Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83 results about "Aeronautical industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The aerospace industry is a global aggregate of public institutions and private corporations focused on research, technology, and manufacturing of products related to flight, atmospheric and beyond. Although a relatively new industry, its scope in national defense, communications, and commercial air travel made the aerospace industry one of the defining enterprises of the 20th century, and it promises to be at least as important in the future.

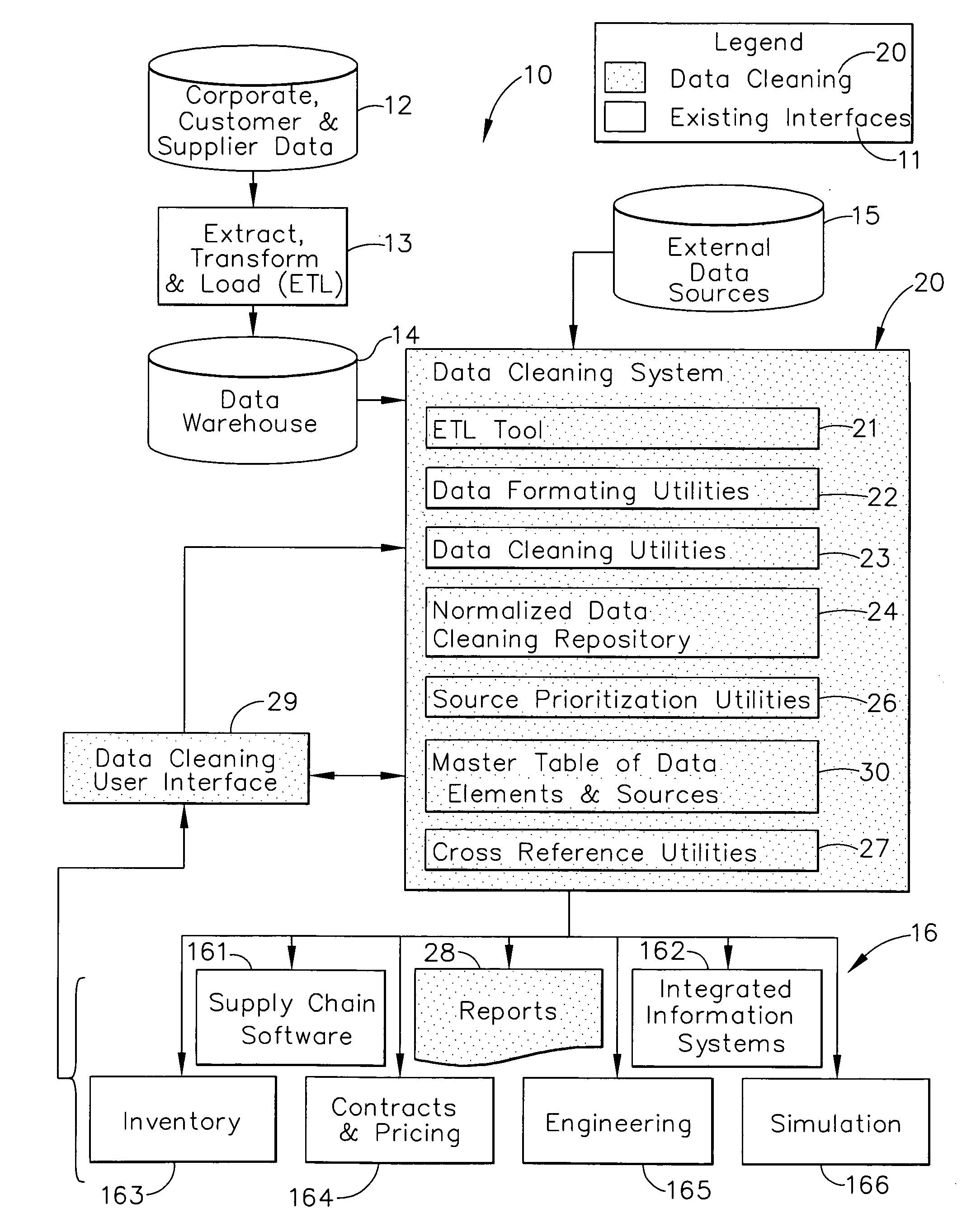

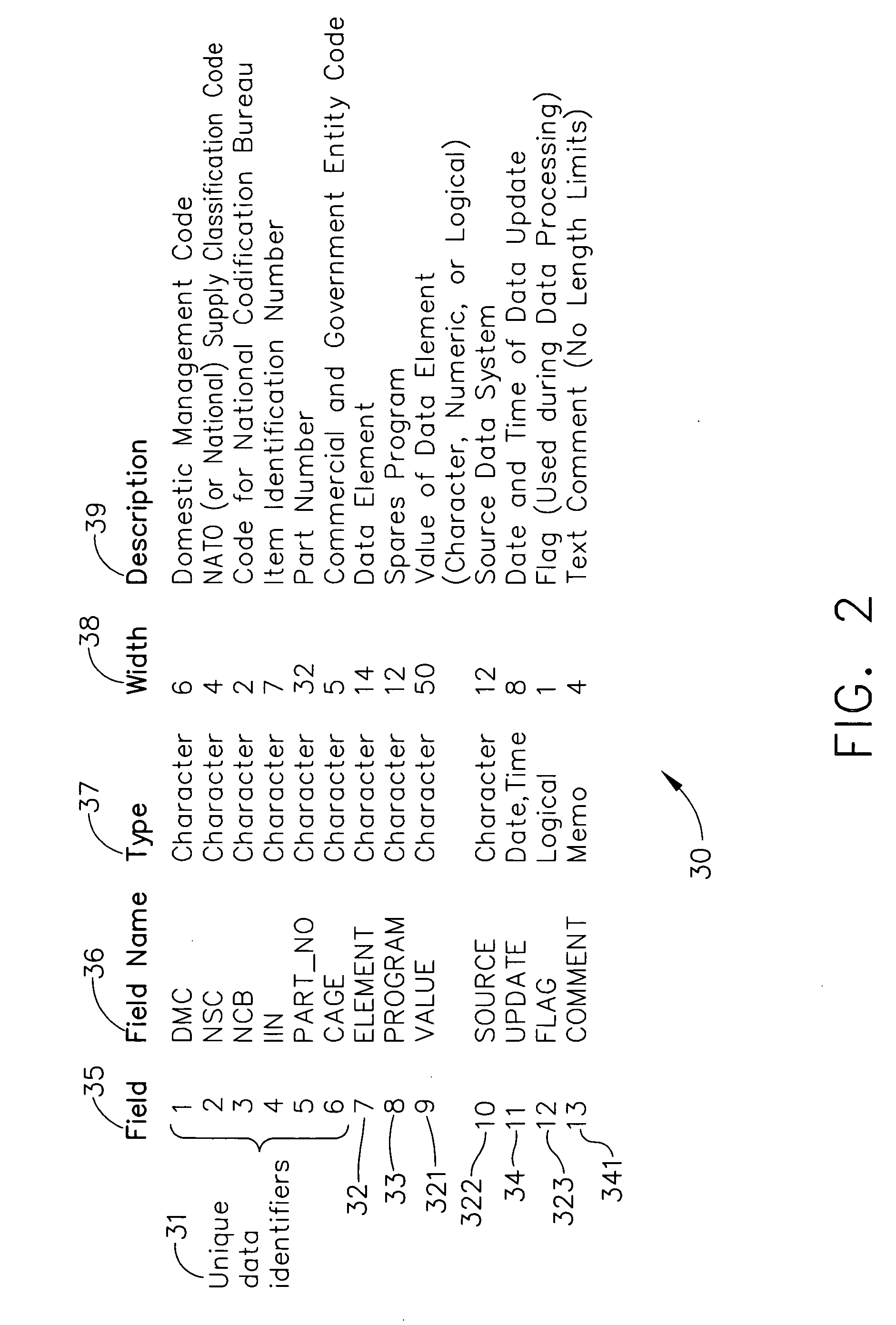

Adaptive data cleaning

InactiveUS20060238919A1Digital data information retrievalRecord information storageAnalysis dataData system

A data cleaning process includes the steps of: validating data loaded from at least two source systems; appending the validated data to a normalized data cleaning repository; selecting the priority of the source systems; creating a clean database; loading the consistent, normalized, and cleansed data from the clean database into a format required by data systems and software tools using the data; creating reports; and updating the clean database by a user without updating the source systems. The data cleaning process standardizes the process of collecting and analyzing data from disparate sources for optimization models enabling consistent analysis. The data cleaning process further provides complete auditablility to the inputs and outputs of data systems and software tools that use a dynamic data set. The data cleaning process is suitable for, but not limited to, applications in aircraft industry, both military and commercial, for example for supply chain management.

Owner:THE BOEING CO

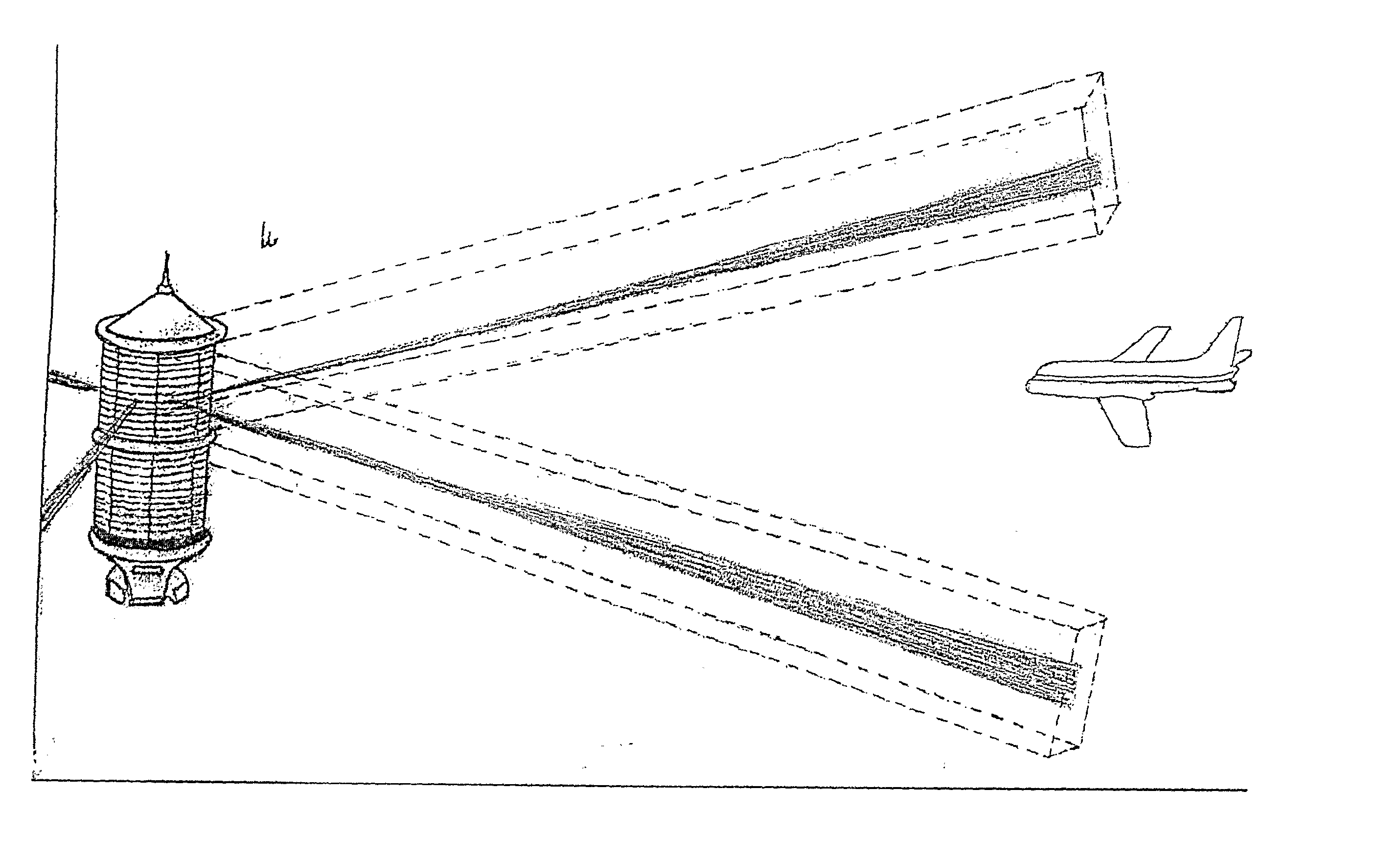

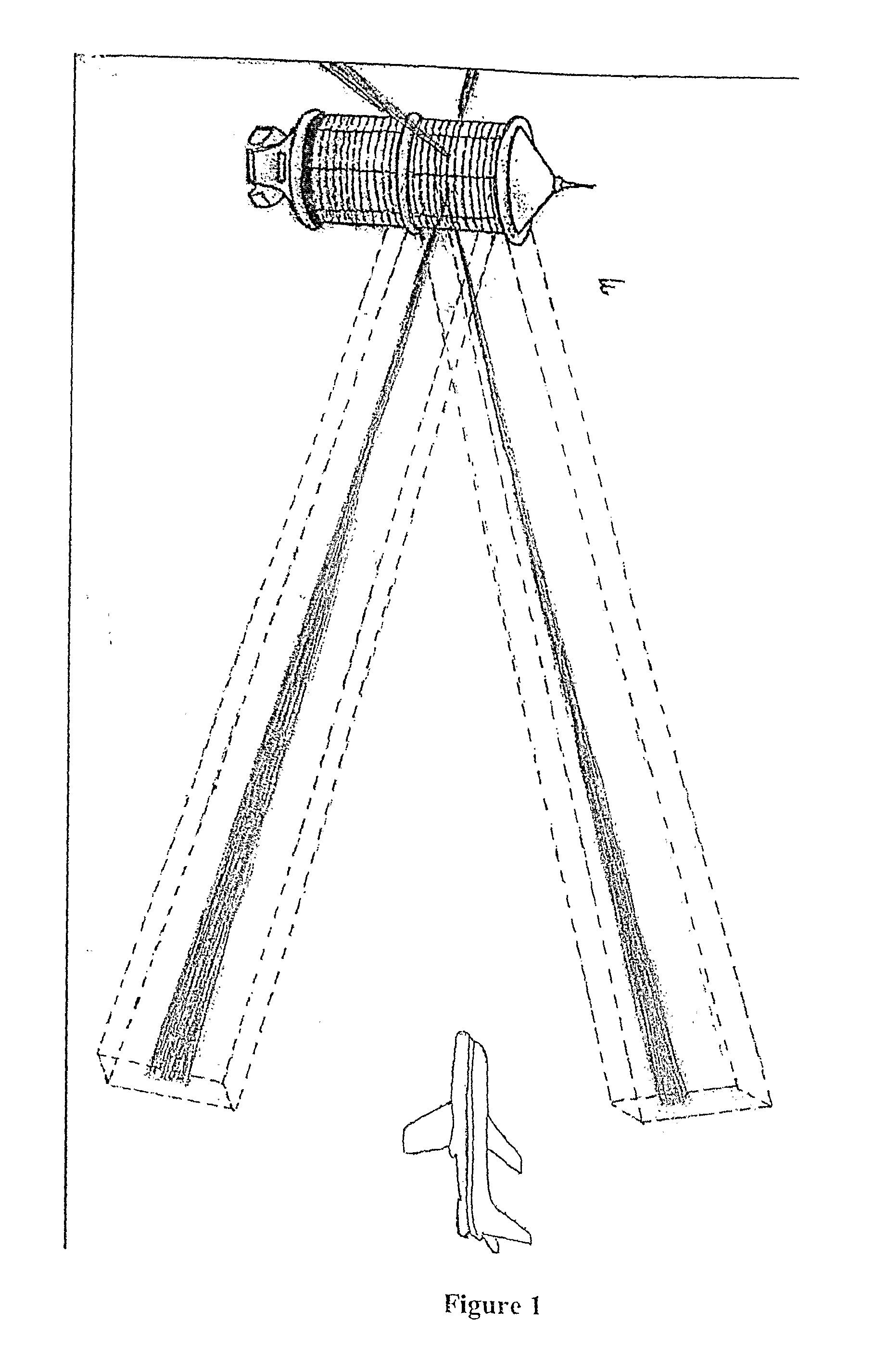

Lighting Device

InactiveUS20080094819A1Adjustable light intensityProvide rigidityLighting applicationsLighting support devicesAviationLight beam

A lighting device comprising, one or more semiconductor light-sources for generating a light beam, at least a motor for rotating said light beam, and a controller for controlling speed of rotation of the motor and intensity of the light-source and monitoring the operating conditions, detecting failures of the lighting device and / or, any of its components and setting off alarms which could be audio / visual and / or, radio or, telecom equipment using land and / or, air and / or, satellite links. The light beam generated by the light-sources is rotated. The light assembly broadly finds application in aviation industry, obstacle beacons, lighthouses and entertainment industry.

