Preparation method and application of eichhornia crassipes cellulose xanthate calcium salt

A technology of calcium xanthate and cellulose, which is applied in the field of resources and the environment, can solve the problems such as the lack of preparation technology of cellulose xanthate, and achieve the effects of high chemical modification efficiency, improved adsorption effect, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

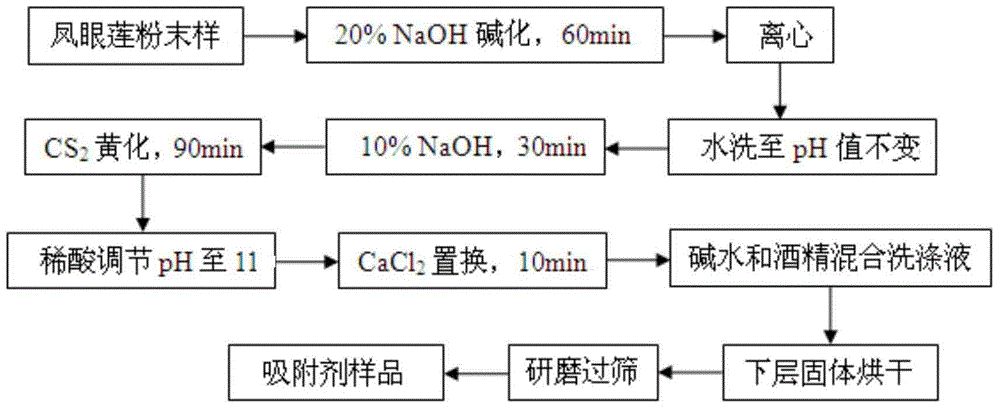

[0031] A preparation method of water hyacinth cellulose xanthate calcium salt, the preparation steps are:

[0032] 1) Add 100 mL of 20% (w / v, weight-to-volume ratio, the same below) sodium hydroxide solution to every 5 g of water hyacinth stem and leaf straw powder sample, and stir for 60 minutes in a constant temperature (30°C) electromagnetic stirrer (the same below) , centrifuge, pour out the upper layer of black liquor, and the lower layer of solid is alkalized cellulose;

[0033] 2) transfer the alkalized cellulose into a conical flask, wash with distilled water until the pH value is stable, centrifuge, and discard the liquid phase;

[0034] 3) Add 100mL of 10% sodium hydroxide solution to the solid in step 2), and wash the cellulose on the bottle wall into the bottle with 8-15ml of distilled water, stir for 30min, then slowly add 0.2mL of CS 2 , 30°C, stirred for 90 minutes;

[0035] 4) The material obtained in step 3) is subjected to solid-liquid separation, and the l...

Embodiment 2

[0041] Embodiment 2: the application of a kind of water hyacinth cellulose xanthate calcium salt in heavy metal wastewater treatment, its application process is:

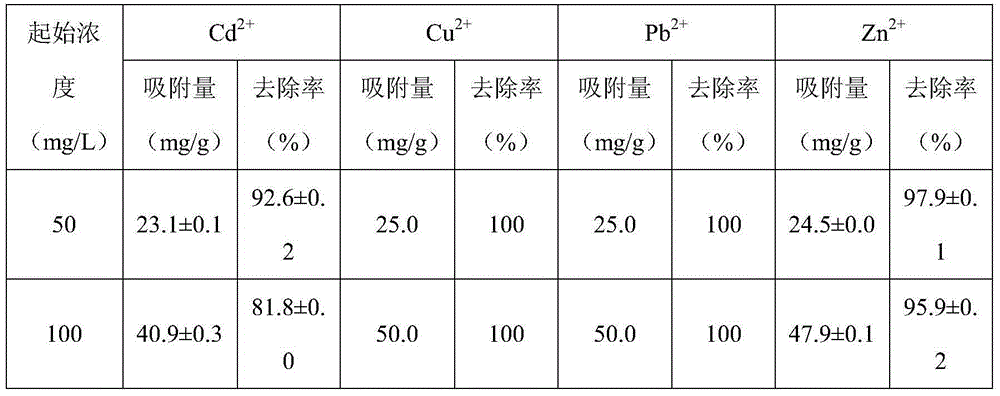

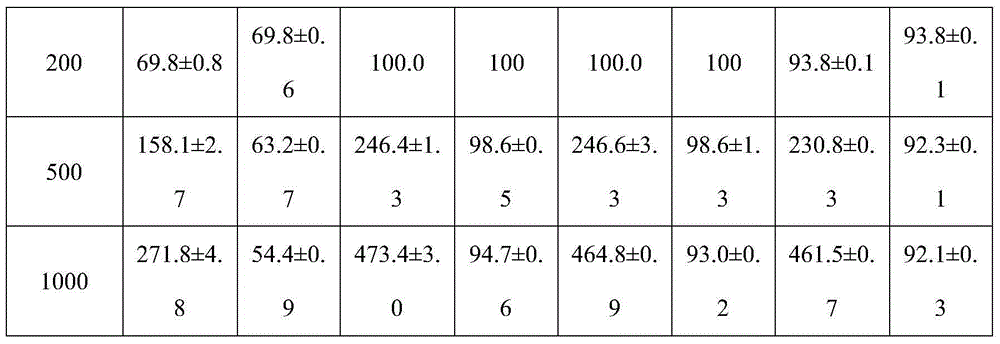

[0042]Get the water hyacinth cellulose xanthate calcium salt adsorbent 0.10g that makes in embodiment 1, add the Cd of 50mL1000mg / L 2+ The solution was shaken in a constant temperature shaker at 25°C for 30min, and the shaker speed was 150rpm. After the adsorption was completed, it was filtered, and the Cd in the solution after adsorption was determined by atomic absorption method. 2+ Concentration, according to Cd before and after adsorption 2+ The concentration calculated for the adsorbent material for Cd 2+ the amount of adsorption. The experimental results show that the adsorption capacity of the adsorbent prepared in Example 1 is 271.8±4.8 mg / g.

[0043] Under the same conditions as the above adsorption conditions (0.10g adsorbent, 50mL solution containing heavy metals, oscillating adsorption for 30min in a ...

Embodiment 3

[0047] Control group 1-5, compared with the technical scheme described in embodiment 1, do following processing respectively:

[0048] Contrast 1, its preparation steps are:

[0049] 1) Add 100mL of 20% (w / v, weight to volume ratio, the same below) sodium hydroxide solution to every 5g of water hyacinth stem and leaf straw powder sample; stir in a constant temperature (30°C) electromagnetic stirrer for 60min, centrifuge, pour The upper layer of black liquor is discharged, and the lower layer of solid is alkalized cellulose.

[0050] 2) Transfer the alkalized cellulose into the Erlenmeyer flask, then add 100mL of 10% (w / v) sodium hydroxide solution to the solid, and wash the cellulose on the bottle wall into the bottle with a small amount of distilled water, and stir for 30 minutes. Then slowly add 0.2mL CS 2 (carbon disulfide), 30°C, stirring for 90 minutes;

[0051] 3) The material obtained in step 2) is subjected to solid-liquid separation, and the liquid phase is discard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com