High-transparence toughened PA12/PA56 alloy material and preparation method thereof

An alloy material and toughening technology, which is applied in the field of preparation of high-transparency and toughened PA12/PA56 alloy materials, can solve the problems of less research on transparent toughening and modification, and achieve high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

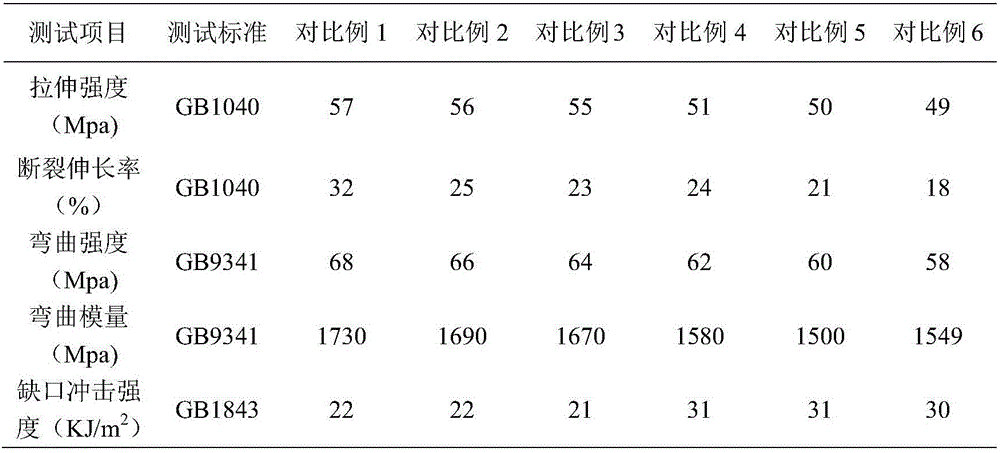

Examples

Embodiment Construction

[0034] The invention provides a high-permeability and toughening PA12 / PA56 alloy material, which comprises the following raw materials in percentage by weight:

[0035] PA12 resin 10~30;

[0036] PA56 resin 55~86.9;

[0037] Toughener 2~8;

[0038] Light guide powder 0.2~2;

[0039] Antioxidant 0.2~1;

[0040] Lubricant 0.5~2;

[0041] Nucleation inhibitor 0.2-2.

[0042] As a preferred solution, the moisture content of PA12 and PA56 required for a high-permeability and toughening PA12 / PA56 alloy material is both below 0.1%. Both PA66 and PA6 are mass-produced resins on the market. For example, PA12 can use Japanese Ube raw resin, and PA56 can use Shandong Kaisai Biological Co., Ltd. raw material resin.

[0043] The toughening agent is a liquid transparent toughening agent, such as Shenzhen Jindaquan special toughening agent A-610 for nylon.

[0044] The light guide powder is a nano-scale silicone resin, such as Japan Sekisui light guide powder or Huizhou fluorescent li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com