Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Volatile completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

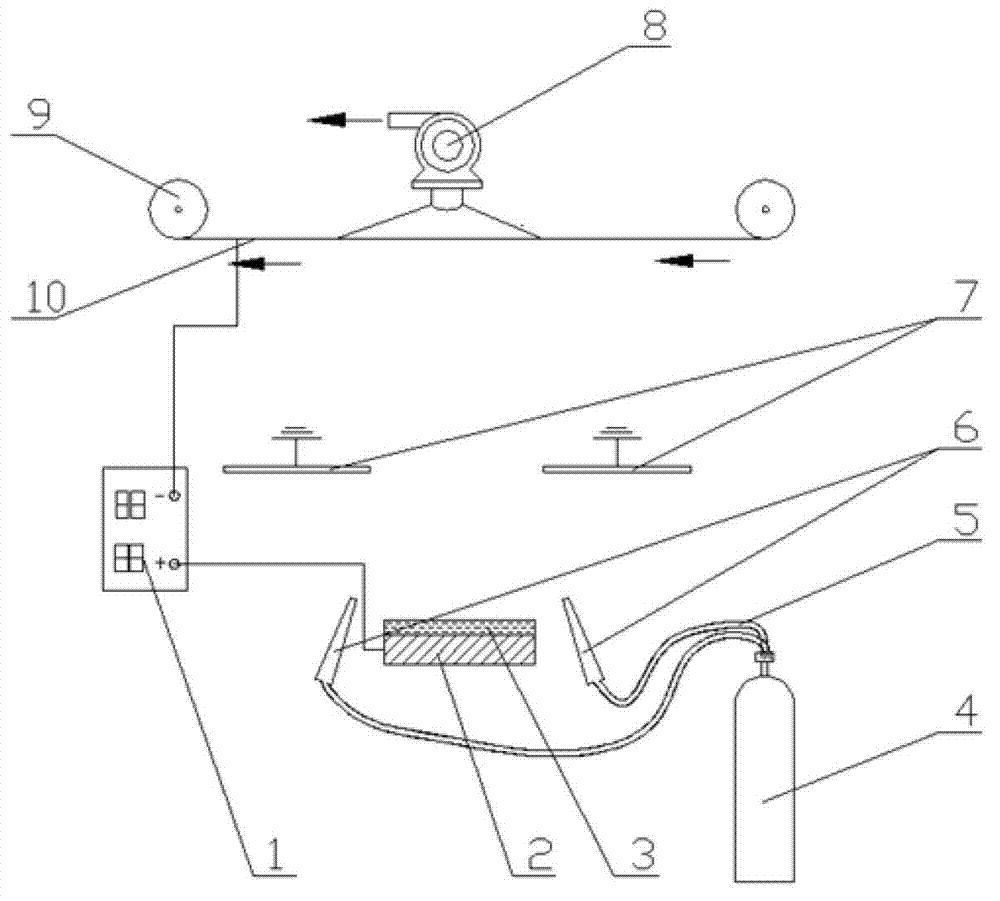

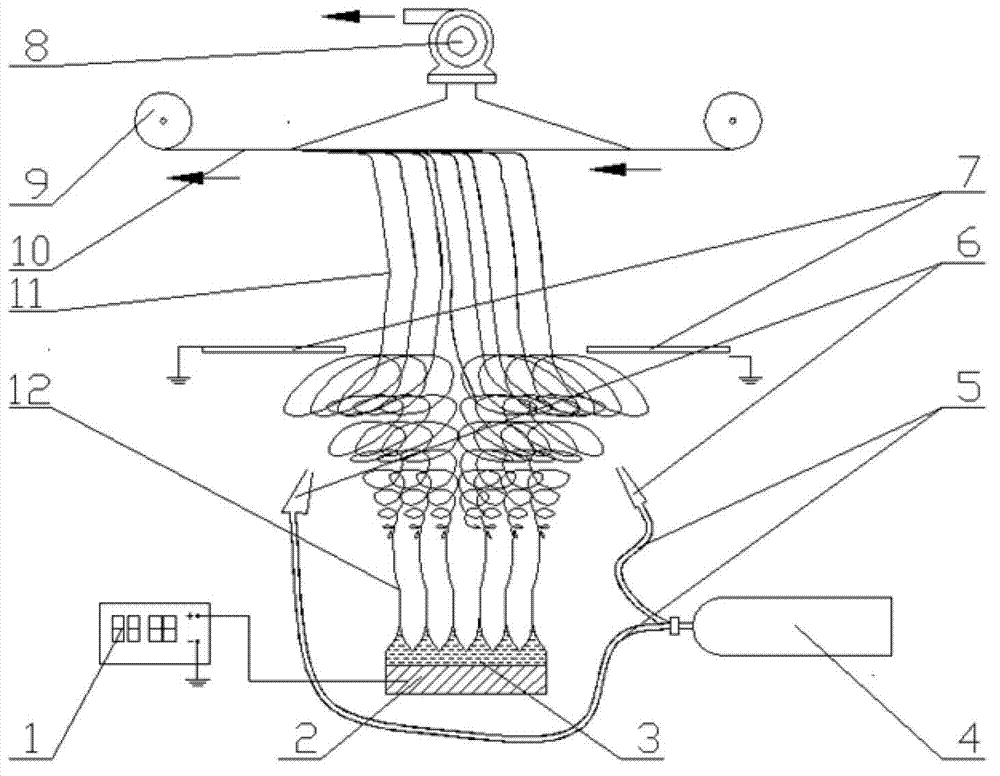

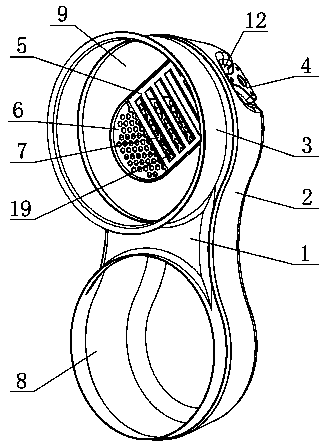

Nanofiber low-voltage electro-spinning device with auxiliary electrodes

InactiveCN102965743AQuality improvementExtended flight timeFilament/thread formingAuxiliary electrodeFlight direction

The invention discloses a nanofiber low-voltage electro-spinning device with auxiliary electrodes and relates to an electrostatic spinning device. The electro-spinning device is provided with a high-voltage DC power supply, a conducting pole plate, array nozzles, a high pressure air source, airway tubes, auxiliary electrodes, a fan, rollers and a collection plate; the positive pole of the high-voltage DC power supply is connected to the conducting pole plate, and the negative pole of the high-voltage DC power supply is grounded; polymer solution is located on the conducting pole plate, so that jet flow can be created on the upper surface of the solution during electro-spinning; the high pressure air source is connected to the array nozzles through the airway tubes, so that high pressure air can be provided for the array nozzles; the array nozzles are arranged between the auxiliary electrodes and the conducting pole plate so as to jet air flow for changing the flight direction of fiber, so that the nanofiber is guided to get through a gap between the auxiliary electrodes along with the air flow and deposit onto the collection plate; the auxiliary electrodes are arranged above two sides of the polymer solution and grounded; the fan is arranged above the collection plate, so that the fiber is deposited onto the collection plate by air pumping; and the collection plate is arranged above the auxiliary electrodes as a deposition base plate of the nanofiber.

Owner:XIAMEN UNIV

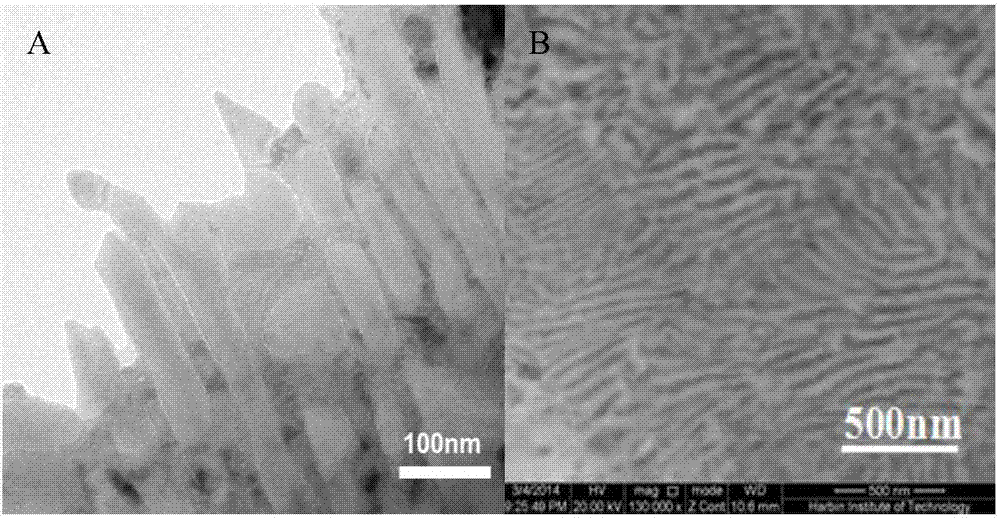

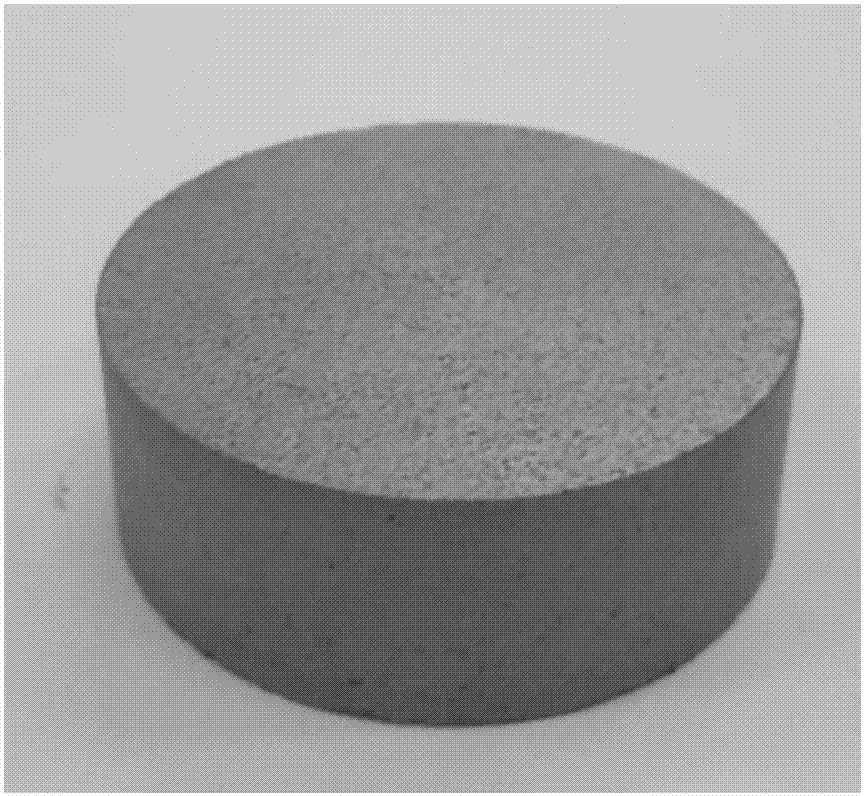

Brake pad material for high-speed railway passenger train and preparing method thereof

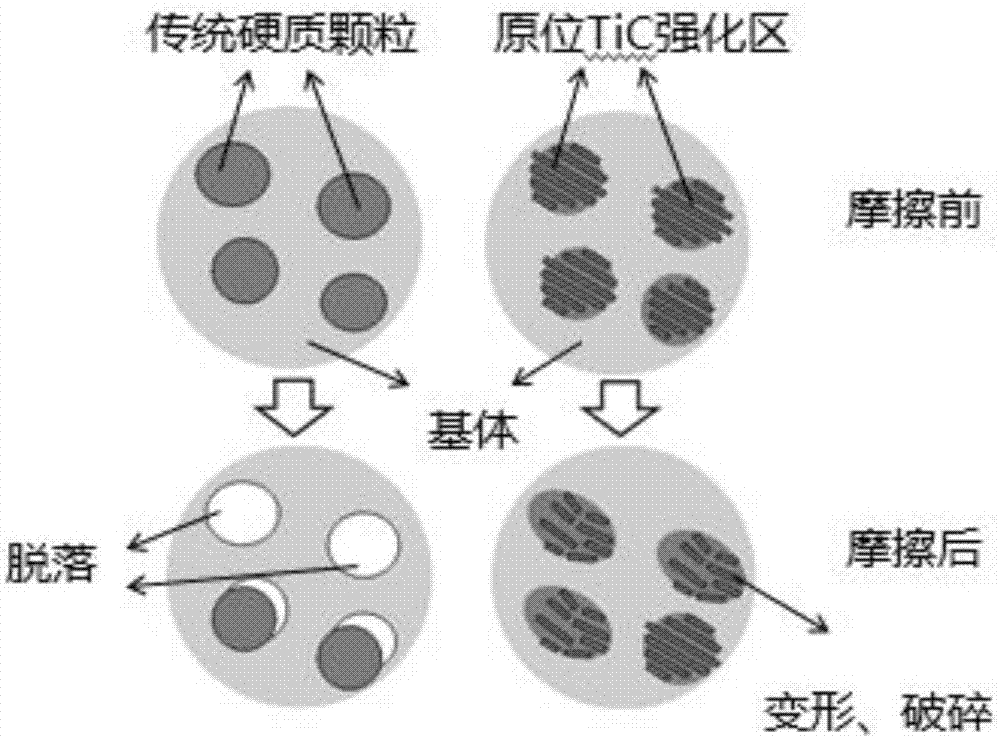

ActiveCN107460362ASolve the hardnessPoor ability to solve deformationTransportation and packagingMetal-working apparatusAdhesiveManganese

