Improved device and method for growing high-temperature oxide crystals through heat exchange method with seed crystals arranged on top

A high-temperature oxide, heat exchange technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of high equipment conditions, inability to real-time control and observation of crystal growth, complex process, etc. Points and growth centers, preventing the deposition of volatiles, and reducing the effect of dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

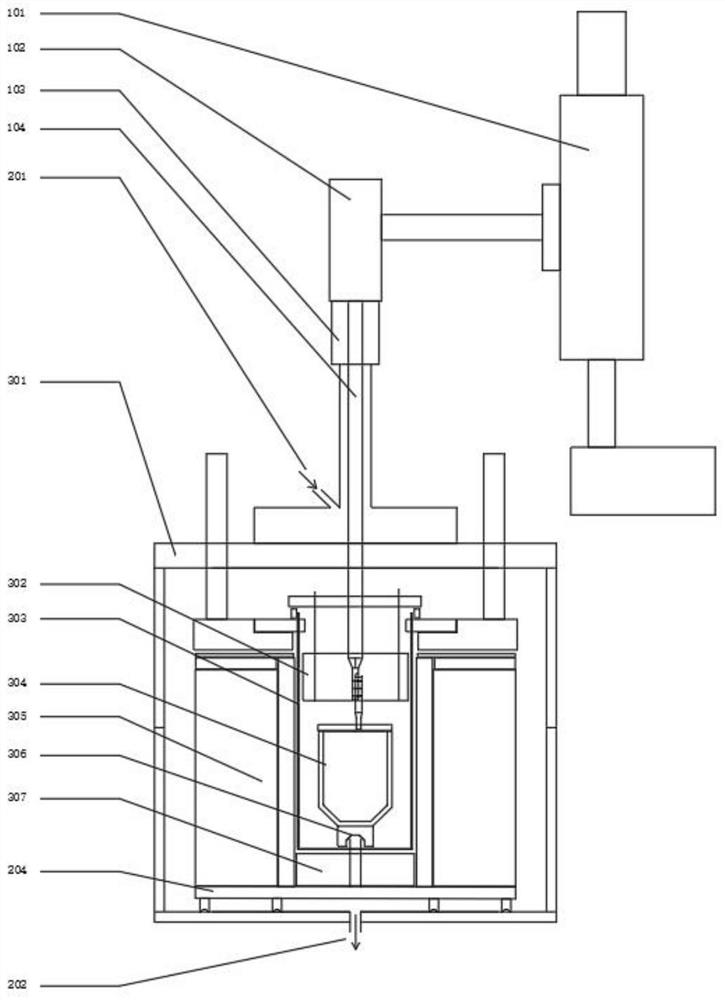

[0044] A method for growing a sapphire crystal by placing an improved heat exchange method on a seed crystal comprises the following steps:

[0045] a. Put the alumina raw material into the 301 of the crystal furnace: 304: the crucible in the vacuum chamber, fix the 105: seed crystal on the seed crystal rod 101: lift and lift 102: the rotating mechanism 104: the bottom end of the water-cooled crystal rod Part, seed rod 101: lifting mechanism and 102: rotating mechanism are connected with 103: weighing mechanism, cover the upper furnace cover of the crystal furnace, and pump the crystal 301: vacuum chamber furnace to 1.0×10-1Pa,

[0046] b. Use (inert gas and reducing gas) mixed gas flow atmosphere to pass through 201: inlet port and fill 301: vacuum chamber furnace to maintain a suitable range of vacuum in the furnace (1 ~ 500Pa), 303: U on the outer wall of the crucible The type heating element is energized and heated at a rate of 1500-5000W / h until 304: the raw material in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com