Owner:VAISH HIMANGSHU RAI

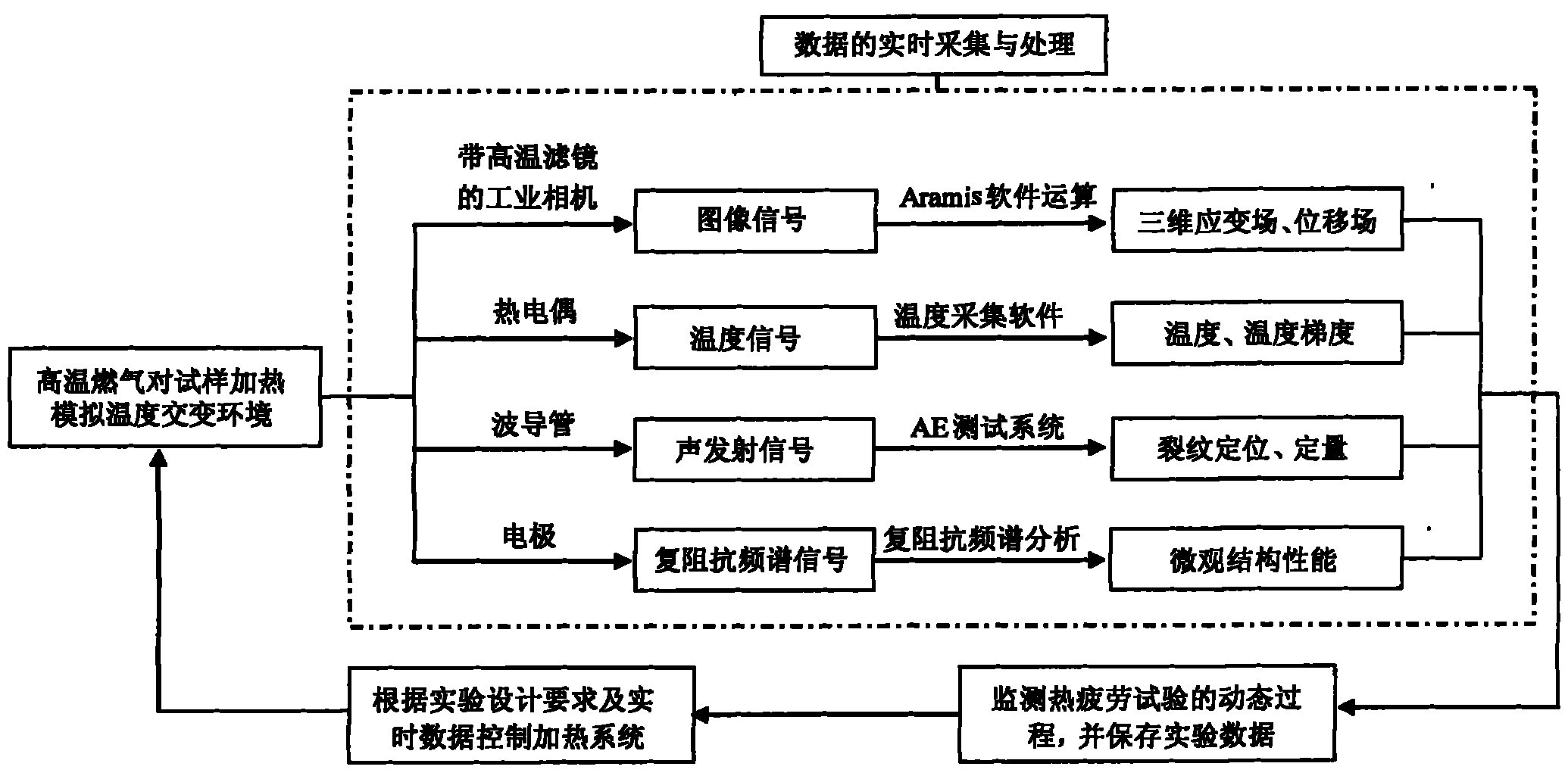

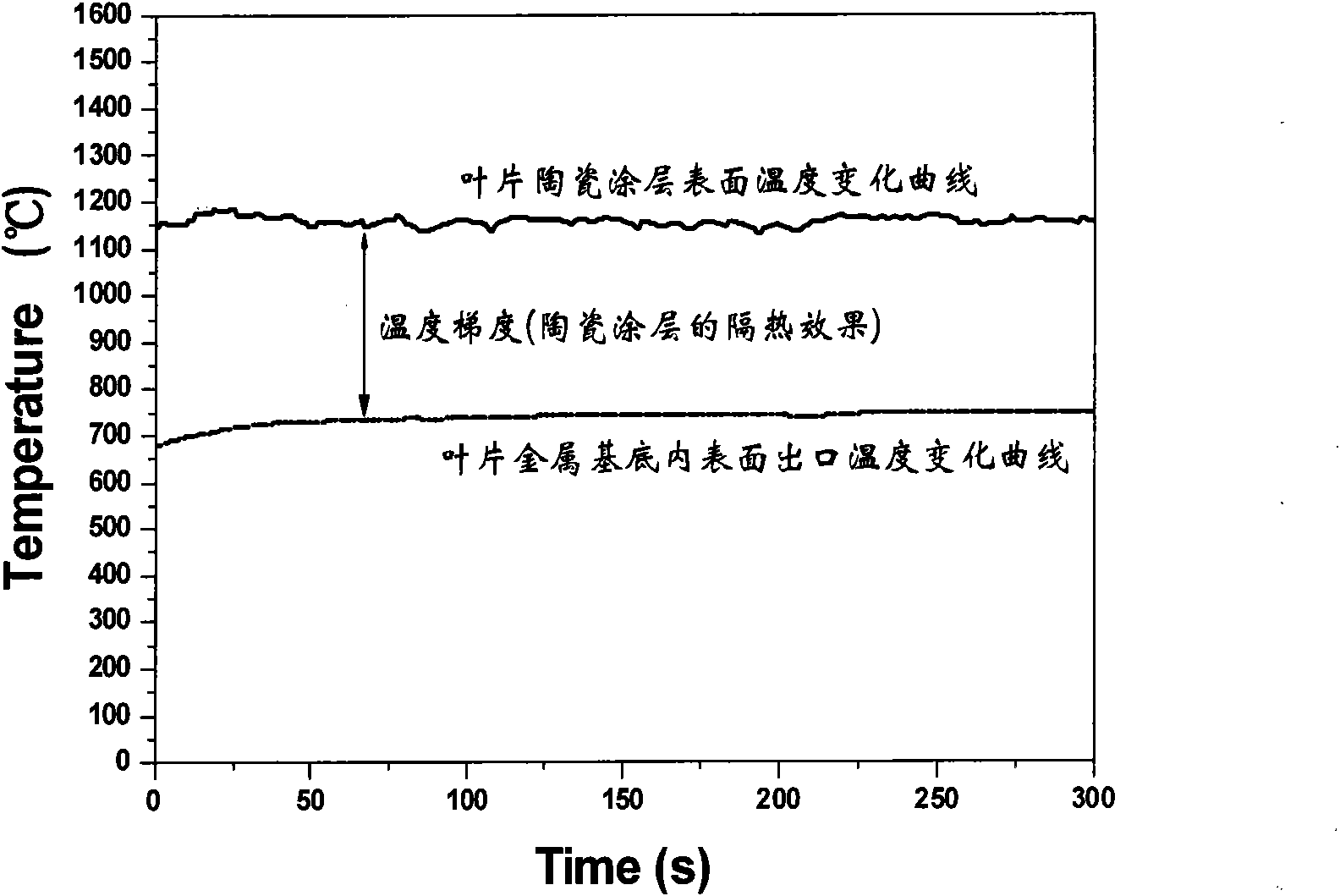

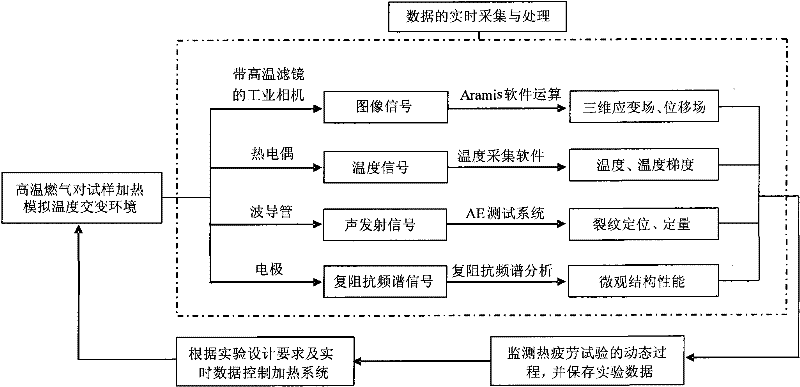

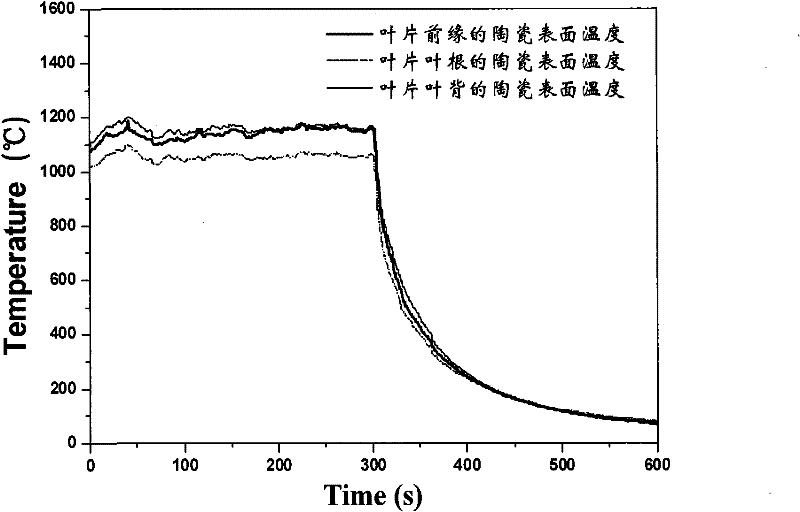

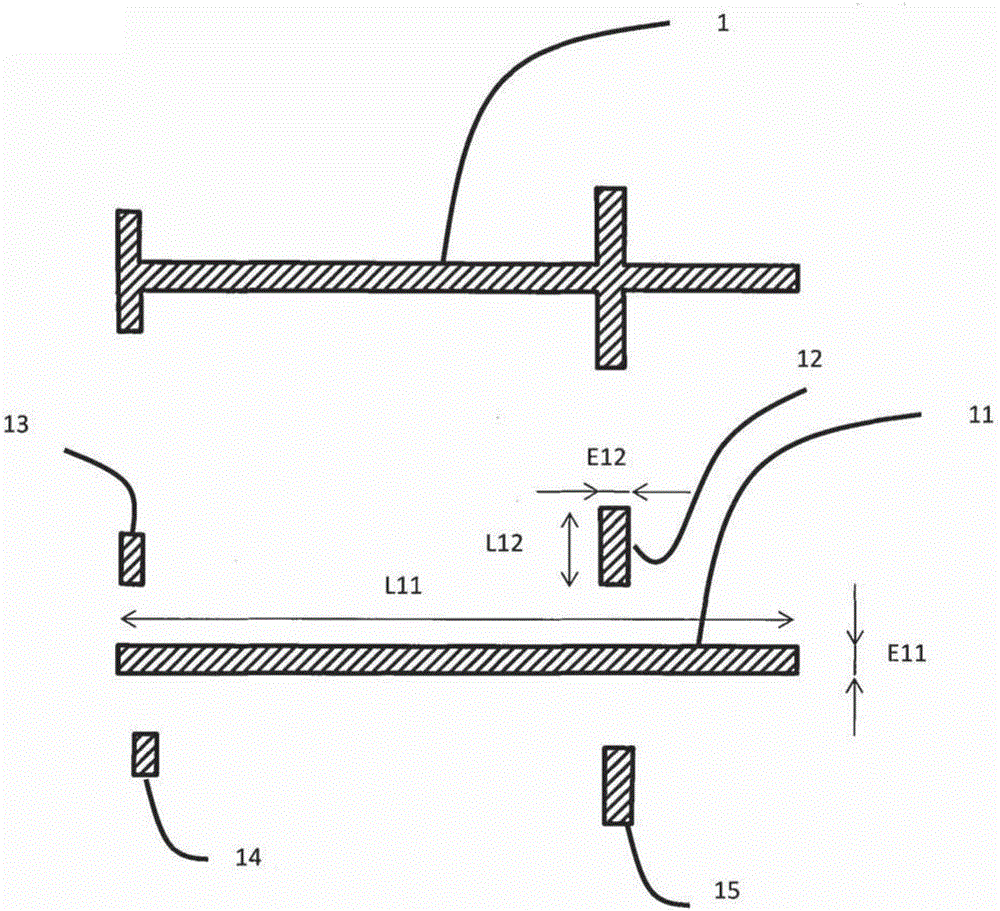

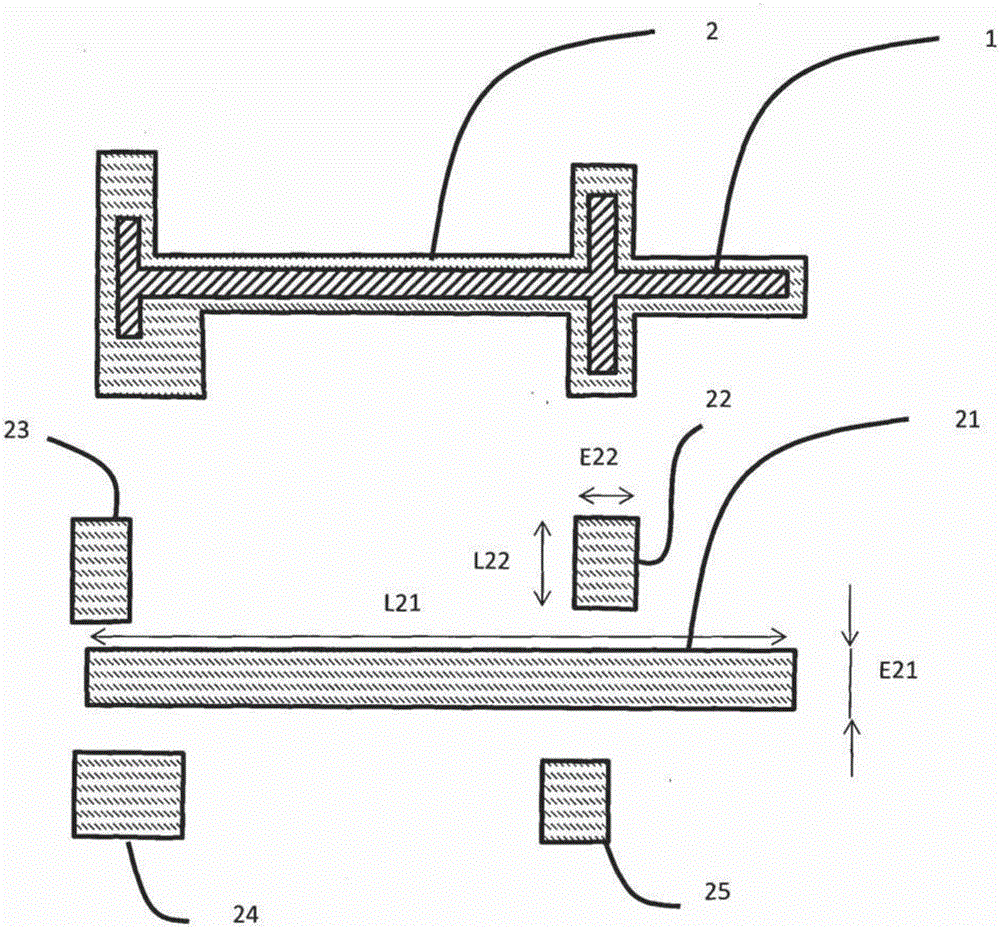

Simulation test method of thermal fatigue failure of blade with thermal barrier coating

ActiveCN101776645AMonitor temperature in real timeReal-time monitoring of temperature gradientsMaterial analysis using acoustic emission techniquesThermometers using electric/magnetic elementsAviationCeramic coating

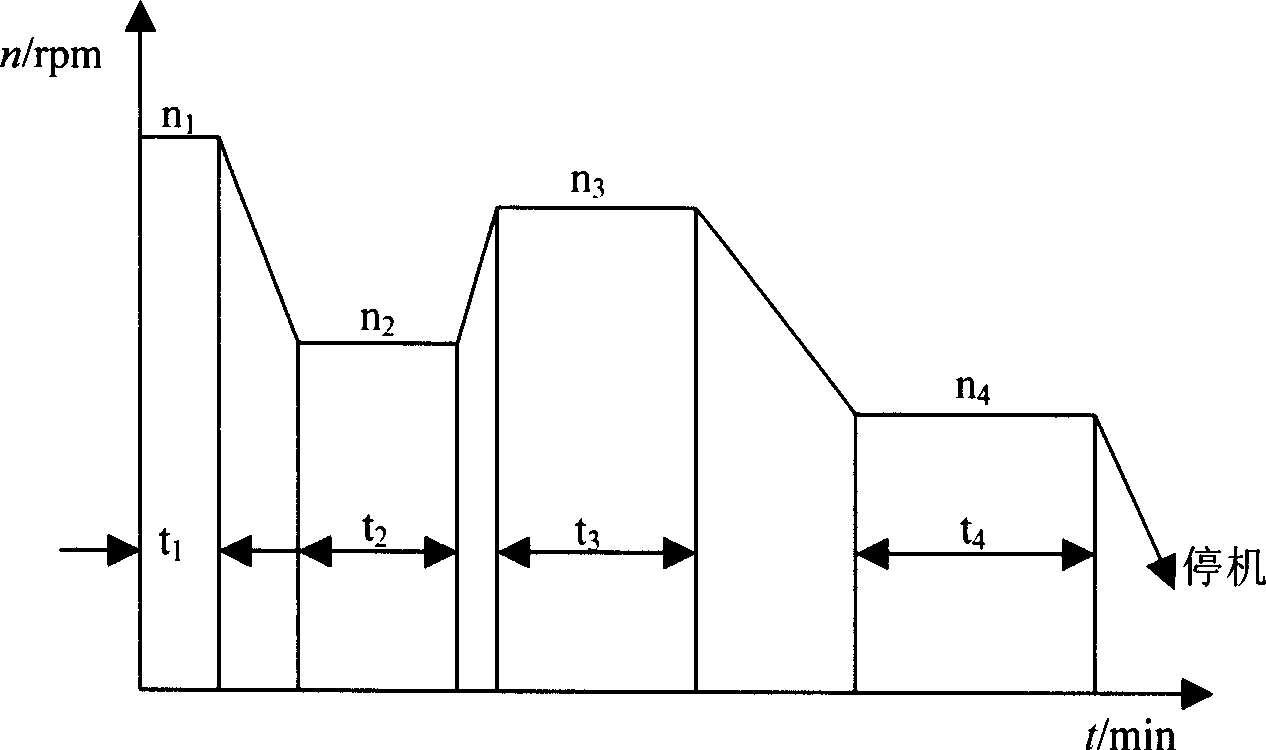

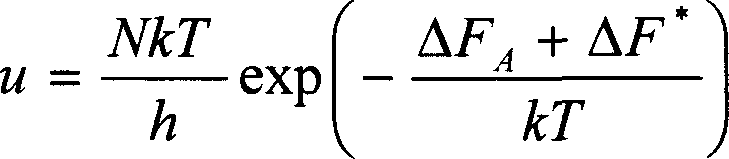

The invention belongs to the technical field of turbine blade performance detection in the aviation industry, in particular to a simulation test method of thermal fatigue failure of a blade with thermal barrier coating. The method can simulate the thermal fatigue work environment of temperature alternating circulation of various blades in an aircraft engine with high performance, and simultaneously tests and analyzes data, such as temperature, temperature gradient, surface topography image evolution, three dimensional deformation field, three dimensional displacement field, interface oxidation layer and thickening rule thereof, thermal fatigue flaw initiation and expansion, cooling airflow and the like of a blade sample with a thermal barrier coating, thus realizing real-time monitoring of three dimensional thermal strain and stress of the blade in the process of thermal fatigue experiments, and providing an important means for predicting thermal fatigue damaging position and invalidation time of the blade. The experimental data obtained by the method can provide important experiment basis for effectively evaluating the failure mechanism of the aircraft engine blade in the environment of high-temperature gas and predicting ceramic coating dropping position, dropping time and service life.

