Wastewater composite adsorption-flocculation material

A composite adsorption and flocculation technology, applied in the fields of adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. and other problems, to achieve the effect of good effluent quality, good treatment effect and stable treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

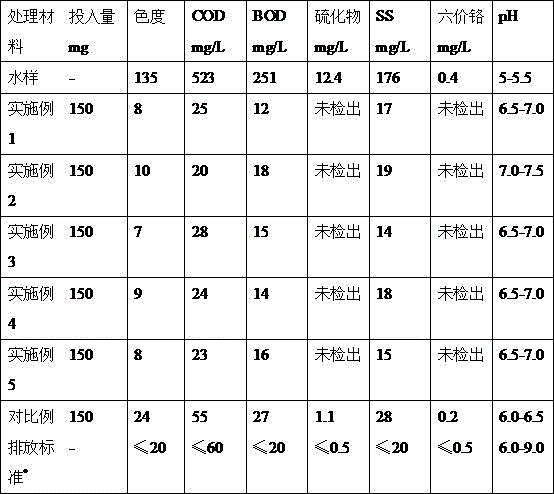

Examples

Embodiment 1

[0013] Embodiment 1: A composite adsorption-flocculation treatment material for wastewater, including an adsorbent and a flocculant, the adsorbent includes the following raw materials in parts by mass: 30 parts of bagasse cellulose xanthate, 20 parts of hollow brick particles, bagasse woody 10 parts of magnesium sulfonate, 8 parts of expanded vermiculite particles and 7 parts of modified attapulgite; the flocculant includes 25 parts of raw material polysilicate ferric chloride and 15 parts of hydrophobically modified lignin fiber in the following mass parts , 30 parts of nonionic polyacrylamide, 6 parts of polyepichlorohydrin, 15 parts of polyhydroxy aluminum silicon chloride and 5 parts of activated carbon powder.

Embodiment 2

[0014] Embodiment 2: A composite adsorption-flocculation treatment material for wastewater, including an adsorbent and a flocculant, the adsorbent includes the following raw materials in parts by mass: 20 parts of bagasse cellulose xanthate, 15 parts of hollow brick particles, bagasse woody 5 parts of magnesium sulfonate, 5 parts of expanded vermiculite particles and 5 parts of modified attapulgite; the flocculant includes 30 parts of raw material polysilicate ferric chloride and 20 parts of hydrophobic modified lignin fiber in the following mass parts , 40 parts of nonionic polyacrylamide, 10 parts of polyepichlorohydrin, 17 parts of polyhydroxy aluminum silicon chloride and 8 parts of activated carbon powder.

Embodiment 3

[0015] Embodiment 3: A composite adsorption-flocculation treatment material for wastewater, including an adsorbent and a flocculant, the adsorbent includes the following raw materials in parts by mass: 40 parts of bagasse cellulose xanthate, 25 parts of hollow brick particles, bagasse woody 15 parts of magnesium sulfonate, 10 parts of expanded vermiculite particles and 10 parts of modified attapulgite; the flocculant includes 20 parts of raw material polysilicate ferric chloride in the following parts by mass, and 10 parts of hydrophobically modified lignin fiber , 20 parts of nonionic polyacrylamide, 2 parts of polyepichlorohydrin, 10 parts of polyhydroxy aluminum silicon chloride and 3 parts of activated carbon powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com