High damping composite plate

A composite board, high damping technology, applied in the field of vibration reduction, can solve the problems of low damping efficiency, poor flame retardancy, wide temperature, narrow frequency bandwidth, etc., to achieve high temperature resistance performance improvement, excellent flame retardant performance, vibration reduction Good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The damping layer of this embodiment 1 is made by mixing 35% polymer resin, 45% graphite and 20% filler; wherein, the above polymer resin includes 30% polyurethane and 70% polyvinyl chloride, and the filler includes 25% % aluminum powder and 75% silica.

[0025] The damping layer of this embodiment is obtained by kneading the polyurethane material, polyvinyl chloride, graphite, aluminum powder and silicon dioxide in the above formula in a kneader. Wherein, the paddle speed of the kneader is 65 rpm, and the kneading time is 8 minutes.

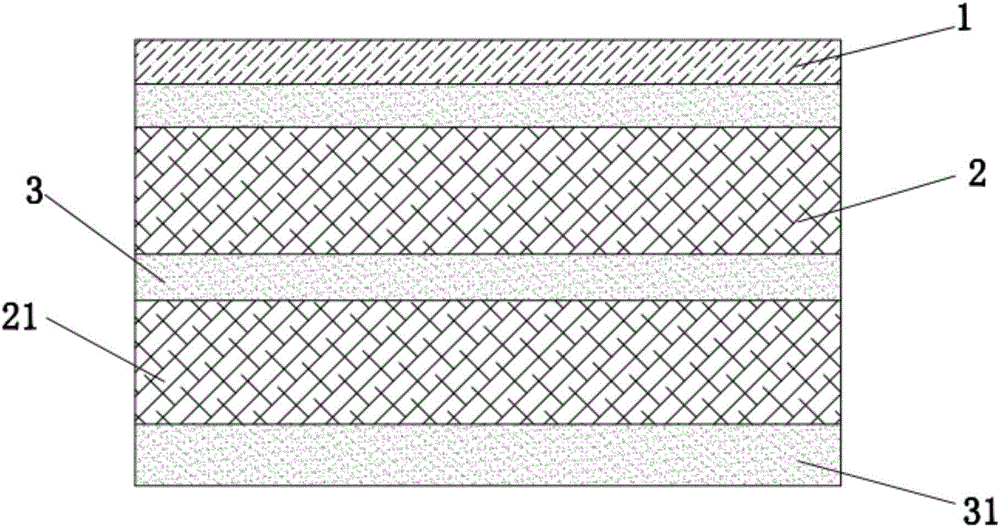

[0026] A kind of high damping composite board of the present embodiment, specifically as figure 1 As shown, in the high-damping composite panel of this embodiment, two damping layers are superimposed on one side of the constraining layer 1, namely the first damping layer 2 and the second damping layer 21; and the thickness of the damping layer is 0.5mm. The constrained layer 1, the first damping layer 2 and the second damping layer 21 a...

Embodiment 2

[0030] In Example 2 of the present invention, on the basis of the high damping composite plate structure in Example 1, the thickness of the constrained layer 1 is set to 0.2 mm, the thickness of the damping layer is set to 0.6 mm, and the thickness between the constrained layer 1 and the first damping layer 2 The thickness of the acrylic resin film layer 3 is 0.1 mm, the thickness of the acrylic resin film layer 3 between the first damping layer 2 and the second damping layer 21 is 0.2 mm, and the thickness of the bottom organic adhesive layer 31 is 0.3 mm.

[0031] The components and preparation method of the damping layer in Example 2 are the same as those in Example 1.

Embodiment 3

[0033] Embodiment 3 of the present invention changes the composition of its damping layer on the basis of the high damping composite plate structure of Embodiment 1; the damping layer of this embodiment is made of 40% polymer resin, 30% graphite and 30% It is prepared by mixing fillers; wherein, the polymer resin includes 25% polyurethane and 75% polyvinyl chloride, and the filler includes 40% aluminum powder and 60% silicon dioxide.

[0034] The damping layer of this embodiment is obtained by kneading the polyurethane material, polyvinyl chloride, graphite, aluminum powder and silicon dioxide in the above formula in a kneader. Wherein, the paddle speed of the kneader is 80 rpm, and the kneading time is 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com