Owner:XIANGTAN UNIV

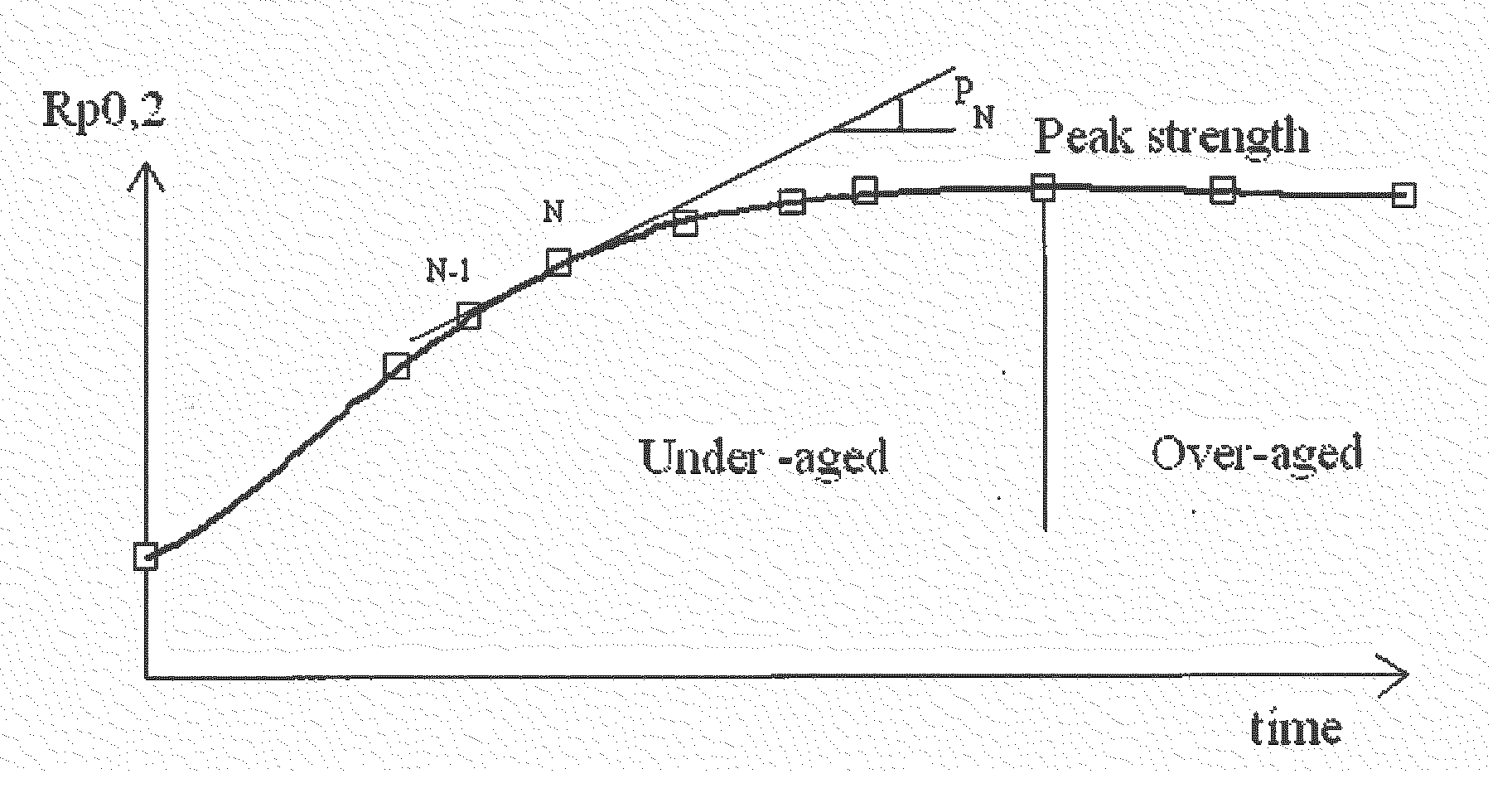

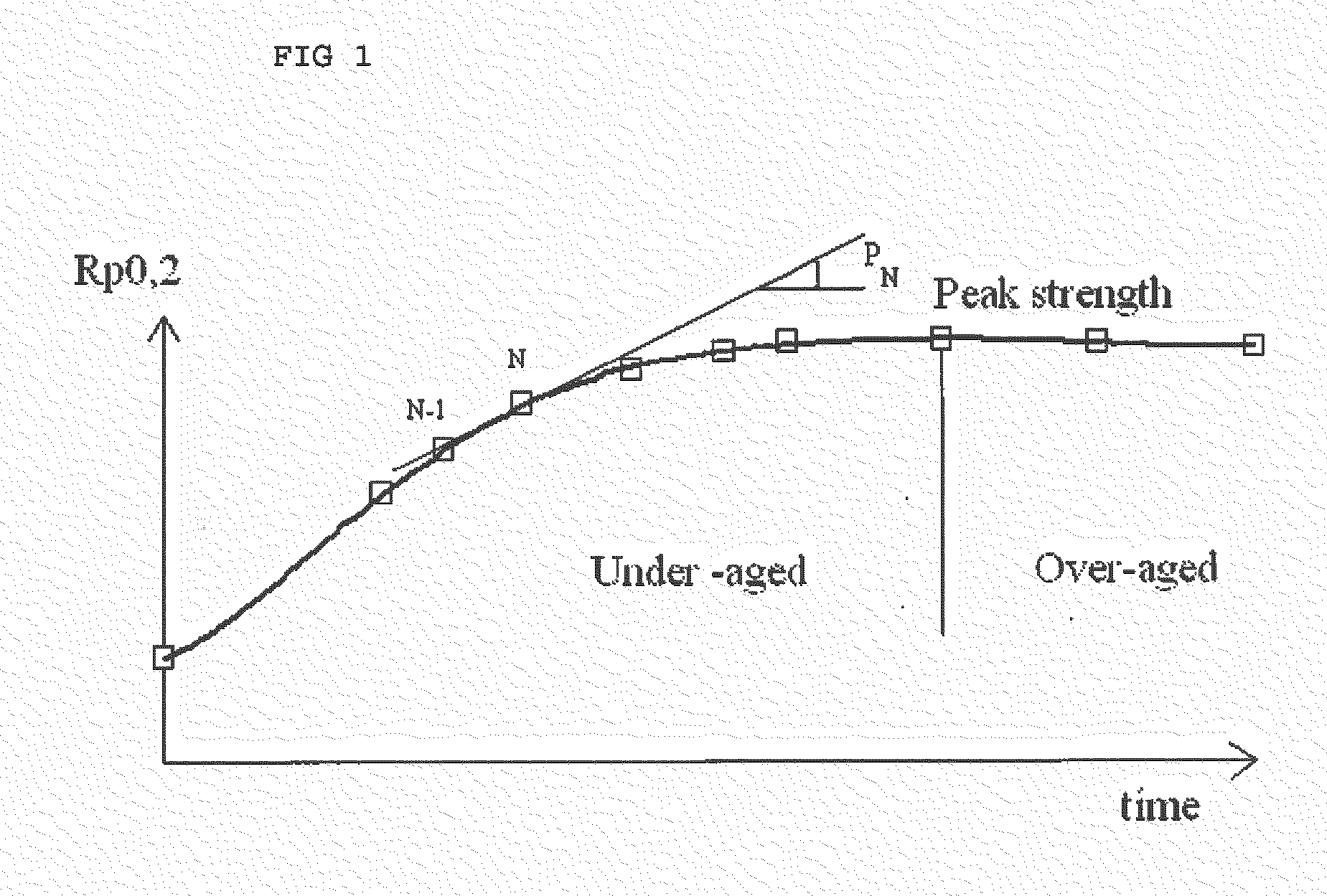

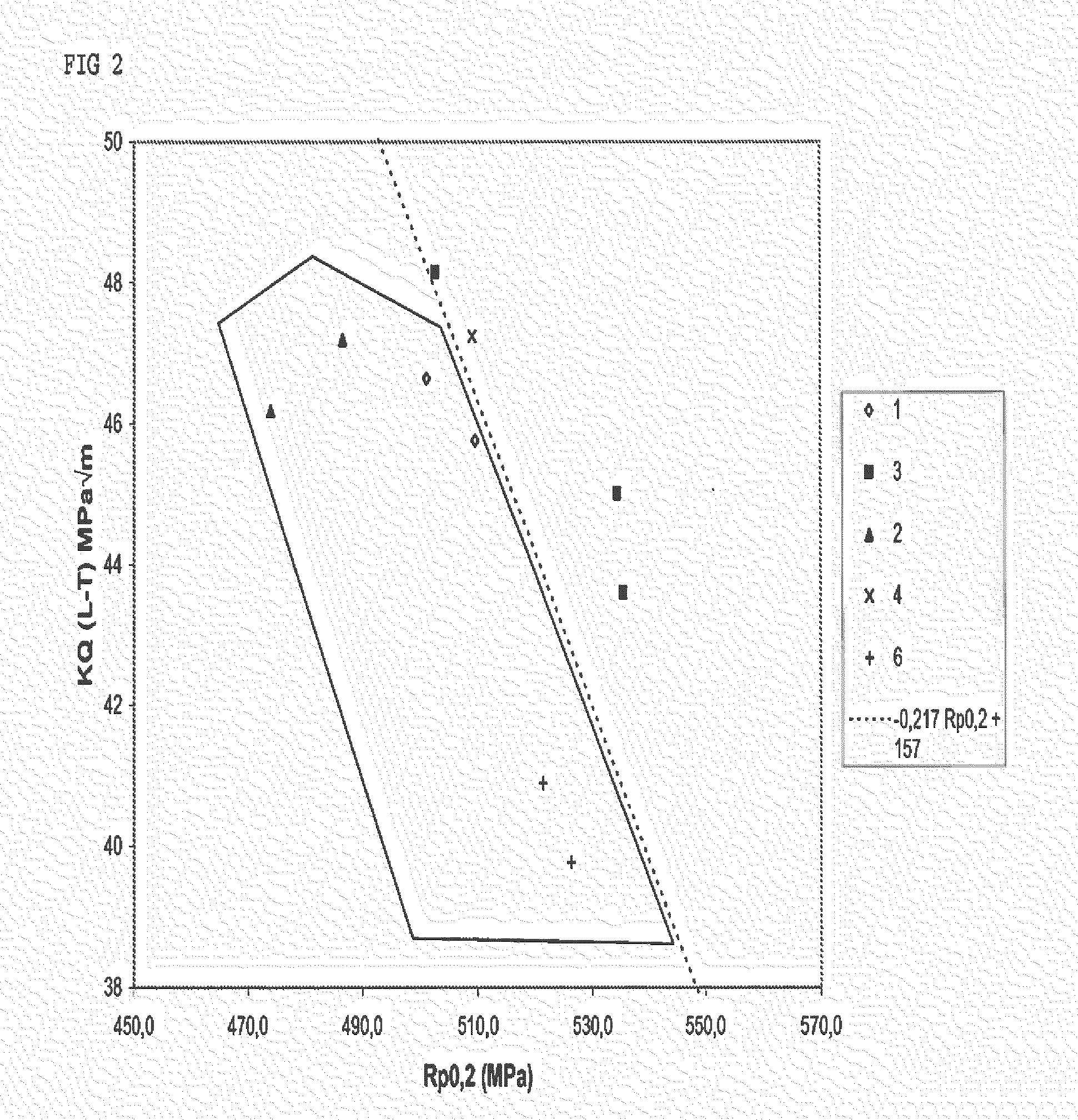

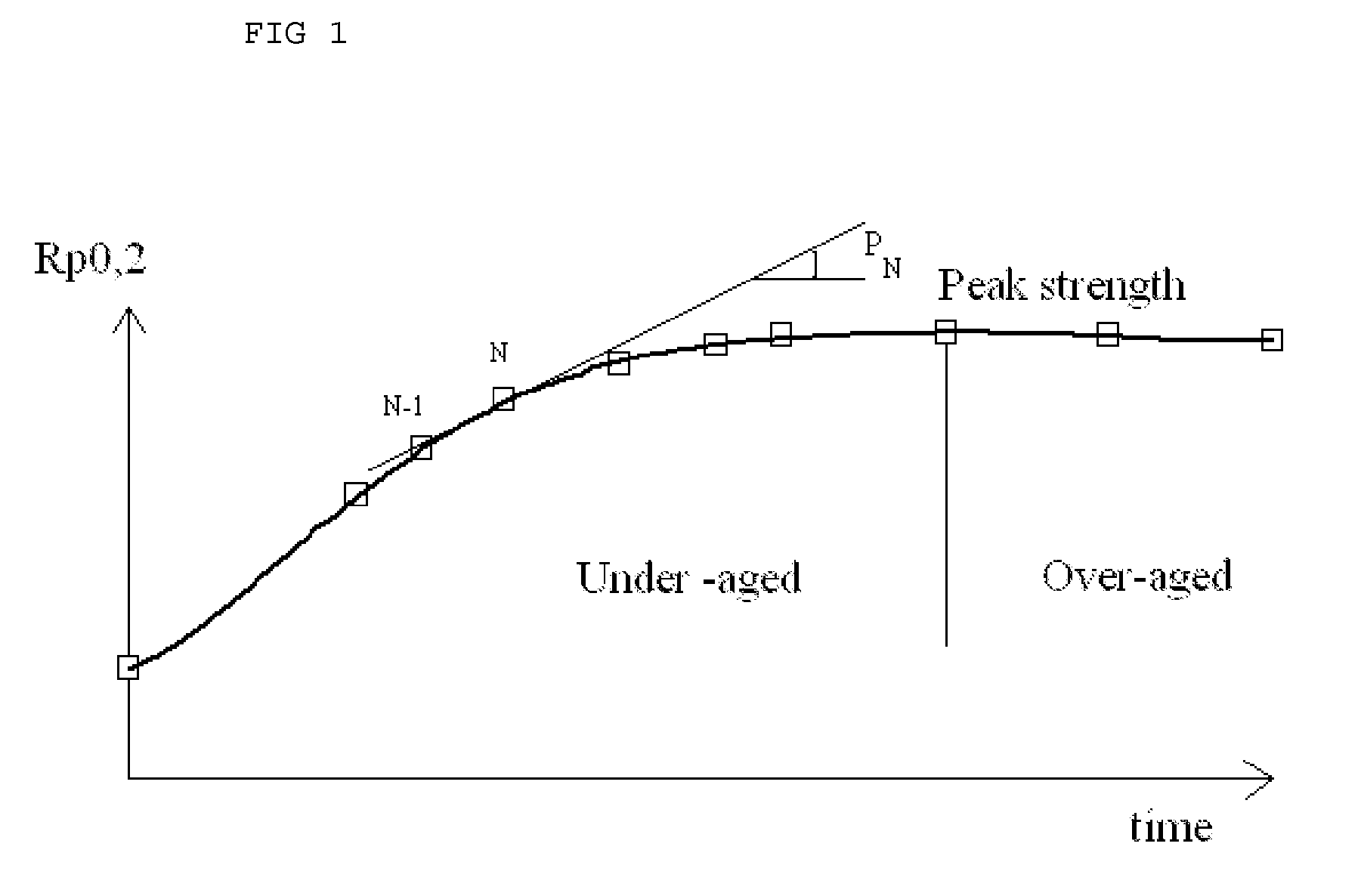

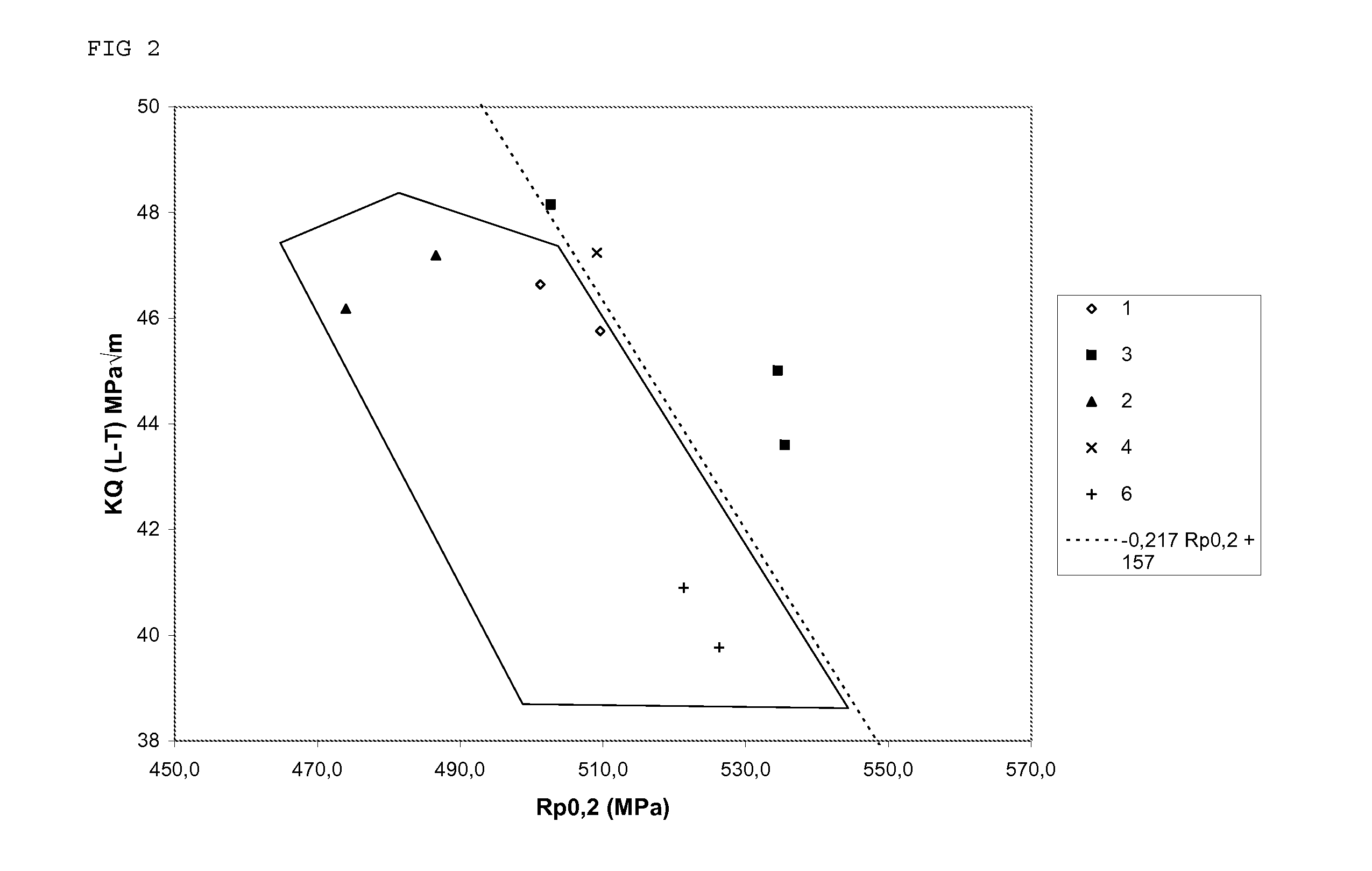

Aluminum-Copper-Lithium Alloy With Improved Mechanical Strength and Toughness

The invention relates to a wrought product such as an extruded, rolled and / or forged aluminum alloy-based product comprising, in weight %: Cu: 3.0-3.9; Li: 0.8-1.3; Mg; 0.6-1.0; Zr: 0.05-0.18; Ag: 0.0-0.05; Mn: 0.0-0.5; Fe+Si≦0.20; Zn≦0.15; at least one element from among: Ti: 0.01-0.15; Sc: 0.05-0.3; Cr: 0.05-0.3; Hf: 0.05-0.5; other elements ≦0.05 each and ≦0.15 total, remainders aluminum. The invention also relates to the process for producing said product. The products according to the invention are particularly useful in the production of thick aluminum products intended for producing structural elements in the aeronautical industry.

Owner:CONSTELLIUM ISSOIRE

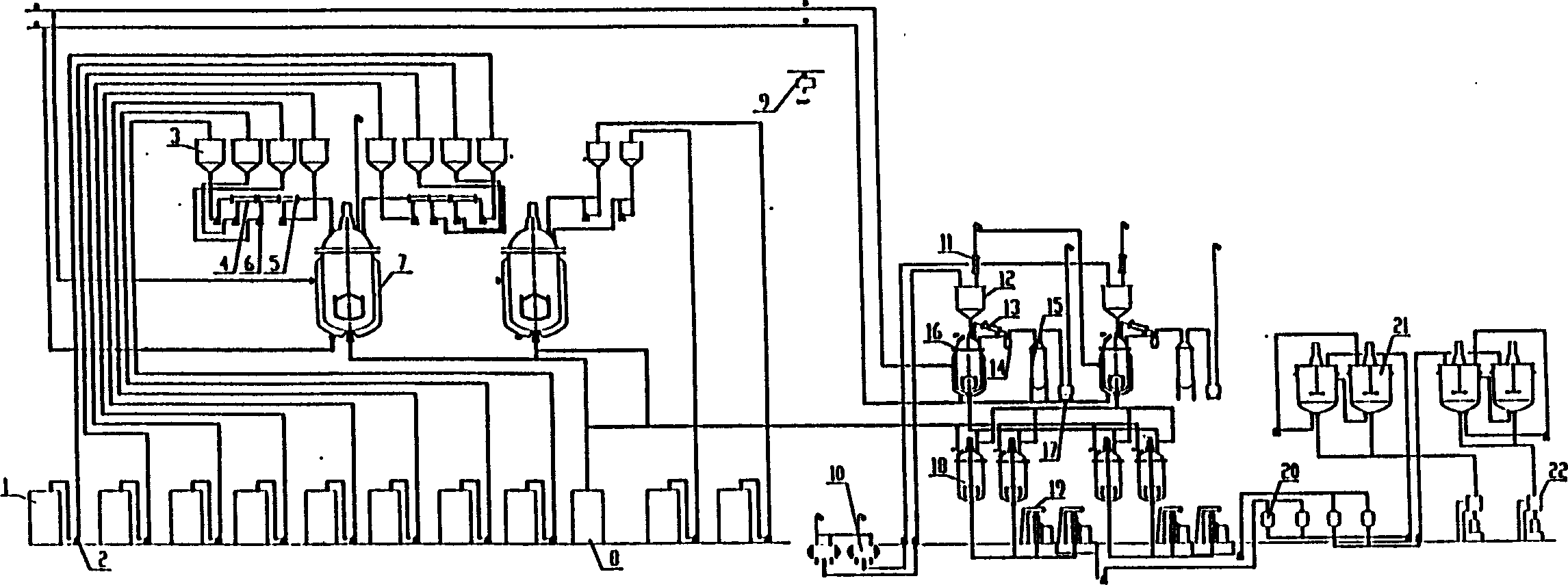

Low crack type high speed steel roll and its centrifugal casting method

The invention discloses a low-crackle type high speed steel roll and its centrifugal casting method, wherein the steel comprises the following chemical constituents (by weight percent): C 1.5-2.0%, W 3.0-6.0%, Mo 1.5-3.0%, V 3.0-10.0%, Cr 3.0-10.0%, Ni 1.5-3.0%, Mn<1.5%, Si<1.5%, RE 0.08-0.20%, K 0.05-0.15%, Mg 0.04-0.10%, wherein 0.20 B22D 13 / 12 C22C 38 / 18 1 13 2 2006 / 1 / 19 1803339 2006 / 7 / 19 1331626 2007 / 8 / 15 2007 / 8 / 15 2007 / 8 / 15 Zhengzhou Institute of Aeronautical Industry Management Henan 450005 Fu Hanguang Jiang Zhiqiang Shi Jinfa li zhengjian 61200 The Patent Agency of Xi'an University of Communications No.28, Xianning, Road, the City of Xi'an, Shanxi Province 710049

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Chromizing-free anodic oxidation treatment method of surface of aviation 2 department and 7 department aluminium alloy

The invention discloses a chromizing-free anodic oxidation treatment method of the surfaces of an aviation 2 series and 7 series aluminium alloys, which is an improvement of a surface anodic oxidation treatment method of a sample in a standard aluminium and an aluminium alloy sulfuric acid anodic oxidation technology (HB / Z 233-93) of the PRC aviation industry, a processing solution contains no chromium in an anodic oxidation step, and an anodic oxidation solution comprises sulfuric acid and a modifier. The film weight of a prepared anodic oxidation film is within a range from 10 mg / dm <2> to 75 mg / dm <2> through the matching of anodic oxidation technology conditions, and in addition, the invention meets the corrosion resistance of a film layer and the combination property of the anodic oxidation film and an organic coating and also prolongs the fatigue life of workpieces manufactured by the aviation 2 series and 7 series aluminium alloys.

Owner:BEIHANG UNIV

Casting process for aluminum alloys

The invention relates to a wrought product such as an extruded, rolled and / or forged aluminum alloy-based product, comprising, in weight %: Cu: 3.0-3.9; Li: 0.8-1.3; Mg: 0.6-1.0; Zr: 0.05-0.18; Ag: 0.0-0.5; Mn: 0.0-0.5; Fe+Si≦0.20; Zn≦0.15; at least one element from among: Ti: 0.01-0.15; Sc: 0.05-0.3; Cr: 0.05-0.3; Hf: 0.05-0.5; other elements ≦0.05 each and ≦0.15 total, remainder aluminum. The invention also relates to the process for producing said product. The products according to the invention are particularly useful in the production of thick aluminum products intended for producing structural elements in the aeronautical industry.

