Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70 results about "Cellulose xanthate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose xanthate (SELL-you-lohs ZAN-thate) is a compound produced from cellulose in the viscose process for making rayon. The subscript "n" in the chemical formula indicates that many molecules chain together to make up the polymer.

A kind of production method of superfine high-strength high-modulus viscose fiber

InactiveCN102296373AIncrease contact areaIncreasing the thicknessSpinnerette packsArtificial filaments from viscoseCellulosePolymer science

The invention discloses a production method of ultra-fine, high-strength and high-modulus viscose fibers. The cellulose xanthate polymer spinning viscose which is still in a viscous flow state is provided with viscose ejection holes and coagulation baths respectively. The composite spinneret of the spray hole is sprayed out, and is solidified and formed by a low-acid, high-zinc, low-salt and low-temperature coagulation bath, and then combined with bath stretching and air stretching, and drawn by nozzles with different ratios , inter-disk drafting and plasticizing drafting, and then post-treatment to obtain a fineness of 0.44~0.78dtex, dry strength ≥ 3.1cN / dtex, wet strength ≥ 2.1cN / dtex, wet modulus ≥ 0.5cN / dtex, whiteness ≥82.0% ultra-fine high-strength high-modulus viscose fiber. The invention realizes the effective coordination of the ultrafine denier fiber spinning forming process and drafting, and the normal implementation of the spinning process, and the produced ultrafine high-strength high-modulus viscose fiber has a uniform structure, and the fiber strength and modulus are 50% higher than conventional varieties. %above.

Owner:CHTC HELON

Method for producing temperature-regulating viscose fibers

InactiveCN104389039AImprove qualityImprove responseArtificial thread manufacturing machinesArtificial filaments from viscoseCellulosePolymer science

The invention discloses a method for producing temperature-regulating viscose fibers. The method comprises the following steps: by taking natural cellulose as a raw material, preparing soluble cellulose xanthate by virtue of processes such as alkalizing, aging and yellowing, and dissolving the cellulose xanthate in dilute alkali liquor so as to prepare the viscose, wherein aids are added in the process. According to the equipment and process improvement, the chemical reaction effect and filtering effect are improved, and the aim of improving the quality of the viscose is achieved, so that the aims of adjusting the fineness and improving the physical properties of the product are achieved; and in the process of blending phase change capsule materials, grinding and secondary micro porous filtration are performed. The phase change capsule material is added before spinning and is mixed with the viscose solution to be uniform; and meanwhile, when the viscose fiber is positioned in a macromolecular amorphous form and passes through a low-diameter spinning round hole, proper draft degree and forming process conditions are selected, and the aim of adjusting the fineness of the fibers is achieved. The produced temperature-regulating viscose fibers are low in fineness, high in strength and high in caloric content value and have good bidirectional temperature regulating functions; and the product has the characteristics of moisture absorption and discharge capacities, breathability, sunlight resistance, moth-eaten resistance, anti-static property and simplicity in spinning.

Owner:SATERI JIUJIANG FIBER CO LTD

Cellulose/alginate composite fiber and its preparing method

ActiveCN1858312AGood hygroscopicityPromote healingFilament/thread formingConjugated cellulose/protein artificial filamentsFiberCellulose

The present invention discloses a kind of composite cellulose / alginate fiber and its preparation process. Technologically, the present invention features that viscous sodium alginate solution prepared in certain technological condition and cellulose xanthate in certain weight proportion are mixed to form the spinning solution, and the through further spinning and refining steps, the composite cellulose / alginate fiber is prepared. The composite fiber consists of cellulose 85-99.8 weight portions and sodium alginate 0.02-15 weight portions. The composite fiber has high hygroscopicity and high mechanical performance and can promote the healing of skin inflammation. The composite fiber may be used in weaving fabric with good hand feeling, high ygroscopicity, high wet strength and high size stability, and is suitable for use in medical field and in making various kinds of high grade underwear, etc.

Owner:潍坊欣龙生物材料有限公司

Method for preparing cellulose and silicon dioxide composite coloured fiber and coloured fiber made thereby

ActiveCN101070633ASimple processEasy to operateMonocomponent cellulose artificial filamentWet spinning methodsCelluloseColour fastness

The invention relates to the cellulose and colored silica fiber composites and the processing method. Process the spinning liquid glue from cellulose xanthate, silica, sodium hydroxide and water. Add colorants in and mix them to be colored liquid viscose. This colored fiber composites with a permanent fire flame retardant, has high color fastness, widely chromatogram, dyeing equably, and cost cheaply. It can be used in color spinning so that to avoid staining processes and Reduce environmental pollution and the waste of energy.

Owner:潍坊欣龙生物材料有限公司

Old clothes recovery method

InactiveCN102660791AImprove protectionPromote regenerationArtificial filaments from viscoseRecovery methodDecomposition

The invention relates to an old clothes recovery method, which comprises the following steps of: using old cotton clothes as a raw material to prepare cotton pulp, processing by the use of caustic soda and carbon disulfide to obtain orange sodium cellulose xanthate, dissolving in a dilute sodium hydroxide solution to form viscous viscose glue, filtering and maturating viscose glue, standing at 38 DEG C for 20h, followed by deaeration, carrying out wet spinning, adding a solidification liquid which is composed of sulfuric acid, sodium sulphate and zinc sulfate, letting sodium cellulose xanthate in viscose glue react with sulfuric acid in the solidification liquid for decomposition, regenerating cellulose and precipitating, washing, desulphurizing, bleaching and drying cellulose fiber to form viscose fiber. By the utilization of the old clothes recovery method for preparation of viscose fiber, viscose fiber is woven into various mat products, thus changing waste into valuables. The technology provided by the invention is easy to operate and is convenient for popularization and utilization.

Owner:GUANGDONG JUYANG ENVIRONMENTAL PROTECTION TECH

Preparation method for flame-retardant spinning viscose

ActiveCN102345174AImprove filtering effectImprove spinnabilityMonocomponent cellulose artificial filamentPolymer scienceSodium metasilicate

The invention discloses a preparation method for flame-retardant spinning viscose. The preparation method comprises the following steps of: adding a sodium metasilicate type flame retardant into a dissolved viscose solution; stirring to prepare a flame retardant dissolving solution with effective flame retardant concentration of 4-10 percent by weight; adding the flame retardant dissolving solution into yellowed cellulose xanthate viscose to be mixed, stirred and dissolved; filtering, ripening and defoaming to prepare flame-retardant spinning viscose with alpha cellulose content of 8.0-12 percent by weight, effective content of effective flame retardant relative to the alpha cellulose of 30-40 percent by weight, alkali content of 7.0-10.0 percent by weight, viscosity of 30-50s determined by a falling ball method and ripening degree of 15-30ml determined by 10 percent NH4Cl. The preparation method for the flame-retardant spinning viscose is simple, and easy to operate and has high filterability and spinnability; and compared with other (such as phosphorus series) flame-retardant viscoses, the flame-retardant spinning viscose has greatly-reduced cost.

