the influence on seeding operation from labor experience is excluded, and the seeding temperature of the novel crystal can be judged accurately.

Owner:SUN YAT SEN UNIV

Heat preservation crystal oven longitudinal height adjusting device

The invention discloses a heat preservation crystal oven longitudinal height adjusting device. The adjusting device comprises a heat preservation crystal oven, and further comprises a support, a lifting device, a fixing piece and a connecting piece, wherein the support supports the heat preservation crystal oven, the heat preservation crystal oven is connected with the lifting device through the connecting piece, the heat preservation crystal oven moves up and down through the lifting device, and the heat preservation crystal oven is positioned and fixed through the fixing piece. According tothe adjusting device, the positions of a traction conveying roller and an auxiliary supporting roller on a production line are kept fixed and unchanged, the longitudinal height of the heat preservation crystal oven is only adjusted, existing several adjusting points are changed into one adjusting point, so that the adjusting process is simplified, because of single-point adjustment, the levelnessof the production line is effectively guaranteed, an adjusting method is simple and working hours are saved.

Owner:孙彦斌

Double-smelting-position alternate vacuum self-consuming furnace

The invention relates to the field of metal smelting equipment, in particular to a double-smelting-position alternate vacuum self-consuming furnace. The double-smelting-position alternate vacuum self-consuming furnace is provided with a lifting guide frame and a crystal oven. The lifting guide frame is provided with an electrode clamping device. A fake electrode is connected to the electrode clamping device in a clamping manner, and a self-consuming electrode is welded to the bottom of the fake electrode. A sealing cover is arranged between the crystal oven and the fake electrode. A transposition base capable of rotating in a reciprocating manner between two smelting positions is installed at the bottom of the lifting guide frame. A fixing frame is installed at the position, correspondingto the two smelting positions, below the electrode clamping device. The crystal oven is of a double-layer wall structure, and a water cooling device is arranged in the double-layer wall structure. Anelectroslag feeding port and an inert gas inflation opening stretching into the crystal oven are further formed in the oven wall of the crystal oven correspondingly. By means of the double-smelting-position alternate vacuum self-consuming furnace, the double-smelting-position alternate manner is adopted, uninterrupted continuous smelting with zero waiting time is achieved, and the smelting efficiency is greatly improved; and meanwhile a vacuum airtight crystallizer is adopted, the desulfurization effect in the smelting process is greatly improved, and the smelting quality is improved.

Owner:大冶市精成模具有限公司

Crystal furnace control method and system

InactiveCN109487332AExtended service lifePrevent oxidationBy pulling from meltMetallurgyCrystal oven

The invention discloses a crystal furnace control method and system. The method herein includes: after a crystal furnace system is started, controlling interior vacuum degree of the crystal furnace through a vacuum pump and a diffusion pump; after the interior vacuum degree of the crystal furnace reaches a preset vacuum degree target, allowing the crystal furnace to start to treat materials; adjusting a growth environment according to process requirements, and starting generation of crystal; after crystal growth, cooling; shutting down the crystal furnace system after processing. The crystal growth process can be fully automated; oxidation of the special material of a furnace body can be prevented by controlling the interior vacuum degree of the crystal furnace; the service life of the crystal furnace is greatly extended. The crystal furnace control method and system are widely applicable to the field of crystal furnace control.