Owner:CONSTELLIUM ISSOIRE

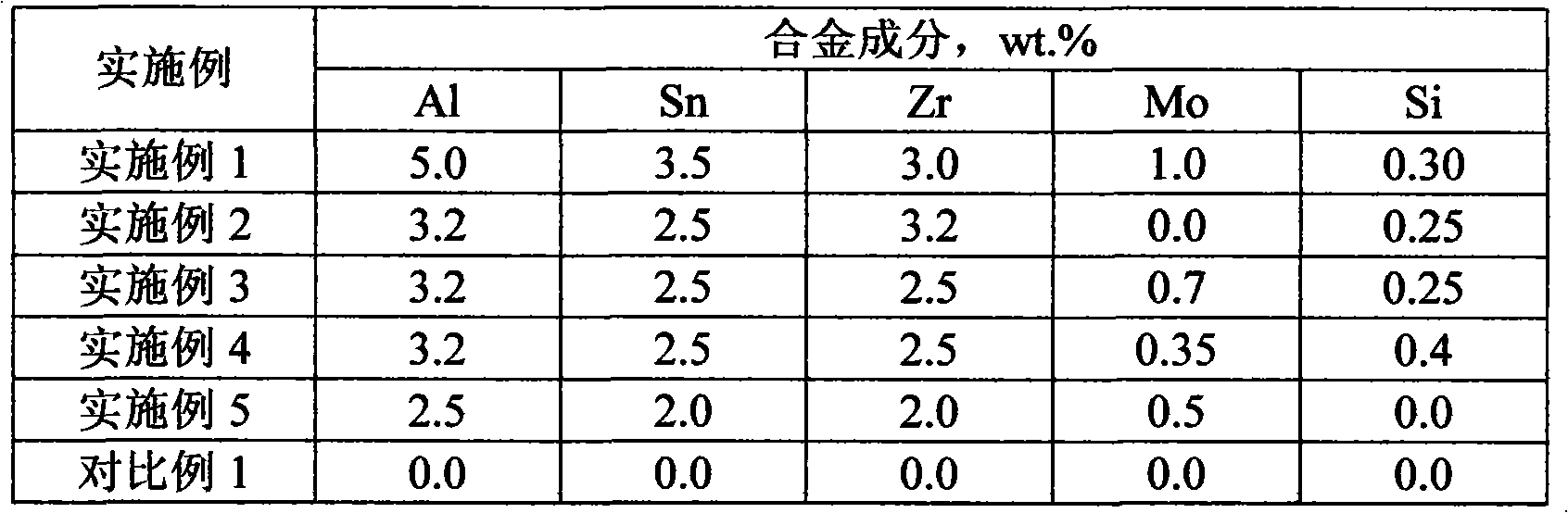

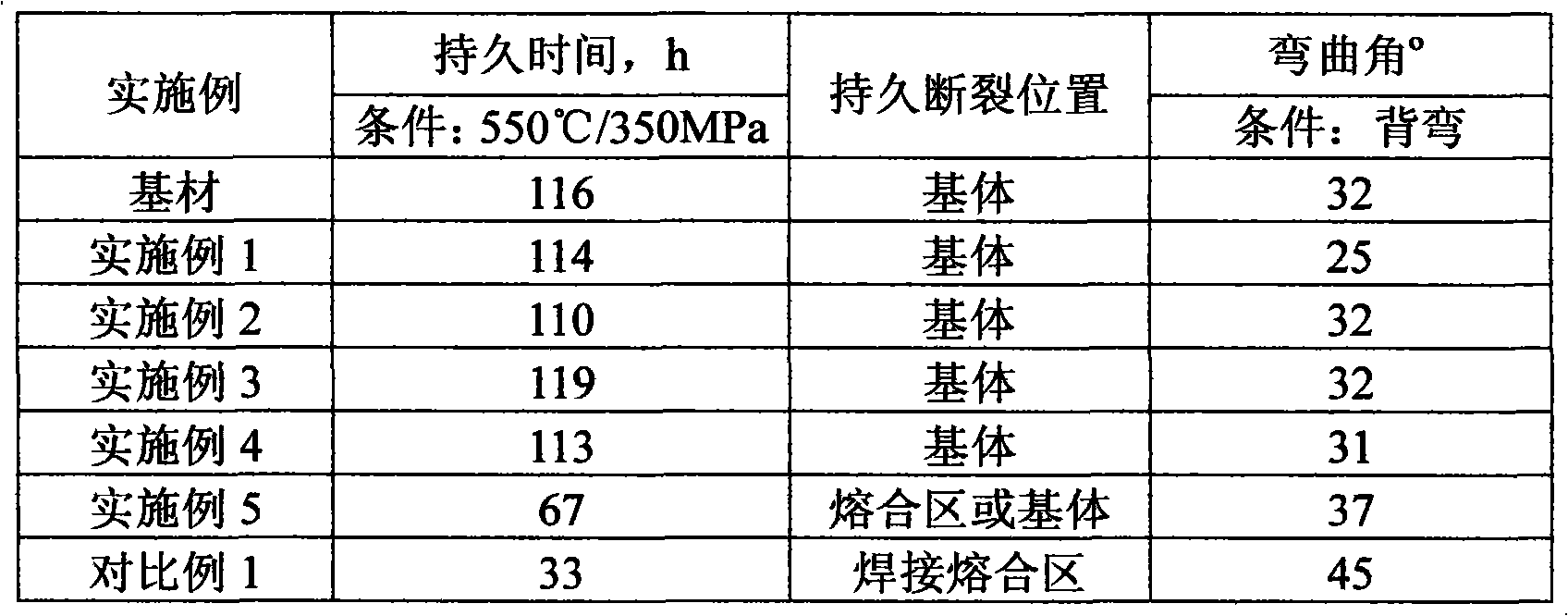

Low-cost titanium alloy welding wire suitable for welding titanium alloy at high temperature of over 520 DEG C

InactiveCN101966631ATaking into account plasticityTaking into account the high temperature thermal deformation resistanceWelding/cutting media/materialsSoldering mediaRoom temperatureTitanium alloy

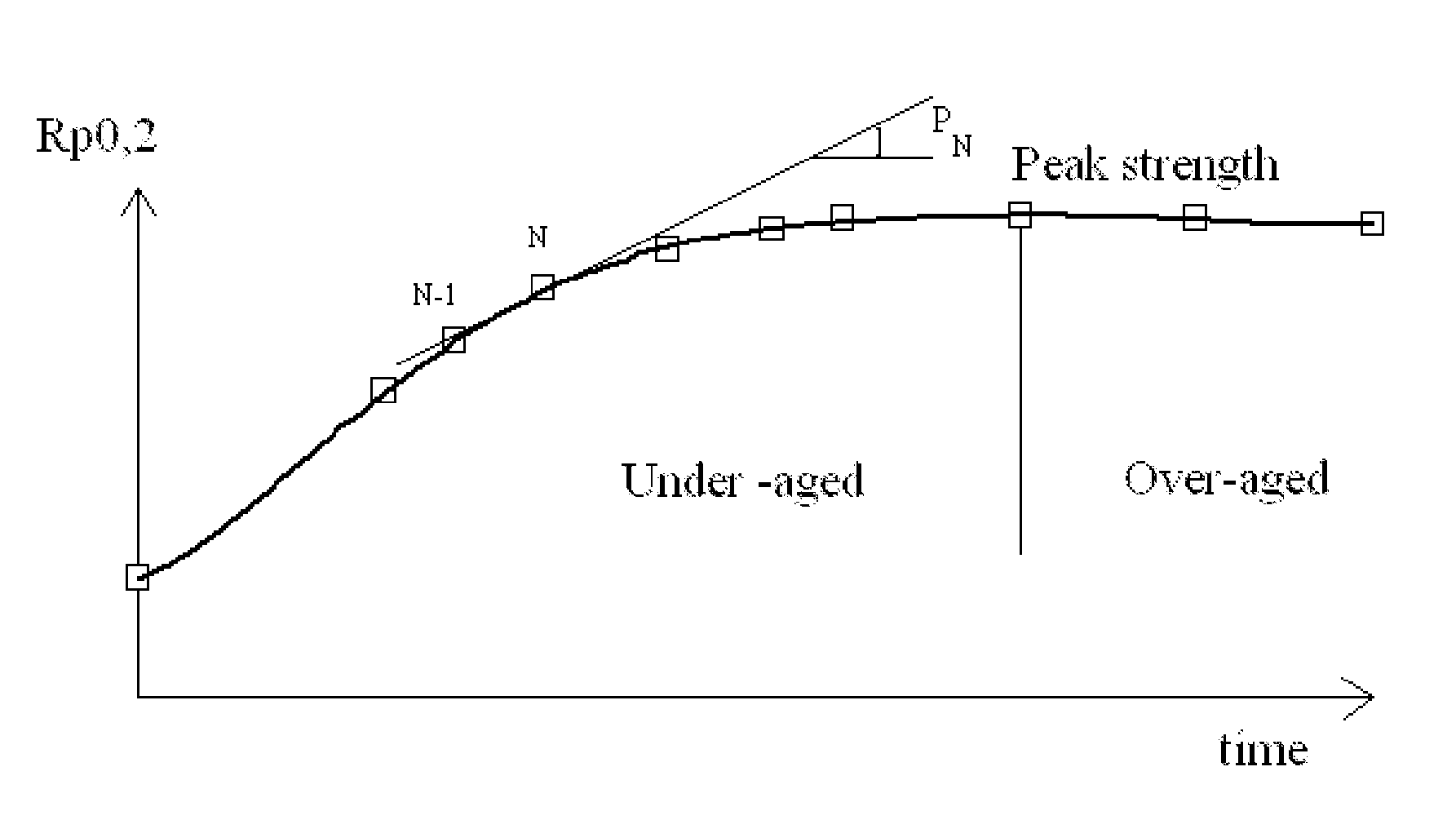

The invention discloses a low-cost titanium alloy welding wire suitable for welding titanium alloy at a high temperature of over 520 DEG C. The welding wire comprises Al, Sn, Zr, Mo and Si five alloy elements and is characterized in that: the Si is increased to share part of the high-temperature strengthening effect of the Al, Sn and Zr, so that the added amount of the alloy elements is reduced, the metal in a weld zone has relatively high deformation capability, the cracking tendency of a high-temperature titanium alloy weld is restrained, and meanwhile, the metal in the weld zone also keeps the strength of a base material, high-temperature lasting resistance and room-temperature deformation capability. Besides the ingredient range of the welding wire, the invention also provides three different types of optimal welding wire ingredients and a thermal treatment process according to the different requirements of aerospace industry on sheet welding. The welding wire in the invention can be produced by a conventional process, is high in yield and therefore is low in cost. Along the widespread application of the high-temperature titanium alloy in the aerospace field, the welding wire has a promising application prospect and is expected to create huge social and economical benefit.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

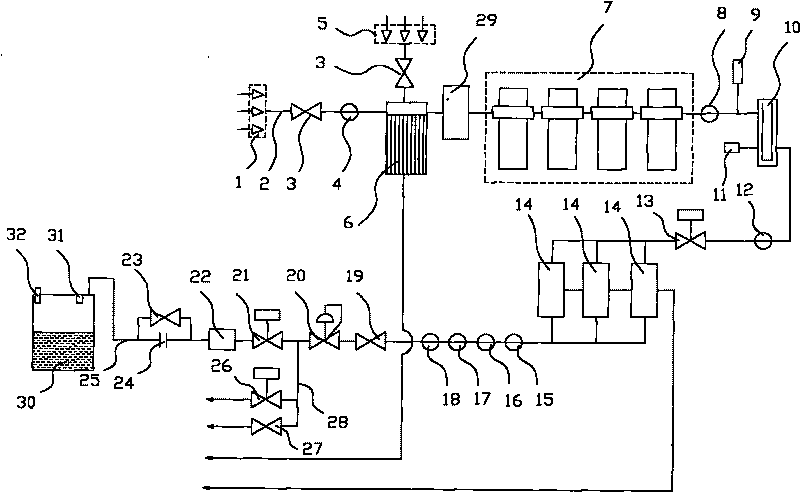

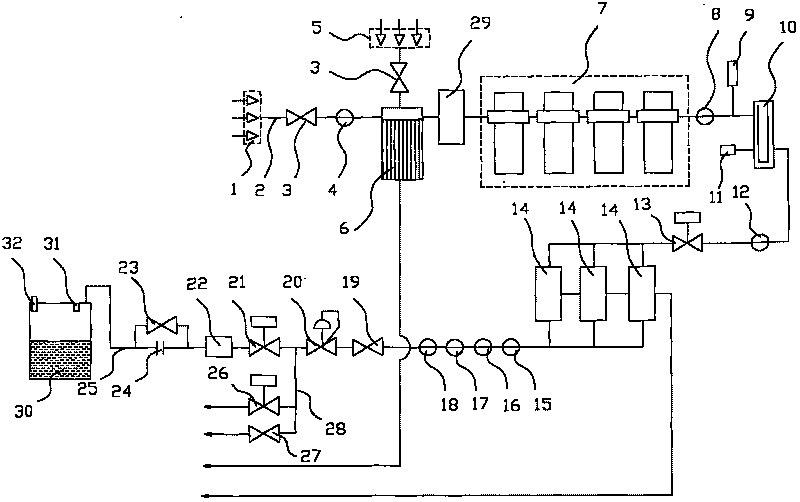

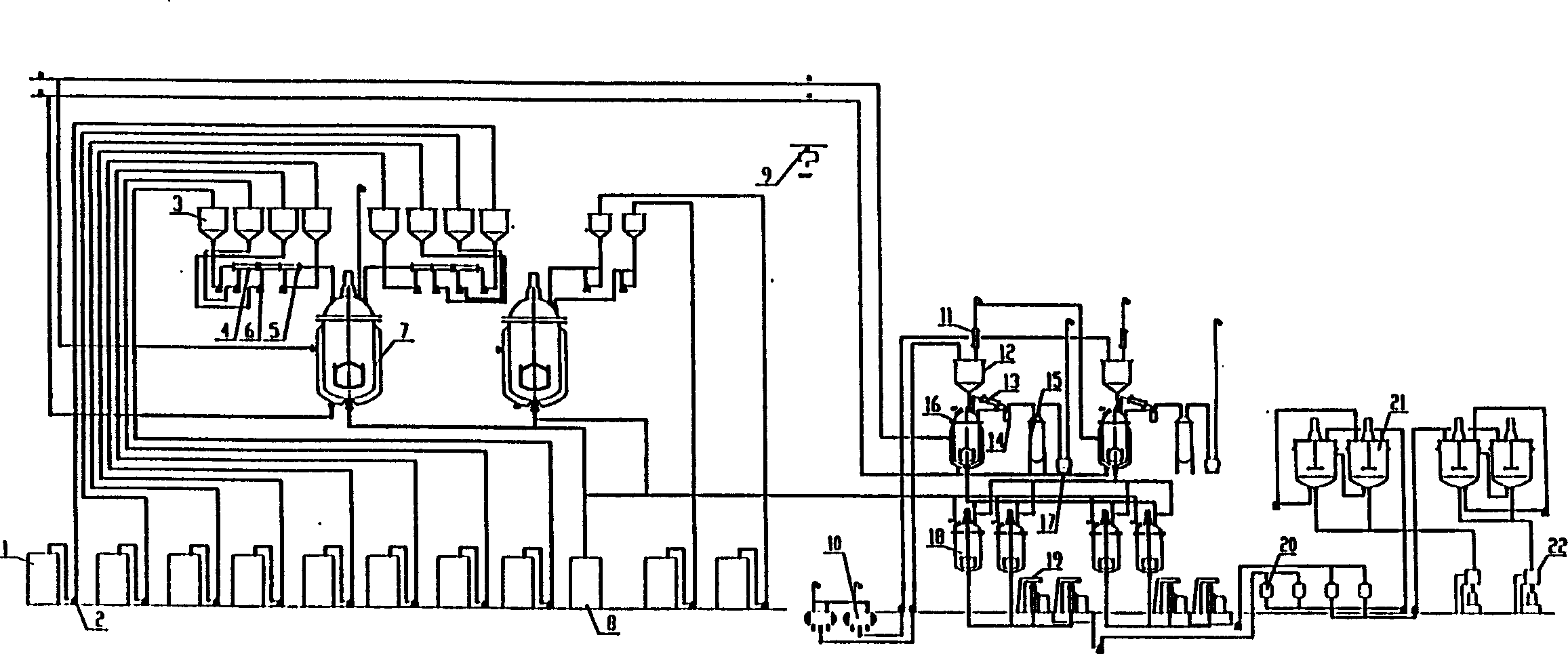

Inert system for civil airplane

InactiveCN101708776ASuppress fire explosionSmall sizeFuel tank safety measuresFire rescueAviationAutomatic control

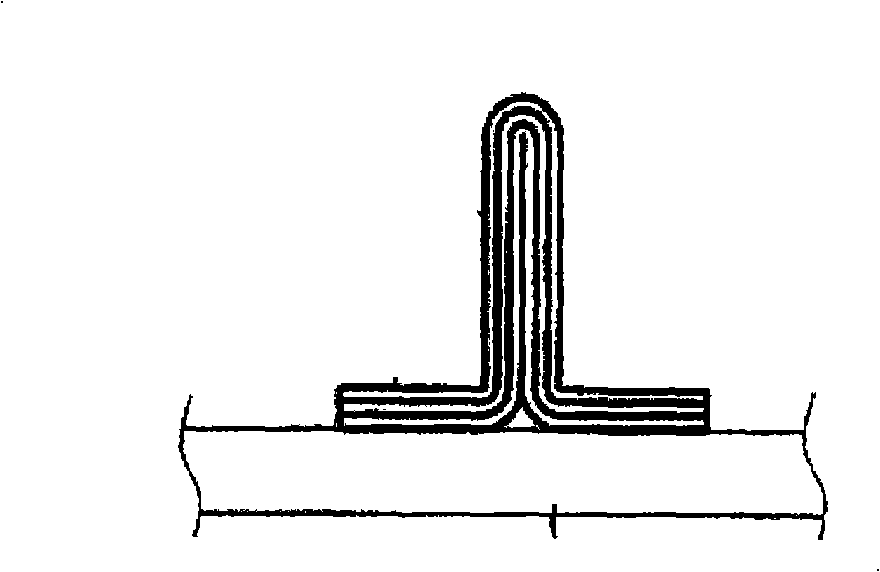

The invention discloses an inert system for a civil airplane, relates to a composite-film separated nitrogen making system, and belongs to the field of aviation industry machining building. The inert system for the civil airplane comprises an air pre-treating system, a gas film separating system and an automatic control system, wherein compressed air is output from the air pre-treating system and the gas film separating system under the control of the automatic control system; high-temperature compressed gas produced by an engine compressor of the airplane passes through a supply pipeline and the air pre-treating system to supply compressed air to the gas film separating system; cold air produced by an external duct of the airplane engine passes through a fan supply pipeline to supply cold air for refrigeration to the air pre-treating system; and the gas film separating system consists of a plurality of composite-film pipe components with the same or different separation coefficients and the optimum working temperatures which are connected through manifolds, and outputs and distributes nitrogen gas to each fuel tank of the airplane through parallelly connected pneumatic or electric variable-flow valves and a low-flow hole.

Owner:张星

Dimethyl diphenyl room-temperature vulcanized silicone rubber as well as production process and application thereof

InactiveCN101851334ALow purity requirementMeet demanding requirementsOther chemical processesCoatingsAviationTetramethylammonium hydroxide

