Aluminum-Copper-Lithium Alloy With Improved Mechanical Strength and Toughness

a technology of copper-lithium alloy and mechanical strength, applied in the field of aluminum-copper-lithium alloy products, can solve the problems of quench sensitive products, reduced yield strength, and reduced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0096] In this example, a plurality of slabs with dimensions 2000×380×120 mm of which the composition is provided in table 1 were cast.

TABLE 1Composition in weight % and density ofAl—Cu—Li alloys cast in plate form. (Ref: reference;Inv: invention).DensitySiFeCuMnMgZnAgLiZr(g / cm3)10.0120.0223.540.380.32—0.240.890.102,706(Ref)20.0120.0233.530.380.32——0.910.102,699(Ref)30.0120.0323.530.380.67—0.250.930.102,698(Inv)40.0110.0223.5 0.380.67——0.940.102,692(Inv)50.0780.0883.520.380.34—0.250.910.102,705(Ref)60.0150.0293.500.390.310.390.240.950.102,707(Ref)

Ti: target 0.02% by weight for alloys 1 to 6

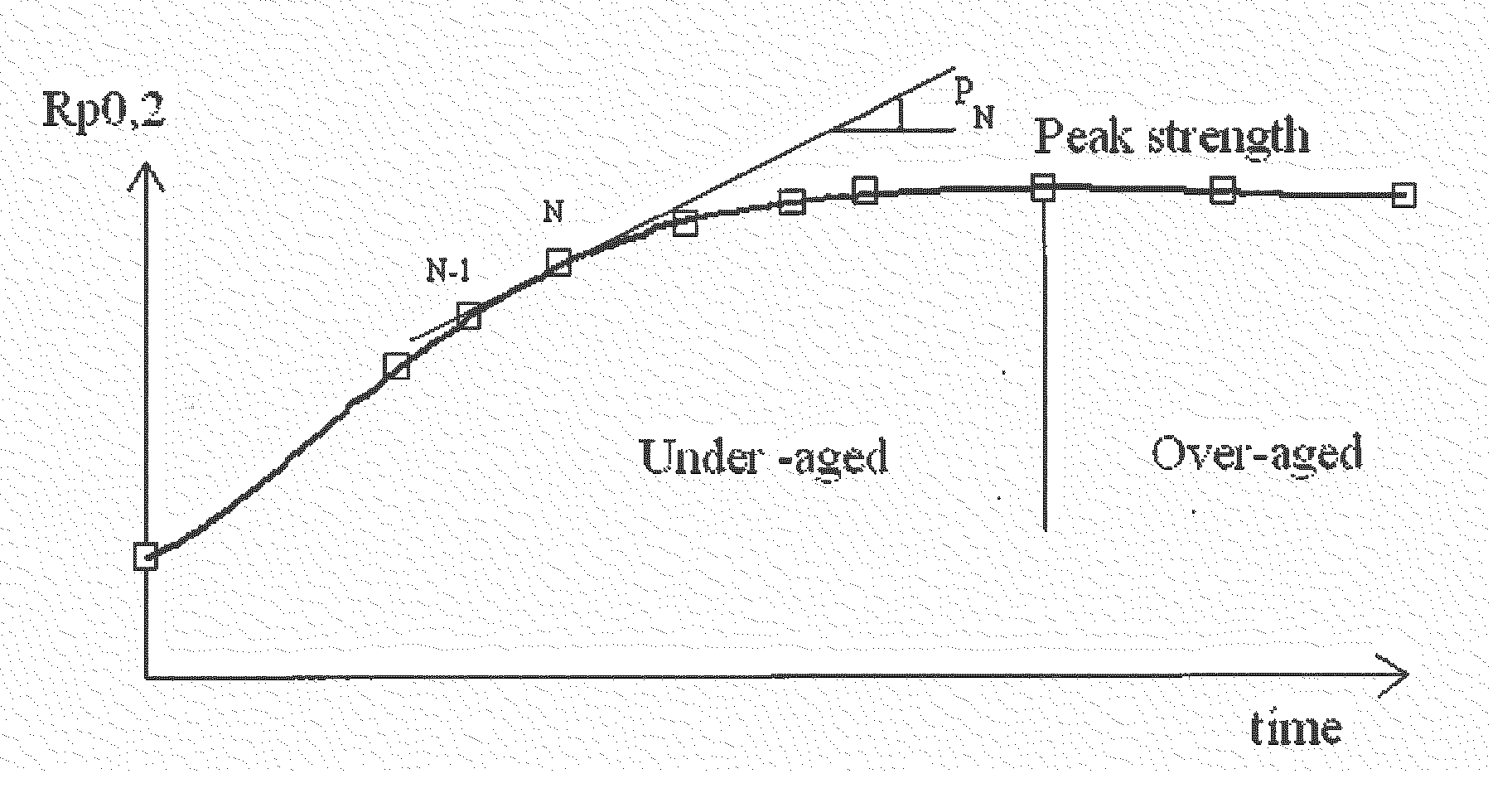

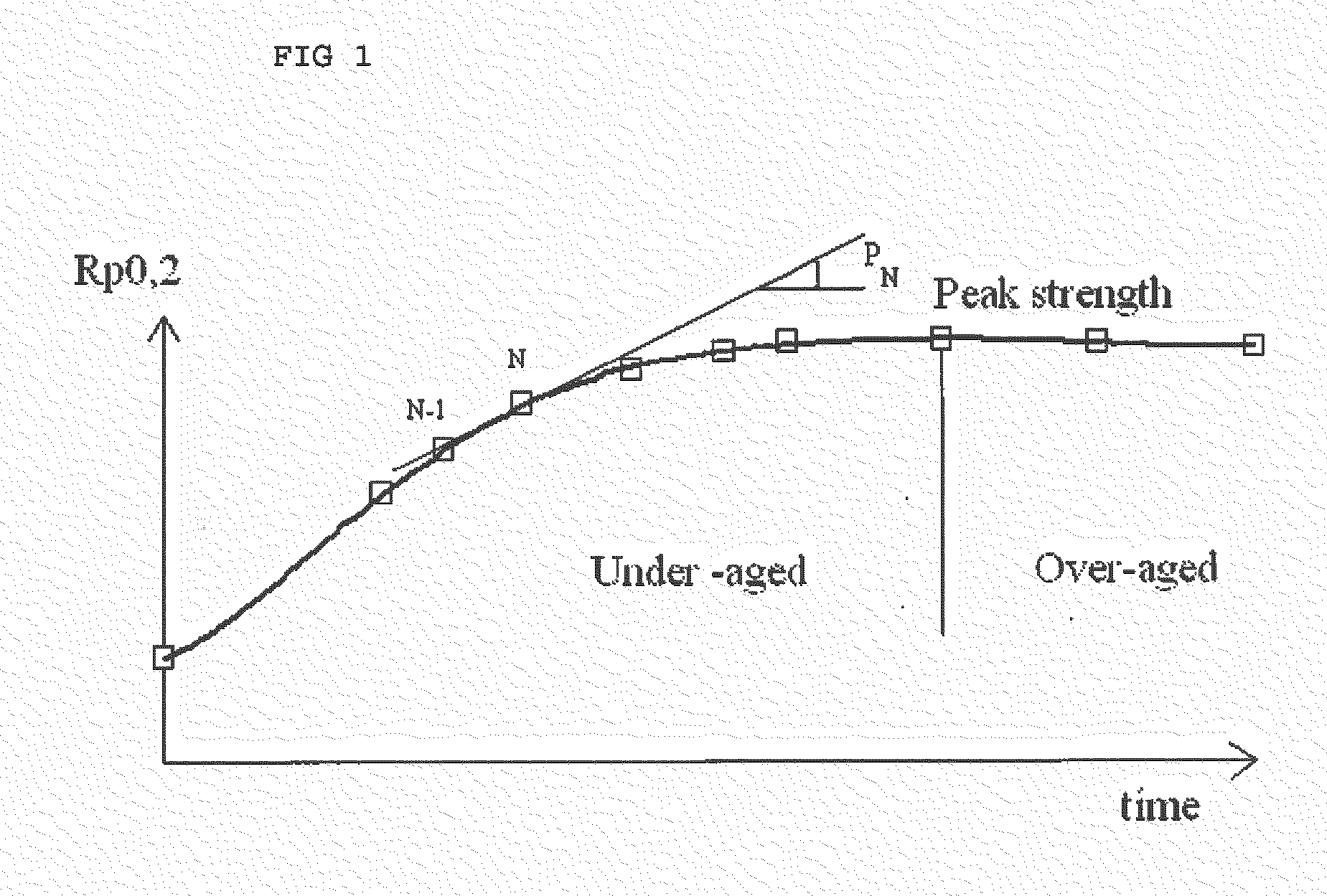

[0097] The slabs were homogenized at around 500° C. for around 12 hours, then cut and scalped so as to obtain parts with dimensions of 400×335×90 mm. The parts were hot rolled to obtain plates with a thickness of 20 mm. The plates were solution treated at 505+ / −2° C. for 1 h, quenched with water at 75° C. so as to obtain a cooling rate of around 18° C. / s and thus simulate the properties obtaine...

example 2

Reference

[0101] In this example, a plurality of slabs with a thickness of 406 mm of which the composition is provided in table 3 were cast.

TABLE 3Composition in weight % and density ofAl—Cu—Li alloys cast in plate form.DensityAlloySiFeCuMnMgZnAgLiZr(g / cm3) 820500.030.063.510.410.3 0.020.370.840.092,713(Ref)211183 921950.030.044.2 0.4 0.351.060.112,700(Ref)1764721021950.030.053.870.020.310.010.351.060.112,695(Ref)271257

