Benzoxazine compositions with core shell rubbers

A composition, benzoxazine technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of not meeting the needs of heat-curable compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

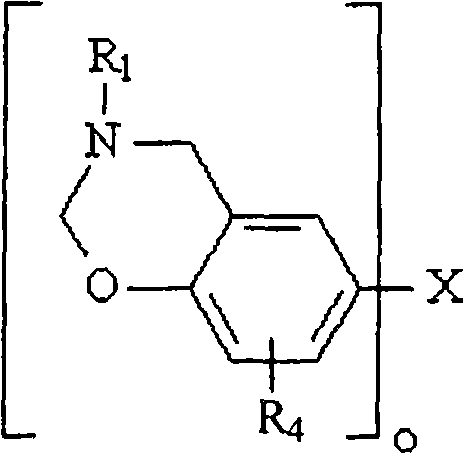

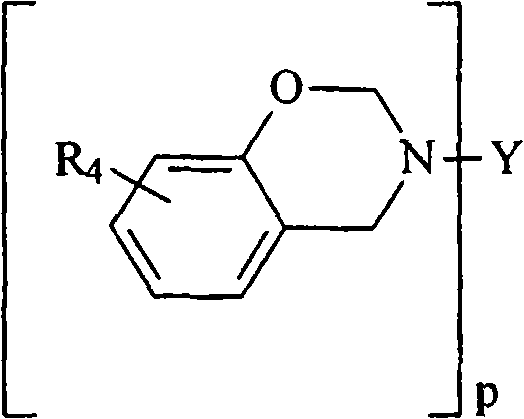

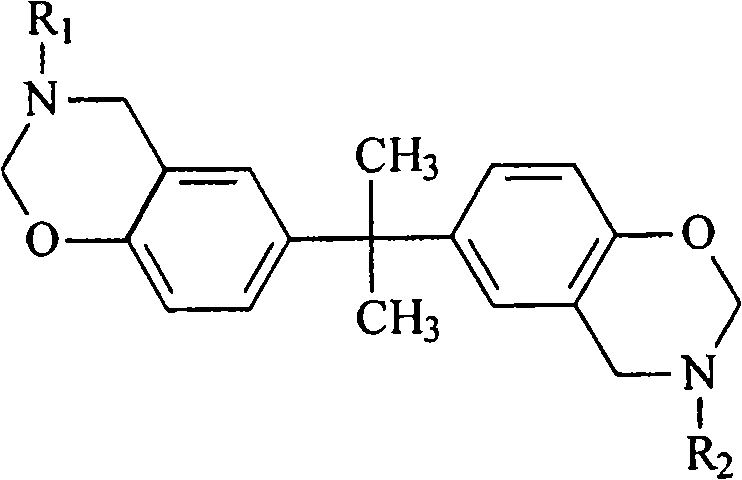

Method used

Image

Examples

Embodiment

[0064] Here a series of samples were prepared from benzoxazine and epoxy resin, core shell rubber, nanoparticulate silica and / or epoxidized p-aminophenol as shown in Tables 1a and 1b below. Sample Nos. 1, 4, and 7 are listed as controls without core-shell rubber, relative to Sample Nos. 2-3, 5-6, and 8, respectively.

Table 1a

Table 1b

1 Benzoxazines also include monofunctional benzoxazines.

*Epoxidized p-aminophenol, commercially available from Huntsman Specialty Chemical.

[0065] Prepare each sample as follows:

[0066] Warming the benzoxazine at 160°F made it flowable without initiating cure.

[0067] The remaining ingredients were added to the speedmixer vessel and heated with mixing at a mixing speed of 2400 rpm for a period of 15 minutes at a temperature of 160°F until a substantially homogeneous composition was observed to form. The composition thus formed was poured directly into the mold before curing.

[0068] Thus, in an autoclave, the samples des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com