Owner:广州恩锐施智能科技有限公司

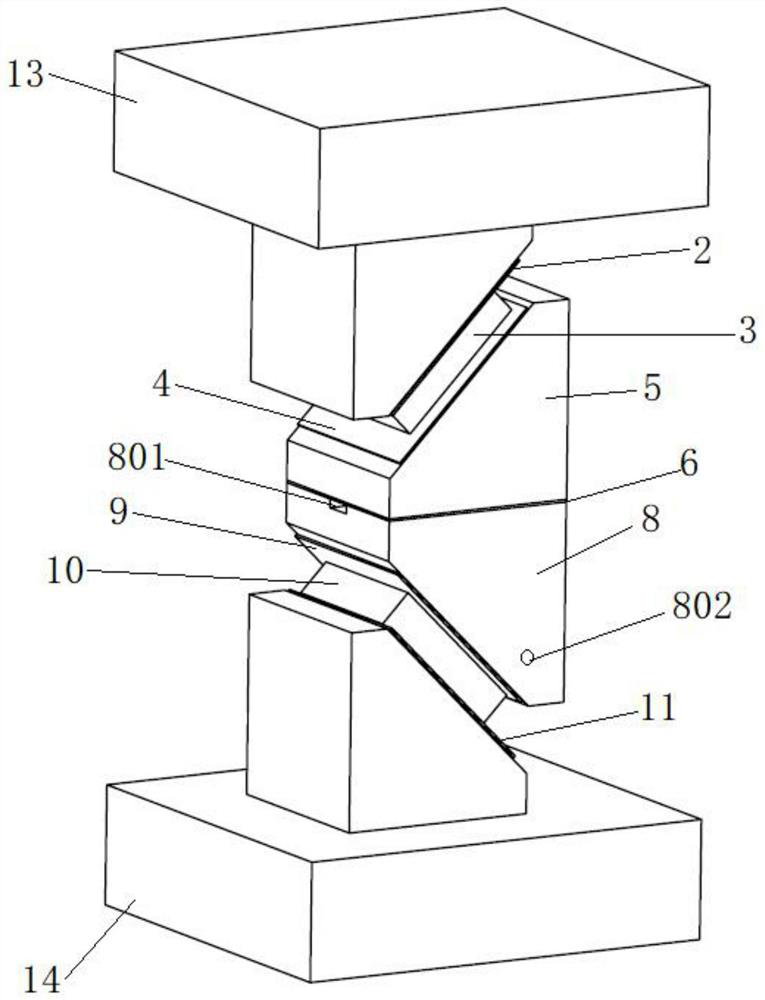

Improved device and method for growing high-temperature oxide crystals through heat exchange method with seed crystals arranged on top

InactiveCN114150383AGood for taking awayImprove cleanlinessAfter-treatment apparatusPolycrystalline material growthChemical physicsCzochralski method

The invention discloses a device and a method for growing a high-temperature oxide crystal by an improved heat exchange method with a seed crystal arranged on the top, which are characterized in that a kyropoulos method, a Czochralski method (CZ), a heat exchange method (HEM), a temperature gradient method (TGT), a Bridgman-Stockbarger method and a kyropoulos method (KY method) are combined together; according to the special high-temperature vacuum crystal furnace, gas flows in from the center of the top of a hearth from top to bottom, absolute uniform and symmetrical flow out from the center of the bottom is ensured through flow planning, and gradients of all parts in different growth stages are achieved by adjusting the gas flow in different stages and the pumping speed of a vacuum pump. The method comprises the following steps: charging a furnace, vacuumizing, introducing flowing protective gas, heating and melting materials, washing seed crystals, changing the gas inlet and outlet proportion, carrying out real-time gradient adjustment, seeding by a pulling method, carrying out a hole shrinkage process, increasing the shouldering process of a heat exchange method for increasing the gas flow, controlling a crystal growth interface (adjusting a convex interface to be slightly convex or close to a flat interface), and carrying out equal-diameter growth by combining HEM heat exchange with a KY technology (namely carrying out equal-diameter growth by combining HEM heat exchange with a KY technology). A weighing diameter control technology is optimized; amp is ended through a KY method; and removing the crucible, and performing in-situ annealing by gradually increasing the pressure of the protective gas. According to the invention, the existing method is combined to produce the large-size high-temperature oxide crystal.