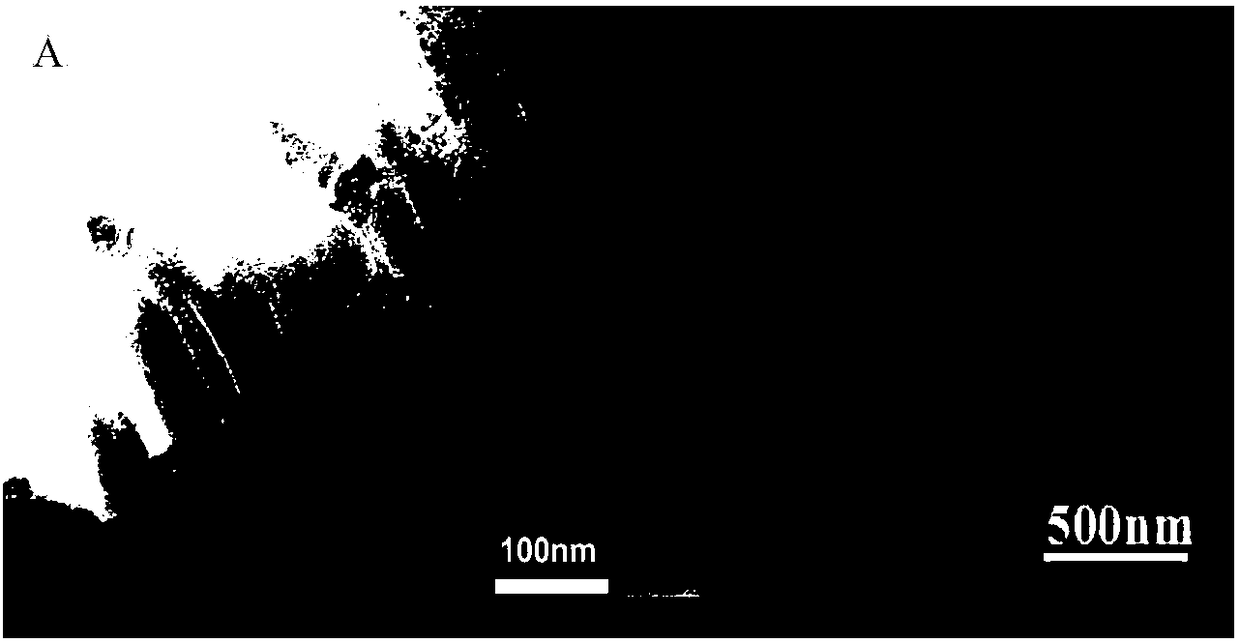

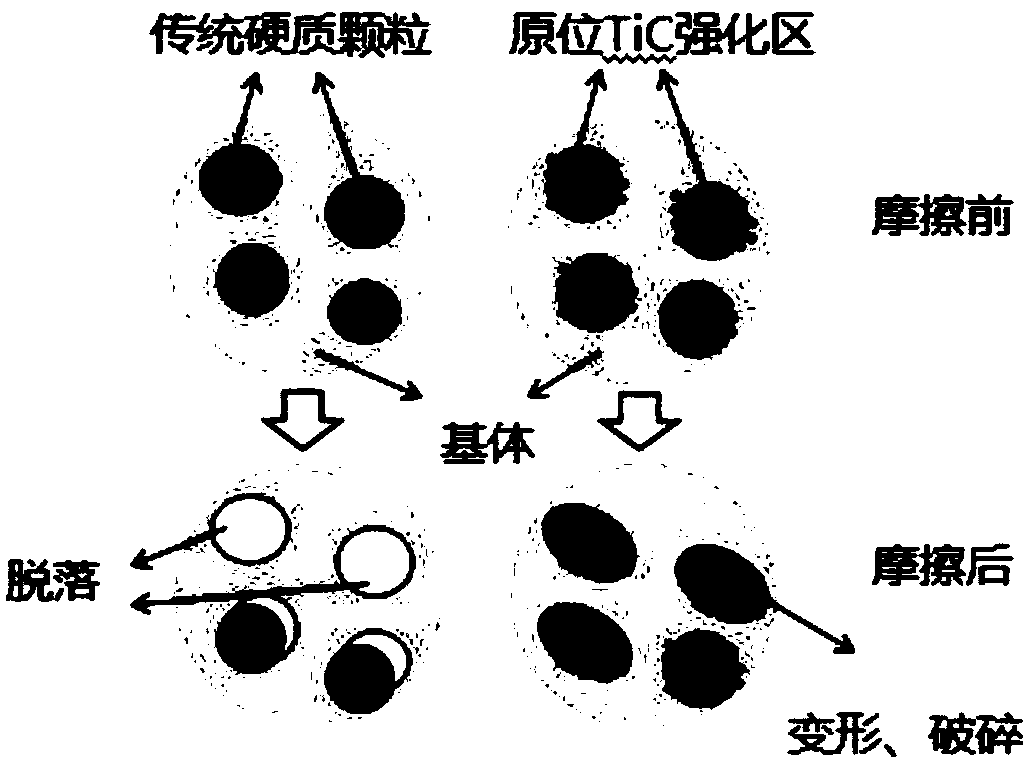

The invention discloses a brake pad material for a high-speed railway passenger train and a preparing method thereof and belongs to the technical field of powder metallurgy friction materials. The brake pad material is prepared by the following steps: after drying and sieving powdery raw materials, feeding the raw materials into a mixer, and spraying an adhesive; after mixing the materials, placing the materials in a steel mould, and carrying out pressing; and then, carrying out sintering at a reduction atmosphere, and then, carrying out heat treatment in a reduction atmosphere, wherein the powdery raw materials comprise copper powder, iron powder, Ti2AlC powder, chromium powder, nickel powder, manganese powder, silicon dioxide, graphite, boron nitride and molybdenum disulfate. The invention further provides the preparing method of the brake pad material. In the invention, in-situ TiC obtained through the Ti2AlC is used as a main friction component, the material of an in-situ nanometer TiC layered framework is prepared, the copper is accordingly used as a matrix, a small quantity of other metals is added, the content of lubricating components, such as the graphite, is regulated, and a novel material with a great brake effect and a low wear rate is finally obtained. The material is suitable for being used as the brake pad material for the high-speed railway passenger train.

Owner:哈尔滨新干线轨道交通科技有限公司

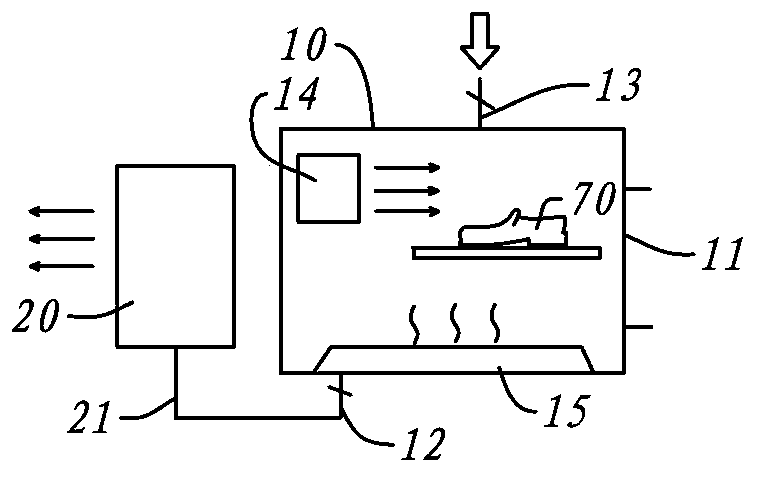

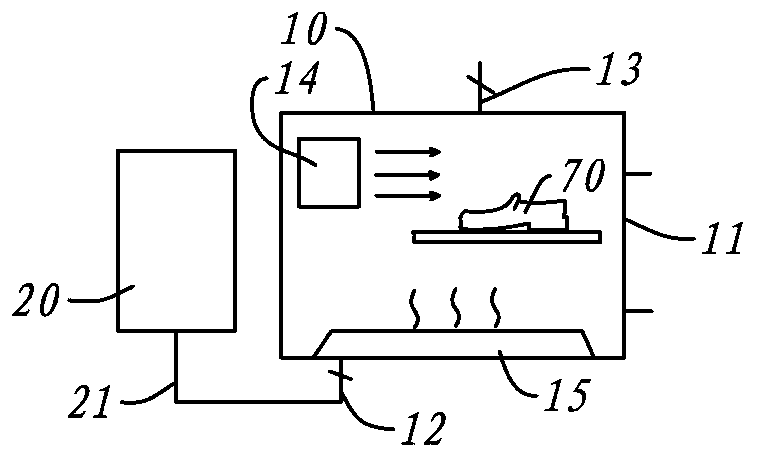

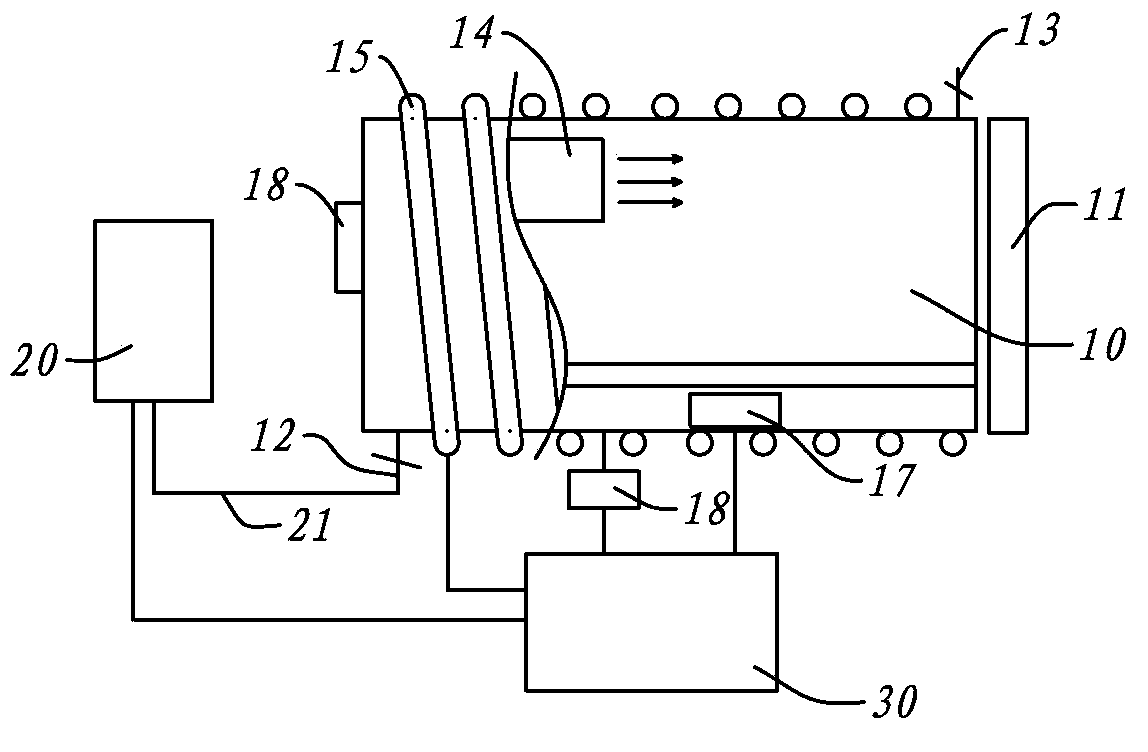

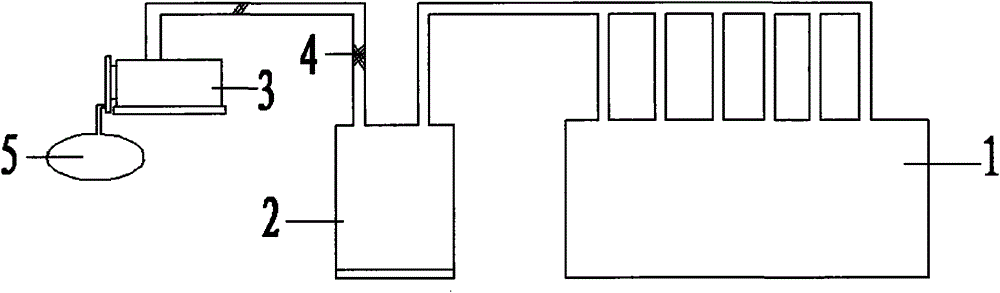

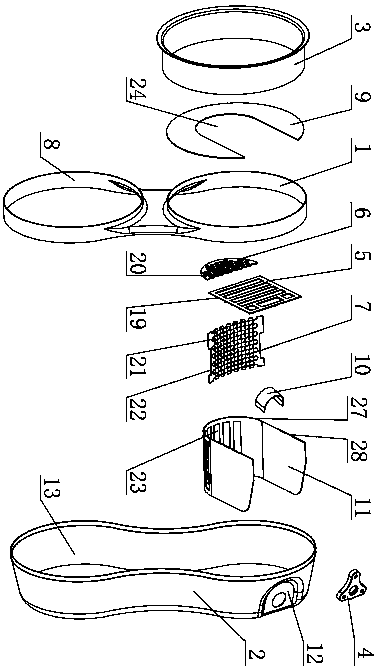

Shoe VOC volatilization sampling apparatus and method

InactiveCN103439150AVolatile fastQuick collectionWithdrawing sample devicesExhaust valveProcess engineering

The present invention discloses a shoe VOC volatilization sampling apparatus and a method. The apparatus is characterized in that the apparatus comprises an accommodation chamber, the volume of the accommodation chamber can accommodate a pair of the whole shoes, the accommodation chamber is provided with a heat conduction outer wall, comprises an openable sealing door and a gas exhaust valve, and further comprises a heater capable of heating gas in the accommodation chamber, and the gas exhaust valve and the accommodation chamber form a complete gas path. With the apparatus, rapid VOC detection with the whole shoe manner is achieved, characteristics of high precision, rapidness and convenient operation are provided, and the novel shoe VOC detection mode is established.