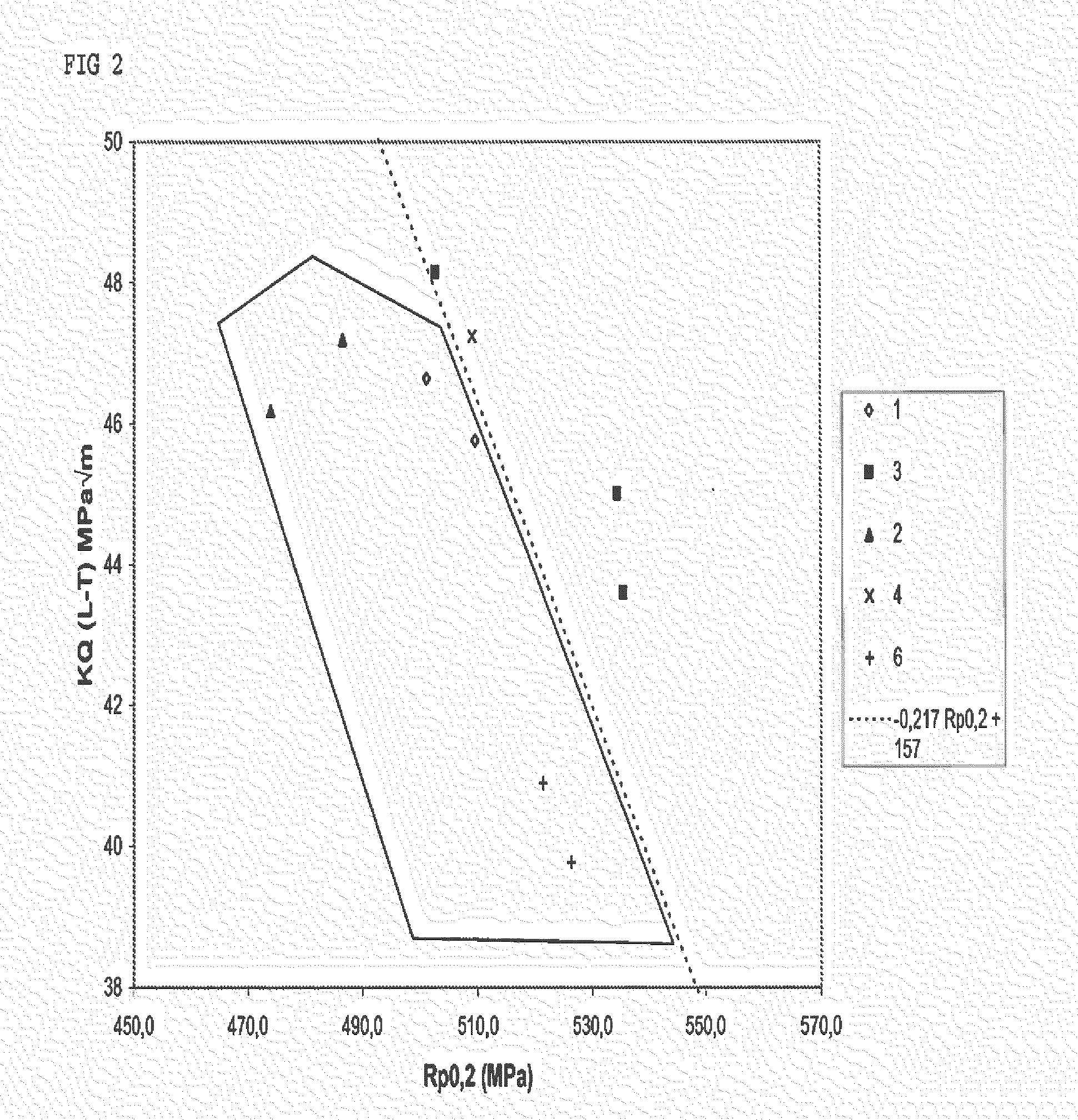

[0102] The slabs were homogenized, then scalped. After homogenization, the slabs were hot rolled in order to obtain plates with a thickness of 50 mm. The plates were solution treated, quenched with cold water and stretched with a permanent elongation of between 3.5% and 4.5%

[0103] The plates were then subjected to aging for between 10 h and 50 h at 155° C. Samples were obtained at half-thickness in order to measure the static mechanical tensile properties as well as the toughness KQ. The test pieces used to measure the toughness had a width W=80 mm and a thickness ...

example 3

[0105] In this example, a plurality of slabs with dimensions 2000×380×120 mm of which the composition is provided in table 5 were cast.

TABLE 5Composition in weight % and density ofAl—Cu—Li alloys cast in plate form. (Ref: reference;Inv: invention).DensitySiFeCuMnMgZnAgLiTiZr(g / cm3)110,0350,0593,560,350,32—0,250,900,030,112,706(Ref)120,0350,0583,660,350,68—0,250,890,020,122,702(Inv)130,0360,0593,570,341,16—0,250,860,020,122,697(Ref)

[0106] The slabs were homogenized fat around 500° C. for around 12 hours, then cut and scalped so as to obtain parts with dimensions of 400×335×90 mm. The parts were hot rolled to obtain plates with a thickness of 20 mm. The plates were solution treated at 505+ / −2° C. for 1 h, and quenched with cold water. The plates were then stretched with a permanent elongation of 3.5%.

[0107] The plates were subjected to artificial aging for between 18 h and 72 h at 155° C. Samples were taken at half-thickness in order to measure the static mechanical tensile propert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com