Owner:黄鼎雯 +2

A Crystal Furnace Device Compensating the Gouy Phase Shift to Increase Nonlinear Interactions

ActiveCN111060452BEnhanced interactionImprove thermal conductivityMaterial analysis by optical meansGaussian beamIndium

The invention belongs to the technical field of nonlinear optics, and in particular relates to a crystal furnace device for compensating Gouy phase shift to increase nonlinear interaction. The purpose of the present invention is to overcome the problem that the Gouy phase shift cannot be compensated by the Gaussian beam passing through the nonlinear crystal in the existing nonlinear optics experiments. Indium foil, upper Peltier element, second indium sheet, upper wedge-shaped metal furnace, third indium foil, nonlinear crystal, lower wedge-shaped metal furnace, fourth indium foil, lower Peltier element and fifth indium For the thin sheet, the inclined surfaces on the upper wedge-shaped metal furnace body and the lower wedge-shaped metal furnace body of the present invention are inclined backward and backward respectively, so that the nonlinear crystal is separated from the surface of the upper Peltier element and the lower Peltier element along the axial direction. The distance between them increases sequentially, so that the nonlinear crystal forms a temperature gradient along the axial direction.

Owner:山西斯珂炜瑞光电科技有限公司

A crystal temperature capture method and automatic capture device for crystal growth by pulling method

ActiveCN105603512BReal-time heating temperatureAccurate judgmentBy pulling from meltCzochralski methodCrucible

The invention discloses a seeding temperature capturing method for crystal growth adopting a czochralski method. The method comprises the steps that a crucible for containing a crystal material in a crystal oven is heated at a constant speed with a certain heating rate to the target temperature, and the target temperature is higher than that of a melting point of the crystal material; a curve formed by crucible temperature changing along with time in the temperature rising process is obtained, and the temperature corresponding to a point with the maximum slope in the curve is selected as seeding temperature. According to the seeding temperature capturing method for crystal growth adopting the czochralski method, only by means of simple heating operation, the seeding temperature of a crystal can be selected by utilizing the curve of the temperature changing along with the time in the temperature rising process. The invention further provides automatic capturing equipment for the seeding temperature, a seeding temperature obtaining unit is used for obtaining the curve of the temperature changing along with the time in the temperature rising process, so that the seeding temperature of the crystal is selected and obtained, the influence on seeding operation from labor experience is excluded, and the seeding temperature of the novel crystal can be judged accurately.