Owner:莆田出入境检验检疫局综合技术服务中心

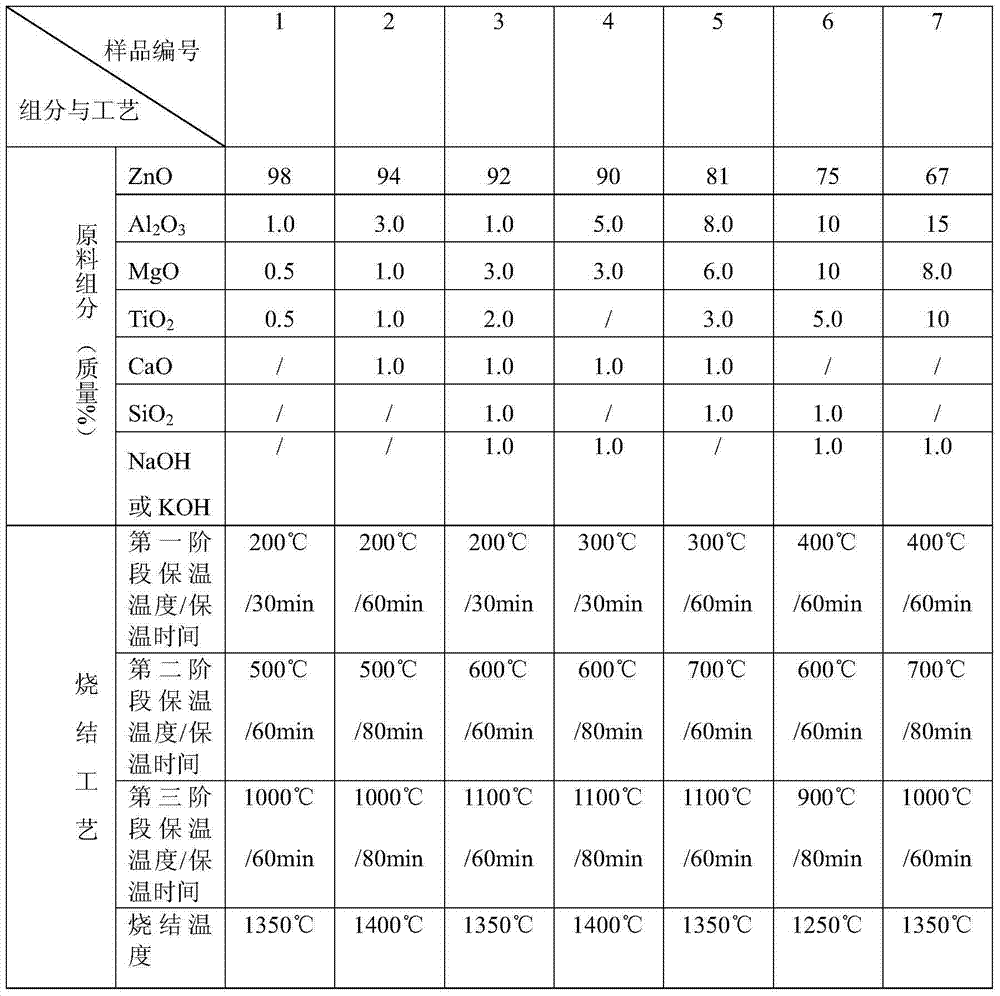

Preparation method of low-resistivity zinc oxide ceramic material

The invention relates to a preparation method of a low-resistivity zinc oxide ceramic material, belonging to the technical field of electronic materials. The preparation method provided by the invention comprises the steps of taking four powder materials of ZnO, Al2O3, MgO and TiO2 as raw materials (CaO, SiO2, NaOH or KOH can also be added), and performing ball milling, granulation, forming and sintering to obtain the low-resistivity zinc oxide ceramic material, wherein the weight mixture ratio of the raw material components is that ZnO: Al2O3: MgO: TiO2 = (65-98): (1-15): (0-10): (0-10), and a sectional type sintering process under the condition of isolating an oxygen atmosphere is adopted during sintering. The process flow provided by the invention is simple and feasible, and is suitable for industrial production; the prepared low-resistivity zinc oxide ceramic material has the characteristics of low resistivity (which can achieve 10<-1> omega.cm), high energy density (which is higher than 500J / cm<3>), and good stability (the resistance temperature coefficient can achieve 10<-3> omega / DEG C, and the relative density is as high as 97%).

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Production process of active lime

The invention discloses a production process of active lime. The process comprises the following steps of (1) screening and pretreatment of limestone, (2) mixing, (3) preheating, (4) calcining, (5) cooling and (6) post-treatment. Firstly, an additive used in the production process reduces underfiring and overburning of the lime, increases the decomposition speed of CaCO3, shortens the calcining time, correspondingly reduces the energy consumption and is beneficial to industrial popularization. Furthermore, carbon is also added, decompression operation is adopted after preheating and before cooling separately, correspondingly the elements sulfur and carbon which remain in lime raw materials can be volatilized out more thoroughly, and the recombination of the elements with calcium oxide is avoided, so that the purity of the active lime is improved, and the activity degree of quicklime is further improved.

Owner:新兴永和河北能源科技股份有限公司

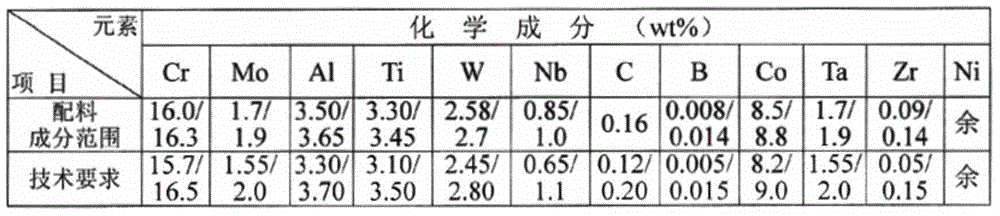

Method for preparing K438 alloy by adopting K438 alloy return material

InactiveCN103556004AIncrease profitReduce wasteIncreasing energy efficiencyChemical compositionIngot

The invention relates to a method for preparing a K438 alloy by adopting a K438 alloy return material. The technical scheme is as follows: the preparation method comprises the following steps of carrying out purifying treatment on the K438 alloy return material; smelting the K438 alloy return material into a return material charge bar; regulating the chemical components of the return material charge bar; smelting the return material charge bar into a finished product K438 alloy ingot. The method disclosed by the invention can be used for producing the K438 alloy which meets the requirement for usage of a product, increases the utilization ratio of materials and reduces the waste of precious metal resources.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

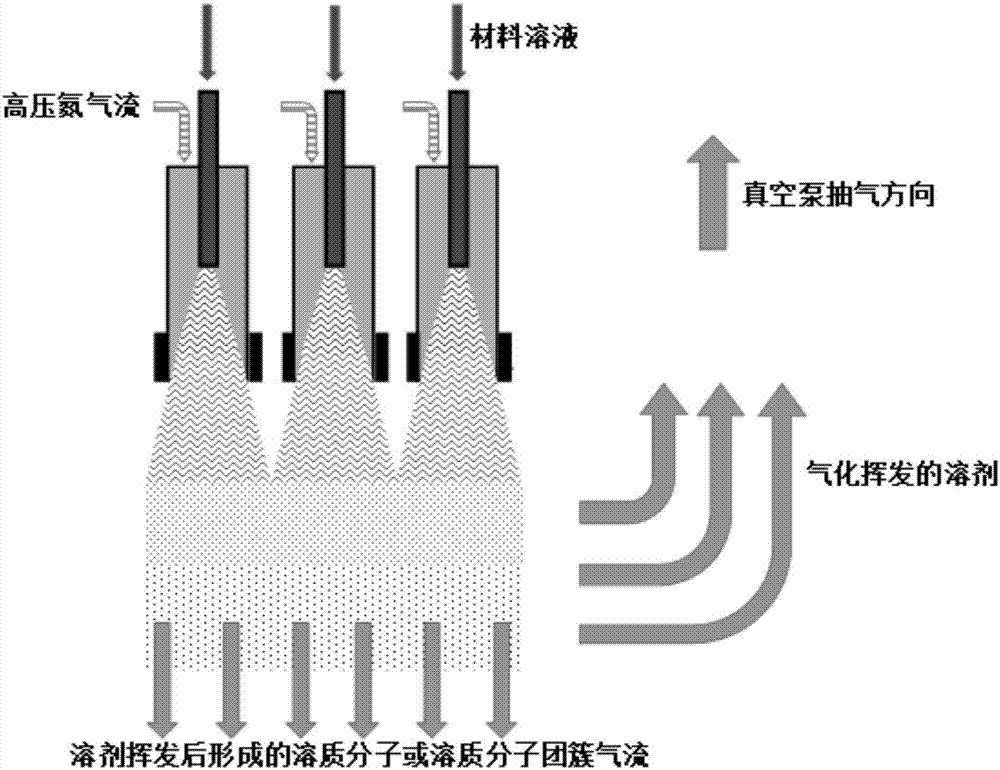

OLED and film deposition method thereof

ActiveCN107359277AUniform thicknessSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceSolvent

The invention relates to an OLED and a film deposition method thereof. The film deposition method comprises the following steps of: preparing a material solution: dissolving a material to be deposited in a solvent to obtain the material solution; and providing an atomization device comprising an atomization system, a cavity, a vacuum tube and a support plate; and depositing: placing a substrate on the support plate, switching on a vacuum device, vacuuming the cavity through the vacuum tube, and atomizing the material solution through the atomization system to deposit the material solution on the substrate. The film deposition method of the OLED utilizes a combination of vacuum and a spray process to deposit the film of the OLED, does not need to heat and sublimate the material to be deposited at a high temperature, and is suitable for materials hard to sublimate or liable to thermally decompose. Further, droplets formed by spray are small, and the vacuum environment allows the solvent to be uniformly volatilized, thereby forming a uniform film thickness.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