Owner:潍坊欣龙生物材料有限公司

Method for preparing viscose fiber

InactiveCN101104959AEasy to getImprove filtering effectMonocomponent cellulose artificial filamentWet spinning methodsHigh sodiumSulfate

The invention discloses a preparation method of viscose fibers, which is characterized in that the cellulose pulp is used in the viscous glue preparation procedure; the cellulose pulp together with an additional modifier are processed to cellulose xanthate with high esterification degree and ripeness degree; the spinning procedure is performed under such conditions as low coagulation bath temperature, low acidity and high sodium sulfate concentration, without using zinc sulfate which results in serious environmental pollution; the thickness of fiber skin is increased by drafting; and the produced viscose fiber has high strength and high wet modulus. The invention solves the problem of zinc pollution in the prior art, produces viscose fibers with high strength, high wet modulus, and good tension, and overcomes the disadvantages that the fabric is easy to deform, instable in size and nonresistant against base when the viscose fiber is in wet state. Compared with the prior viscose staple fibers, the fabric made of the inventive fibers is superior in high strength and good resistance against deformation and alkali.

Owner:CHTC HELON

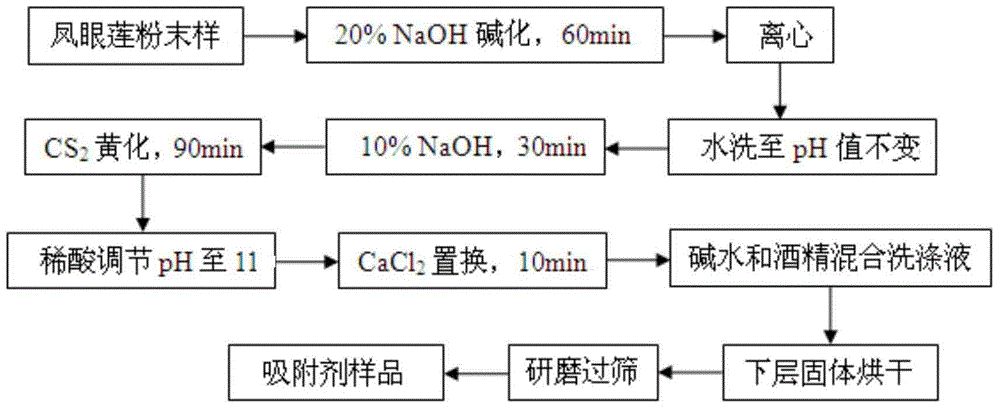

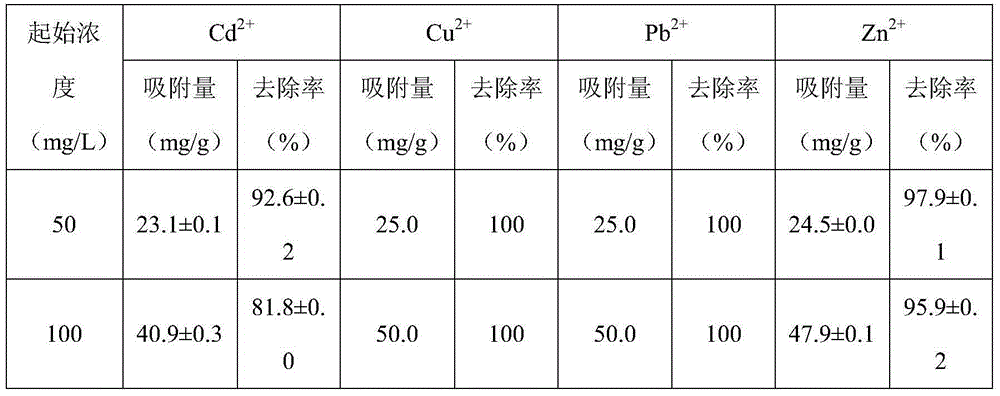

Preparation method and application of eichhornia crassipes cellulose xanthate calcium salt

ActiveCN103977773AImprove adsorption capacityReduce secondary pollutionOther chemical processesWater/sewage treatment by sorptionSoil remediationCellulose xanthate

The invention discloses a preparation method and application of eichhornia crassipes cellulose xanthate calcium salt. The method uses the straws of aquatic plant eichhornia crassipes, namely water hyacinth as a raw material to be converted into cellulose xanthate salt, and the cellulose xanthate salt utilized as an adsorbent can be used for efficiently adsorbing and removing heavy metal ions in water and also can be used in the fields of soil remediation, environmental protection, ecological construction and the like. The adsorbing capacity of the adsorbent prepared by the preparation method to heavy metal is superior to that of an adsorbent prepared by other plant straws under the same modification condition, and the special advantage of the eichhornia crassipes plant material is embodied. The invention provides a new plant biomass utilization way and provides an effective way for exerting the advantage of the eichhornia crassipes living plant repairing polluted water and relieving the secondary pollution of the eichhornia crassipes to water after water repair.

Owner:HUAZHONG AGRI UNIV

Homogeneous composite cellulose/titanium oxide powder microspheres and its preparing process

A homogenized composite cellulose / titanium oxide powder microsphere is prepared through mixing superfine titanium oxide particles with industrial cellulose xanthate viscose, adding oil phase and surfactant to form water-in-oil suspension, heating, solidifying to obtain the spheres, washing with organic solvent, regenerating with acid, screening and floatage to obtain microspheres. Its advantages are high hydrophilicity, good roundness, high porosity, low cost and high resistance to acid and alkali.

Owner:ZHEJIANG UNIV

Method for preparing high strength cellulose and silicat composite fibre and prepared composite fibre

InactiveCN101089258AReduce the impact of physical and mechanical propertiesGood physical and mechanical propertiesMonocomponent cellulose artificial filamentWet spinning methodsPolymer scienceCellulose xanthate

The present invention discloses a method for preparing high-tenacity cellulose and silica composite fiber and its prepared composite fiber. Said method includes the following steps: adopting cellulose to prepare cellulose xanthate, then adopting cellulose xanthate, silica, sodium hydroxide and water and uniformly mixing them to obtain polyblend viscose whose composition contains (by wt%) 5.0%-8.2%% of alpha-cellulose, 18%-60% of silica, 9.0%-11.0% of sodium hydroxide and the rest is water, dissolving to obtain polyblend spinning solution, then wet spinning so as to obtain the invented high-tenacity composite fiber containing cellulose and silica.