Owner:SUN YAT SEN UNIV

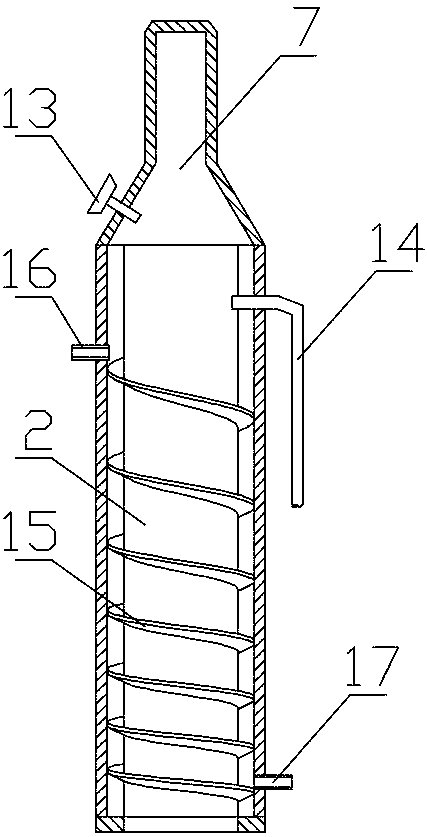

Bridgman-stockbarger crystal growth device and application thereof

The invention provides a Bridgman-Stockbarger crystal growth device. The Bridgman-Stockbarger crystal growth device comprises a furnace body, a crucible, a lifting unit, a heating unit, a temperature measurement unit, a temperature acquisition unit and a control unit, the lifting unit controls the crucible to lift in the furnace body; the furnace body can be oppositely opened, so that the crystal growth process can be conveniently observed at any time; the heating device is arranged in the heating furnace; the furnace body comprises a high-temperature area, a gradient area and a low-temperature area; the high-temperature area and the low-temperature area are independently controlled in temperature; the temperature measuring device detects the temperature of the crucible; the temperature acquisition unit acquires the temperature detected by the temperature measuring device; the control unit controls lifting of the lifting unit and heating of the heating unit. According to the invention, the defects of high height, heavy weight, difficult observation, difficult maintenance, difficult data acquisition and the like of the crystal furnace are overcome, the small-sized furnace body is utilized to facilitate preliminary understanding of the crystal growth condition, and the small-sized furnace body can also be used for a display experiment and occupies a small space. The experimental period is short, and data can be quickly accumulated. And small-size crystal growth can be carried out, and reference is provided for large-size crystal growth.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Lining for polysilicon crystal oven wall protection and manufacturing method thereof

ActiveCN101775639BHighlight substantive featuresSignificant progressAfter-treatment apparatusPolycrystalline material growthCrystal ovenIron oxide

The invention relates to a lining for polysilicon crystal oven wall protection and a manufacturing method thereof; the shape of the lining is in a regular hemispherical opaque three-dimensional structure, and the upper part thereof is open; the mass ratio of the components is as follows: silicon dioxide is more than 99.6 weight percent, alumina is less than 800ppm, and ferric oxide is less than 40ppm. The process comprises the following steps: raw material high-purity quartz is put into granulating equipment for wet granulation, grout is then taken out and fully stirred, placed and poured into a pressure device, and injected into a plaster mold; in pre-grouting, the plaster mold is slightly vibrated, and the grout is put into the mold and stays still so that the grout is fully dehydrated, and demolded; after demolding, the grout is dried in a dryer, an embryo prepared is put into a kiln to be sintered, and the opaque quartz lining is prepared after sintering; and finally a layer of silicon nitride is sprayed on the inner wall of the opaque quartz lining. The invention produces the matched oven wall protection quartz lining according to the technical requirements of a multicrystalfurnace, effectively prevents the harm of silicon leakage in the crystallization process of the crystal oven to the multicrystal furnace, and is simple and practical.

Owner:常熟华融太阳能新型材料有限公司

Method for preparing special magnesium borate for oriented silicon steel

The invention relates to the field of oriented silicon steel plate manufacture, in particular to a method for preparing special magnesium borate for oriented silicon steel. The method solves the problems of poor adhesion, dispersibility and electromagnetic performance and the like of the conventional boron aid. The method comprises the following steps of: (1) pouring aqueous solution of magnesiumbicarbonate and boric acid in a ratio into a reaction kettle; (2) performing sedimentation treatment on the mixed solution; (3) then conveying the sediment into a pyrolysis tank, adding finished magnesium borate crystal seeds and silane coupling agent into the pyrolysis tank, and producing a mixture of nano magnesium carbonate and metaboric acid by using a liquid phase precipitation method; (4) filter-pressing the pyrolysis product to obtain filter cakes; (5) treating the filter cakes in a high-temperature crystal oven to form nano magnesium borate powder with complete crystal; and (6) grading the material discharged out of the high-temperature crystal oven with jet milling to obtain a screened substance of less than or equal to 320 meshes. All indexes of the special magnesium borate are superior to that of the primary product, and in particular, the adhesion, dispersibility and electromagnetic performance are remarkably improved, and the quality of the oriented silicon steel plate isimproved; and the method has the advantages of simple production process, lower cost and no three-waste pollution.

Owner:山西银圣科技有限公司

Optical cavity

ActiveCN108462029BGuaranteed connectivityReduce phase jitterOptical resonator shape and constructionNon-linear opticsOptical cavityEngineering

The present invention provides an optical resonator. The optical resonator comprises a housing consisting of a main body portion and a rear end cover, wherein the main body portion has a cavity, and the rear end cover is arranged on the main body portion in a mode for sealing an opening at the rear side of the cavity; a red copper crystal oven with nonlinear crystal arranged in the cavity; and piezoelectric ceramics and an output mirror arranged in the rear end cover, wherein the nonlinear crystal, the piezoelectric ceramics and an optical path of the output mirror communicate in order and arearranged in the same straight line. The objective of the invention is to provide an optical resonator capable of reducing phase jittering and improving the phase stability.