Owner:上海爱世博有机硅材料有限公司

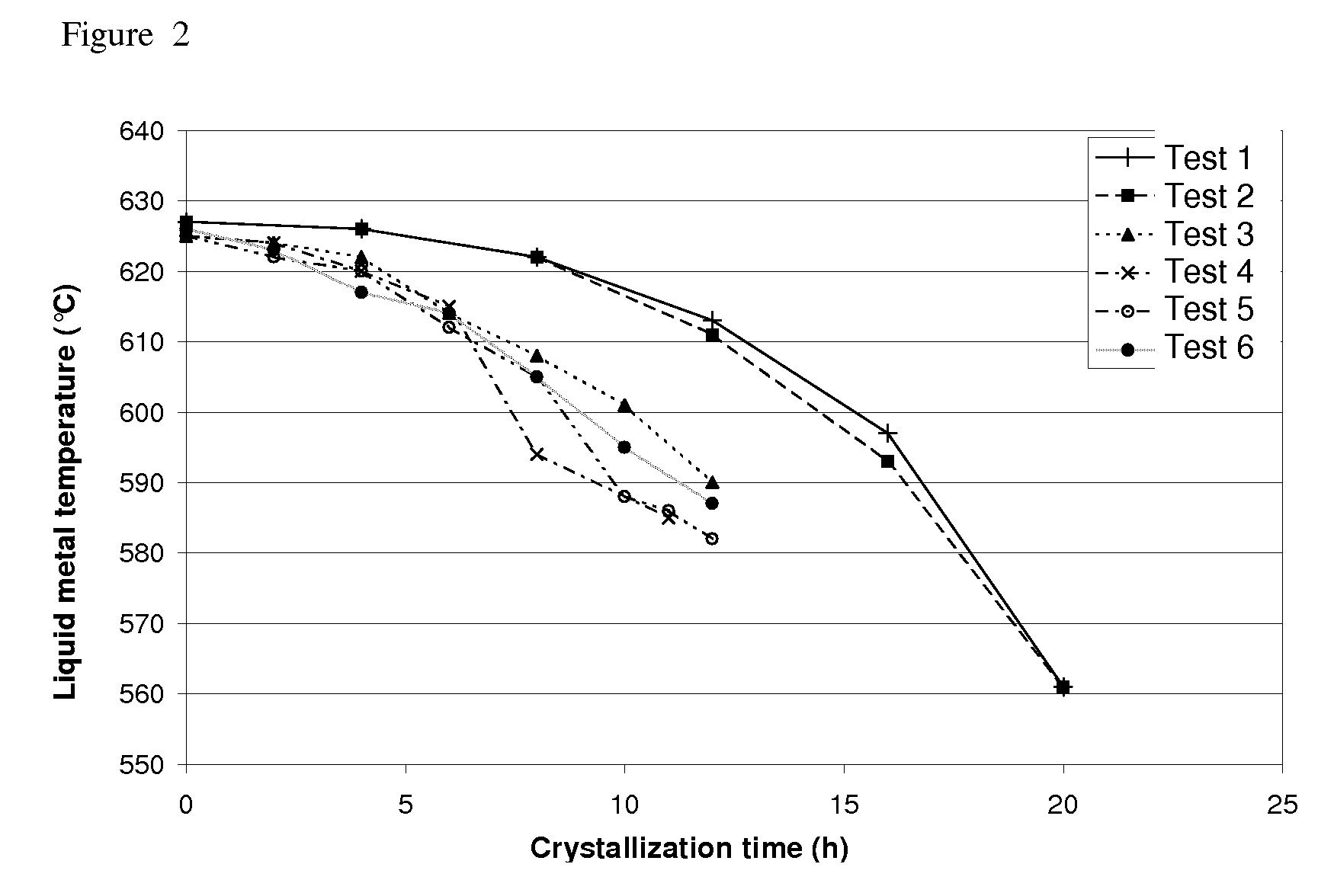

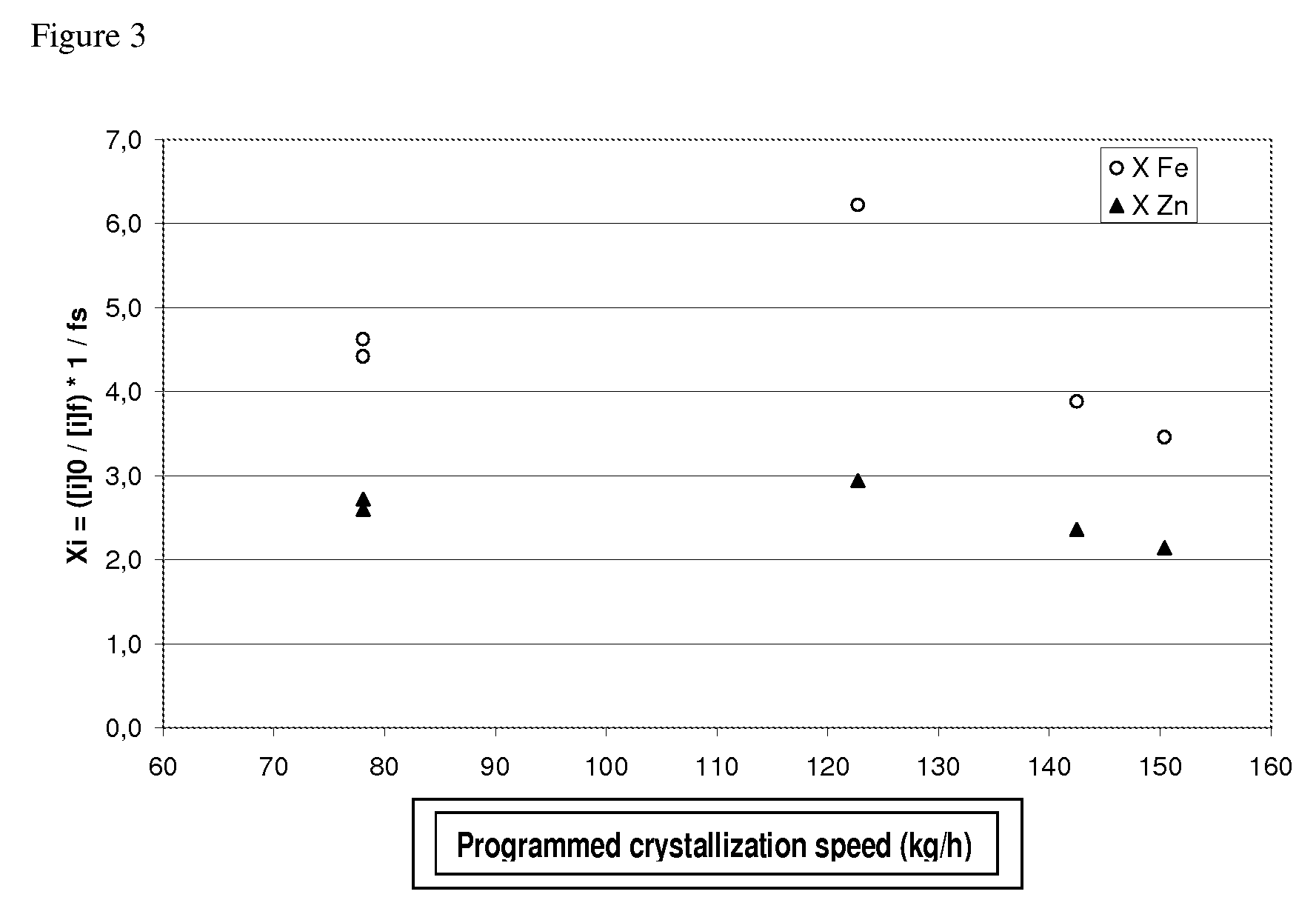

Process for recycling aluminium alloy scrap coming from the aeronautical industry

ActiveUS20090285716A1Easy to recycleManufacturing convertersElectric furnaceRecovery stageAircraft industry

A manufacturing process for a remelt block containing aluminum designed for making aluminum alloy for the aircraft industry in which scrap containing mainly aluminum alloys used in the aircraft industry is supplied during a supply stage, the scrap is melted in a smelting furnace in order to obtain an initial molten metal bath during a smelting stage, the initial molten metal bath is subjected to purification by fractional crystallization in order to obtain a solidified mass and a bath of residual liquid during a segregation stage, and the solidified mass is recovered in order to obtain a remelt block during a recovery stage. The invention is particularly useful for the recycling of aluminum alloys used in the aircraft industry as it makes it possible to purify scrap of series 2XXX or series 7XXX alloys for iron and silicon, without eliminating additive elements such as zinc, copper and magnesium.

Owner:CONSTELLIUM ISSOIRE

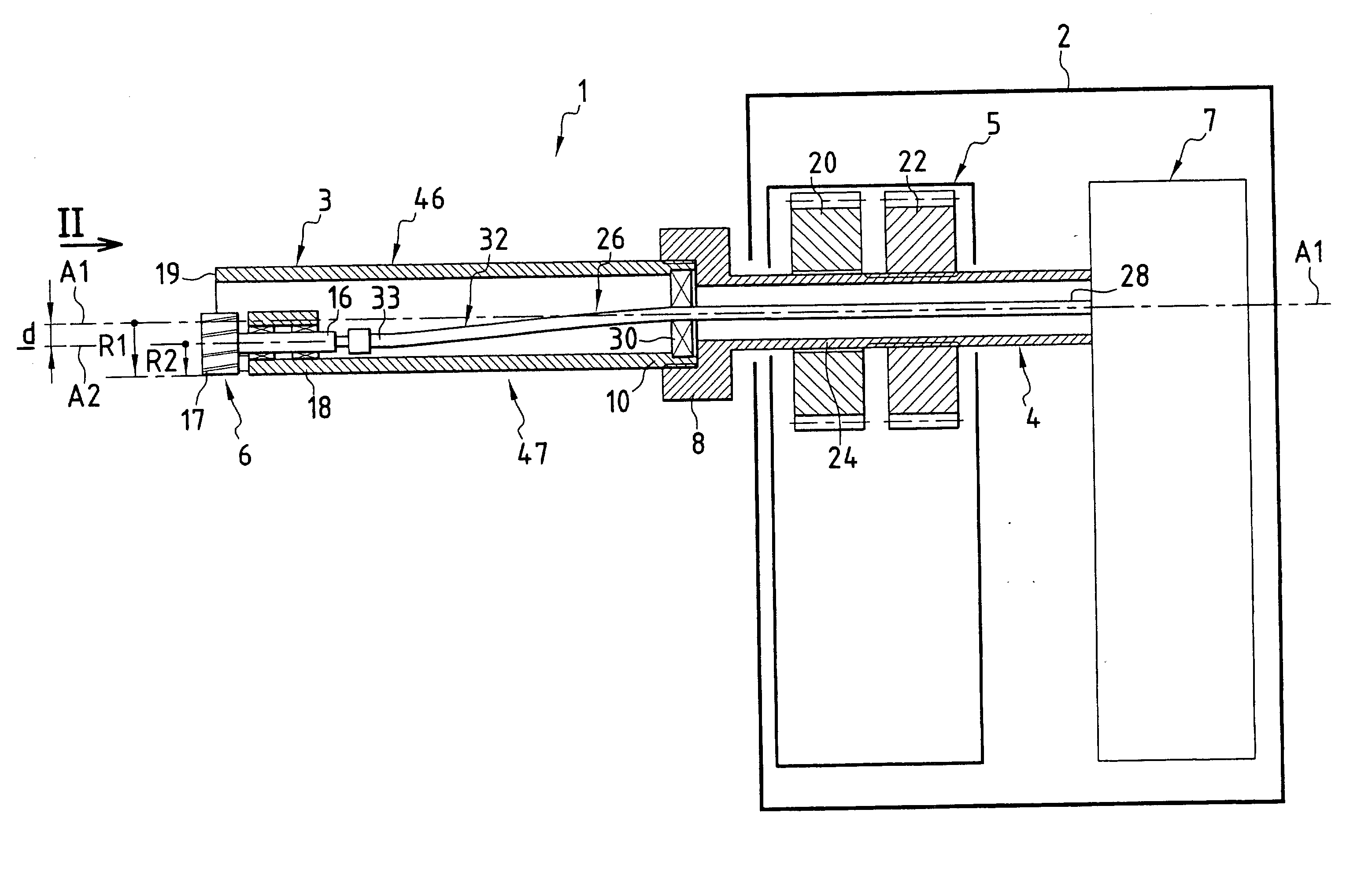

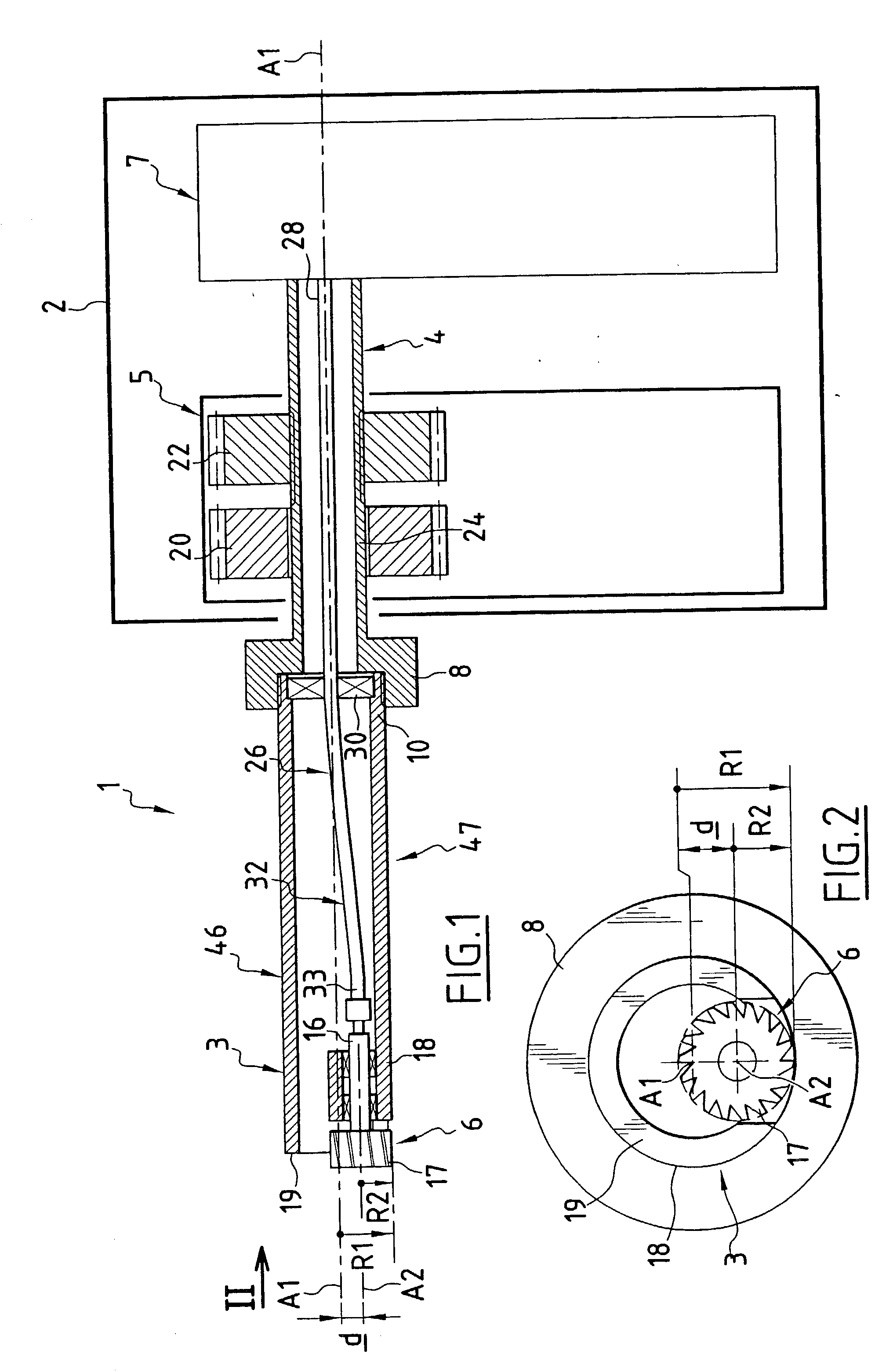

Tool, a machine, and a method for orbitally drilling an orifice

InactiveUS20030102139A1Large aspect ratioAttachable milling devicesWorkpiecesAviationOffset distance

The tool comprises firstly a cutter support for being driven in rotation about a first axis of rotation that is to coincide with the axis of the orifice, and a cutter rotatably mounted on the cutter support to rotate about a second axis of rotation parallel to the first axis of rotation and spaced apart therefrom by a non-zero offset distance. A front segment of the cutter support has maximum radial extent relative to the first axis of rotation that is less than or equal to the radius of the orifice to enable the front segment to penetrate into the orifice during drilling. The tool is particularly applicable to drilling machines used in the aviation industry.

Owner:APEX BRANDS

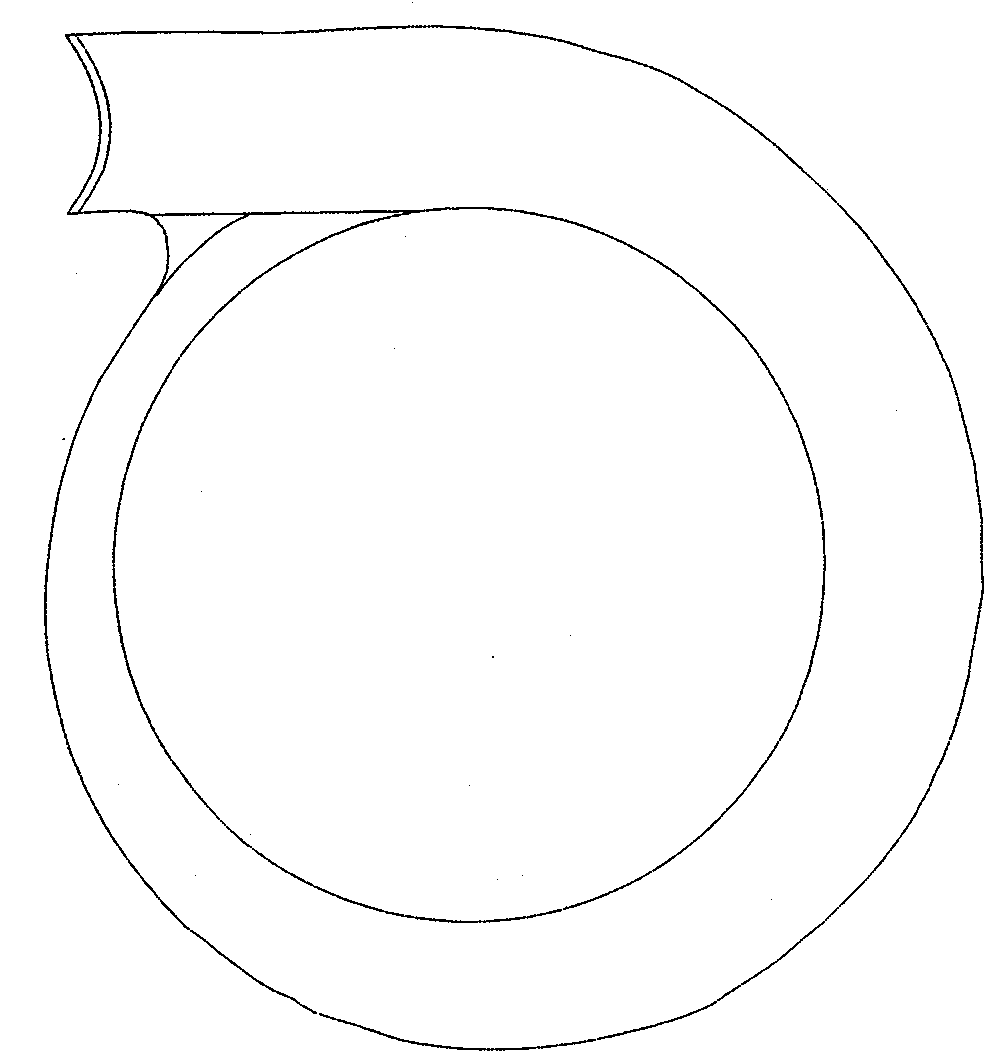

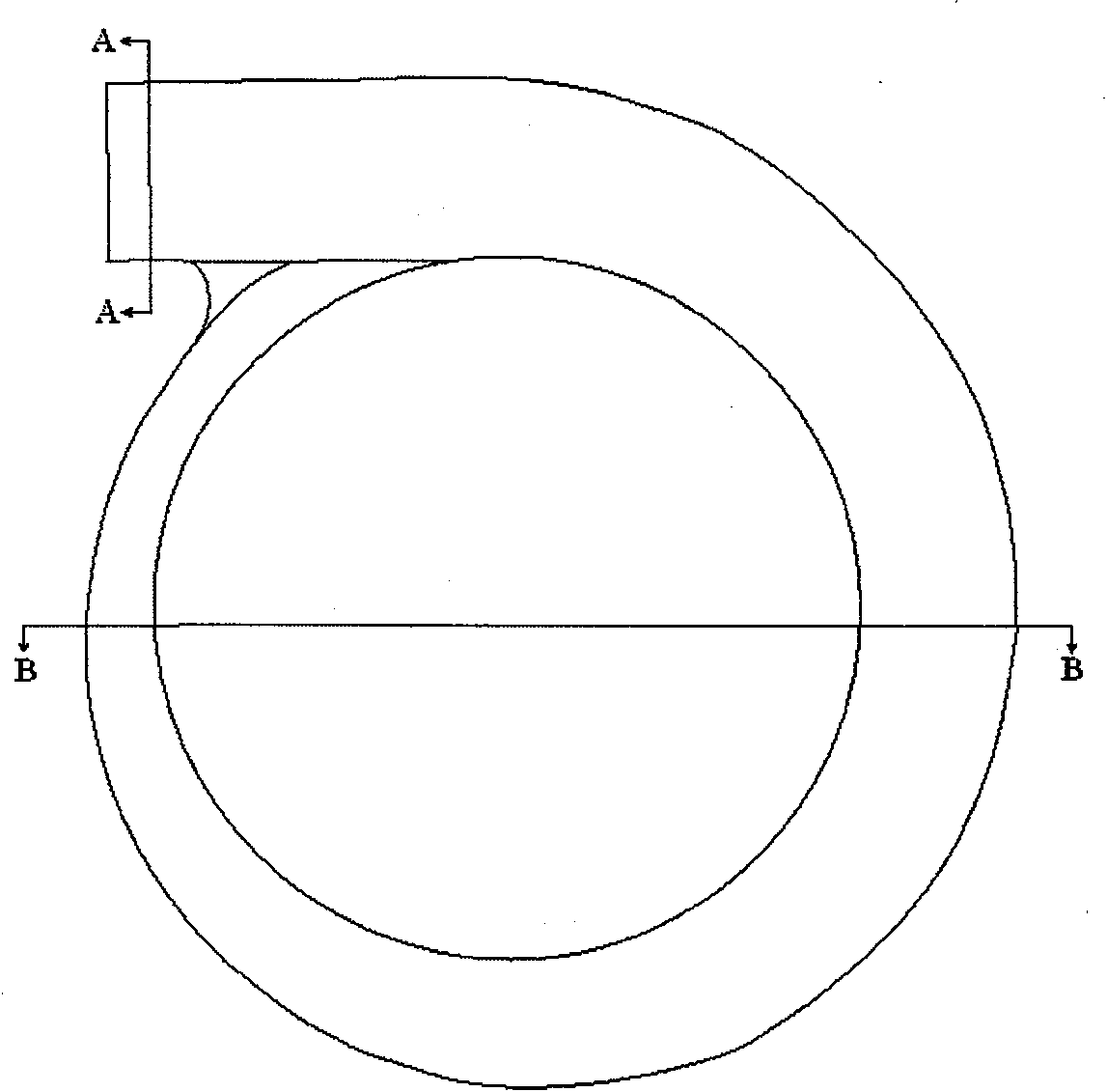

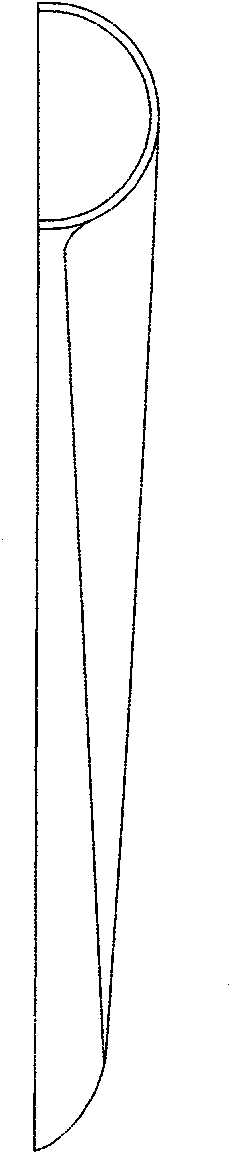

Titanium alloy volute casing piece forming method

The invention relates to a plate metal special-shaped piece processing method, in particular to a titanium alloy volute casing piece forming method, which comprises the following steps that: the size of an outer circle and an inner circle of a preform body is calculated according to a design drawing of a volute casing piece; the material is fed; the size of mould cavity is reduced by 3 to 7 percent when designing a mould, the processing method adopts a numeric-control processing center to process, and the hardness of the mould is more than or equal to HRC45; the formation is carried out in a multi-pass hot-drawing way; and finally the metal volute casing piece is obtained through the mechanical processing and the surface treatment. The titanium alloy volute casing piece is processed through the multi-pass hot-drawing formation technology; the high-temperature-resistant anti-oxidation coat is used for coating the surface of a titanium alloy sheet so as to realize that the titanium material can be heated inside an ordinary resistance furnace; the size reduction range of the mould cavity is found when designing the mould; technological seams are arranged on local part of the preform body so as to prevent local part from being cracked during the formation process; and the industrialized small mass production of the titanium alloy volute casing piece is realized, the quality of the product reaches the level of the similar product in overseas developed countries, and the urgent need of the aviation industry is solved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

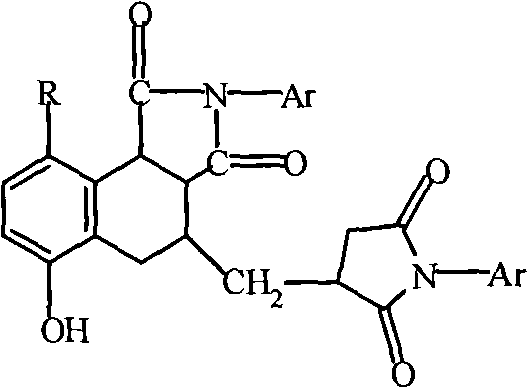

Modification method of continuous PBO fiber for strengthening interface of bimaleimide resin base composite material

InactiveCN101514246AImprove wettabilityImprove adhesionPhysical treatmentFibre typesEpoxyFiber-reinforced composite

The invention relates to a modification method of continuous PBO fiber for strengthening interface of thermosetting BMI resin, belonging to the technical field of advanced composite material. The method is designed for solving the technical problems of the existing fibrous reinforcement resin base composite material that the structural surface thereof is smooth, the active group is few and the cohesiveness of the resin base is weak, the technical proposal is: in a plasma treatment device, the surface of the PBO fiber is modified by adopting the low temperature plasma technology; then the PBO fiber is soaked in bimaleimide resin solution to prepare fibrous reinforcement BMI composite material presoaking material; finally the presoaking material is made into continuous fibrous reinforcement composite material by the high temperature compression molding technique. The adhesiveness of the modified fiber and the resin base is greatly improved, the interface performance is enhanced, the interlaminal shear strength of the composite material is further strengthened and the mechanical property is fine. The product of the invention can meet the increasingly demanding requirements of the modern industry on the composite material, especially the demanding dual requirements of the modern aviation industry on high temperature resistance and mechanical property of the composite material. As the BMI resin has fine electromagnetic performance, thus being capable of replacing epoxide resin as a novel electromagnetic material.