Owner:CHTC HELON

Method for preparing coarse denier and ultra-coarse denier viscose fiber and prepared fiber

InactiveCN101104956AEasy to useBroaden sources of raw materialsArtificial filaments from viscoseMelt spinning methodsCellulosePolymer science

The invention discloses a manufacturing method of coarse-denier and ultra-coarse denier viscose fibers and the fibers produced by the method. The method comprises using a cellulose xanthate polymer in viscous state, spraying from spinneret holes with high aperture into a coagulating bath solution composed of more than two components selected from sulfuric acid, zinc sulfate and sodium sulfate, allowing molding, subjecting the cellulose macromolecules in viscose elastic state to the combined tension of bath solution and air, and proportionally regulating the draft by different draft distributions to obtain coarse-denier or ultra-coarse denier viscose fiber. The method is simple and easy to operate. The produced coarse-denier and ultra-coarse denier viscose fibers have various specifications and excellent performance, and can meet the requirements of rich variety and specification of fibrous raw materials in textile industry. The invention enlarges the application range of viscose fibers.

Owner:CHTC HELON

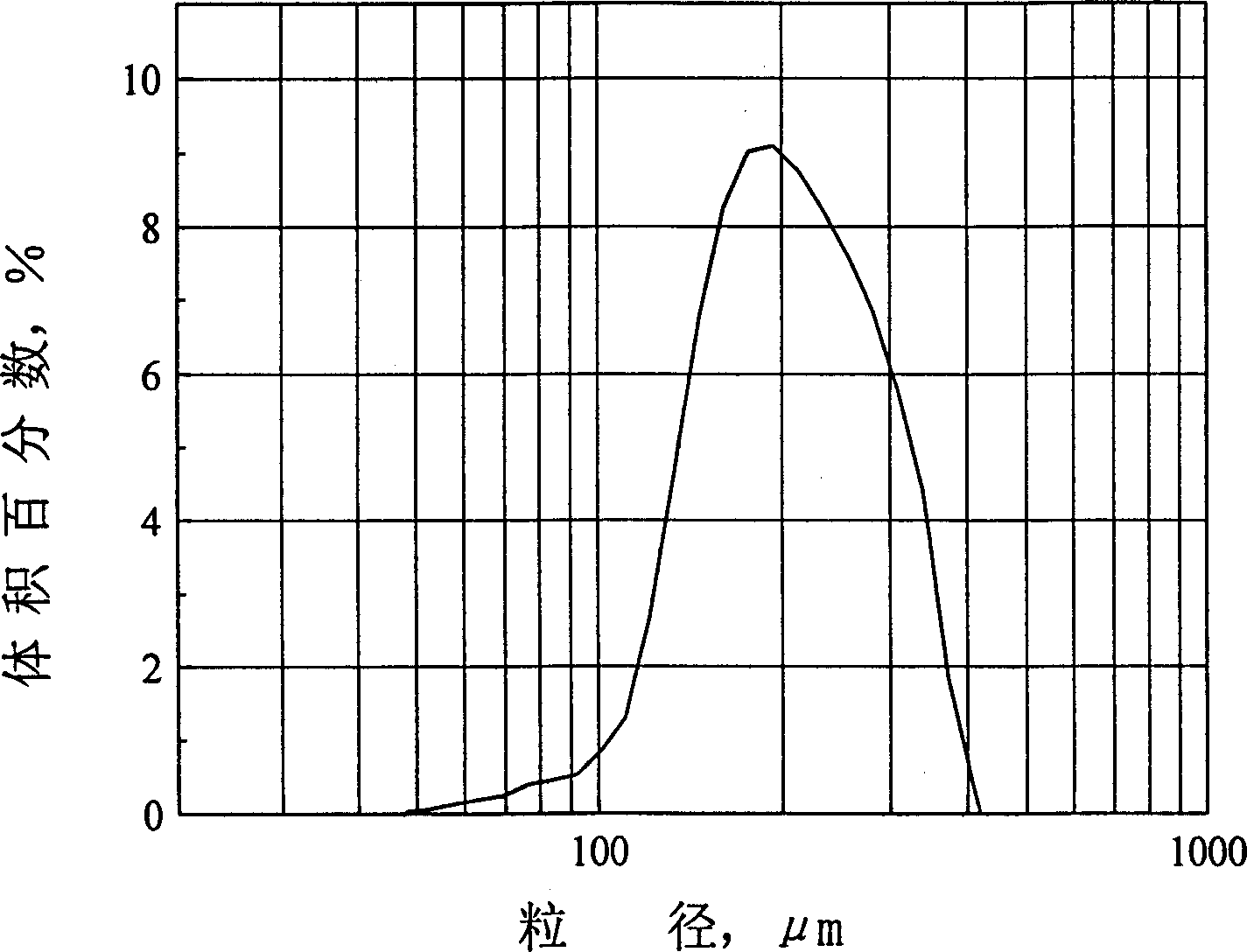

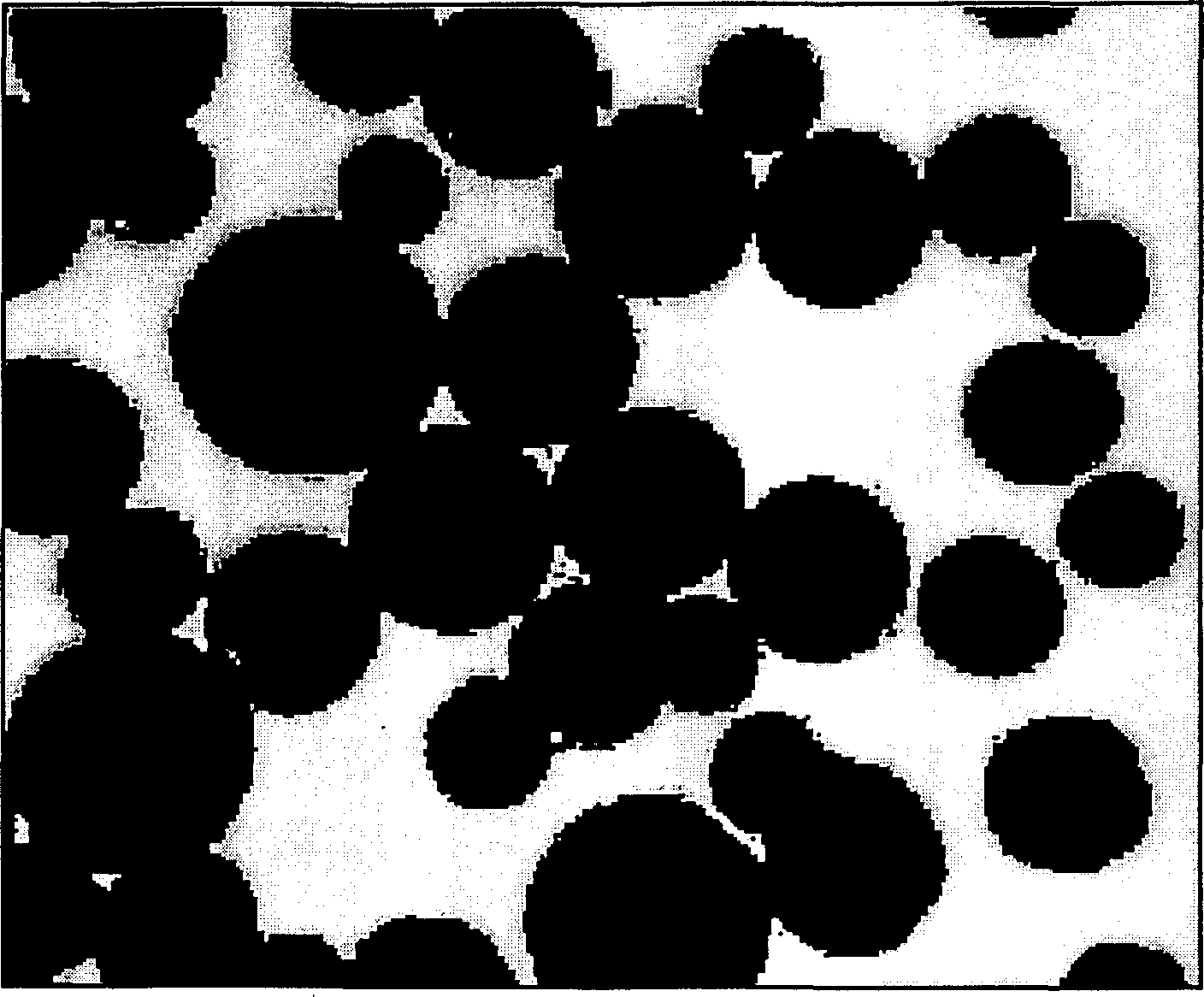

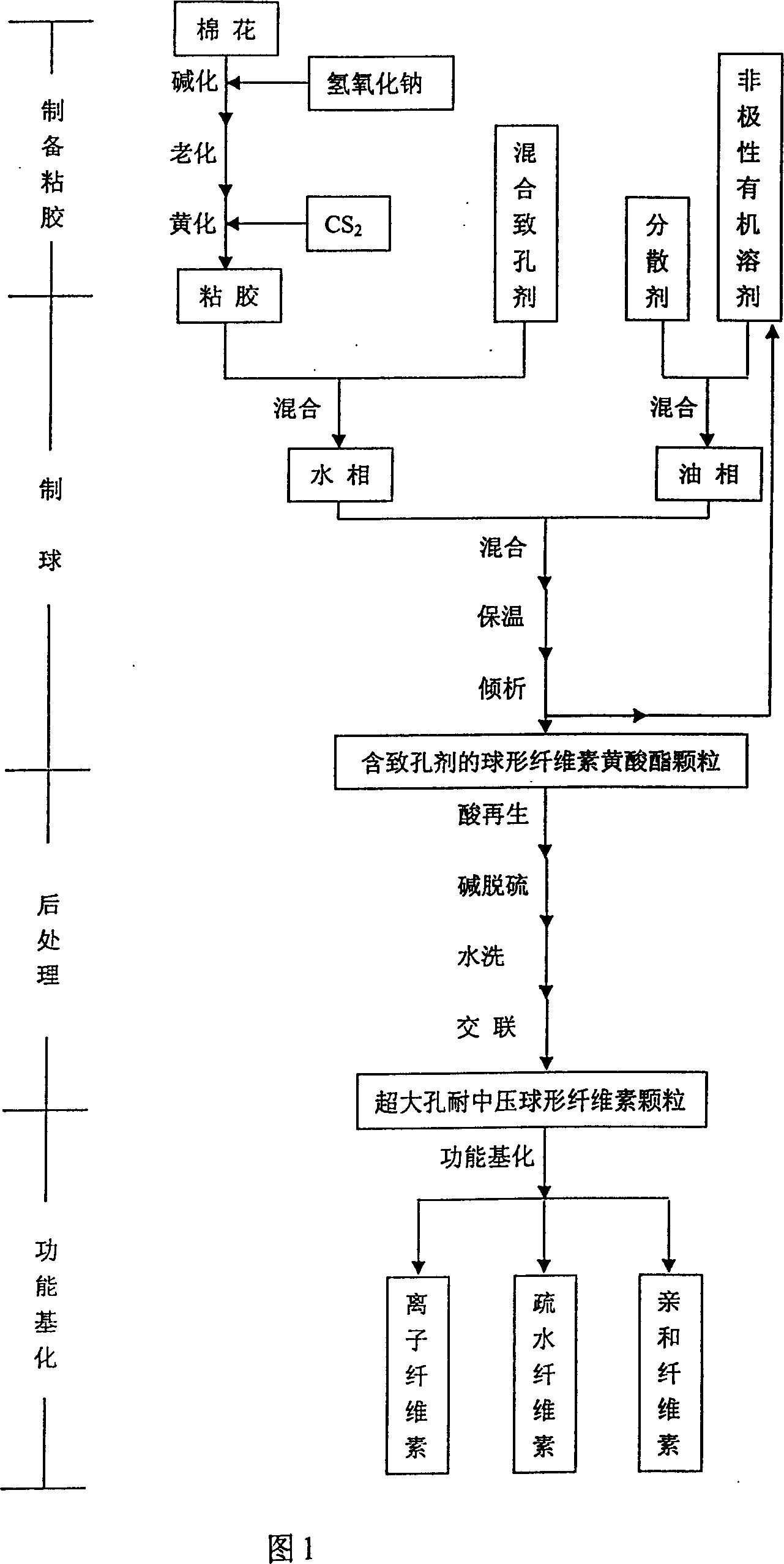

Production of super-macroporous intermediate-pressure-resisting spherical cellulose grain and adsorbent

A medium pressure (5-7 bar) resistant macroreticular spherical cellulose particle is prepared from cotton through alkalizing, ageing, xanthating to obtain cellulose xanthate viscose, mixing it with pore-forming agent, dispersing the mixture in oil phase, phase transfer of hot sol to obtain shperical cellulose xanthate porticles, regenerating by acid, desulfurizing by alkali, and cross-linking. An adsorbent is prepared from said spherical cellulose particles through activating by alkali and reacting respectively on alkyl halide salt, alkyl halide, or aglucone to obtain different kinds of adsorbent.