Owner:SHANXI UNIV

Crystal constant temperature furnace

PendingCN114792923AClean thoroughlyAvoid damageLaser detailsAfter-treatment detailsPhysical chemistryCrystal oven

The invention provides a crystal constant temperature furnace. The crystal constant temperature furnace comprises a crystal holder, a furnace body and a lens, the crystal holder is used for fixing a frequency doubling crystal, and a front-back through containing cavity used for containing the crystal holder is formed in the furnace body and used for conducting constant-temperature heating on the frequency doubling crystal fixed in the crystal holder; the lens is connected to one end of the furnace body and used for sealing one end of the furnace body; the furnace body is provided with an air inlet channel communicated with the containing cavity, the air inlet channel is obliquely arranged towards the lens, and an air outlet of the air inlet channel is located between the frequency doubling crystal and the lens. Clean gas enters the containing cavity through the gas inlet channel, the clean gas is blocked by the lens and flows out along the outlet in one end, opposite to the lens, of the furnace body, and therefore dust and volatile matter on the surface of the frequency doubling crystal are taken away in the blowing process in the gas flowing process, and cleaning of the frequency doubling crystal in the whole crystal constant temperature furnace is achieved.

Owner:KEY & CORE TECH INNOVATION INST OF THE GREATER BAY AREA

Multi-temperature-zone crystal furnace induction heating power supply

PendingCN114423104ASolve mutual interferenceReduce interferenceInduction current sourcesCapacitanceEngineering

The invention discloses an induction heating power supply for a multi-temperature-zone crystal furnace. The induction heating power supply comprises N induction heating power supplies and N-1 coupling transformers TM, wherein N is greater than 2, and a coupling transformer TM is arranged between every two induction heating power supplies; each induction heating power supply internally comprises an inverter and a resonant tank circuit, the resonant tank circuit comprises a matching transformer T, a resonant capacitor C and an induction coil L, a primary coil of the matching transformer T is connected with the inverter, and two ends of a secondary coil of the matching transformer T are respectively connected with the resonant capacitor C and the induction coil L; and a primary coil and a secondary coil of a coupling transformer TM are respectively connected between the secondary coils and the induction coils L of the two adjacent matching transformers T, so that the electromotive force directions of the two adjacent resonance tank circuits are consistent, and the current directions of the dotted terminals of the coupling transformer TM are opposite. According to the invention, independent power adjustment of a plurality of induction heating power supplies can be realized, and the problem of mutual inductance interference of two adjacent inductors in multi-temperature-zone induction heating application in the prior art is solved.

Owner:山西艾德尔电气设备有限公司

A method and system for self-adaptive regulation and control of crystal growth power supply parameters

ActiveCN114046669BIncrease flexibilityImprove intelligenceAfter-treatment apparatusControl devices for furnacesPower parameterEngineering

Owner:JIANGSU EASTONE TECH

Energy-saving production method for layered crystal sodium disilicate

InactiveCN101412518BImprove efficiencyEmission reductionEnergy inputAlkali metal silicatesMass ratioDissolution

The invention relates to an energy-saving process for producing layered crystal sodium disilicate in the field of the process for producing a washing assistant. The process is as follows: (1) the dust content of coal gas is controlled to less than or equal to 50 mg / m<3>, the temperature is controlled to between 30 and 40 DEG C, and the pressure is controlled to between 0.2 and 0.3 MPa; (2) the concentration of a solution is controlled to between 40 and 45 percent, and settled dreg is filtered after dissolution is over; (3) a module adjusting agent is added into the mixture to adjust the mixture to the required module, the mixture is subjected to spray drying and dehydration, and the moisture mass ratio of the produced instant sodium silicate is between 9 and 12 percent; and (4) the temperature of a high-temperature crystal oven is between 600 and 900 DEG C, the gas exhaust temperature is between 500 and 600 DEG C, the crystallization time is kept to between 8 and 15 minutes, and high-temperature crystalline substances which are discharged from the crystal oven are crushed and cooled and the granularity of the high-temperature crystalline substances is controlled to less than 100 meshes. The process adopts the method of replacing high-cost fuel by low-cost fuel to reduce the production cost, utilizes recovery of waste heat of the crystal oven to save the energy and reduce exhaust emission and the cost, and technically reaches the domestic advanced level.