Owner:DALIAN UNIV OF TECH +1

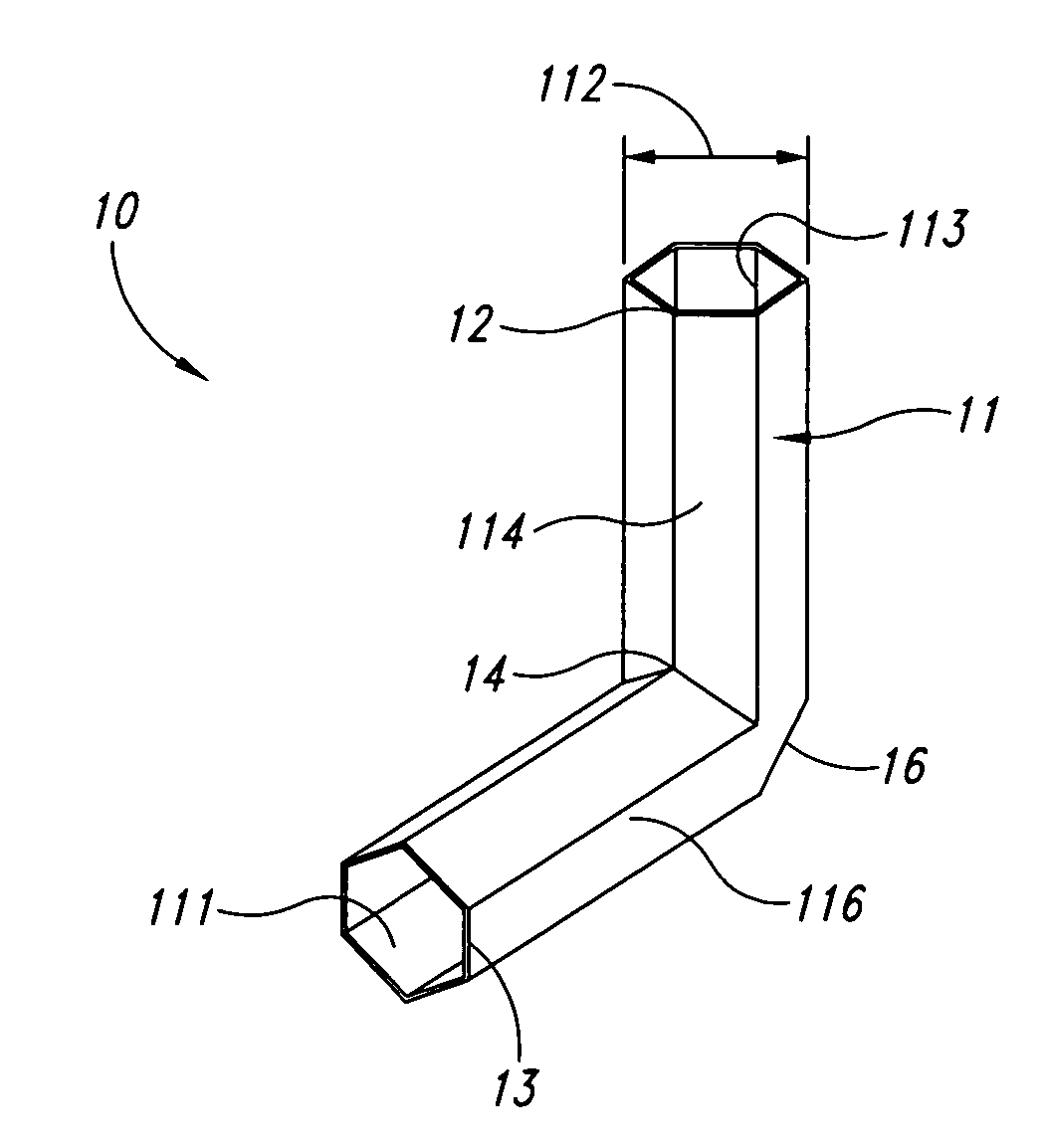

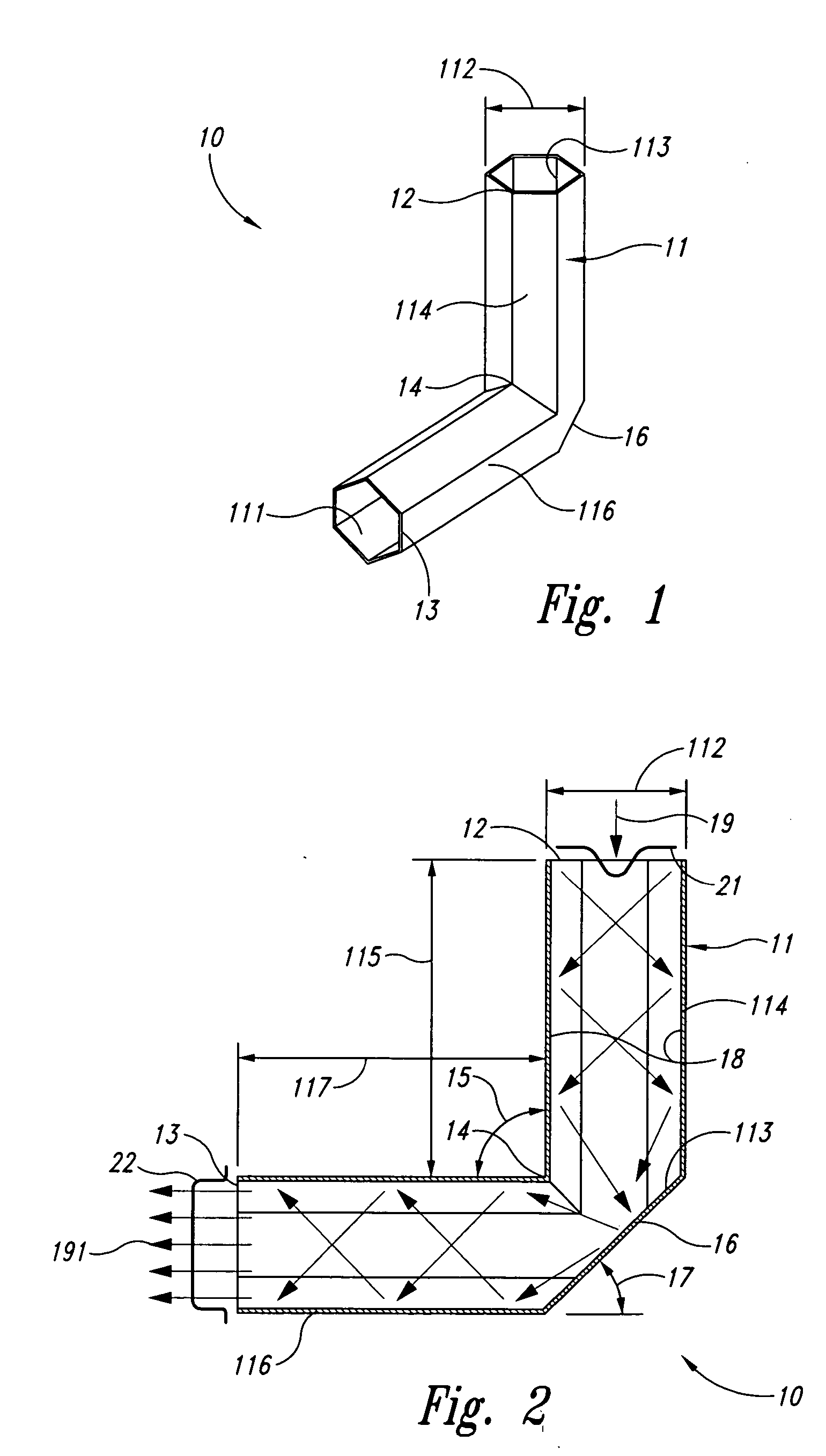

Hex tube light homogenizer splitter

A right angle light diverter includes a hexagonal tube that is bent at a right angle that is coated with a highly reflective coating on the inside surface. An incoming light beam may be homogenized upon entering an input port of the hexagonal tube and may be evenly diverted at a right angle at a reflection section while the homogenized profile may be maintained. A right angle optical splitter may include at least one additional output section. An incoming light beam may be homogenized and may be split into at least two outgoing beams that may be diverted at right angles at reflection sections. The right angle light diverter and the right angle optical splitter may be suitable for, but not limited to, applications in aircraft industry, both military and commercial. They may be used, for example, in connection with airborne laser programs, in commercial airplanes, and in military jets.

Owner:THE BOEING CO

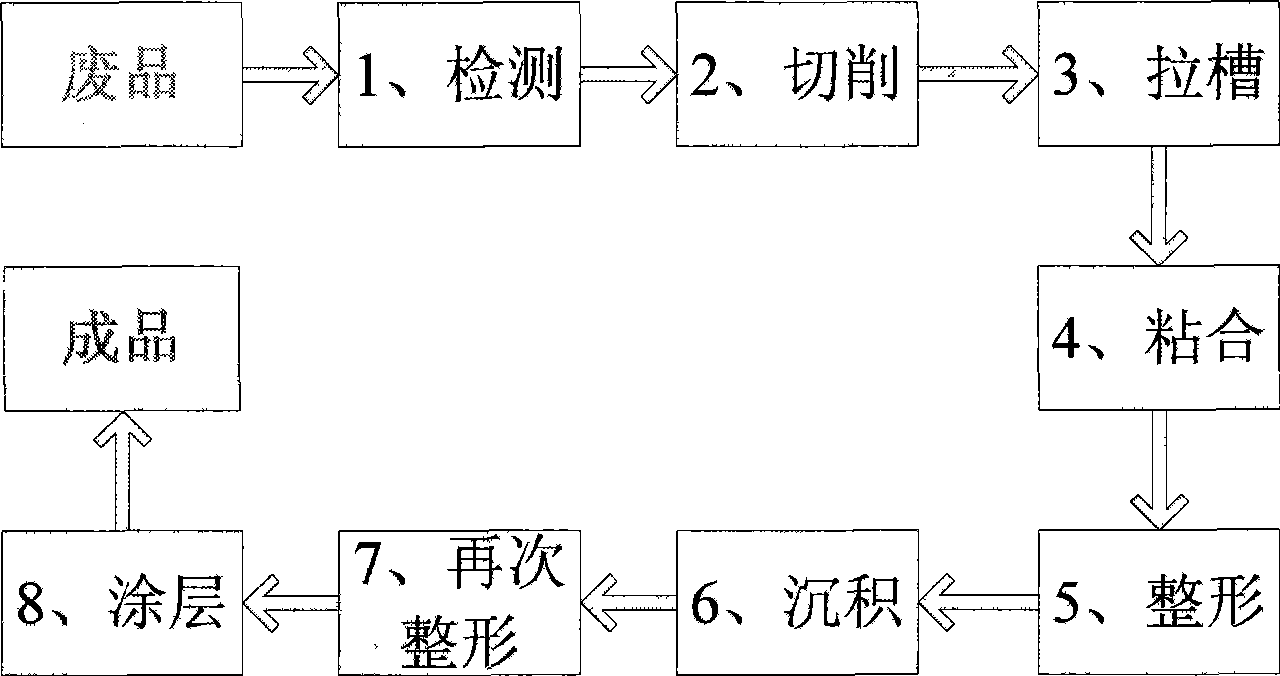

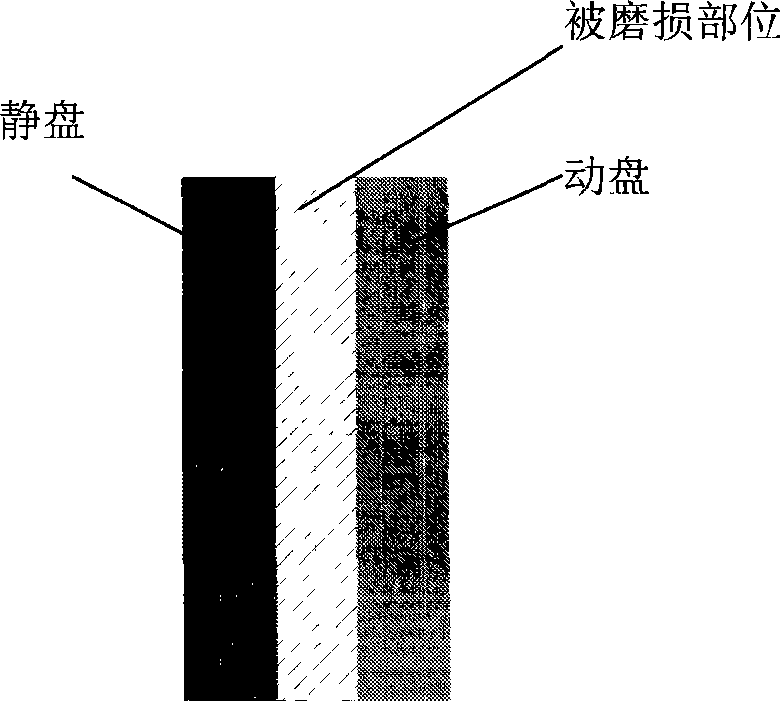

Technique and process for renovating life-terminating carbon / carbon aviation brake disc

The invention relates to a renovation technology of a carbon / carbon aviation brake disc which reaches the service life, and a process thereof. The process comprises the following eight procedures: determining whether the carbon / carbon aviation brake disc which reaches the service life can be repaired by detecting various indexes of the brake disc, and determining the modification indexes; cutting off the worm surface of the brake disc to expose the new internal surface; pulling out a tooth-shape groove on the surface of the brake disc, and meshing two or more brake blades by the tooth-shape groove; macroscopically combining the brake disc by a special high-temperature bonding agent; machining and shaping the bonded brake disc and causing the brake disc to be close to the size of a finished product; performing a chemical vapor deposition process on the bonded brake disc, and causing the spliced brake disc to be connected microscopically; machining and shaping the brake disc treated by the chemical vapor deposition again to meet the requirement of the design size; and finally coating an oxidation resistant coating on a shaped semi-finished product to obtain a renovated finished product. By the technology and the process, about 40% of the carbon / carbon aviation brake discs which reach the service life can be renovated and reutilized, thus saving raw materials, reducing the great expenditure of the astronautical and aeronautical industries, and having environmental protection value.

