Simulation test method of thermal fatigue failure of blade with thermal barrier coating

A technology for simulating testing and thermal fatigue, which is applied to thermometers, measuring devices, and heat measurement of directly heat-sensitive electric/magnetic components, which can solve difficult fatigue failures, failure to test blade deformation, and failure to achieve deformation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention relates to a simulation test method for thermal fatigue failure of a blade with a thermal barrier coating in an aero turbine engine. The implementation of this patent will be further described in detail below in conjunction with the accompanying drawings.

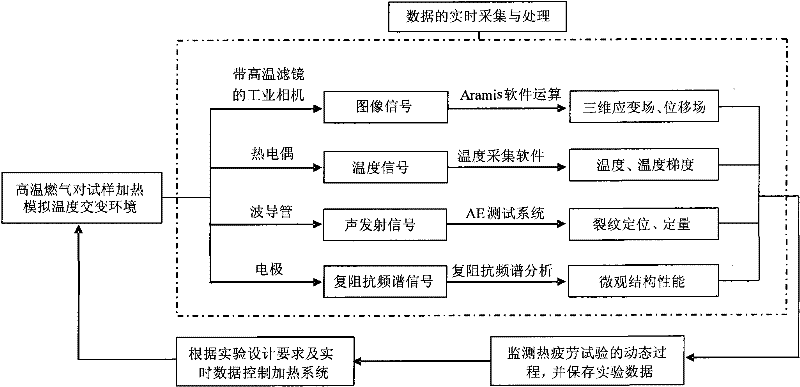

[0046] figure 1 It is a flowchart of the real-time testing method for thermal fatigue failure of a turbine blade provided by the present invention. This embodiment can be carried out according to the following steps:

[0047] The first step is to prepare the sample: the plasma spraying process is used to spray the thermal barrier coating heat insulation material on the surface of a certain type of hollow turbine blade. Its system composition is: transition layer material is NiCrAIY alloy, its thickness is about 100μm; ceramic powder material is containing 8% Y 2 o 3 ZrO 2 , the thickness of the ceramic layer is about 300 μm. Then spray a layer of anti-color ultra-high temperature resistant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com