Method for preparing cellulose filled composite material

A composite material and cellulose technology, which is applied in the field of preparing cellulose-filled composite materials, can solve the problems of limiting the use of cellulose in large quantities, increasing the hybrid performance between plastic matrix and cellulose, and different, achieving low prices and reducing production costs. , The effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

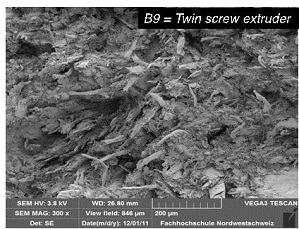

[0036] Weigh 1000 grams of granulated waste newspaper scraps recycled by Creafloc Pellitized. It is recycled waste newspaper, the main component is cellulose, TGA analysis shows that it contains 6.7% water by mass and 20.1% inorganic residues by mass, which may be calcium carbonate, kaolin, clay, etc. It was added in a drying oven for 3 hours, and its moisture mass ratio was measured to be less than 1%. Then weigh 700 grams of Flexirene MT 40A linear low-density polyethylene, 100 grams of Licocene PE MA 4351 polyethylene coupling agent, 100 grams of Licolub H12 internal lubricant, and 100 grams of Bondyram 7103 impact modifier. After fully mixing, add them into a twin-screw extruder for processing, and the processing temperature is controlled at 180°C. After extrusion molding, it is cooled with a cooling tank, and then mechanically cut into granules. After the granules are dried, they can be used for injection molding. figure 1 It is the spline section picture under SEM ...

Embodiment 2

[0039] Weigh 1000 grams of F2 raw material, the source is a mixture of waste newspapers and sawn wood through deinking and bleaching. The water content mass ratio measured by TGA is 8.3%, and the inorganic matter content mass ratio is 17.3%. It was put into a vacuum drier and dried for 3 hours, and its moisture content mass ratio measured was less than 1%. Then weigh 700 grams of PP FPC 100 polypropylene particles, 100 grams of Licocene PP MA 6452 TP polypropylene wax coupling agent, and 100 grams of polypropylene wax lubricant Licocene PP 1302. Except for F2, all other raw materials are fed into the twin-screw extruder, and the extrusion temperature is controlled at about 200°C. Put the F2 into the side feed system of the twin-screw extruder. When the extruder is normally extruded, the product is cooled and cut into granules, and then injected after drying. The actual measured specification is 170mm×10mm×4mm, the tensile elongation rate of the sample bar is 5.7%, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com