Rectangular cold crucible system suitable for continuous fusion casting directional freeze

A technology of directional solidification and cold crucible, applied in the field of cold crucible system, can solve the problem that cold crucible cannot be used to process rectangular cross-section ingots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

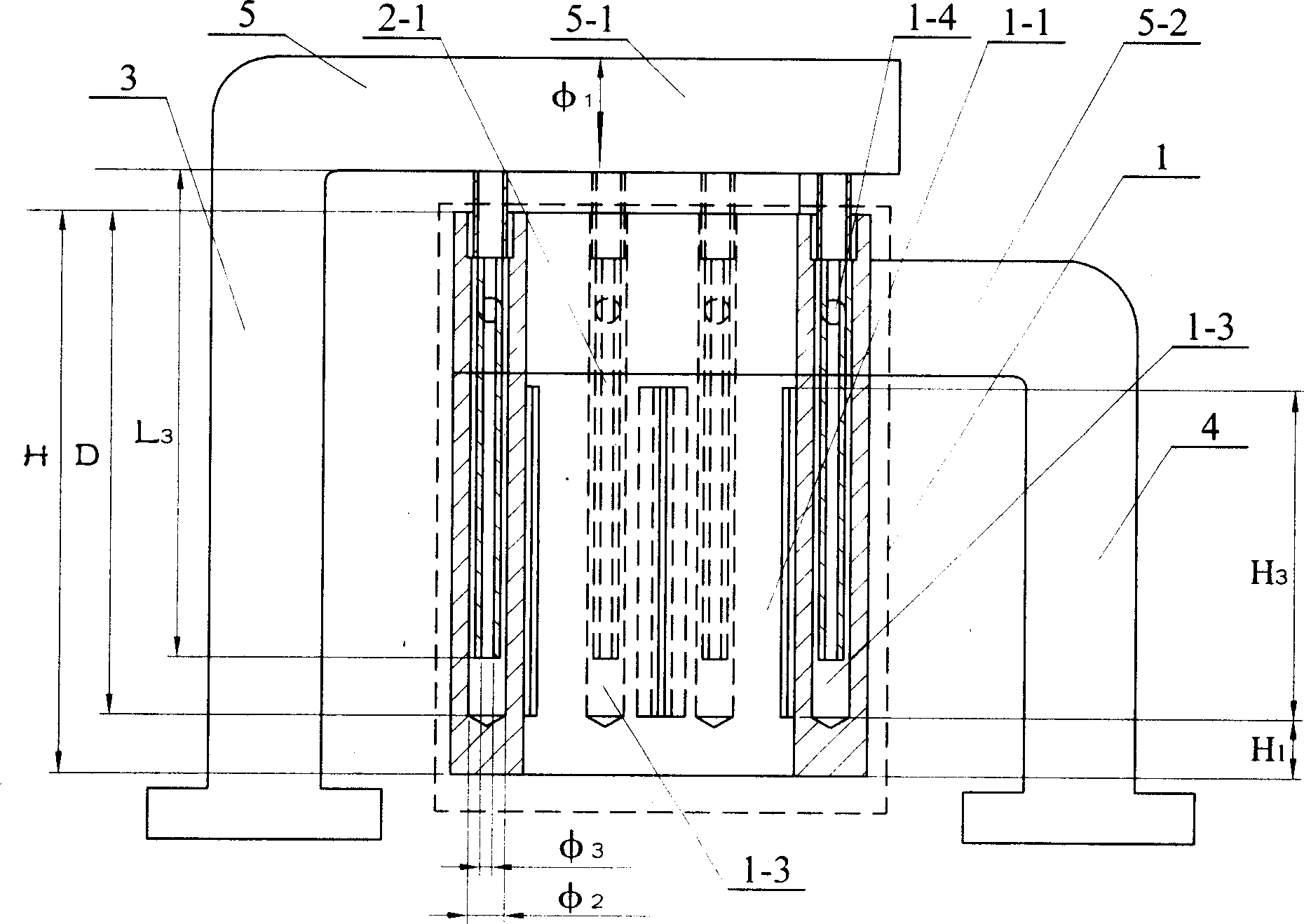

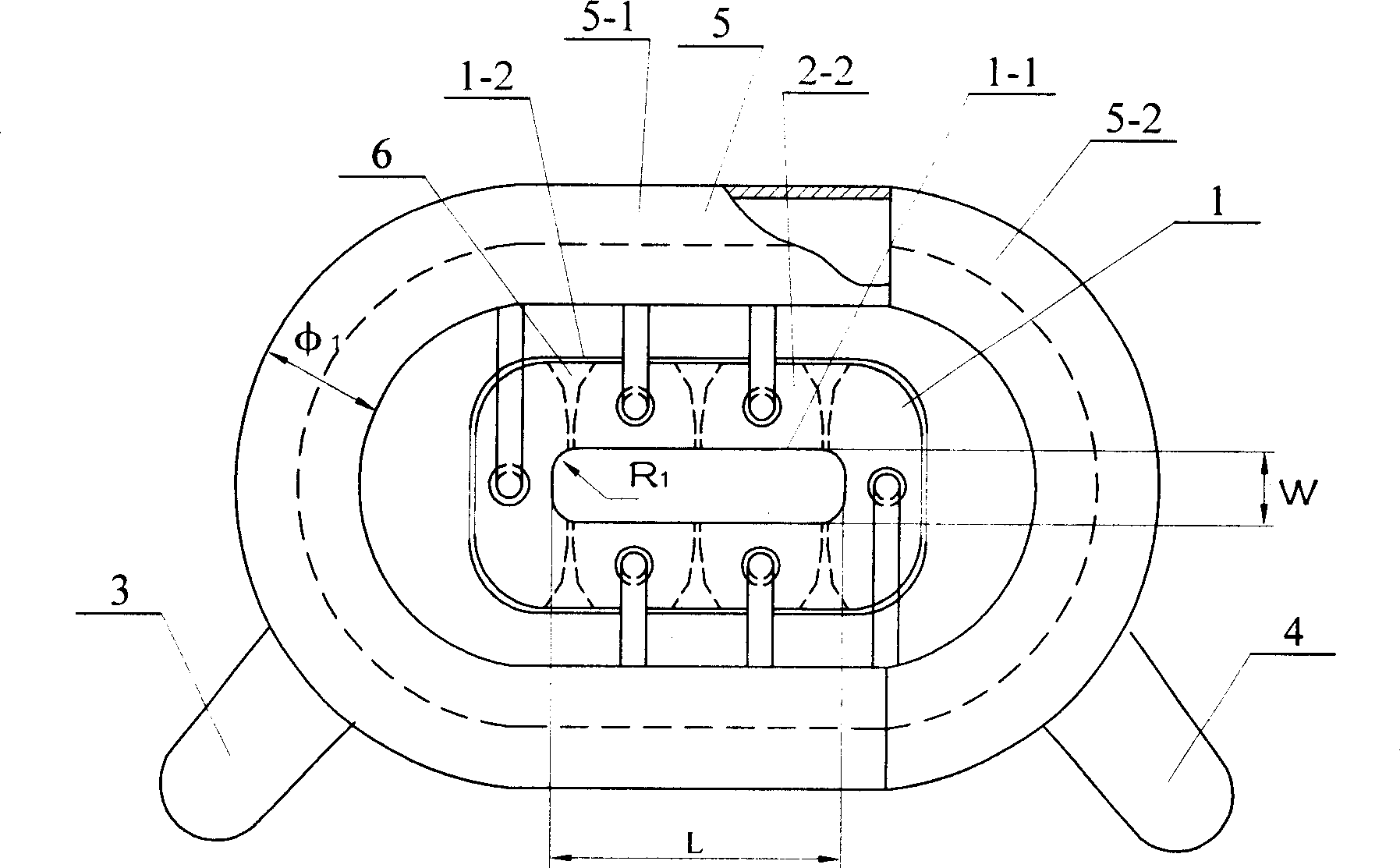

[0005] Specific embodiment 1: Since one of the applicant’s goals is to continue to realize the directional solidification forming of large-size plate-shaped billets of titanium-aluminum-based alloys based on the already declared cold crucible electromagnetic continuous casting and directional solidification technology, first Qualitative analysis of the electromagnetic forming of the shaped parts has been carried out through research. It is found through research that, as the width-to-thickness ratio increases, the electromagnetic pressure difference on the adjacent two sides of the plate-shaped parts with different width to thickness ratios increases, and the magnetic induction intensity appears along the outer contour of the