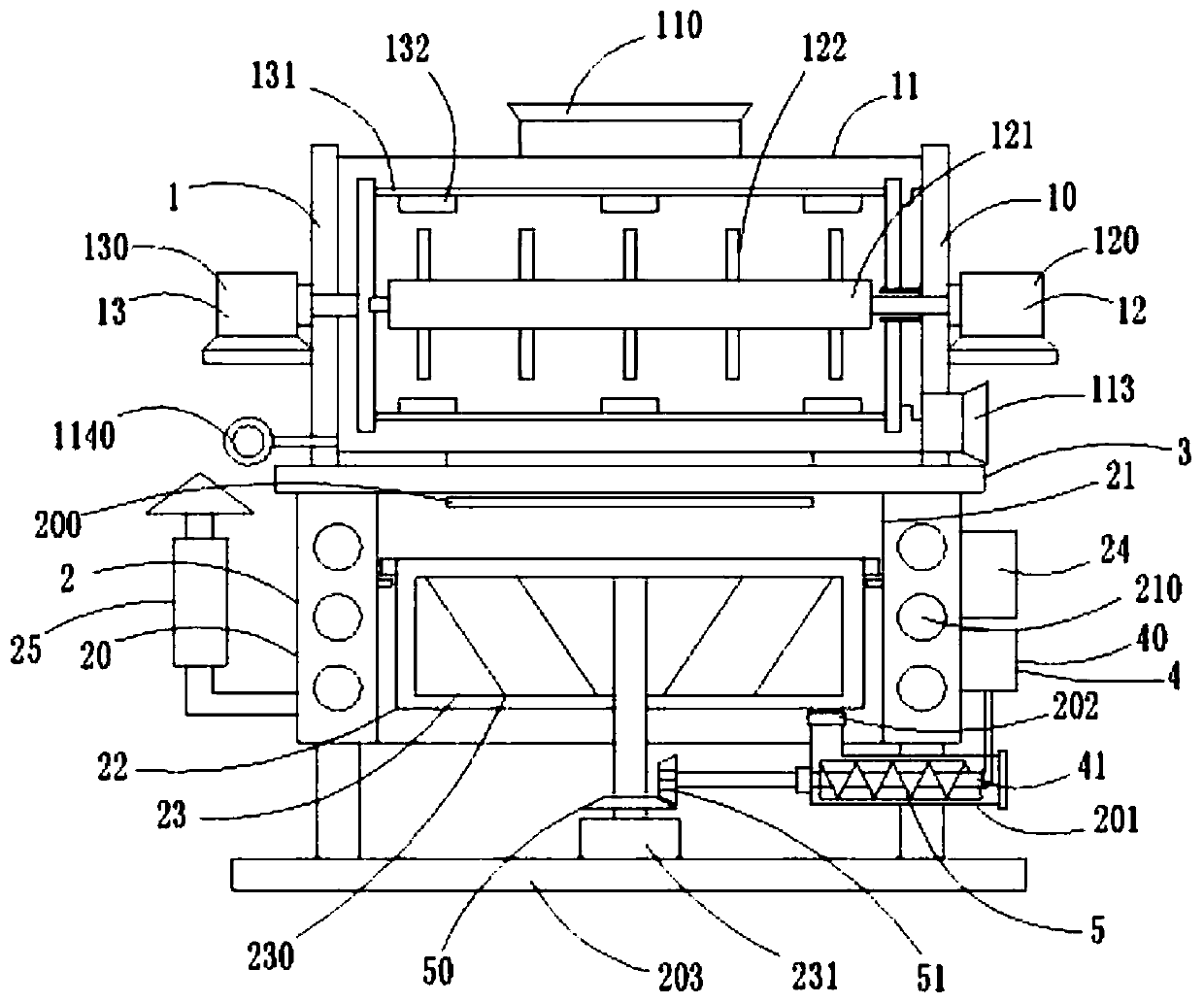

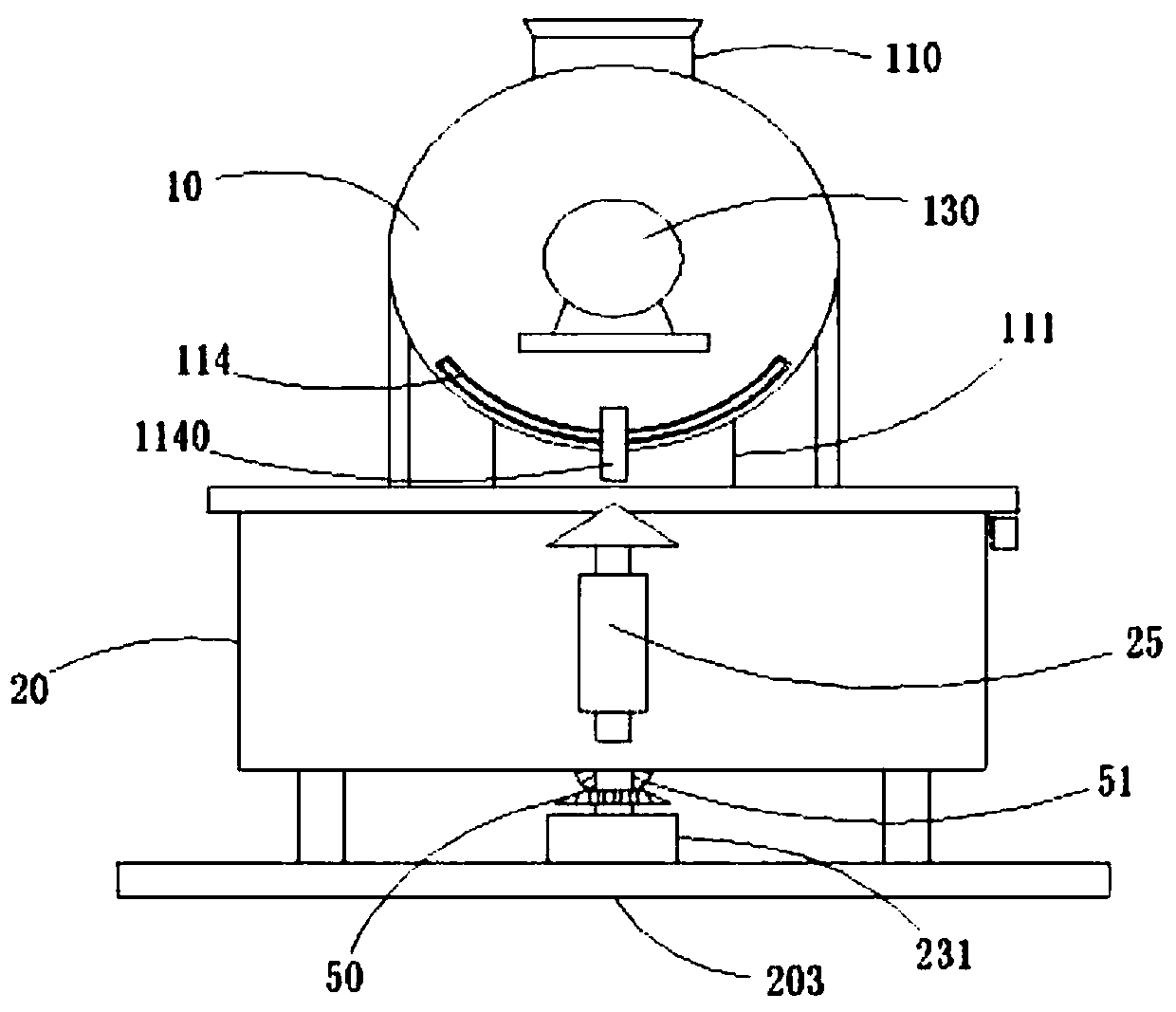

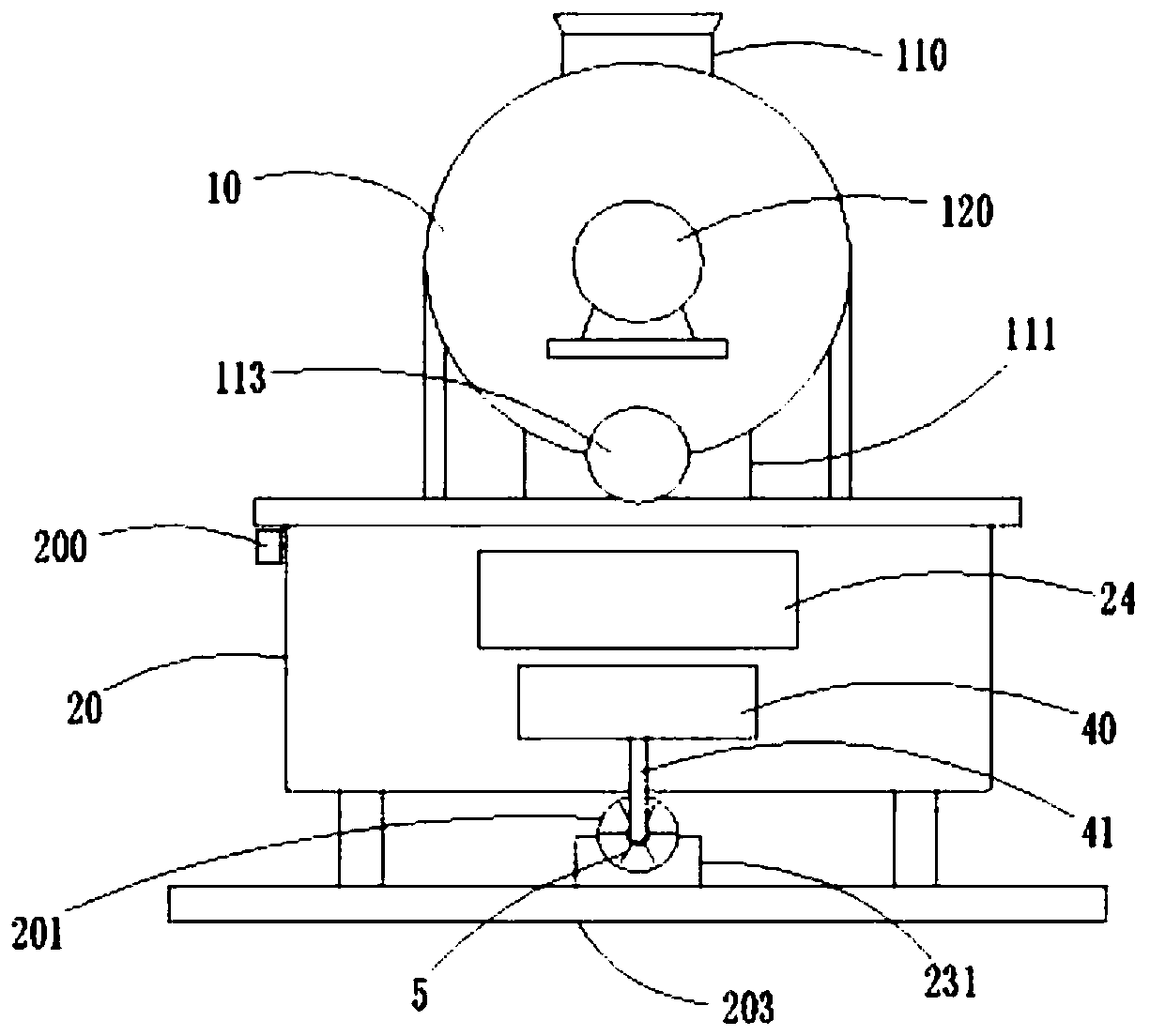

Integrated device for persistent organic contaminated soil remediation treatment

ActiveCN110280578AReduce metal contentImprove qualityContaminated soil reclamationEngineeringElectric control

The invention discloses an integrated device for persistent organic contaminated soil remediation treatment. The device comprises a soil pretreatment device, a soil thermal desorption device, a fixing plate, a bacteria solution delivery device and an electric control box; the soil pretreatment device is arranged at the upper end of the fixing plate, the soil pretreatment device is used for performing crushing and impurity removing on soil, late thermal desorption treatment is facilitated, the soil thermal desorption device is arranged at the lower end of the fixing plate and used for performing thermal desorption treatment on persistent organic pollutants, the organic pollutants in the soil are volatilized, and finally treatment is conducted through a flue gas combustion cylinder, and the bacteria solution delivery device is used for adding the composite bacteria solution into the treated soil, and the electric control box is used for controlling operation of the device. The device is reasonable in structural design, high in treatment efficiency, small in secondary pollution and suitable for mass promotion.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