Owner:EAST CHINA UNIV OF SCI & TECH +1

A heavy metal sewage treatment material

ActiveCN105692771BEasy to produceHigh selectivityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionWater qualityTreated water

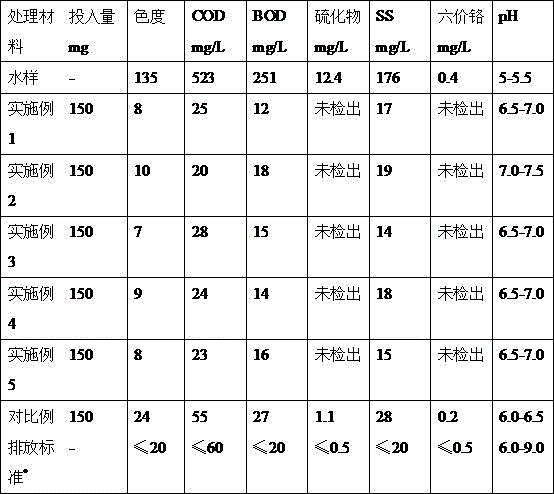

The invention discloses material for treating wastewater containing heavy metal. The material comprises, by weight, 10-20 parts of hydrochloric acid-modified sepiolite, 15-25 parts of pyridine quaternary ammonium salt type cationic polyacrylamide, 5-8 parts of zeolite powder, 3-10 parts of modified attapulgite, 10-15 parts of cellulose xanthate, 2-8 parts of chitosan, 10-25 parts of crosslinking carboxymethyl starch, 5-10 parts of hydroxy propyl cellulose grafted copolymer, 2-8 parts of ferric sulfate, 1-5 parts of lime powder and 3-8 parts of activated carbon powder, wherein hydroxy propyl cellulose grafted copolymer is formed by hydroxy propyl cellulose grafted with 4-vinyl pyridine. The material for treating the wastewater containing the heavy metal has the advantages that the material is used for separating and removing the heavy metal ions in an aqueous solution, is high in selectivity on the heavy metal ions, is capable of efficiently removing pollution, and is easy in raw material regeneration; energy consumption during the sewage treatment is avoided, the material is simple to produce, and the treated water can reach the discharge standards.

Owner:江西态然璞真环保科技有限公司

Flame-retardant silicate fiber, coagulation bath for producing flame-retardant silicate fiber and method for preparing flame-retardant silicate fiber

ActiveCN102605452AGuaranteed flame retardant performanceImprove physical and mechanical performance indicatorsFlame-proof filament manufactureMonocomponent cellulose artificial filamentFour componentCellulose pulp

The invention discloses flame-retardant silicate fiber, a coagulation bath for producing the flame-retardant silicate fiber and a method for preparing the flame-retardant silicate fiber. The coagulation bath for forming the silicate fiber contains H2SO4, ZnSO4, Na2SO4 and silicon series flame retardant. The method comprises the following steps of: (1) preparing cellulose xanthate viscose by using cellulose pulp as a raw material, adding a dissolved precursor solution of the flame retardant, filtering, ageing and defoaming to obtain flame-retardant spinning viscose; and (2) coagulating the flame-retardant spinning viscose in the four-component coagulation bath, drawing, refining, drying to obtain the flame-retardant viscose fiber. By adopting the four-component coagulation bath for preparing the flame-retardant fiber, the loss of the flame retardant in slivers can be reduced, the spinning property is improved, the physical and mechanical property indexes of the flame-retardant fiber are improved, and the production cost of the flame-retardant viscose fiber is reduced.

Owner:潍坊欣龙生物材料有限公司

Wastewater composite adsorption-flocculation material

ActiveCN105692772APromote environmental protectionReduce turbidityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionFiberTurbidity

The invention discloses a wastewater composite adsorption-flocculation material. The wastewater composite adsorption-flocculation material comprises adsorbent and flocculant, and is characterized in that the adsorbent comprises, by weight, 20-40 parts of bagasse cellulose xanthate, 15-25 parts of hollow bric particles, 5-15 parts of bagasse lignin magnesium sulfonate, 5-10 parts of expanded vermiculite particles, and 5-10 parts of modified attapulgite; the flocculant comprises, by weight, 20-30 parts of PSFC, 10-20 parts of hydrophobic modified lignin fibers, 20-40 parts of nonionic polyacrylamide, 2-10 parts of polyepichlorohydrin, 10-17 parts of polyhydroxy aluminum chloride silicon, and 3-8 parts of activated carbon powder. With reasonable formula, wastewater treatment process is simplified, wastewater treatment effect and efficiency are upgraded, and the wastewater composite adsorption-flocculation material is used for treatment of high-turbidity and high-organic content wastewater such as domestic and industrial wastewater.

Owner:辛集市梅花皮业有限公司

Sponge cloth with net

ActiveUS20110232018A1Easy to manufactureEasy to wearBathroom accessoriesCleaning machinesPolymer scienceThin layer

A cellulose sponge cloth based containing a net or grid as internal reinforcement is provided, with the sponge cloth further including a uniform distribution of fibers and / or durably softening polymers that are not water-leachable. The sponge cloth is produced by the viscose process by mixing with the fibers and / or the softening polymers and the pore former with cellulose xanthate and forming the resulting sponge cloth raw material into a thin layer. The grid or net is placed onto this layer, followed by a further layer of the sponge cloth raw material. Alkaline or acidic coagulation and regeneration baths and optional wash baths are used to dissolve the pore former out of the sponge cloth and regenerate the cellulose from the cellulose xanthate. The sponge cloth is bend-resistant, it does not break in the dry state. The sponge cloth is envisioned for cleaning and decontamination in industry and the home.

