Cellulose carbamate filament yarn

A technology of carbamate and cellulose, which is applied in the field of cellulose carbamate fiber filament and regenerated cellulose fiber filament, can solve the problem of energy saving and environmental protection of regenerated cellulose fiber, regenerated cellulose The fiber detection index is difficult to meet the problems of downstream products, and the performance of regenerated cellulose fibers is quite different, so as to achieve the effect of improving product value and use, good spinnability, and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

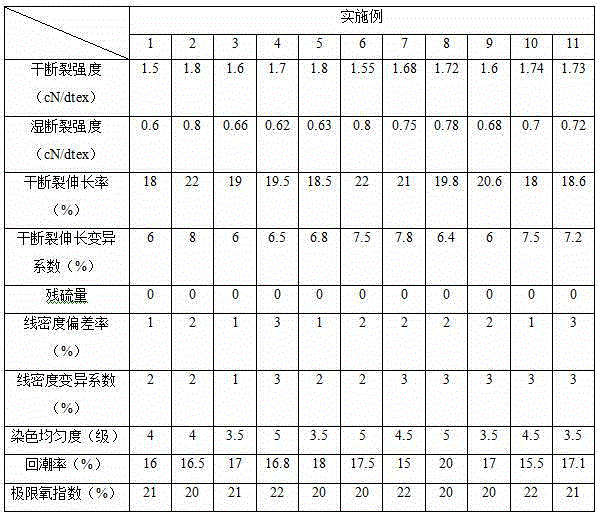

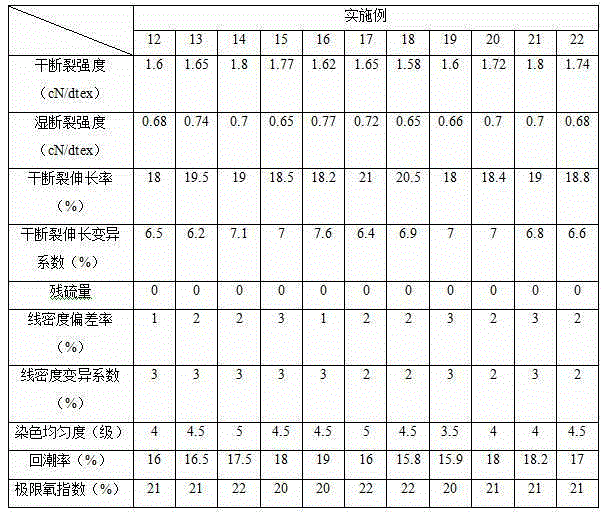

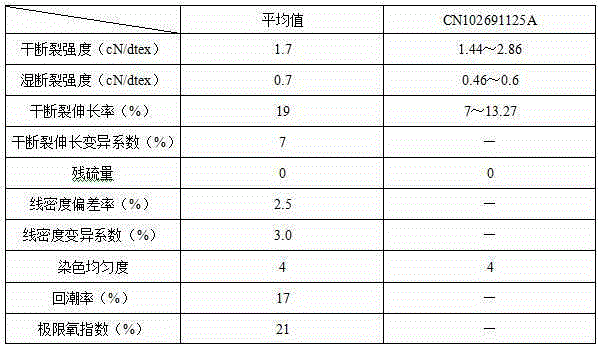

Embodiment 1

[0029] This embodiment proposes a cellulose urethane fiber filament, which is made of activated cellulose through esterification and dissolution to obtain a spinning stock solution, and then through wet spinning Made from silk, the cellulose urethane fiber filament meets the following indicators:

[0030] Dry breaking strength 1.5cN / dtex, wet breaking strength 0.6cN / dtex,

[0031] The dry elongation at break is 18%, and the coefficient of variation of dry elongation at break is 6%.

[0032] The residual sulfur content is 0.

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is: the cellulose urethane fiber filament that this embodiment involves satisfies the following indicators:

[0035] Dry breaking strength 1.8cN / dtex, wet breaking strength 0.8cN / dtex,

[0036] The dry elongation at break is 22%, and the coefficient of variation of dry elongation at break is 8%.

[0037] The residual sulfur content is 0.

Embodiment 3

[0039] On the basis of Example 1, this embodiment optimizes other index parameters of cellulose urethane fiber filaments, as follows:

[0040] The deviation rate of linear density of cellulose urethane fiber filament is 1%, and the coefficient of variation of linear density is 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com