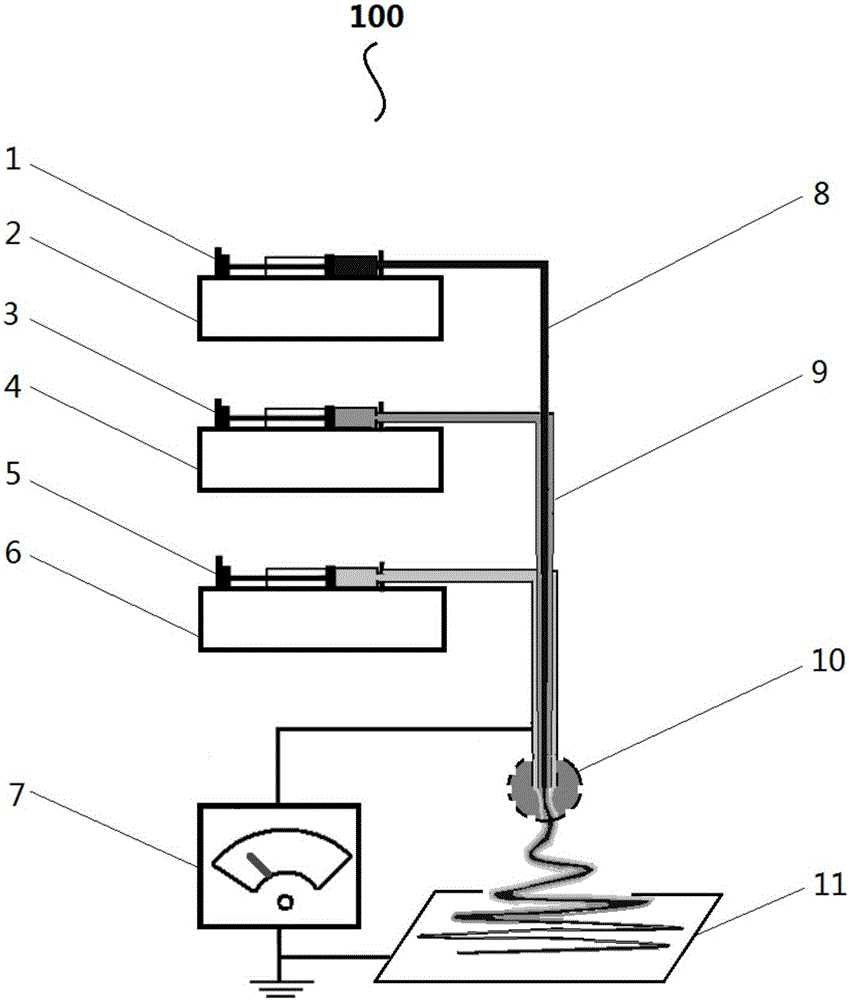

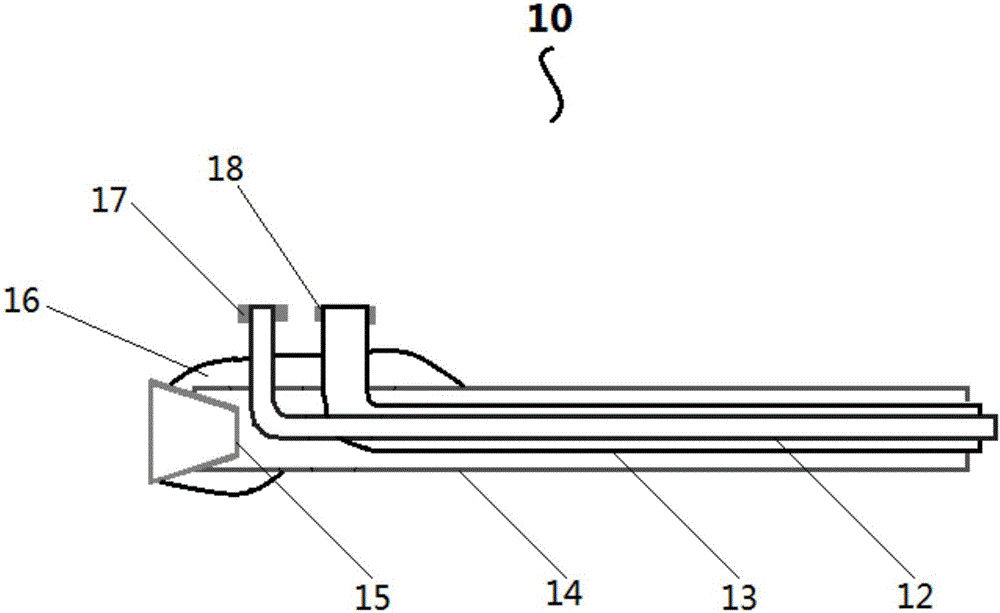

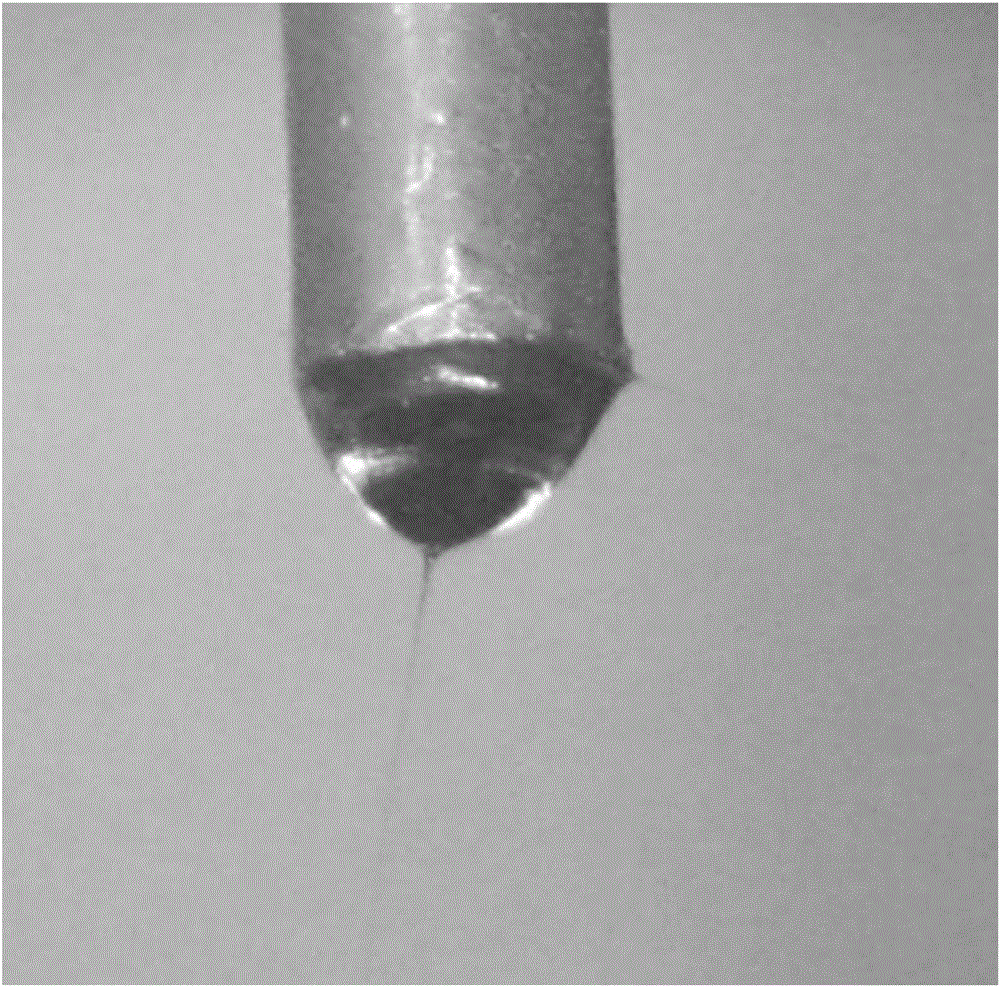

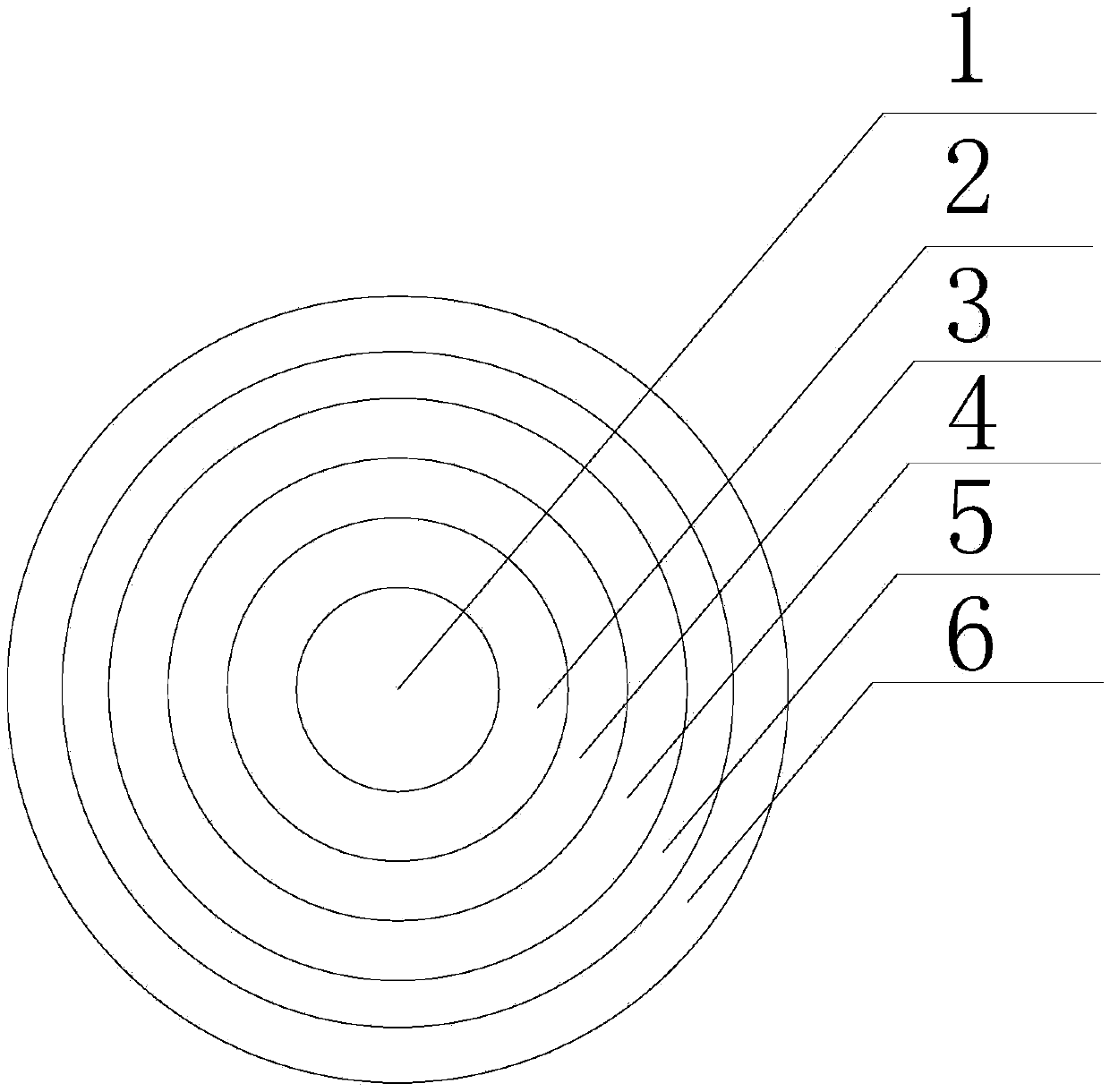

Core-sheath nano-fiber three-stage coaxial electrospinning preparation method and device

The invention provides a core-sheath nano-fiber three-stage coaxial electrospinning preparation method. The core-sheath nano-fiber three-stage coaxial electrospinning preparation method comprises the following steps: step one, respectively filling an inner layer fluid injector, a middle layer fluid injector and an outer layer fluid injector with inner layer fluid, middle layer fluid and outer layer fluid which are dispensed; step two, connecting a three-stage coaxial electrospinning head to a high voltage electrostatic generator, so that the three-stage coaxial electrospinning head is electrified, the inner layer fluid, the middle layer fluid and the outer layer fluid form a Taylor cone at the three-stage coaxial electrospinning head, and jet flow is sent out; and step three, volatilizing the outer layer fluid in the fast stretching process after the jet flow is sent out, finally forming core-sheath nano-fibers and receiving the core-sheath nano-fibers by using a fiber receiving plate. The invention also provides a core-sheath nano-fiber three-stage coaxial electrospinning preparation device which comprises the high voltage generator, the three-stage coaxial electrospinning head, the fiber receiving plate and fluid injection pumps.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

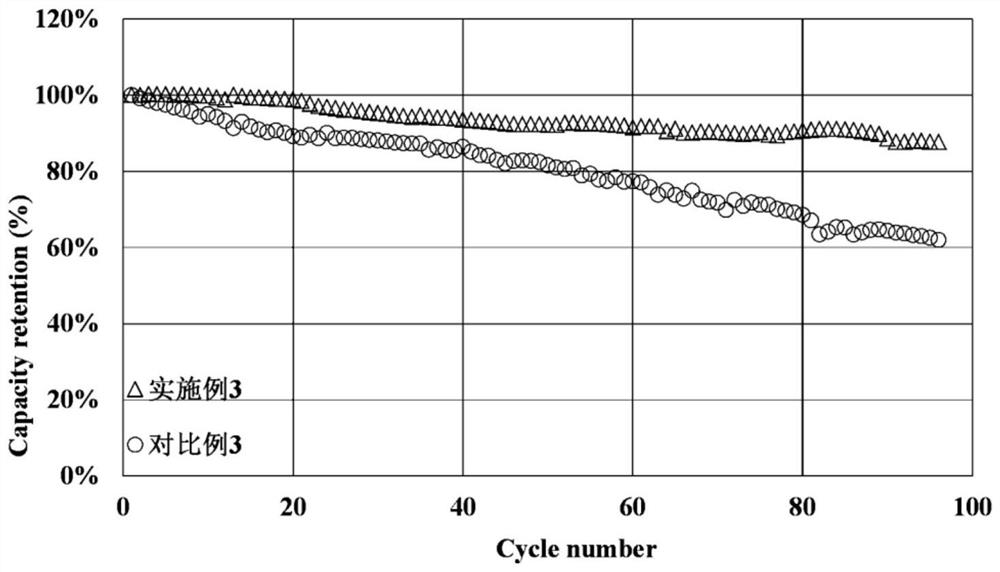

Modified high-nickel positive electrode material and preparation method thereof

PendingCN111606363AEasy to processImprove structural stabilityCell electrodesSecondary cellsHigh volume manufacturingElectrical battery

A preparation method of a modified high-nickel positive electrode material comprises the following steps: uniformly mixing a high-nickel positive electrode material precursor, an additive and a lithium source, carrying out primary sintering in an oxygen atmosphere, crushing, and sieving to obtain a primary sintered high-nickel positive electrode material; washing the primary sintered high-nickel positive electrode material with water, and drying to obtain a washed and dried primary sintered high-nickel positive electrode material; performing primary surface treatment on the washed and dried primary sintered high-nickel positive electrode material to obtain a primary surface treated high-nickel positive electrode material; and uniformly mixing the modifier with the primary surface treatmenthigh-nickel positive electrode material, and then carrying out secondary surface treatment to obtain the modified high-nickel positive electrode material. The residual alkali amount on the surface ofthe material and the specific surface area of a final product are reduced, so that the impedance on the surface of the material is obviously reduced, the gas production phenomenon of the battery is obviously relieved, the structural stability and the cycling stability of the material are improved, the processability of the positive electrode material in the preparation process can be improved, the preparation condition is easy to control, and mass production can be realized.

Owner:SHAANXI COAL & CHEM TECH INST

Extraction technique of lavender essential oil

The invention provides an extraction technique of lavender essential oil. The technique comprises the following steps: picking and cleaning, naturally drying in the shade, activating and pulverizing; adding a sodium chloride solution, and immersing; carrying out atmospheric distillation, and boiling the extracting solution; obtaining a condensate; carrying out oil-water separation; adding an ethanol solution into an activated carbon adsorption column to extract oil in the activated carbon adsorption column, thereby obtaining crude oil; and extracting, stratifying, and separating out the supernatant, thereby obtaining the lavender essential oil. The organic solvent for extraction is the ethanol solution which can be thoroughly volatilized in the extraction process, so the product does not have ethanol residues and does not have any toxic or harmful effect on the human body. The lavender essential oil can be used for preparing cosmetics, washing supplies, medicines and the like, and thus, has wide application range.

Owner:SICHUAN ZIYINGTIANTANG VANILLA TECH DEV CO LTD

Method for processing soft copper foil

InactiveCN101462228AThe unit area is largeEvenly heatedBase-materialsMetal rolling arrangementsMetal foilKerosene

The invention relates to a method for processing a soft copper foil. The copper foil manufactured by the method has the advantages of even hardness, clean surface, brightness, no oil pollution, and higher product qualification rate. The method comprises the following steps: smelting electrolytic copper and then casting the electrolytic copper into a cast ingot; milling the surface of the cast ingot; performing homogenization treatment on the cast ingot in a heating furnace; performing hot rolling on the cast ingot immediately after the treatment; performing acid cleaning on the cast ingot after finishing the hot rolling; blowing and drying the cast ingot after the acid cleaning and then annealing the cast ingot; and performing a cold rolling process after the annealing. The method is characterized in that the cold rolling process adopts four-roller cold rolling, a cold rolling liquid used in the cold rolling is prepared from coal oil, gasoline and rape oil through mixing, and the mixture ratios of the components comprise: 80 to 85 percent of the coal oil, 15 to 17 percent of the gasoline and 5 to 8 percent of the rape oil; after the cold rolling, the semi-automatic continuous annealing is performed directly; and a single layer of a metal foil is heated evenly in a heating body, the single layer at one end is used for uncoiling, the middle part is a furnace body for heating, while the single layer at the other end is used for coiling, and protective gas is kept between 0.3 and 0.5 Pma in the furnace during annealing.

