Low crack type high speed steel roll and its centrifugal casting method

A technology of centrifugal casting and high-speed steel, which is applied in the field of steel rolling, which can solve the problems of high performance requirements, harsh use conditions of rolls, and easy cracks, etc., and achieve high strength and hardness, good economic benefits, good toughness and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The low-crack high-speed steel roll of this embodiment is smelted in an intermediate-frequency induction furnace with a capacity of 1000 kilograms, and its manufacturing process steps are:

[0050] ①Heating and melting ordinary steel scrap, ferrochrome, ferrotungsten, ferrovanadium, ferromolybdenum and nickel plates, and adding carbon with pig iron.

[0051] ② Adjust the composition before the furnace and raise the temperature to 1640°C, add 0.7% ferrosilicon with a silicon content of 75% and 0.5% ferromanganese with a manganese content of 78% for pre-deoxidation, add 0.2% aluminum for final deoxidation, and then leave the furnace .

[0052] ③Crush the compound modifier containing rare earth, potassium and magnesium into small pieces with a particle size of less than 18mm, and after drying at 220°C, place it at the bottom of the ladle, and perform compound modification treatment on molten steel by pouring into the ladle.

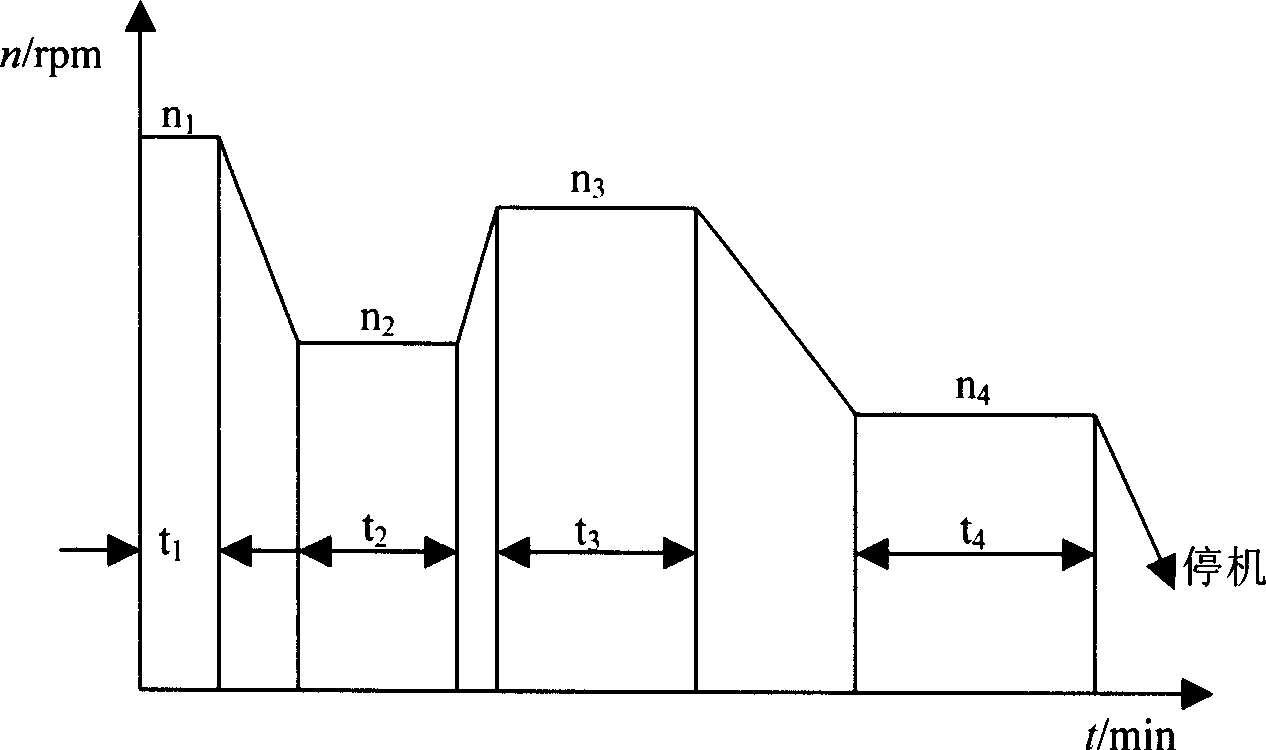

[0053] ④ Manufacture high-speed steel rolls by...

Embodiment 2

[0060] The low-crack high-speed steel roll of the present embodiment is smelted in an intermediate-frequency induction furnace with a capacity of 3000 kilograms, and its manufacturing process steps are:

[0061] ①Heating and melting ordinary steel scrap, ferrochrome, ferrotungsten, ferrovanadium, ferromolybdenum and nickel plates, and adding carbon with graphite.

[0062] ② Adjust the composition before the furnace and raise the temperature to 1605°C, add 0.6% ferrosilicon with a silicon content of 75% and 0.8% ferromanganese with a manganese content of 78% for pre-deoxidation, add 0.15% aluminum for final deoxidation, and then leave the furnace .

[0063] ③Crush the composite modifier containing rare earth, potassium and magnesium into small pieces with a particle size of less than 18mm, and after drying at 200°C, place it at the bottom of the ladle, and perform composite modification on the molten steel by pouring into the ladle.

[0064] ④ Manufacture high-speed steel roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com