Owner:杨力

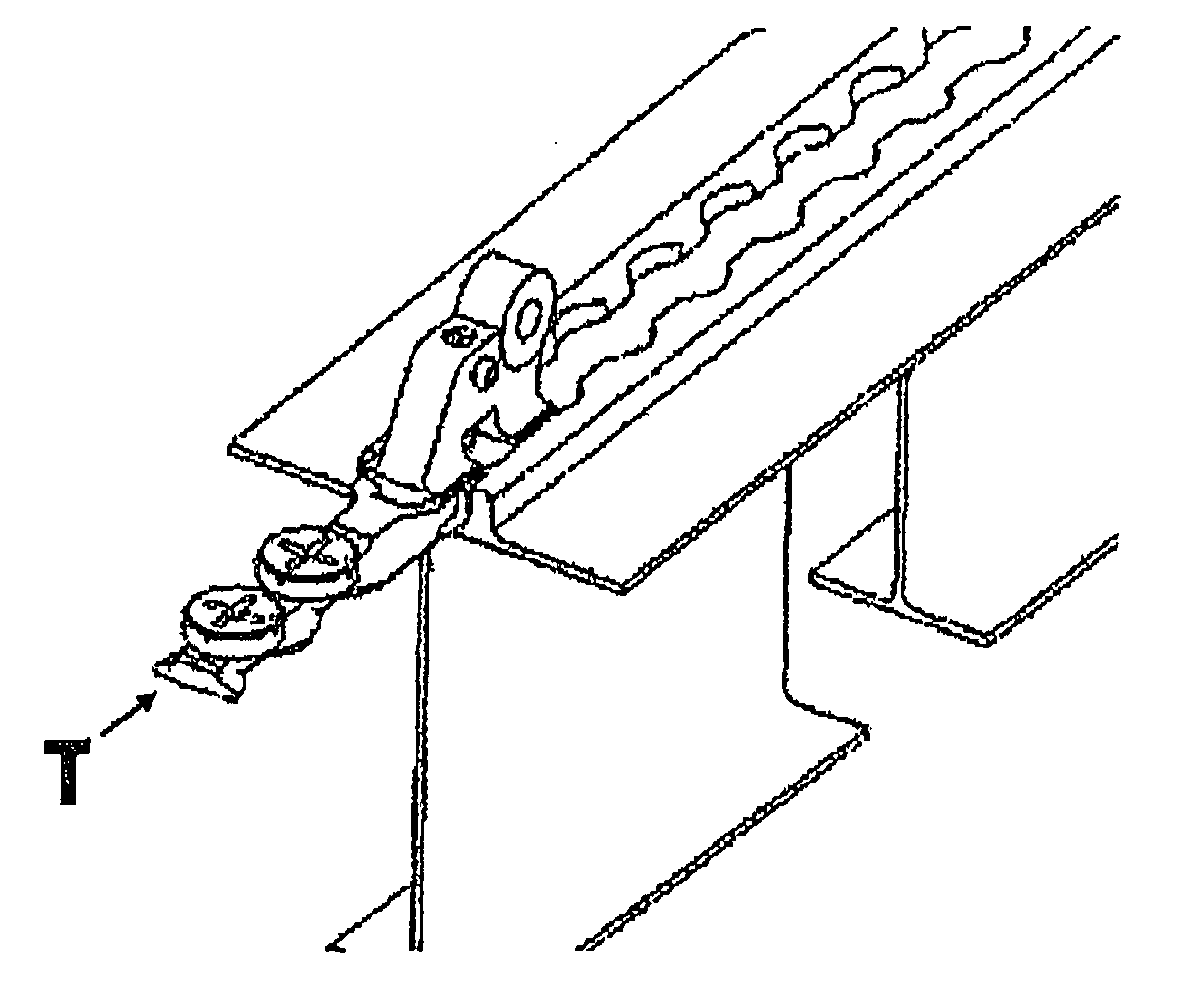

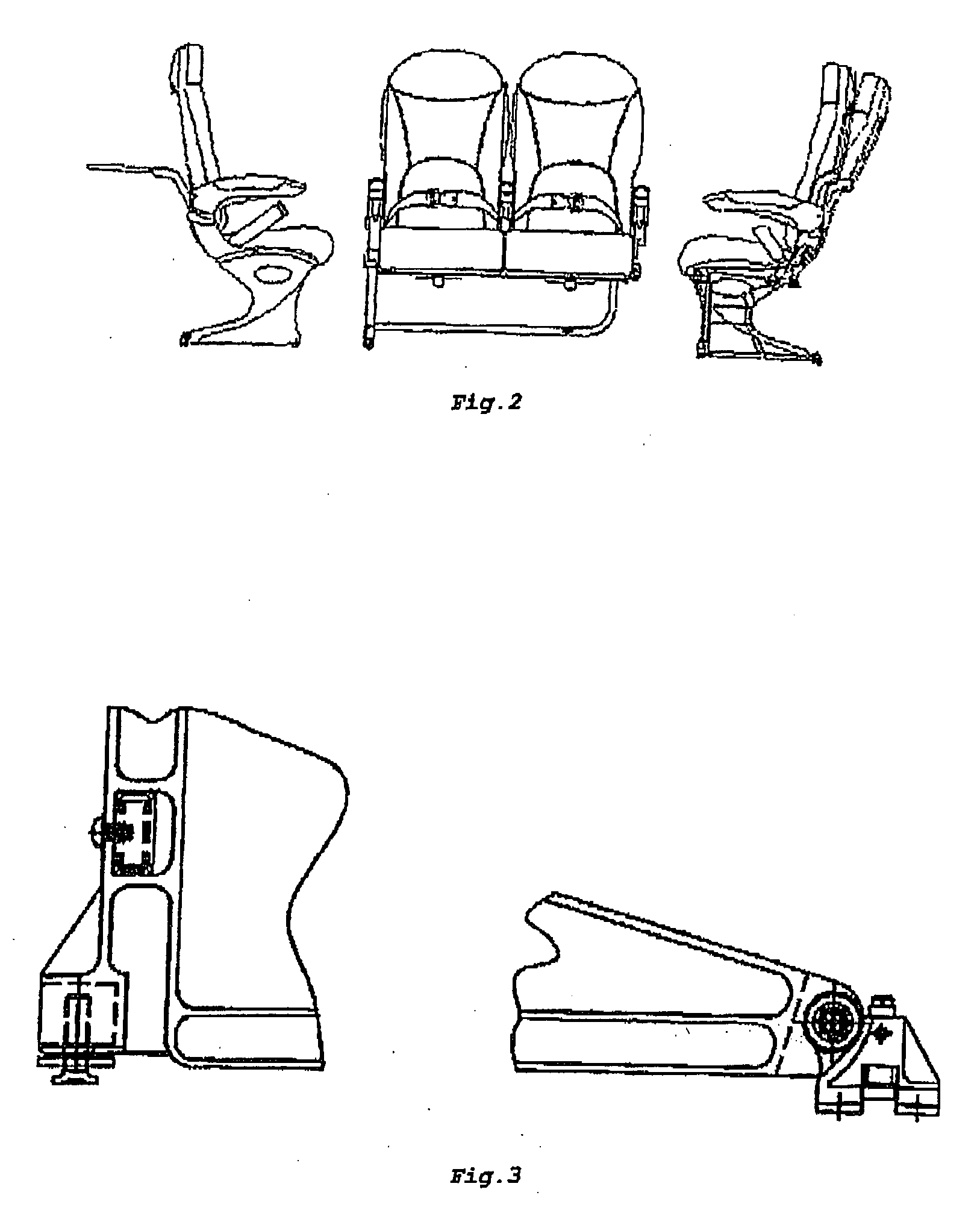

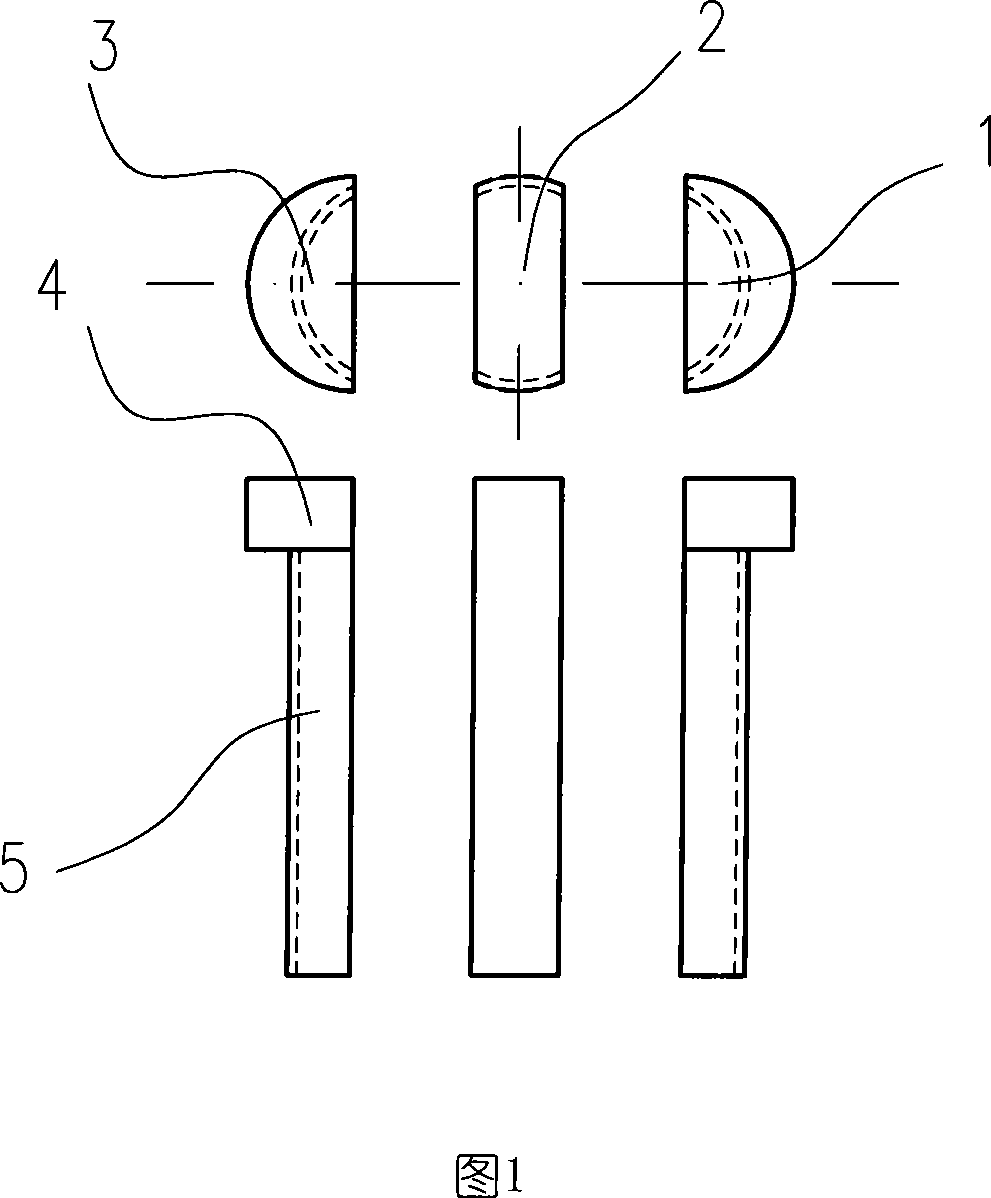

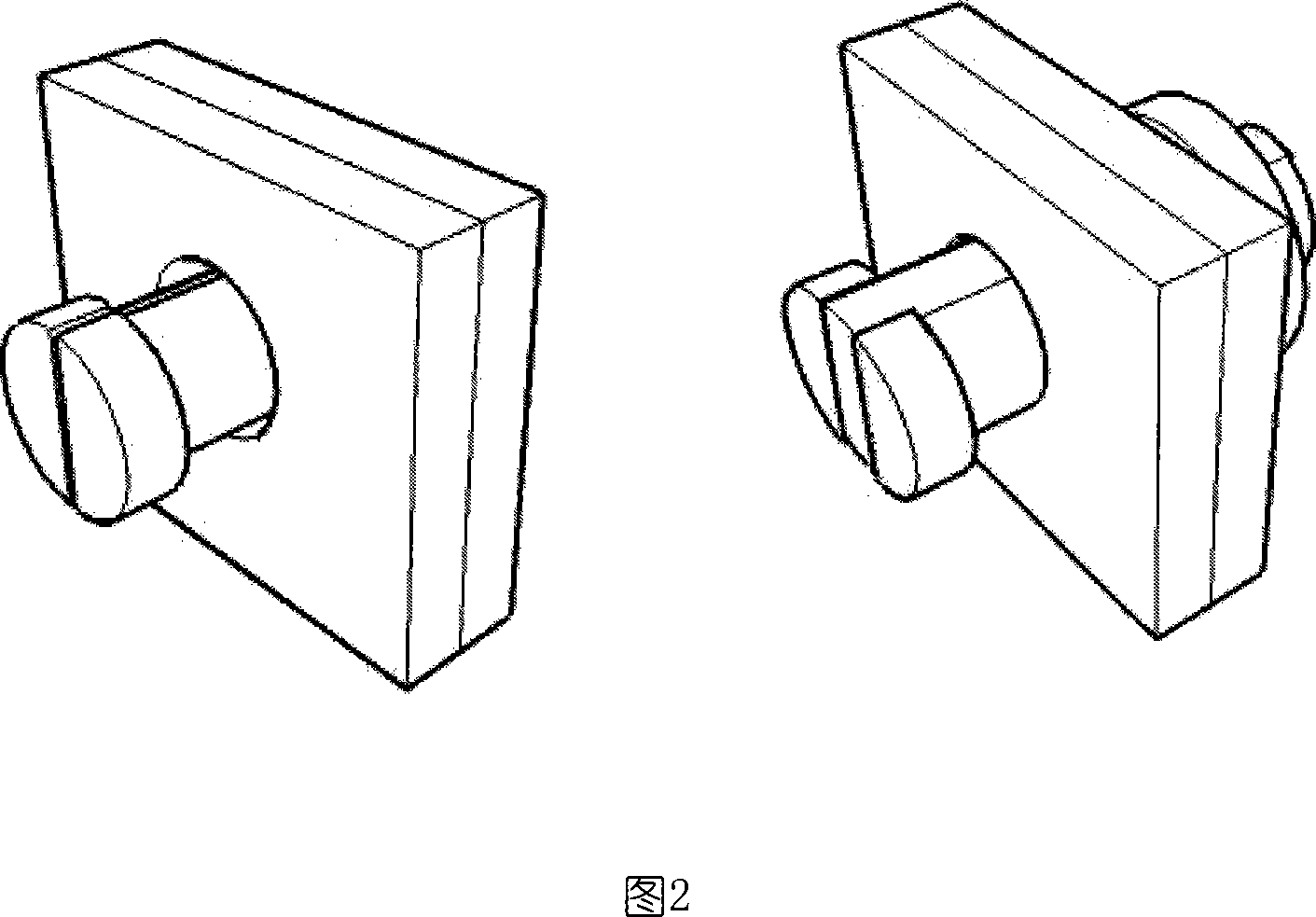

Device for fastening passenger seats on a seat track break in an aircraft

Disclosed is an adapter device D, T that, when installed on the division / break area of fixation tracks in an aircraft, it allows installation and / or positioning of passenger's seat in that area; the device D, T is composed by a main body 1 having two portions 9, 10; the end of the portion 9 is integrated to a part 2 having a fork shape configuring a half-opening 3; close to the end of the portion 10 there is a pair of half-tabs 5, one half-tab 5 symmetrically disposed in relation to the other, on each side of the body 1, on the main body 1, there is a pair of semi-circular tabs 4; on the portion 10, between the pairs of half-tabs 5 and tabs 4, there is one more pair of tabs, 4′, one tab 4′ symmetrically disposed in relation to the other, on each side of the body 1; there is two threaded pass-through holes 11, 11′ located on the portion 10; disc parts 6, 6′ which are actually screws heads are disposed on the portion 10, said screws being installed in the threaded holes 11, 11′. Considering the standardization of seats tracks and fasteners existent in the aeronautical industry, the adapting devices D and T can be used with several types of passengers' seats and tracks, and said devices can be adapted without adversely modifying installation characteristics; as the use of the adapting devices D and T is very simple, thus not demanding any modification or disassembly of the seats and, this way, it does not affect the pre-qualification of such seats.

Owner:YABORA IND AERONAUTICA SA

Bi component paint used as priming lacquer, producing process and usage thereof

InactiveCN1500844AGood chemical resistanceBright colorPolyamide coatingsEpoxy resin coatingsEpoxyLacquer

The two-component primer includes component A and component B mixed in the weight ratio of 3-8. The component A includes epoxy resin liquid 25-40 (in weight portions, the same below), amino resin 1-5, stuffing 30-40; and the component B includes polyamide resin 35-50, xylene 28-36, cyclohexanone 20-28 and drier 1-5. The paint product of the present invention has great adhesion force, good toughness, good antifouling performance, high wear resistance, smoke resistance, gasoline resistance, acid and alkali resistance, high electric insulating performance, shock resistance, heat resistance, cold resistance and good fireproof performance. It is used as primer widely in different fields.

Owner:刘恩禄

Stringpiece with bulb made of composite material

The invention relates to a stringer (11, 21, 31) which is made from a composite material and which is used to stiffen composite panels, particularly those used in the aeronautical industry. The inventive stringer is formed by a base (15) which is used to join same to the panel and a structural element (13, 23, 33) which is equipped with a structural reinforcement (17, 27, 37) at the end opposite the base (15), said structural reinforcement being made from high-modulus unidirectional fibres of the same material as the stringer or another compatible material. The invention also relates to a method of producing said stringer.

Owner:AIBUS ESPAA SL

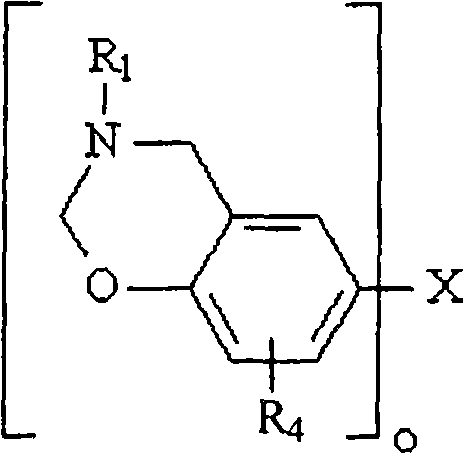

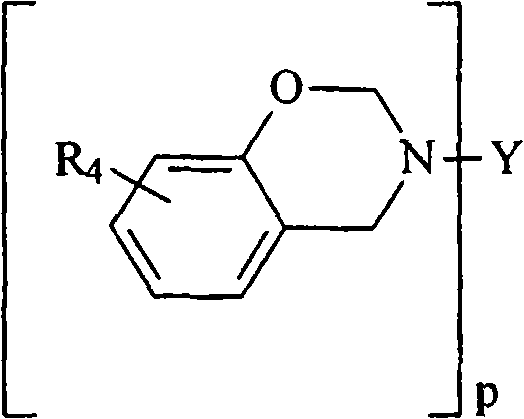

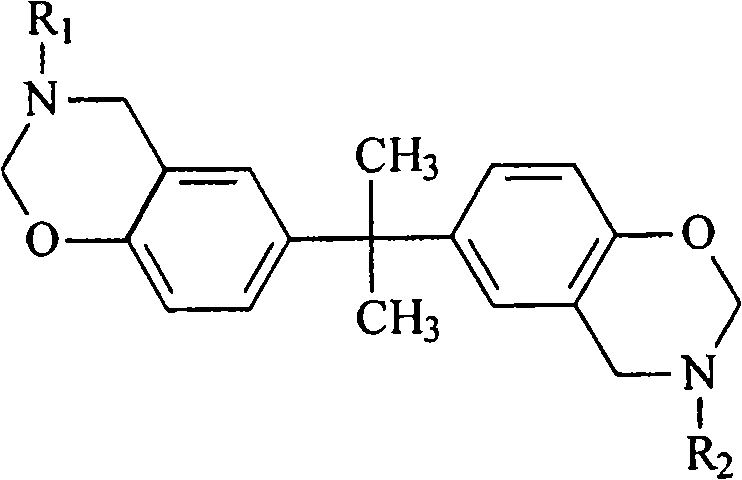

Benzoxazine compositions with core shell rubbers

ActiveCN101578332ANon-macromolecular adhesive additivesHeat-activated film/foil adhesivesAdhesiveCore shell

Curable compositions, such as benzoxazine-based ones together with core shell rubbers, are useful in applications within the aerospace industry, such as for example as heat curable composition for useas a matrix resin or an adhesive, and form the basis of the present invention.