Owner:朱元康

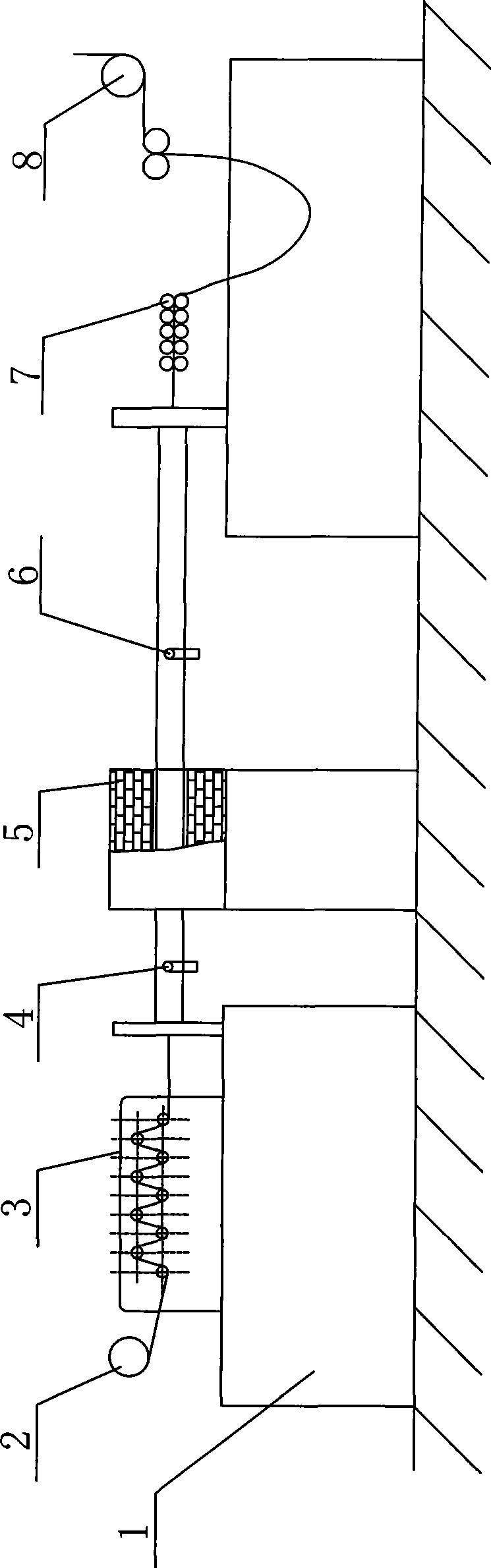

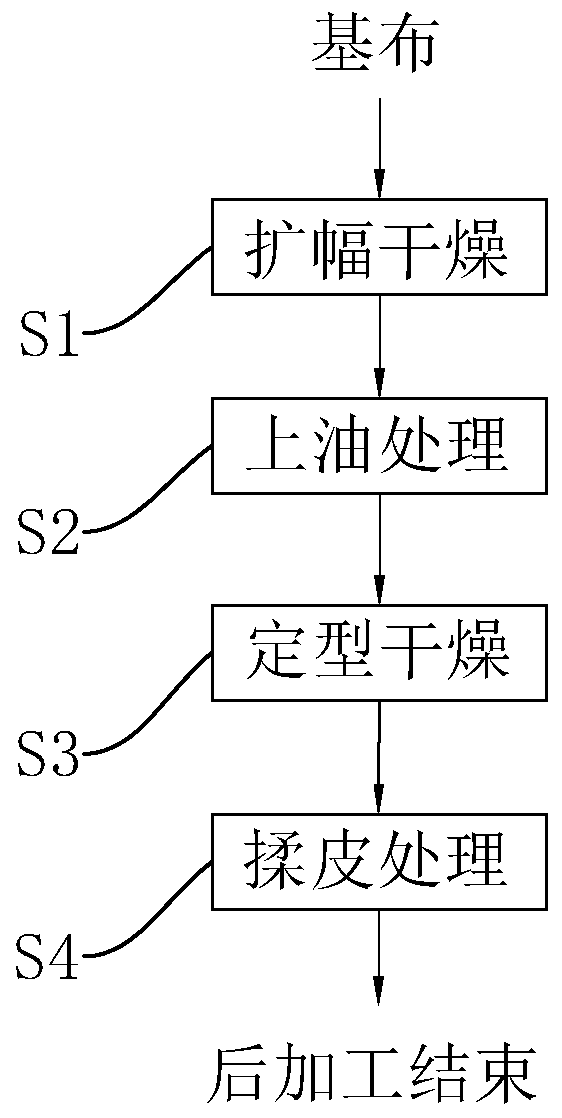

Base fabric post-processing technology for superfine fiber synthetic leather

ActiveCN110306315AHigh tear strengthAvoid wrinklesFabric breaking/softeningGrip property fibresKojic acidFiber

The invention relates to the technical field of preparation methods of superfine fiber synthetic leather, and discloses a base fabric post-processing technology of superfine fiber synthetic leather. Adecreased base fabric is treated by the technology comprising the following steps: S1, expanding and drying; S2, oiling, wherein the base fabric which is expanded and dried in step S1 is repeatedly soaked in an oiling agent. The oiling agent comprises the following chemical components in parts by weight: 40-60 parts of amino silicone oil, 30-50 parts of aminopropanol kojic acid phosphate, 6-9 parts of diatomite, 3-7 parts of talcum powder and 10-14 parts of a surfactant; S3, shaping and drying; and S4, carrying out puffing treatment. By using the oiling agent mentioned above, the tearing strength of the base fabric is improved.

Owner:浙江永祥合成材料有限公司

Melamine tableware and preparation method thereof

The invention belongs to the field of melamine products and particularly relates to melamine tableware and a preparation method thereof. The melamine tableware is prepared from raw materials in percentage by weight as follows: 5%-15% of sodium citrate, 1%-3% of titanium dioxide, 40%-50% of amino molding particles, 10%-15% of wood fibers, 8%-13% of zinc stearate, 0.02%-0.2% of food coloring, 0.04%-0.1% of a curing agent and 15%-25% of plant fibers. The preparation method comprises preparation steps as follows: amino molding plastic powder is prepared, and a finished product is prepared. Steam heating is performed on a material in a kneading machine in the preparation process of the amino molding plastic powder, and water in the material is volatilized rapidly and fully. The plant fiber component is added, so that the strength, the heat resistance and the compactness of the product are more excellent; steam heating is performed on the material, the production efficiency is improved, and the product quality is enhanced.

Owner:襄汾县瑞德合成材料股份有限公司

Cleaning protective agent for insulator of high-speed rail train

ActiveCN110358640AImprove breakdown voltageVolatileInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsTectorial membraneMetal

The invention discloses a cleaning protective agent for an insulator of a high-speed rail train. The cleaning protective agent for the insulator of the high-speed rail train is liquid and comprises the following components in percentages by weight: a detergent, a corrosion inhibitor, a solubilizer, a metal complexing agent, a pH value regulator, a nano material and deionized water. The detergent is a multi-component combined nonionic surfactant and accounts for 1-2.5%, and the corrosion inhibitor accounts for 0.3-1%, the solubilizer accounts for 3-9%, and the metal complexing agent accounts for 0.1-0.8%, the proportion of the pH regulator is determined according to the actual situation, the nano material is solid nano particles and accounts for 0.01-3%, and the rest is the deionized water.By the cleaning machine, the insulator is bright as new after being cleaned, a layer of protective film is formed on the surface of the insulator, so that the insulator is not easily secondarily polluted, and the secondary cleaning time is prolonged.

Owner:ZHENGZHOU ZHONGYUAN LIDA NEW MATERIAL CO LTD

High-strength and high-toughness heat insulation cable

ActiveCN105374440AImprove toughnessHigh strengthInsulated cablesInsulated conductorsEpoxyEPDM rubber

The invention discloses a high-strength and high-toughness heat insulation cable comprising a conductor, an insulating layer, a filling layer, a shielding layer, an armored layer and an external sheath. The raw material of the external sheath comprises the following parts by weight: 55-58 parts of natural rubber, 24-27 parts of polybutadiene rubber, 20-22 parts of EPDM rubber, 13-16 parts of epoxy resin, 5-8 parts of polyamide fibers, 7-10 parts of high-toughness high-heat-insulation performance gel, 12-15 parts of hollow glass microspheres, 11-13 parts of barite powder, 7-10 parts of talcum powder, 7-9 parts of dolomite powder, 3-5 parts of silane coupling agent KH-550, 0.5-0.8 part of sulfur powder, 0.7-1.1 parts of promoter TMTD, 2.2-2.5 parts of promoter TMTM, 1.6-2 parts of dicumyl peroxide, 0.5-1.5 parts of stearic acid, 1-1.5 parts of coconut oil, 3-5 parts of phenyl alkylsulfonate, 0.6-0.9 part of antioxidant SP and 2.5-3.5 parts of antioxidant RD.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

Method for preparing cellular material from biological cross-linking agent crosslinked protein

The invention discloses a method for preparing a cellular material from biological cross-linking agent crosslinked protein. The method comprises the following steps that 1, chitosan is added into an acetic acid solution and is fully hydrated; 2, wheat gliadin is added into an ethanol solution to be fully dissolved; 3, the material obtained in the step 1 and the material obtained in the step 2 are mixed, shear-homogenized, centrifuged and rotationally evaporated through an anti-solvent method, and wheat gliadin compound colloidal particles are obtained; 4, genipin is added into the material obtained in the step 3 to be fully dissolved; 5, normal hexane is added into the material obtained in the step 4 for shearing and homogenizing, and the novel cellular material is prepared after freeze drying. The obtained cellular material is rich in raw material source, low in cost and high in porosity and specific surface area, has certain anti-pressure ability, and has certain prospects in the fields of biological catalysis, chemical industry, medicine, food and the like.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing silica sol with large particle size

InactiveCN103880023ASuppression packageVolatile completelySilicon compoundsPhysical chemistrySilicon oxide

The invention relates to a method for preparing silica sol with large particle size. The method includes: firstly preparing a high-purity silicon dioxide mother nucleus solution by using monatomic silicon, then coating the mother nucleus and purifying the silica sol. Since methanol is added in hydrolysis, silicon dioxide coating can be inhibited, such that the prepared silicon dioxide mother nucleuses are distributed in a narrow particle size, thereby being beneficial to obtaining silica sol with large particle size, in which particle size is uniform. The mother nucleus solution is evaporated in vacuum to completely volatilize the methanol, and high temperature steam is filled from the bottom during evaporation and purification to volatilize the methanol more completely, so as not to generate unbeneficial influence to subsequent coating; and for the silica sol with large particle size obtained after multiple coating procedures, a detection shows that various indexes of the prepared silica sol are located on an international advanced level.