Owner:KALLE AG

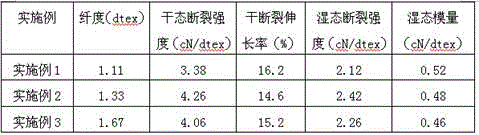

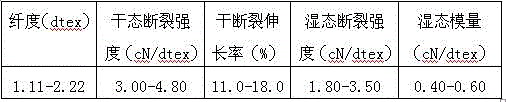

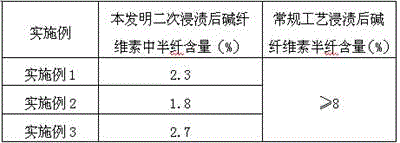

Method used for producing high wet modulus cellulose fiber

InactiveCN106498527AHigh purityImprove yellowing effectArtificial filament physical treatmentArtificial thread manufacturing machinesCellulose fiberAlpha-Cellulose

The invention provides a method used for producing high wet modulus cellulose fiber. The method comprises a step of secondary dipping after aging and before yellowing. Special technique is adopted, so that the method is capable of reducing generation of hemicellulose in aging, increasing the purity of alpha cellulose in yellowing, and improving yellowing effect. According to the method, zinc oxide is added before spinning, so that in solidification moulding process, generation of zinc cellulose xanthate in viscose is promoted, moulding is delayed, regenerated cellulose macromolecule crystallization and zinc ion crystal nucleus effect are inhibited, and high density small and scattered crystal regions are formed on the surface of viscose threads; and fiber strength and modulus are increased to the highest degree when adding amount of zinc oxide is controlled to be 1.2 to 2.0%.

Owner:CHTC HELON (WEIFANG) NEW MATERIALS CO LTD

Single-fiber fine-denier viscose filament yarn and production method thereof

InactiveCN104593894ACompact structureSoft touchSpinnerette packsFilament manufactureCellulosePolymer science

The invention discloses a single-fiber fine-denier viscose filament yarn and a production method thereof. The production method comprises the following steps: soaking mixed pulp of cotton, wood and bamboo in a 210-250g / L NaOH solution at a temperature of 38-55 DEG C, and performing oxidative degradation on alkali cellulose at a temperature of 25-50 DEG C; performing yellowing reaction on the alkali cellulose and CS2 with the addition amount accounting for 32.5-35% of the amount of alpha-cell to obtain cellulose xanthate, then, adding dissolved alkali liquor and soft water to dissolve the cellulose xanthate into dissolved gum; grinding the dissolved gum at a temperature of 12-20 DEG C, dissolving, homogenizing, mixing, filtering and ripening to obtain spinning viscose; coagulating the spinning viscose in a coagulating bath, dissolving and regenerating to prepare the fine-denier viscose filament yarn with the fineness of 0.5dtex-1.11dtex. The single-fiber fine-denier viscose filament yarn produced by adopting the preparation method is compact in structure, soft in hand feeling, fine in texture, soft, full, high in elasticity, good in conformality, strong in cleaning capacity, high in moisture absorption, gas permeability, antibacterial, bacteriostatic, and excellent in wearability.

Owner:BAODING SWAN NEW FIBER MFG CO LTD

Preparing method for urea solution used for vehicles

InactiveCN105921014ARemove completelyEasy to handleGas treatmentDispersed particle separationIon exchangeN-methylsuccinimide

The invention discloses a preparing method for a urea solution used for vehicles. The preparing method comprises the following steps that by weight, 20-35 parts of urea, 60-80 parts of high-purity water, 5-10 parts of ethanol, 4-7 parts of N-methylsuccinimide and 1-3 parts of polyoxyethylene stearate are weighed; urea and high-purity water are mixed and stirred, and a urea solution is obtained; a cellulose xanthate adsorbent is added into the urea solution, stirring and filtering are carried out, and a clarified urea solution is obtained; then ion exchange is carried out, and a purified urea solution is obtained; finally, the purified urea solution, ethanol, N-methylsuccinimide and polyoxyethylene stearate are stirred evenly, and the urea solution used for vehicles is obtained. The method has the advantages of being simple in preparing process, high in production efficiency, environmentally friendly, low in cost, remarkable in impurity removing effect and the like, and industrial production is easy to achieve.

Owner:NANNING XIAYANG CHEM TECH CO LTD

Negative ion cellulose/alginate composite fiber and its preparing method

InactiveCN100415959CLess investmentLow costFilament/thread formingConjugated cellulose/protein artificial filamentsWound healingCellulose

The present invention discloses a kind of composite negative ion cellulose / alginate fiber and its preparation process. Technologically, the present invention features that viscous sodium alginate solution prepared in certain technological condition, functional finishing agent slurry of negative ion generating material and cellulose xanthate in certain weight proportion are mixed to form the spinning solution, and the through further spinning and refining steps, the composite negative ion cellulose / alginate fiber is prepared. The composite fiber consists of cellulose 76-99.6 weight portions, sodium alginate 0.02-15 weight portions and negative ion generating material 0.02-9 weight portions. The composite fiber may be used in weaving fabric with the functions of killing bacteria, protecting skin, promoting wound healing, generating negative ion, etc. and is suitable for use in medical field and in making various kinds of high grade underwear, etc.

Owner:BOFINE TEXTILE

Material for treating wastewater containing heavy metal

ActiveCN105692771AEasy to produceHigh selectivityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionWater qualityTreated water

The invention discloses material for treating wastewater containing heavy metal. The material comprises, by weight, 10-20 parts of hydrochloric acid-modified sepiolite, 15-25 parts of pyridine quaternary ammonium salt type cationic polyacrylamide, 5-8 parts of zeolite powder, 3-10 parts of modified attapulgite, 10-15 parts of cellulose xanthate, 2-8 parts of chitosan, 10-25 parts of crosslinking carboxymethyl starch, 5-10 parts of hydroxy propyl cellulose grafted copolymer, 2-8 parts of ferric sulfate, 1-5 parts of lime powder and 3-8 parts of activated carbon powder, wherein hydroxy propyl cellulose grafted copolymer is formed by hydroxy propyl cellulose grafted with 4-vinyl pyridine. The material for treating the wastewater containing the heavy metal has the advantages that the material is used for separating and removing the heavy metal ions in an aqueous solution, is high in selectivity on the heavy metal ions, is capable of efficiently removing pollution, and is easy in raw material regeneration; energy consumption during the sewage treatment is avoided, the material is simple to produce, and the treated water can reach the discharge standards.

Owner:江西态然璞真环保科技有限公司

Preparation process of high-toughness tencel fibers for clothes

InactiveCN106894114AImprove toughnessNo residueArtificial filaments from cellulose solutionsCellulose/protein filament chemical after-treatmentFiberHigh pressure

A preparation process of high tenacity tencel fibers for clothing. The preparation process of the present invention uses logs as raw materials for fiber preparation, and obtains broken wood after extrusion and crushing, soaks in dilute alkali solution, and obtains alkali cellulose solution after filtration; Aging, yellowing, aging and other processes to obtain cellulose xanthate solution, use acidic solution to precipitate cellulose, and prepare pure wood cellulose pulp; use negative pressure suction to reduce the boiling point and water content of the cellulose solution to the optimum Spinnability. Using high-pressure spinning technology, the solvent in the thin stream of spinning solution is quickly volatilized by hot air flow, and solidified into primary fibers. Citric acid is used as a crosslinking agent to improve fiber toughness. A kind of preparation method of bamboo fiber for high tear-resistant clothing provided by the present invention, its operation is simple, does not use organic solvent, green environmental protection, citric acid carries out post-finishing to primary fiber, can form network connection structure on fiber surface, makes The fiber toughness has been significantly improved and the wrinkle resistance has been significantly increased.