plate. The saddle-shaped distribution tends to be lower at the straight side part and gradually higher at the corner part. When the aspect ratio is too large (>3), it is always difficult to form a predetermined shape at the corners of the plate. This is the r...

specific Embodiment approach 2

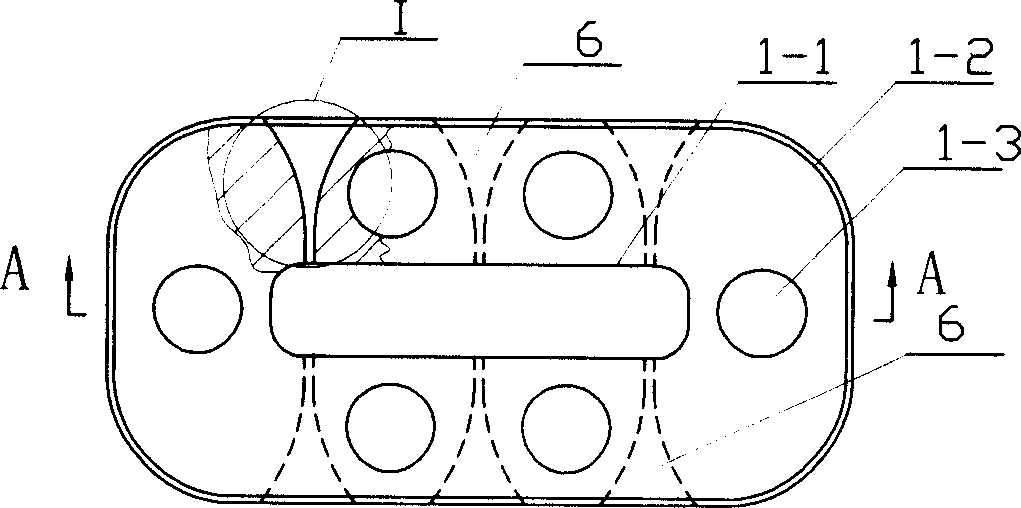

[0007] The second embodiment is different from the first embodiment in that this embodiment focuses on the influence of the radius of the transition fillet between the two adjacent surfaces of the cavity 1-1 on the melting of the sheet metal. Regardless of the transition fillet radius between the two adjacent surfaces of the cavity, only the technical solution described in the first embodiment can achieve the purpose of the present invention, but if the transition fillet radius is taken into account, the magnetic field will be obtained. Crucible system with more even distribution.

[0008] On the premise of ensuring the technical solution of the first embodiment, the transition fillet radius of the cavity in the cold crucible is also an important factor affecting the uniform melting of the rectangular sheet. The heating capacity of the fillet part and R 0 (Fillet radius) is proportional to the square, that is q 0 = ...

specific Embodiment approach 3

[0011] Specific embodiment three: The technical solutions described in the first and second embodiments can achieve the purpose of the present invention well. If the wall thickness of the crucible, the structure of the seam, and the position of the seam on the crucible are taken into consideration, it will be better. The distribution of the magnetic field and the intensity of the magnetic field inside the crucible are well adjusted, so as to better achieve the purpose of the present invention.

[0012] The smaller the wall thickness, the better the magnetic permeability of the crucible, so as long as the wall thickness can ensure processing.

[0013] The effect of the split shape of the crucible on the magnetic permeability of the crucible is as follows: within a certain height range, when the split shape is triangular, the magnetic current density in the crucible is the largest, and when the crucible split is square, the magnetic current density is the smallest. The magnetic curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com