Owner:SHANDONG SNTON GROUP CO LTD

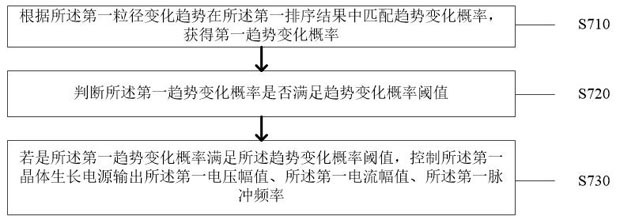

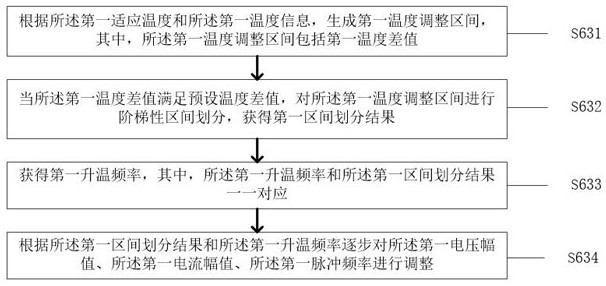

Self-adaptive regulation and control method and system for crystal growth power supply parameters

ActiveCN114046669AIncrease flexibilityImprove intelligenceAfter-treatment apparatusControl devices for furnacesVoltage amplitudeComputational physics

The invention discloses a self-adaptive regulation and control method and system for crystal growth power supply parameters, and the method comprises the steps: obtaining a first control parameter according to a first crystal growth power supply; obtaining first particle size characteristic information; inputting the first particle size characteristic information and the first temperature information into a particle size change trend prediction model to obtain first particle size change trend information; sorting the trend change probability according to a preset sorting rule to obtain a first sorting result; obtaining a first particle size change trend according to the first sorting result; judging whether the first particle size change trend meets a preset particle size change trend or not; and if the preset particle size change trend is met, controlling the first crystal growth power supply to output the first voltage amplitude, the first current amplitude and the first pulse frequency. The technical problems that in the prior art, the state change of the crystal and the temperature difference in the crystal furnace are not considered, so that the flexibility is low, and the probability of sintering failure is increased are solved.

Owner:JIANGSU EASTONE TECH

Preparation method of cad/cam personalized zirconia one-piece implant

InactiveCN104688365BImprove aestheticsReduce potential riskDental implantsPersonalizationAbrasive blasting

The invention discloses a preparation method for a CAD / CAM individuality zirconia one-stage implant. The method comprises the steps of firstly, analyzing the bone substance, bone mass, the distance between the jaw and the gingiva, and the thickness of the gingiva of the anodontia region of a patient to obtain data, using the exocad software for designing the thread form of an implant body, the length and diameter of the implant body, the height and the form of the gingiva through portion and the abutment height, then adopting a CAM grinding mill for machining medical zirconia materials to obtain a zirconia implant, placing the zirconia implant into a crystal oven to be sintered, conducting cooling to reach the normal temperature, then mechanically polishing the gingiva through portion of the implant body and the upper abutment, conducting surface abrasive blasting roughing treatment on the inner section of an implanted bone, and finally conducting cleaning and sterilization. The CAD / CAM technology is utilized for manufacturing the individuality one-stage implant which is better suitable for anodontia patients on different hardness tissue conditions, and the one-stage implant can be more widely applied compared with traditional implants.

Owner:杭州口腔医院集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com