Owner:陆曹生

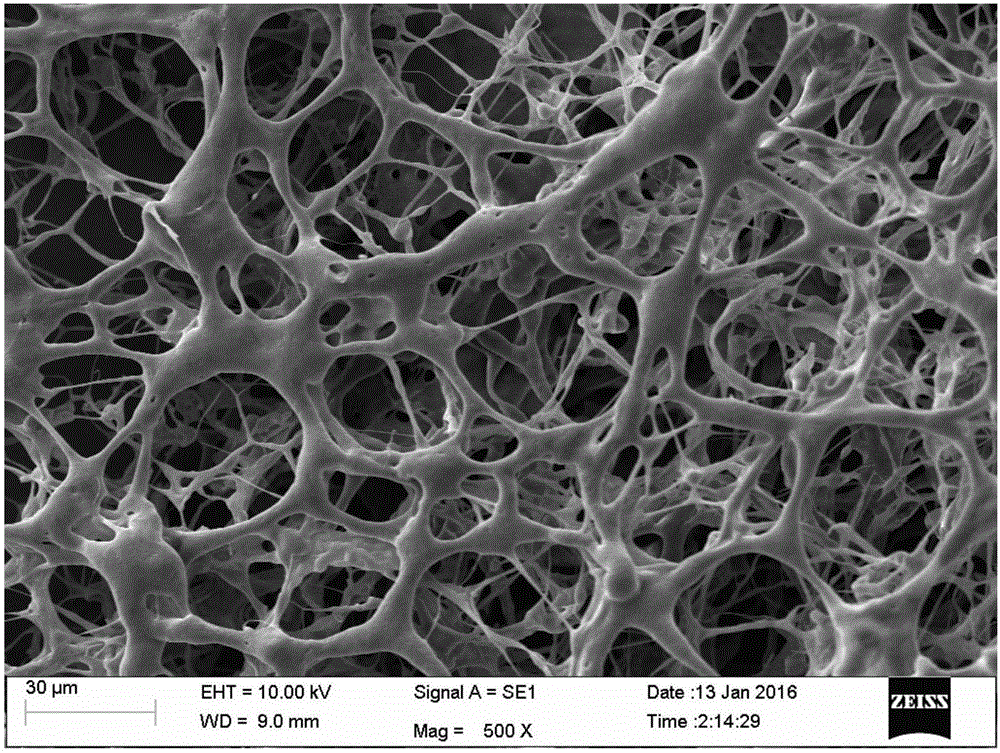

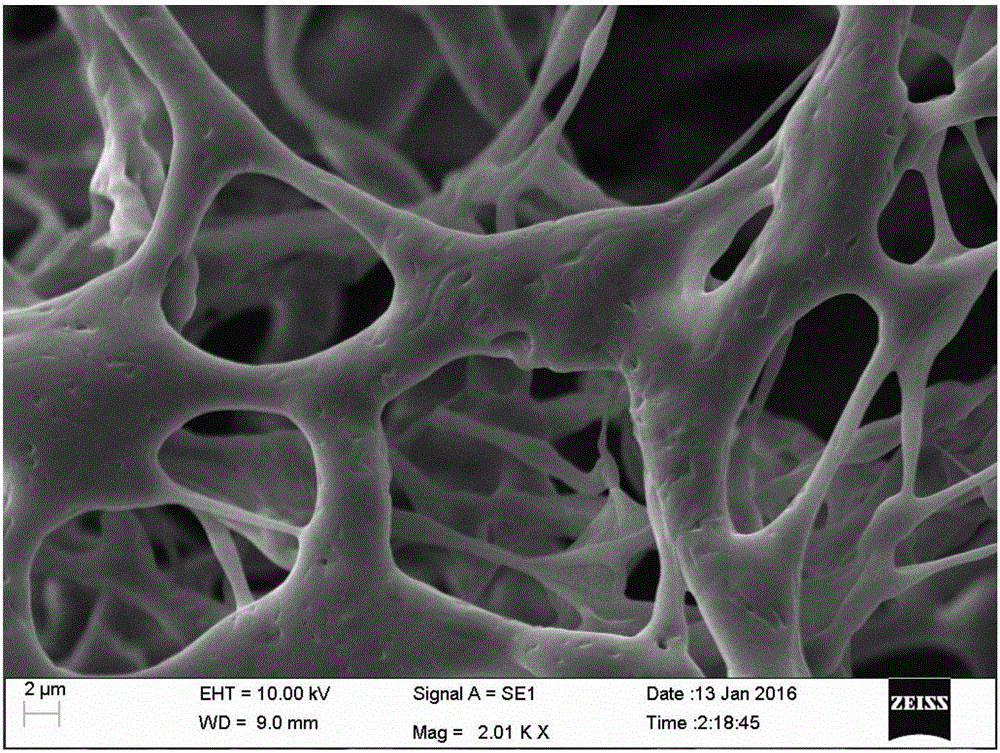

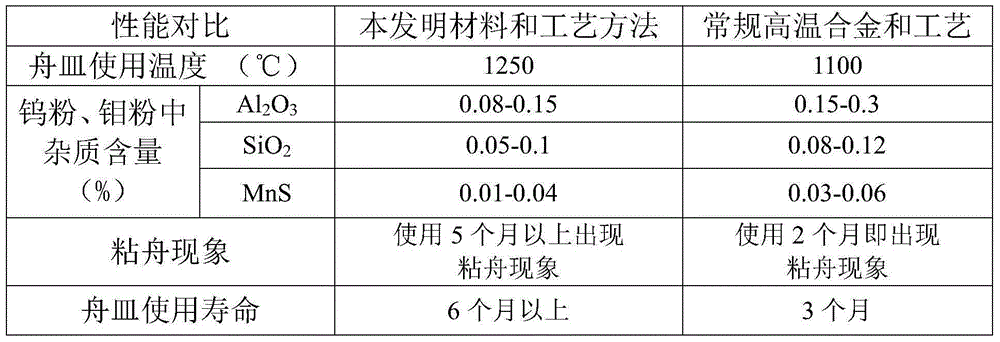

Material for manufacturing boat and process method for manufacturing boat through material

ActiveCN105220016AImprove appearance qualityReduce manufacturing costFoundry mouldsFoundry coresReducing atmosphereUltimate tensile strength

The invention discloses a material for manufacturing a boat and a process method for manufacturing the boat through the material. The material comprises, by weight, 58%-62% of Ni, 0-0.2% of Ti, 0-0.15% of Si, 0-0.1% of C, 0-0.05% of Re, and the balance W and other impurities. The boat manufactured from the material through the process method has higher high-temperature strength performance under the conditions of a reducing atmosphere with the high temperature of 1250 DEG C, and can be used for six moths without deformation or cracking. Besides, in the using process, the phenomenon that materials adhere to the boat hardly occurs, the impurity content of reduced tungsten powder and the impurity content of reduced molybdenum powder can be reduced significantly, and the production efficiency and quality of the tungsten powder and the molybdenum powder are improved effectively.

Owner:CHENGDU XINGYU PRECISION CASTING

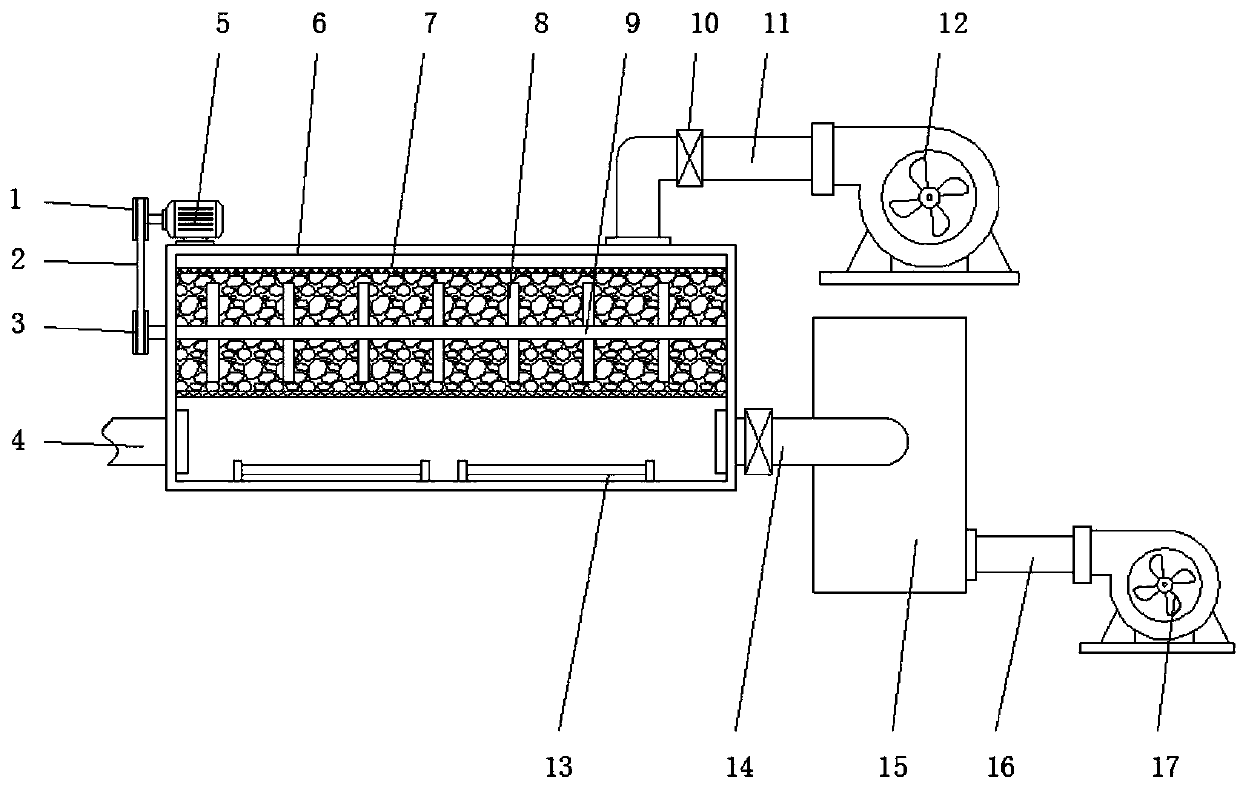

Activated carbon adsorption and desorption regeneration device for organic waste gas treatment

InactiveCN111228959AIncrease temperatureIncrease profitGas treatmentDispersed particle separationActivated carbonCombustion chamber

The invention discloses an activated carbon adsorption and desorption regeneration device for organic waste gas treatment. The activated carbon adsorption and desorption regeneration device comprisesa waste gas treatment box. An infrared heating device works, so that the temperature of activated carbon in the waste gas treatment box is increased, adsorbed components on the activated carbon are desorbed and volatilized, and the desorbed and volatilized components are fed into a catalytic combustion device to be combusted and decomposed into hot air such as CO2 and H2O steam by starting a desorption fan; one part of the hot air returns to an activated carbon adsorption box to continue to heat the activated carbon, the other part of the hot air is emptied through the desorption fan, the activated carbon can be regenerated by circulating in the hot air multiple times, and the utilization rate of the activated carbon is increased; the path of a gas passing through a combustion chamber is increased through a partition plate, and the flow speed of the gas in the combustion chamber can be reduced, so that the time of the gas in the combustion chamber is prolonged, and the gas is combustedmore sufficiently and thoroughly.

Owner:湖北中涂科技有限公司

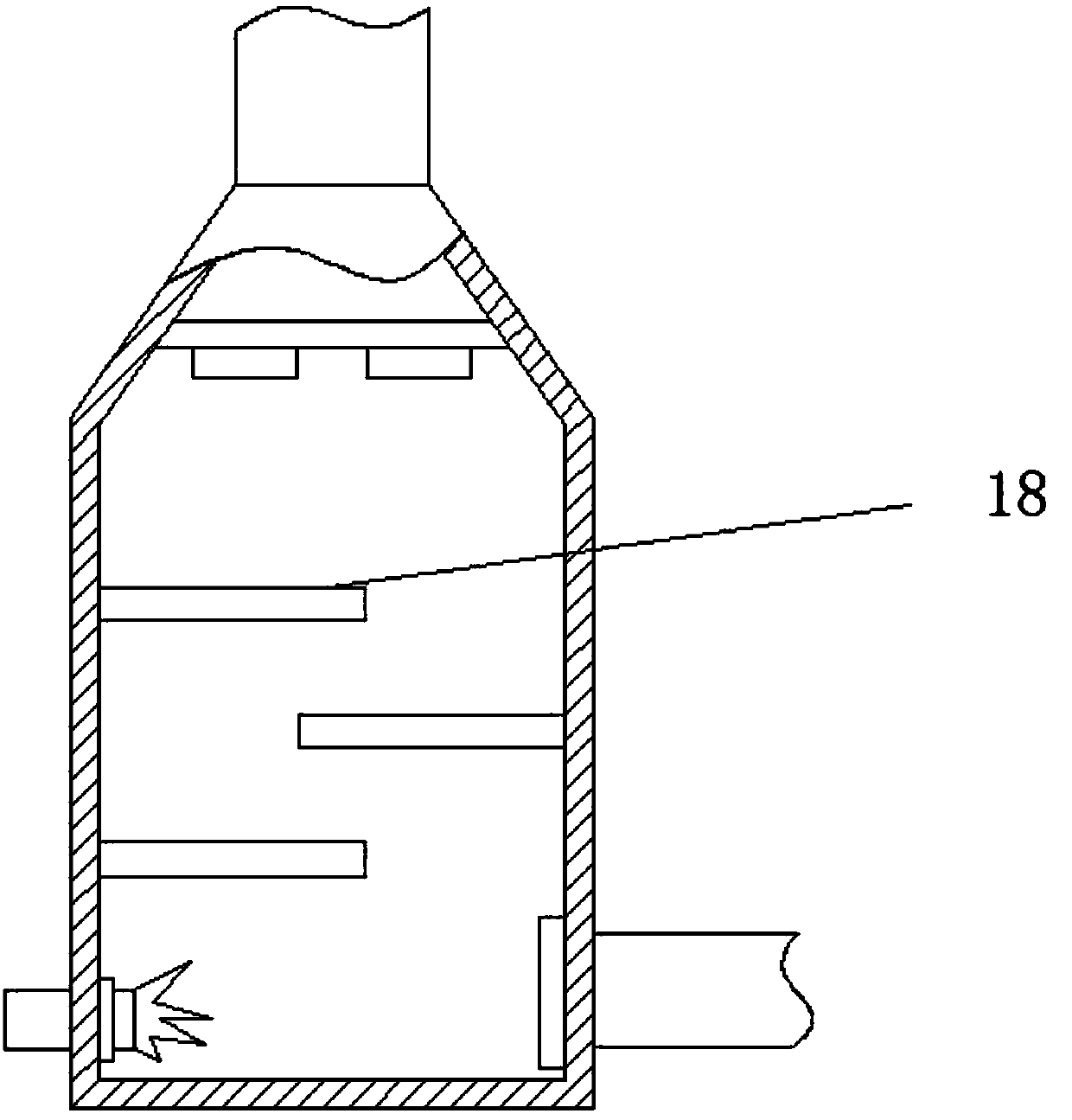

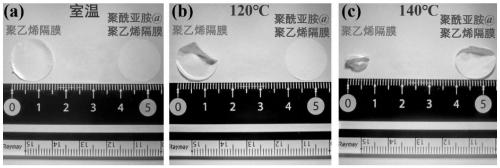

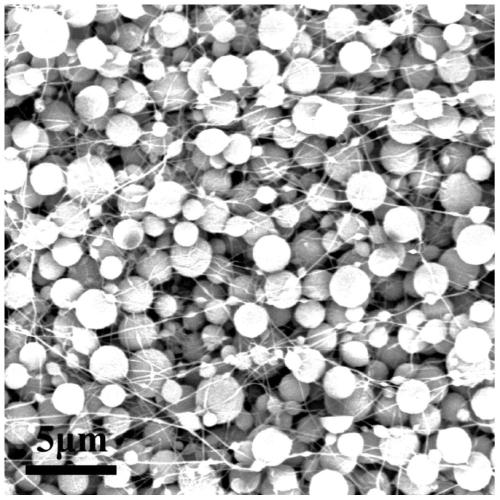

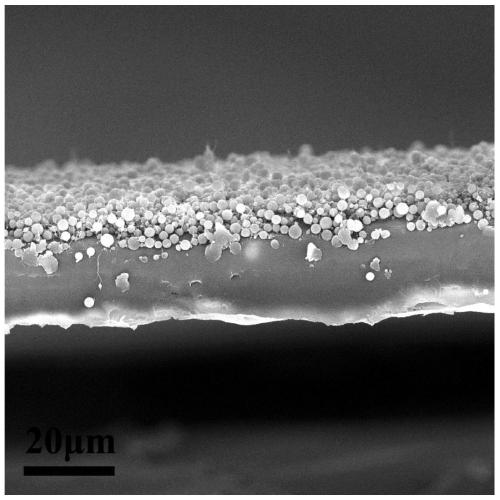

Method for modifying lithium battery diaphragm by temperature-resistant macromolecules and corresponding lithium battery diaphragm

InactiveCN111129396AImprove Coulombic efficiencyImprove Coulombic efficiency and prolong battery cycle lifeLi-accumulatorsCell component detailsElectrical batteryPhysical chemistry

The invention discloses a method for modifying a lithium battery diaphragm by using temperature-resistant macromolecules and a corresponding lithium battery diaphragm. The method comprises the steps of fully mixing and stirring a required temperature-resistant macromolecular material and an organic solvent to prepare a precursor solution with a certain mass fraction; cutting the lithium battery diaphragm to be modified, and fixing the cut lithium battery diaphragm on an electrostatic spinning spraying device; adjusting parameters such as the voltage of the electrostatic spinning spraying device, the rotating speed of a roller, the solution injection speed and the distance between a high-pressure needle head and a roller collecting device, and electrostatic spraying or spinning the precursor solution onto the lithium battery diaphragm; and turning off the electrostatic spinning spraying device at the arrival of the required time, flattening the lithium battery diaphragm, and carrying out vacuum drying to obtain the modified lithium battery diaphragm. The modified diaphragm provided by the invention can greatly improve the electrochemical performance and safety performance of the lithium metal battery.

