Extruded products for aeroplane floors made of an aluminium-copper-lithium alloy

A technology of extruded products and alloys, used in the field of aerospace and aerospace construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

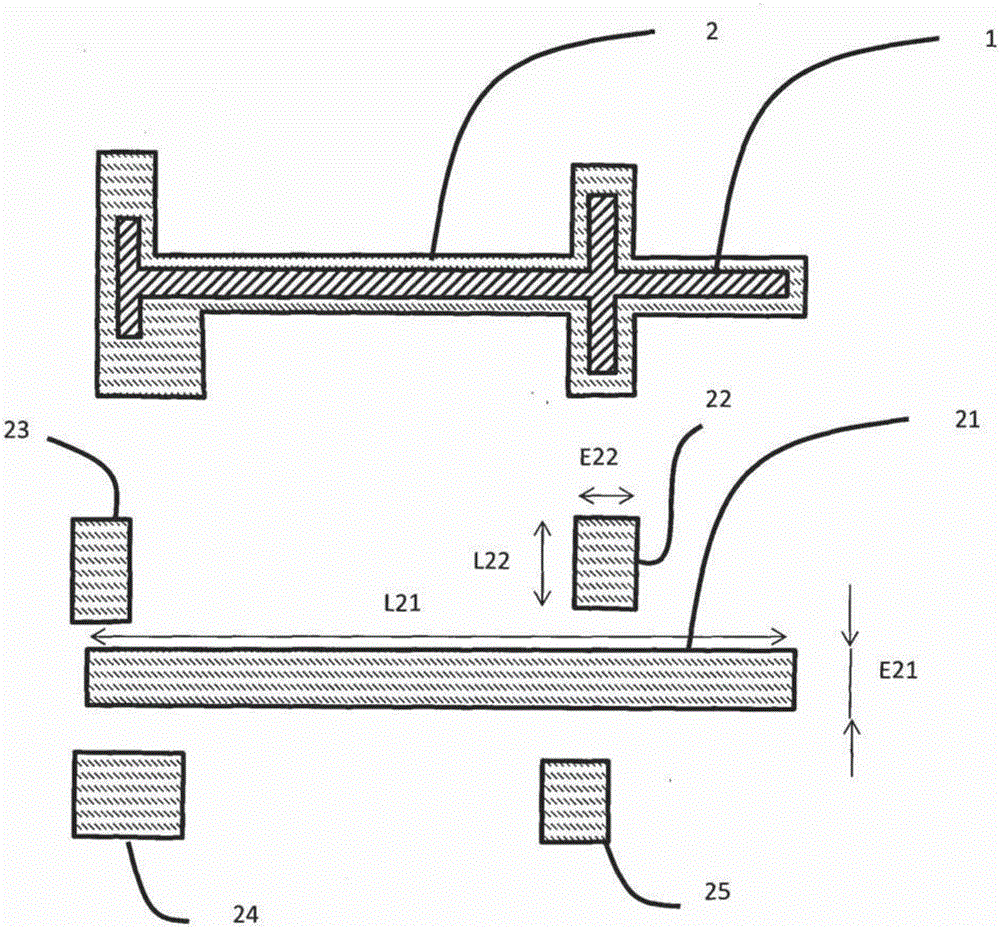

[0056] In this example, machined extrusions made of AA2196 alloy were prepared. Articles C, D, and E had raw flanks whose dimension perpendicular to the length dimension of the raw core was at least 20% longer than the length of the machined flank.

[0057] A rough shaped body made of AA2196 alloy was cast and homogenized at about 520°C.

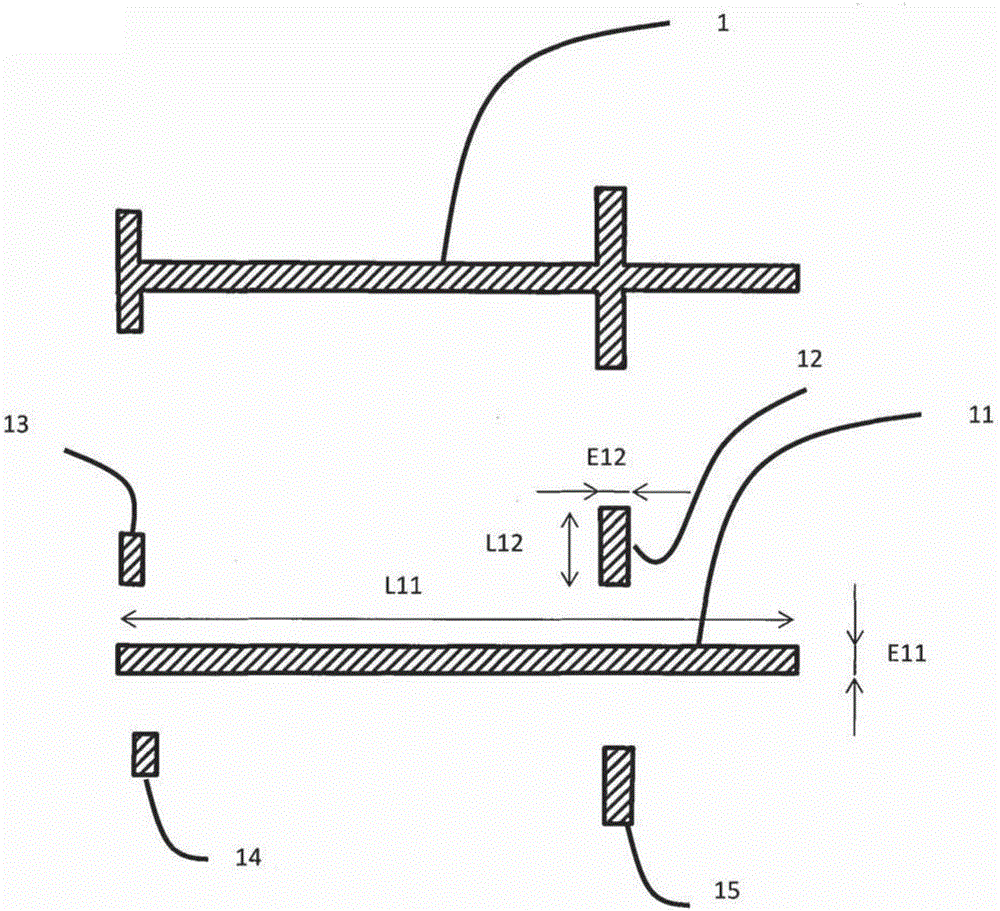

[0058] The rough shaped body was extruded to obtain a rough profile with a core of the length of the core and the properties of at least one flank given in Table 1 .

[0059] Table 1: Geometric properties of crude profiles

[0060]

Core length (mm)

Core thickness (mm)

Flank Length(mm)

Flank Thickness(mm)

A*

242

21

20

16

B*

242

30

22

20

C α

242

25

25

15

D α

242

21

36

15

E α **

242

21

36

28

[0061] *flank thickness direction perpendicular to the length direction of the nucleus

[0062] α Fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com