Owner:广东洪兴实业股份有限公司

Warp direction viscose fabric and preparation method thereof

InactiveCN101705560ASolve the defect that the color is dark and not brightSoft touchWoven fabricsYarnHeat resistanceEngineering

The invention relates to a warp direction viscose fabric and a preparation method thereof and provides a textile fabric with soft handfeel and good luster and a preparation method thereof. The warp yarn can be divided into gray yarn and color yarn, the yarn count is 45D-225D, and the warp direction viscose fabric is woven by using viscose as warp thread; and the viscose fabric is prepared by the following steps: firstly removing impurities in the cotton linter through physical and chemical methods, extracting cellulose, dipping, maturing, cooling, yellowing, dissolving to obtain the molecular solution of soluble cellulose xanthate-viscose, then performing coagulation forming of viscose in acid bath by using the spinning jet to obtain continuous, thin and white wires, washing and oiling to form the viscose fabric. The fabric provided by the invention is made from viscose fabric, the constructional material of the viscose fabric is cellulose, the viscose fabric has low macromolecule polymerization degree, better hygroscopicity and dyeing performance, better heat resistance, light resistance and borer resistance, the arrangement of the viscose fabric is not tight enough, but the elasticity of the viscose fabric is not good; and the viscose fabric textile has soft handfeel so as to attract more and more consumers.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Negative ion cellulose/alginate composite fiber and its preparing method

InactiveCN1858311ALess investmentLow costFilament/thread formingConjugated cellulose/protein artificial filamentsWound healingCellulose

The present invention discloses a kind of composite negative ion cellulose / alginate fiber and its preparation process. Technologically, the present invention features that viscous sodium alginate solution prepared in certain technological condition, functional finishing agent slurry of negative ion generating material and cellulose xanthate in certain weight proportion are mixed to form the spinning solution, and the through further spinning and refining steps, the composite negative ion cellulose / alginate fiber is prepared. The composite fiber consists of cellulose 76-99.6 weight portions, sodium alginate 0.02-15 weight portions and negative ion generating material 0.02-9 weight portions. The composite fiber may be used in weaving fabric with the functions of killing bacteria, protecting skin, promoting wound healing, generating negative ion, etc. and is suitable for use in medical field and in making various kinds of high grade underwear, etc.

Owner:BOFINE TEXTILE

Diesel tail gas treating agent production method

InactiveCN105854603AGood processing effectThere will be no phenomenon of blocking the SCRGas treatmentDispersed particle separationPore diameterCocamidopropyl betaine

The invention discloses a diesel tail gas treating agent production method. The method includes steps: weighing, by weight, 30-40 parts of carbamide, 80-100 parts of high-purity water, 8-12 parts of methanol, 3-5 parts of aminooxoacetic acid and 2-5 parts of cocamidopropyl betaine; mixing the carbamide and the high-purity water, and stirring to obtain a carbamide solution; adding a cellulose xanthate adsorbent into the carbamide solution, stirring, filtering, and removing solid impurities to obtain a clear carbamide solution; filtering through a nanofiltration membrane with the pore diameter being 1-2nm to obtain a pure carbamide solution; mixing with the methanol, the aminooxoacetic acid and the cocamidopropyl betaine, and well stirring to obtain a diesel tail gas treating agent. The diesel tail gas treating agent production method has advantages of technical simplicity, high production efficiency, environment friendliness, low cost, remarkable impurity removal effects and the like.

Owner:NANNING XIAYANG CHEM TECH CO LTD

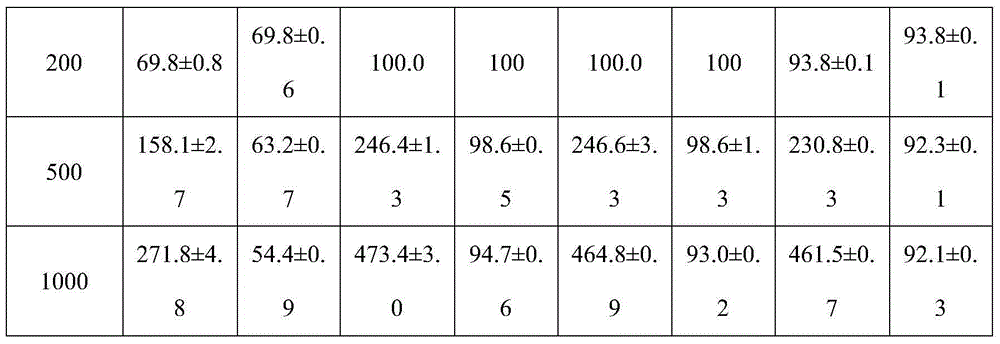

Channel augmentative method for fiber sphere separating medium

InactiveCN101053822ALarge apertureFast deliveryOther chemical processesCelluloseChromatographic separation

The invention discloses a pore channel expanding method for a cellulose sphere separated substrate, with steps of: 1) preparing compound water phase by mixing gelling starch solution and cellulose xanthate viscose and agitating the same uniformly; 2) thermosetting to form a ball shape by combining an oil phase and a surfactant to form an inverse suspension disperse system, and rising the temperature; 3) removing starch by washing the solidified microsphere by boiled water for five times, adding amylase solution after cooled, then table separating, and water washing; 4) regenerating to obtain the sphere separated substrate by washing the microsphere using organic solvent and regenerating via acid, thus a macropore cellulose sphere separated substrate is obtained. The cellulose sphere separated substrate of the invention has characteristics of large aperture and high pore-size distribution, in addition to advantages of good hydrophilicity, degree of sphericity, acid and alkali resistance and low cost. A test experiment shows that the substrate is applicable to biological macromolecule chromatographic separation medium.

Owner:ZHEJIANG UNIV

Chloroprene latex adhesive composition

InactiveCN105255393ANon-macromolecular adhesive additivesMacromolecular adhesive additivesCellulosePolymer science

A chloroprene latex adhesive composition is prepared form chloroprene latex, apatite powder, xanthonic acid cellulose ether, cyclodextrin and white carbon black according to proportions. The adhesion of chloroprene latex is large, so that apatite powder and xanthonic acid cellulose ether are added to serve as packing in the formula, and thus the prepared adhesive composition has high adhesion performance.