Owner:汉高知识产权及控股有限公司

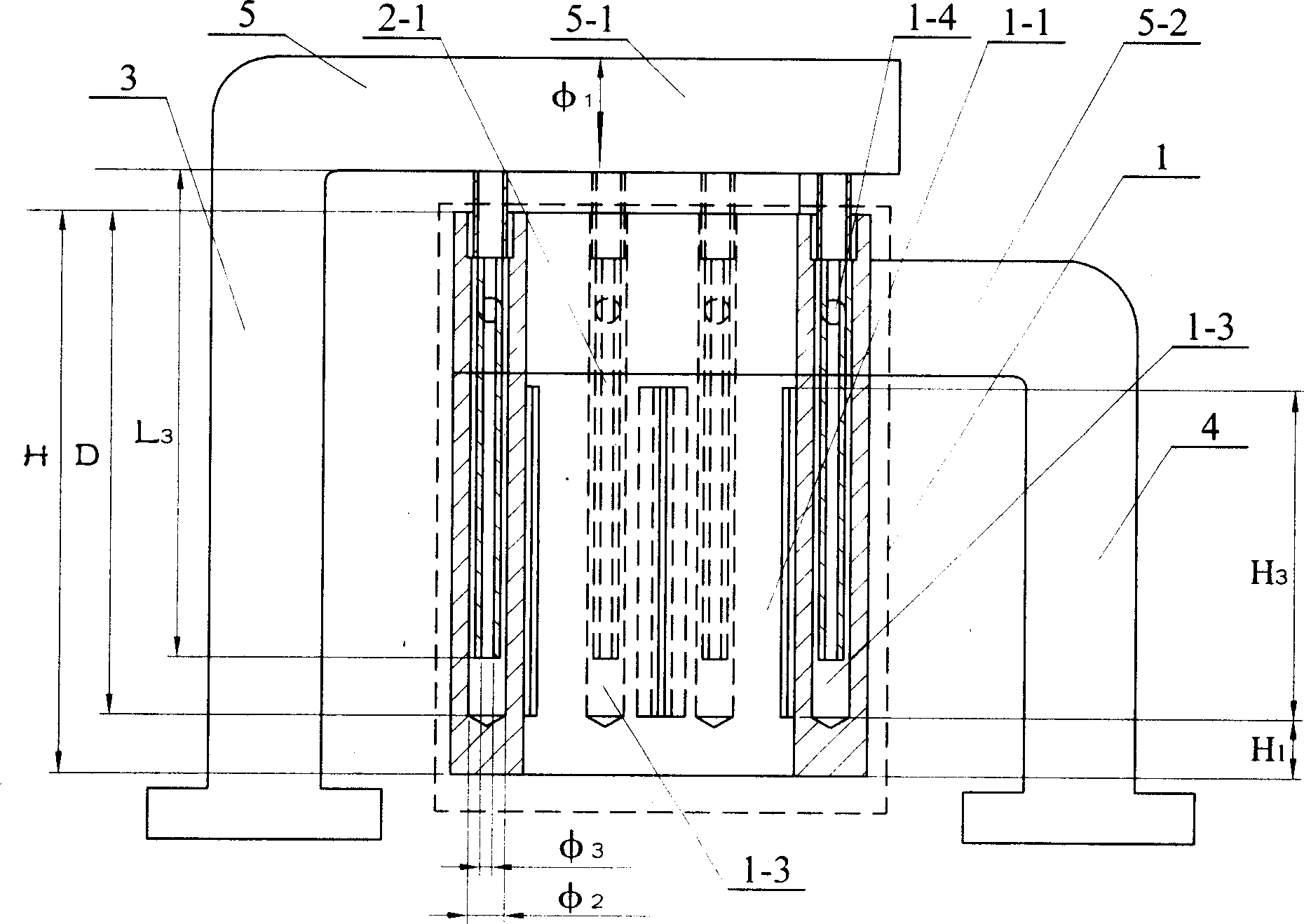

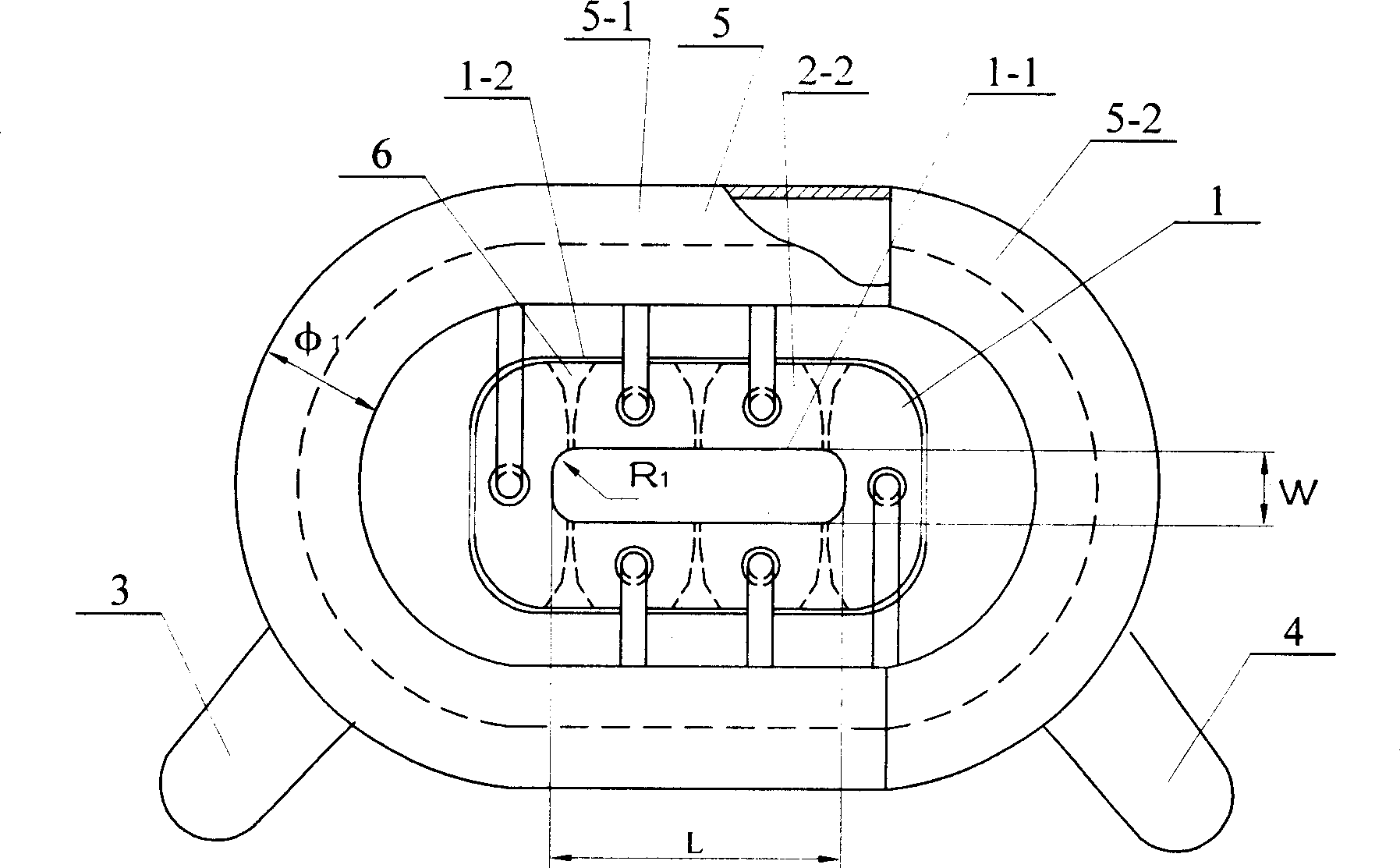

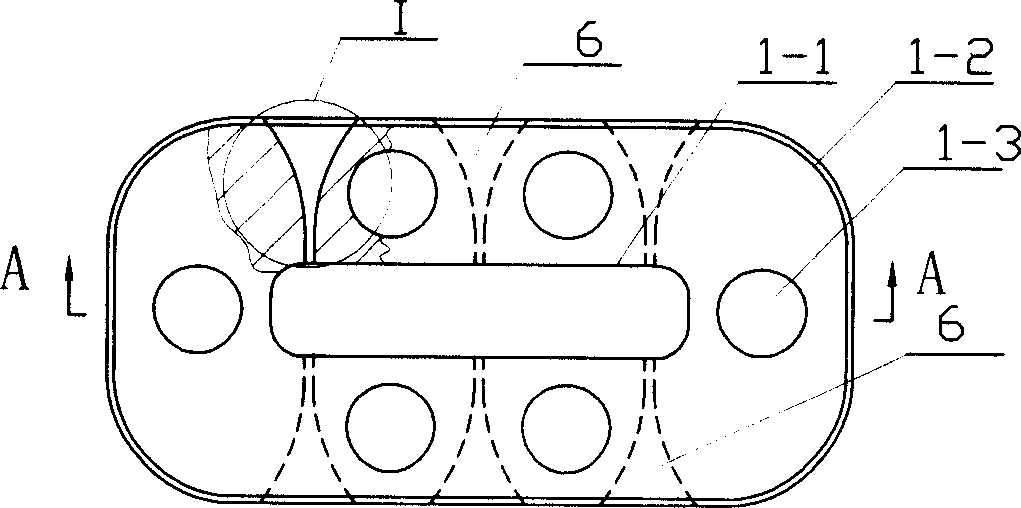

Rectangular cold crucible system suitable for continuous fusion casting directional freeze

The rectangle cold crucible system fit to casting continually and directional solidification comprises mould cavity 1-1 of crucible body 1 with proportion of width, length and height as 1:2~6:10~20 that belongs to fillet transition of two near surfaces and four square platform of big end down; opening splits with number about 6~18 run through outer surface 1-2 to mould cavity 1-1 on crucible body 1. This invention has no pollution to material, prepares heterotype alloy blank of high quality, overcomes the limit to rectangular intersection blank and fits to requirement of metallurgical and aerospace industry.

Owner:HARBIN INST OF TECH

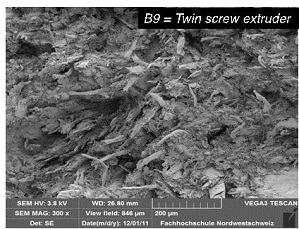

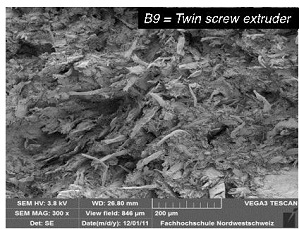

Method for preparing cellulose filled composite material

The invention relates to a method for preparing a cellulose filled composite material and belongs to the technical field of composite material preparation. The method comprises the following steps: weighing 1,000-1,100 weight parts of raw material, namely cellulose; drying for 3 hours until the mass percentage of water is less than 1 percent; weighing 60 to 80 weight parts of polyolefin, 5 to 15 weight parts of coupling agent, 5 to 15 weight parts of lubricating agent, 5 to 15 weight parts of impact resistant modifier and 5 to 15 weight parts of dispersing agent; fully mixing raw materials, and processing by using an extruder; and cooling by using a cooling tank, cutting the material to have the required shape, and drying. The prepared composite material has high mechanical properties and thermoplastic property. The composite material can be used for manufacturing various structural products; and the products have different shapes, such as office supplies, living goods (such as plastic basins, doors and windows and rail fences), crossbeams, bearing building materials, electronic product insulating shells, parts in the automobile industry, and interior decoration parts in the aviation industry.

Owner:SHANGHAI UNIV

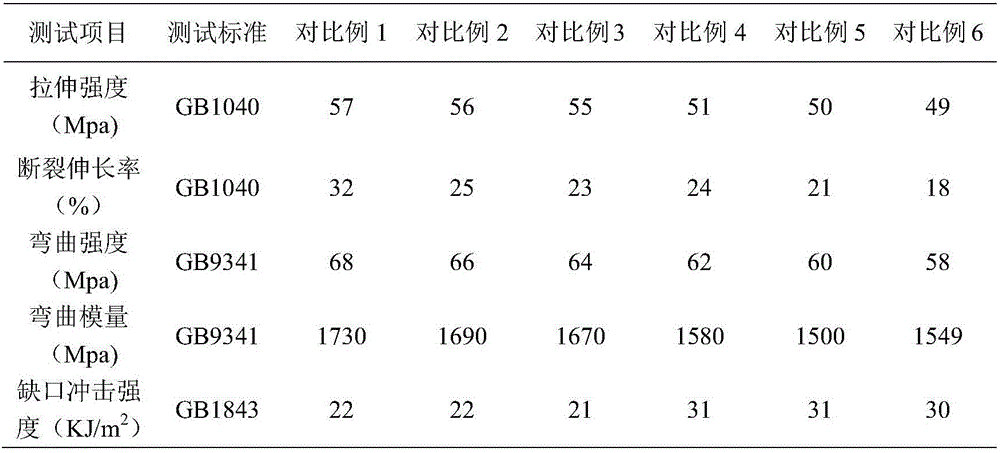

High-transparence toughened PA12/PA56 alloy material and preparation method thereof

The invention provides a high-transparence toughened PA12 / PA56 alloy material. The high-transparence toughened PA12 / PA56 alloy material can be used in the field of special industries with high transparence requirement. The formula of the material comprises 10-30 wt% of PA12 resin, 55-86.9 wt% of PA56 resin, 2-8 wt% of a flexibilizer, 0.2-2 wt% of light guiding powder, 0.2-1 wt% of an antioxidant, 0.5-2 wt% of a lubricant and 0.2-2 wt% of a nucleation inhibitor. A preparation method of the material comprises the following steps: uniformly stirring all component raw materials through a high mixer, adding the stirred raw materials to a double screw extruder, carrying out melt extrusion, cooling the extruded material, air-drying the cooled material, granulating the air-dried material, and strongly magnetizing obtained granules to obtain the material. The material has high toughness, has the transparence comparable to common nylon, and can be used in the fields of the aviation industry, automobile manufacturing, the electric appliance industry, image, medical science and food packaging.

Owner:GUANGDONG WAYLAM ENG PLASTICS

Split one-way bolt fastener

The present invention relates to a body-separated type one-way bolt fastener, belonging to the field of mechanical assembly technology. Said bolt body is composed of three portions, including two side bar bodies and one intermediate bar body, said three portions can be combined into a bolt whole body. The outer profile of cross-section of main body portion of every side bar body is equipped with a section of minor arc, said curved face has screw threads. Said intermediate bar body is mainly used for preventing side bar body from falling and has anti-drawing measure. When two side bar bodies and intermediate bar body are combined together, the cross-section of combined bolt whole body is circular, and its curved surface has screw threads, so that when said three portions are combined into a bolt whole body, said bolt whole body can be fixed by using general nut.

Owner:TSINGHUA UNIV

Bi component paint used as top coating, producing process and usage thereof

InactiveCN1500845AGood chemical resistanceStrong adhesionPolyurea/polyurethane coatingsShock resistanceBisphenol

The two-component finish paint includes component A and component B. The component A is mainly hydroxy bisphenol propane and epoxy chloropropane synthesized resin; and the component B is isocyanate and diaminotoluene affixture. The present invention also relates to the production process and usage of the paint product. When the finish paint is used, the two components are mixed and the finish paint is cured via crosslinking of hydroxy group and isocyanate to reach natural drying at normal temperature. The paint product of the present invention has great adhesion force, good toughness, good antifouling performance, high wear resistance, salty fog resistance, gasoline resistance, acid and alkali resistance, high electric insulating performance, shock resistance, heat resistance, cold resistance and good fireproof performance. It is used as finish paint widely in different fields.

Owner:刘恩禄

Low crack type high speed steel roll and its centrifugal casting method

The invention discloses a low-crackle type high speed steel roll and its centrifugal casting method, wherein the steel comprises the following chemical constituents (by weight percent): C 1.5-2.0%, W 3.0-6.0%, Mo 1.5-3.0%, V 3.0-10.0%, Cr 3.0-10.0%, Ni 1.5-3.0%, Mn<1.5%, Si<1.5%, RE 0.08-0.20%, K 0.05-0.15%, Mg 0.04-0.10%, wherein 0.20 B22D 13 / 12 C22C 38 / 18 1 13 2 2006 / 1 / 19 1803339 2006 / 7 / 19 1331626 2007 / 8 / 15 2007 / 8 / 15 2007 / 8 / 15 Zhengzhou Institute of Aeronautical Industry Management Henan 450005 Fu Hanguang Jiang Zhiqiang Shi Jinfa li zhengjian 61200 The Patent Agency of Xi'an University of Communications No.28, Xianning, Road, the City of Xi'an, Shanxi Province 710049

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

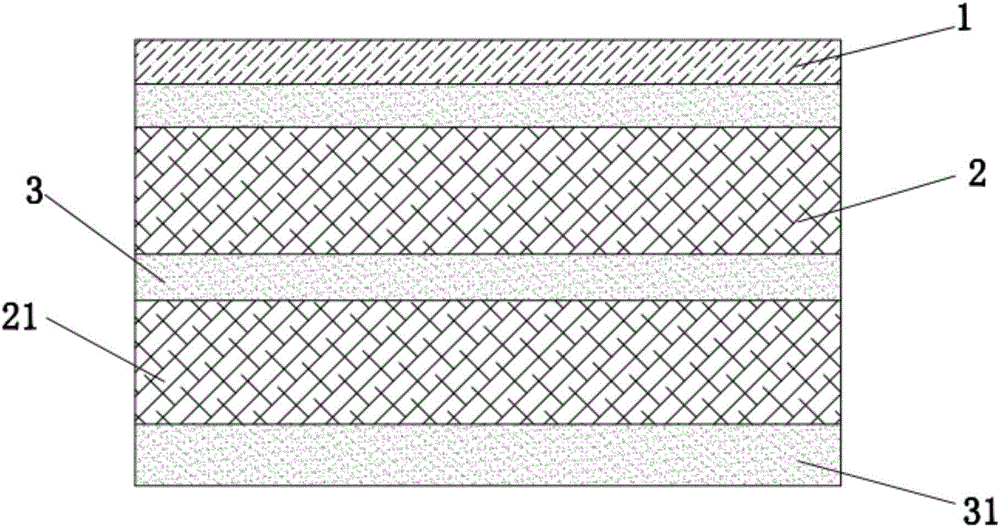

High damping composite plate

ActiveCN106393909AImprove damping performanceHigh modulus of elasticitySynthetic resin layered productsMetal layered productsAviationEngineering

The invention provides a high damping composite plate. The composite plate comprises a restraint layer and damping layers. Multiple damping layers are laminated and adhered on one surface of the restraint layer. The provided high damping composite plate is a novel whole resin system dedicatedly developed for the aviation industry, does not contain any asphalt or harmful volatile, is flame retardant, has the advantages of wide frequency range and wide temperature range, and solves the problems that conventional damping plates in the aviation industry are not environment-friendly, and the damping efficiency is low.

Owner:西安立远新材料科技开发有限公司

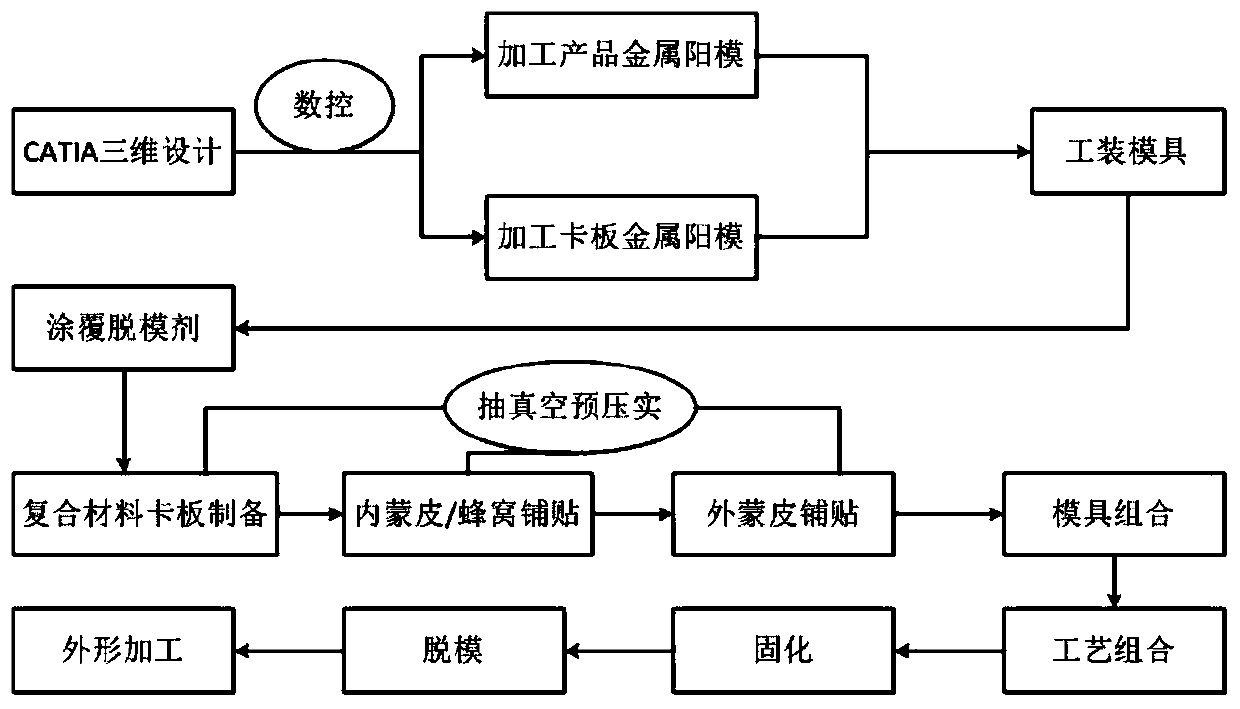

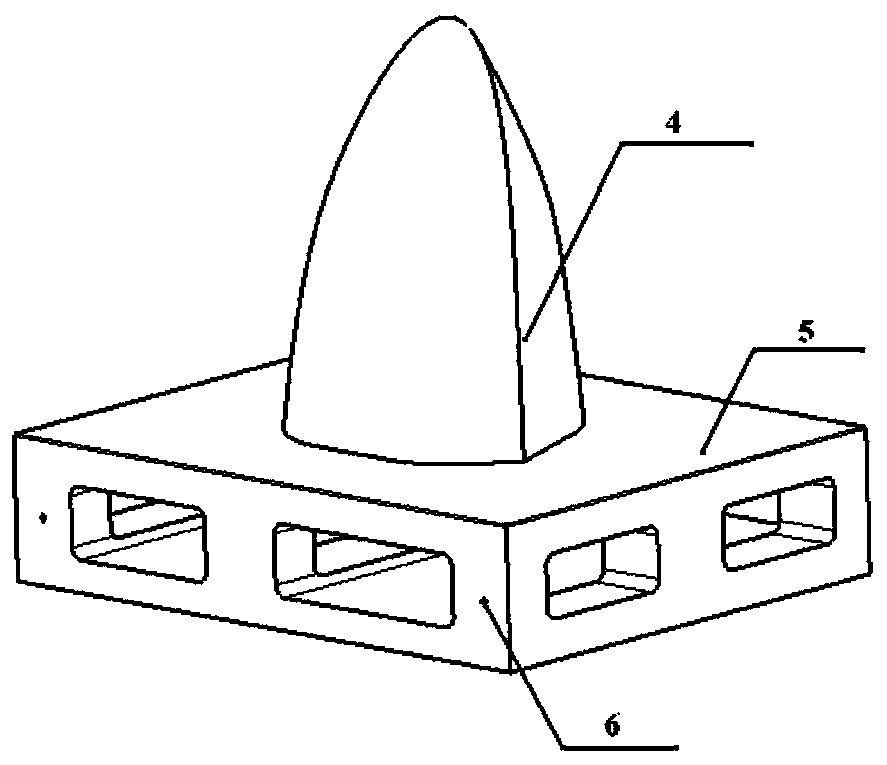

Co-curing manufacturing die and co-curing manufacturing process method for integral bow capof unmanned aerial vehicle

InactiveCN110356018ASolve quality problemsSolve the problem of pavingHoneycombCarbon fiber composite

The invention discloses a co-curing manufacturing die and co-curing manufacturing process method for an integral bow cap of an unmanned aerial vehicle, and belongs to the technical field of carbon fiber composite material forming processes in the aviation industry. The co-curing manufacturing die comprises a product metal male die, a product metal male die base, a profile clamping plate metal maledie and a base, wherein the size of the profile structure of the product metal male die is consistent with the size of the inner structure of the bow cap product; the size of the profile structure ofthe profile clamping plate metal male die is consistent with the size of the profile structure of the bow cap product; and the process steps of paving, vacuumizing, curing and demoulding are adoptedto manufacture the integral bow cap of an integrally formed honeycomb sandwich structure. According to the co-curing manufacturing die and the co-curing manufacturing process method, the profile precision and the outer surface quality and precision can be ensured, the processing time is shortened in the whole processing process, the number of the processing procedures is reduced, and the cost is saved.

Owner:XIAN AISHENG TECH GRP +1

Simulation test method of thermal fatigue failure of blade with thermal barrier coating

ActiveCN101776645BSolve critical engineering problemsWide temperature rangeMaterial analysis using acoustic emission techniquesThermometers using electric/magnetic elementsAviationCeramic coating

The invention belongs to the technical field of turbine blade performance detection in the aviation industry, in particular to a simulation test method of thermal fatigue failure of a blade with thermal barrier coating. The method can simulate the thermal fatigue work environment of temperature alternating circulation of various blades in an aircraft engine with high performance, and simultaneously tests and analyzes data, such as temperature, temperature gradient, surface topography image evolution, three dimensional deformation field, three dimensional displacement field, interface oxidation layer and thickening rule thereof, thermal fatigue flaw initiation and expansion, cooling airflow and the like of a blade sample with a thermal barrier coating, thus realizing real-time monitoring of three dimensional thermal strain and stress of the blade in the process of thermal fatigue experiments, and providing an important means for predicting thermal fatigue damaging position and invalidation time of the blade. The experimental data obtained by the method can provide important experiment basis for effectively evaluating the failure mechanism of the aircraft engine blade in the environment of high-temperature gas and predicting ceramic coating dropping position, dropping time and service life.

Owner:湖南新生代新材料科技有限公司

Extruded products for aeroplane floors made of an aluminium-copper-lithium alloy

Owner:CONSTELLIUM ISSOIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com