Owner:王晓伟

Globular cellulose DNA immunoadsorbent

InactiveCN1111430CImprove adsorption capacityGood clinical effectPharmaceutical non-active ingredientsImmunological disordersCelluloseChlorobenzene

The present invention is one medical adsorbent material. Short cotton velvet as material is processed successively through bleaching with sodium hypochlorite, treatment with sodium hydroxide and carbon disulfide to obtain cellulose xanthate derivative, which is heated and solidified at 85-95 deg.c for 1-3 hr through suspension process utilizing chlorobenzene and carbon tetrachloride as dispersing medium to obtain globular cellulose. The globular cellulose is then activated with epoxychloroproane in alkali condition and reacted with DNA solution to result in globular cellulose DNA immunoadsorbent with DNA content of 0.5-3.0 mg each milliliter resin. The said immunoadsorbent is superior to carbonized resin DNA immunoadsorbent in DNA fixing amount and adsorptivity and is one new product for treating systematic lupus erythematosus.

Owner:NANKAI UNIV

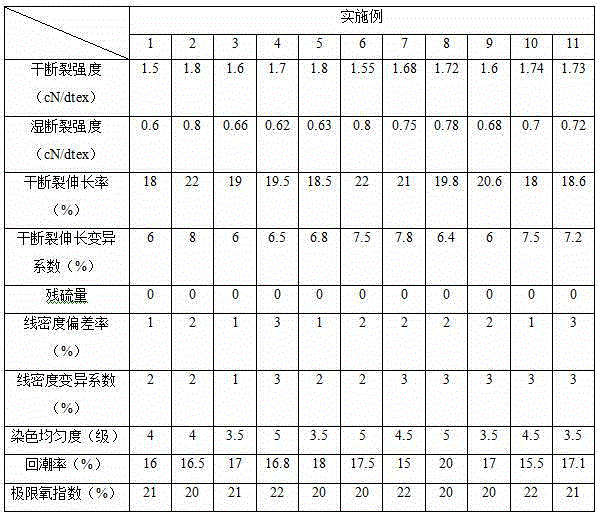

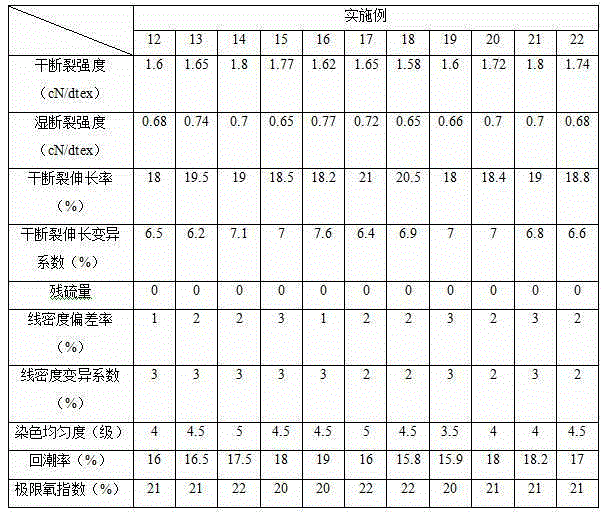

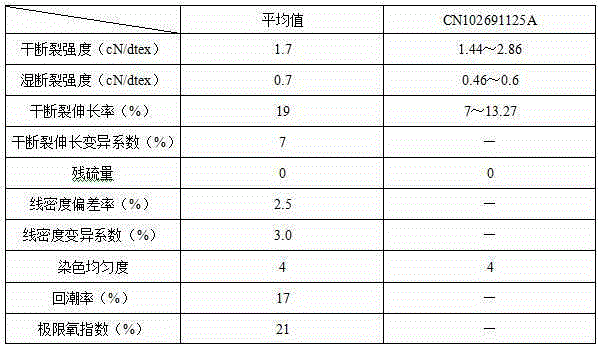

Cellulose carbamate filament yarn

ActiveCN106702513AImprove spinnabilityImprove performanceArtificial filaments from cellulose solutionsArtificial filaments from cellulose derivativesBreaking strengthCarbamate

The invention discloses a cellulose carbamate filament yarn. The cellulose carbamate filament yarn is prepared by the following steps of esterifying and dissolving activated cellulose to obtain a cellulose carbamate solution, so as to replace a spinning solution prepared from cellulose xanthate; performing wet type spinning, so as to obtain the cellulose carbamate filament yarn. The prepared cellulose carbamate filament yarn has the characteristics that the dry break strength is more than or equal to 1.5cN / dtex, the wet break strength is 0.6 to 0.8cN / dtex, and the dry elongation at break is 18 to 22%; the cellulose carbamate filament yarn is a low-strength and high-tension type regenerated cellulose fiber; the product property is good, residue is avoided, and the cellulose carbamate filament yarn can be applied to civil industries of clothes fabrics, nonwoven cloth, sanitary products and the like.

Owner:YIBIN GRACE GROUP CO LTD

Flame retardant heat insulating material

InactiveCN106673581AEfficient flame retardantImprove corrosion resistanceCalcium silicatePolyvinyl alcohol

The invention discloses a flame retardant heat insulating material which comprises the following matters in parts by weight: 10-18 parts of glass beads, 8-15 parts of calcium silicate, 3-5 parts of nonionic acrylic acid, 6-10 parts of crushed crude pearlite, 1-3 parts of organosilicone modified epoxy resin, 2-6 parts of hydrogenated acrylonitrile butadiene rubber, 2-4 parts of tourmaline negative ion powder, 6-14 parts of a polyacrylate emulsion, 1-6 parts of polypropylene fibers, 2-4 parts of ammonium polyphosphate, 6-9 parts of magnesium carbonate, 2-6 parts of sugarcane bagasse cellulose xanthate, 2-5 parts of melamine cyanurate acid, 4-9 parts of sepiolite fibers, 2-8 parts of silicon carbide, 5-9 parts of triisocyanocyanate, 2-5 parts of polyvinyl alcohol, 1-6 parts of a nuclear shell macromolecular polymerized emulsion and 2-5 parts of glass fibers. The flame retardant heat insulating material disclosed by the invention is efficient and flame retardant, corrosion-resistant, good in airtightness, stable in physical and chemical properties and high in aging resistance and weather resistance, has excellent heat insulating, fireproof and sound-absorbing properties, has a certain eliminating effect on indoor peculiar smells and various harmful gas and is low in comprehensive production cost.

Owner:GUANGXI BEIHAI HAOBANG NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com