Owner:杭州阳名新能源设备科技有限公司

Method and device for producing black copper by sludge containing copper

The invention provides a method and device for producing black copper by sludge containing copper. The method comprises the following steps that S1, the sludge containing copper is dewatered to the water content of 10-40wt% to form dewatered sludge; S2, the dewatered sludge is mixed with a fusing agent to be subjected to bottom blowing oxidation smelting in a full-slag smelting pool to form oxidizing smelting slag; S3, the oxidizing smelting slag is subjected to side blowing reduction smelting in a reduction smelting pool to obtain a reduced smelting product; and S4, the reduced smelting product is subjected to sedimentation treatment to obtain the black copper and furnace slag. According to the method and device for producing the black copper by the sludge containing copper, the sludge containing copper is treated by using the technology, the problems of long process, high tailing copper content, high sulfur content and the like when the copper is recycled from the sludge containing copper in the prior art are effectively solved, and the recovery rate of valuable metal is improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

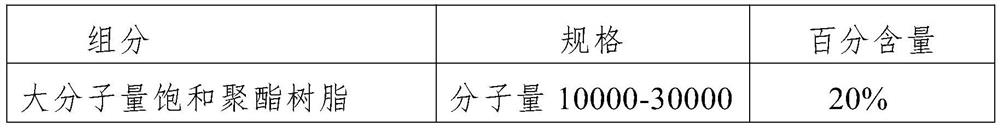

Low-temperature cover plate ink and preparation method thereof

The invention relates to low-temperature cover plate ink which comprises a first component, wherein the first component is prepared from the following components in percentage by mass: 20-30 percent of large-molecular-weight saturated polyester resin, 20-30 percent of small-molecular-weight hydroxyl saturated polyester resin, 10-20 percent of carbon black, 15-25 percent of isophorone, 10-20 percent of glycol ether, 1-3 percent of silicon dioxide for thickening, 5-15 percent of silicon dioxide for extinction, 5-10 percent of dispersing agent, 0.1-1 percent of leveling agent, 0.1-1 percent of defoamer and 1-3 percent of silane coupling agent. Before the ink is used, an isocyanate curing agent is added according to the amount of 5-10% of the first component, and the mixture is uniformly stirred and then coated or printed on the surface of a base material. Experiments prove that the ink of the formula can be completely cured on a PET or CPI base material after being baked at 55-75 DEG C for 60 minutes, and after curing, the adhesive force of the ink is 5B grade, the boiling performance is 5B, the dyne value reaches 32-34, the bending performance is 200,000 times, and the appearance isnot changed in a hundred-grid test.

Owner:厦门三德信科技股份有限公司

Device for physically purifying low volatile matter in macromolecular compound

The invention discloses a device for physically purifying a low volatile matter in a macromolecular compound. A heating tank of the device adopts heating oil to heat or adopts an electric heating way; the heat conduction oil heating of the heating tank is implemented as follows: heat conduction oil is filled into the heating tank, then the heat conduction oil is heated, so that the temperature of the oil is increased to a needed temperature, and then the hot oil is transported to a place needing to be heated through a circulating oil pump; the electric heating way is implemented as follows: an electric heating plate or an electric heating coil are electrified to heat the place needing to be heated. According to the physical characteristics of the low volatile matter in the macromolecular compound and inorganic mineral powder, an air exhausting pump and multiple filter layers are provided, the low volatile matter completely volatizes through adopting a physical method by utilizing a vacuum negative-pressure environment under the condition that the heating time is limited and the boiling point of the volatile matter is not reached, the consumed time is short, the energy consumption is saved, and the volatile matter can be thoroughly volatized.

Owner:启仲化工(广西)有限公司

Urea mixing device

PendingCN110848007AReduce breakageCompletely brokenInternal combustion piston enginesExhaust apparatusEngineeringMechanical engineering

The invention discloses a urea mixing device. A partition is arranged between a front housing and a rear housing, a breaking plate is fixed to the partition, a front baffle is arranged on the front end part of the partition, an opening is formed in a part corresponding to the partition, of the front baffle, a flow guide plate and a hole plate are arranged on the opening, and an intake port is formed between the flow guide plate and an inner wall surface corresponding to the front housing; a blade opened inwards and towards an injection cavity is formed in the flow guide plate; a plurality of first through holes are formed in the hole plate; grating openings are formed in a wall surface facing the breaking plate, of the partition; and the rear housing is provided with a waist-reducing part.According to the urea mixing device, the plurality of grating openings are formed in the part facing the breaking plate, of the partition, and play a role of secondary breaking on urea drops, and more thorough atomization and volatilization for the urea drops are ensured, so that adequate mixing for mixed gas flow is much benefited, and higher mixing uniformity is achieved. The rear housing is provided with the waist-reducing part, and the flowing speed of the mixed gas flow while passing through the waist-reducing part, is increased, so that a better mixing effect and higher mixing uniformity are achieved.

Owner:无锡亿利环保科技有限公司

Chinese Yew tea and making method thereof

InactiveCN108617813AAvoid compromising qualityReduce green odorPre-extraction tea treatmentDissolutionBrewing

The invention discloses the technical field of health teas and their making and particularly relates to Chinese yew tea and a making method thereof. Chinese yew leaves are subjecting to fixing beforerolling and drying, wherein triple rolling and triple drying are performed alternately; methanol solution of certain concentration sprayed during rolling each time for the purpose of promoting dissolution of paclitaxel compounds in Chinese yew during rolling and the purpose of attaching the dissolved paclitaxel compounds to the surface of the stems of Chinese yew; during brewing, these compounds are promoted to dissolve in water, the content of paclitaxel compounds in tea is increased, and application value of Chinese yew is improved. By dry products produced, the Chinese yew tea includes 1-2parts of stems of Chinese yew and 4-5 parts of tea leaves.

Owner:贵州瑞宸科技有限公司

Ultrasonic-assisted supercritical fluid extraction method for essential oil in cape jasmine leaves

InactiveCN110042000AFacilitated DiffusionEasy extractionEssential-oils/perfumesCavitationFreeze-drying

The invention belongs to the technical field of biological extraction, in particular to an ultrasonic-assisted supercritical fluid extraction method for essential oil in cape jasmine leaves. The method comprises the following steps: 1, selecting clean cape jasmine leaves, performing freeze drying, then, crushing the dried cape jasmine leaves by a crusher, and sieving the obtained powder by a 50-60mesh sieve; 2, weighing a proper amount of cape jasmine leaf powder to be uniformly mixed with a carrying agent, placing the mixture in a supercritical fluid extraction kettle, and performing circulating extraction under assistance of ultrasonic waves at 30-70 DEG C for 30-180 min; 3, after extraction, obtaining an extraction liquid by a separation kettle, and performing vacuum concentration to obtain an essential oil mixture. Dissolution of effective ingredients of plants is reinforced under the cavitation effect of ultrasonic waves, and ultrasonic-assisted supercritical fluid extraction hasthe advantages of low extraction temperature, short time, high oil yield, energy-saving and the like. Fewer impurities such as colloid exist in an essential oil crude extract extracted by the petroleum ether carrying agent, an organic reagent is volatilized thoroughly, and the purity of the essential oil is higher.

Owner:HUNAN UNIV OF ARTS & SCI

Brake pad material for high-speed railway train and preparation method thereof

ActiveCN107460362BBest friction and wear resistanceWon't fall offTransportation and packagingMetal-working apparatusBoron nitrideSilicon dioxide

The invention discloses a brake pad material for high-speed railway trains and a preparation method thereof, belonging to the technical field of powder metallurgy friction materials. The brake pad material is put into the mixer after drying and sieving the raw material powder, sprayed into the binder, placed in a steel mold after mixing and pressed, then sintered in a reducing atmosphere, and then processed in a reducing atmosphere. Made by heat treatment; wherein, the raw material powder is copper powder, iron powder, Ti2AlC powder, chromium powder, nickel powder, manganese powder, silicon dioxide, graphite, boron nitride and molybdenum disulfide. The invention also provides a preparation method of the brake pad material. In the present invention, the in-situ TiC obtained through Ti2AlC is used as the main friction component to prepare the material of the in-situ nano-TiC sheet skeleton, and then copper is used as the matrix, and a small amount of other metals are added to adjust the content of lubricating components such as graphite to finally obtain the Material with excellent dynamic effect and low wear rate. It is suitable as a brake pad material for high-speed railway trains.

Owner:哈尔滨新干线轨道交通科技有限公司

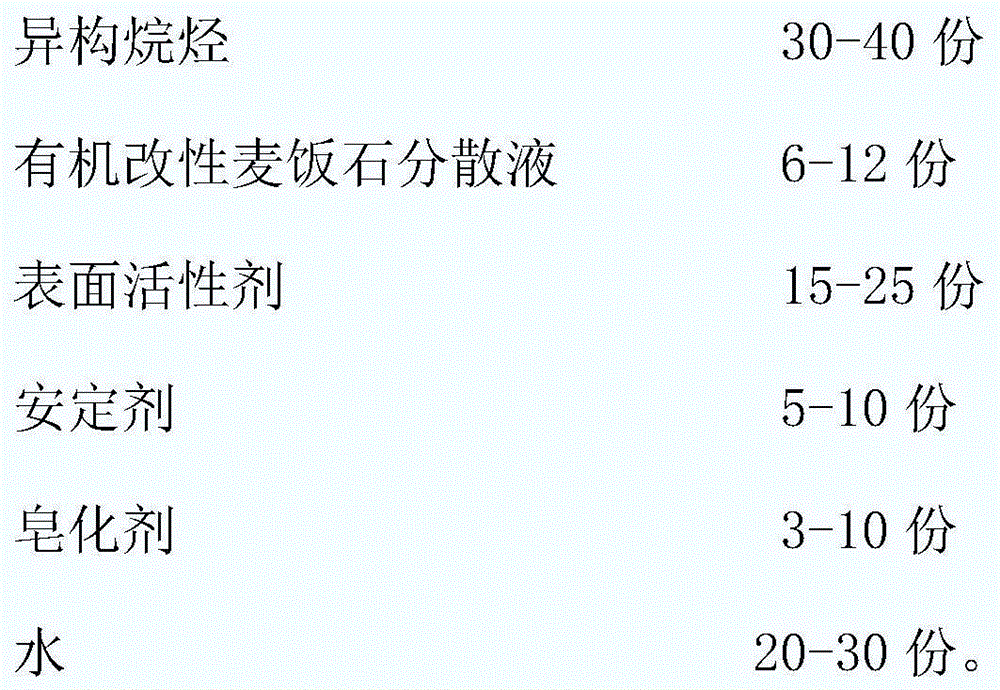

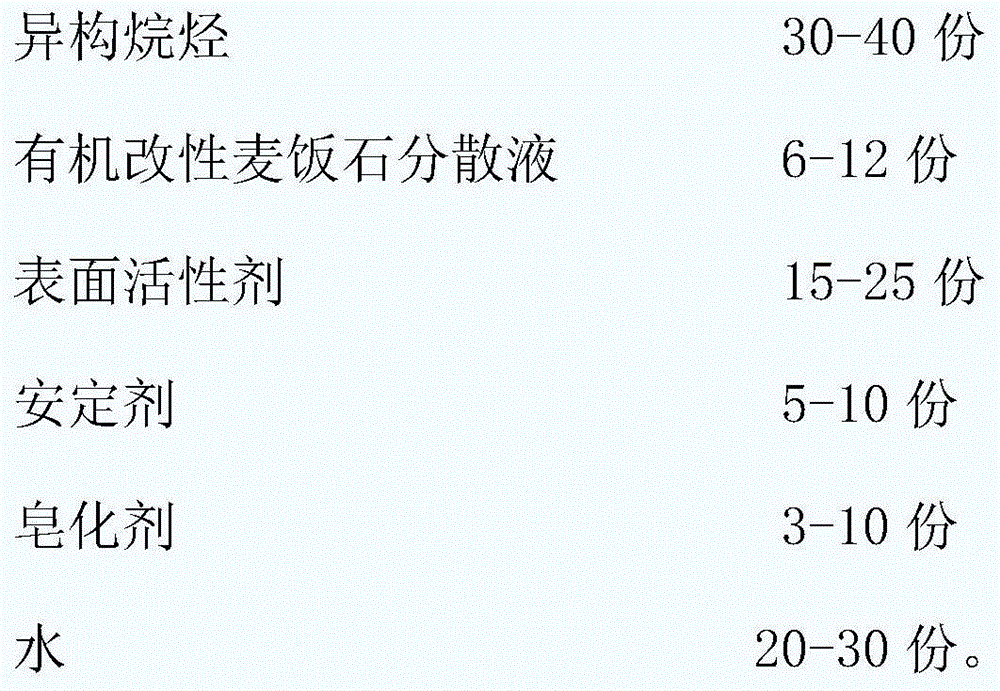

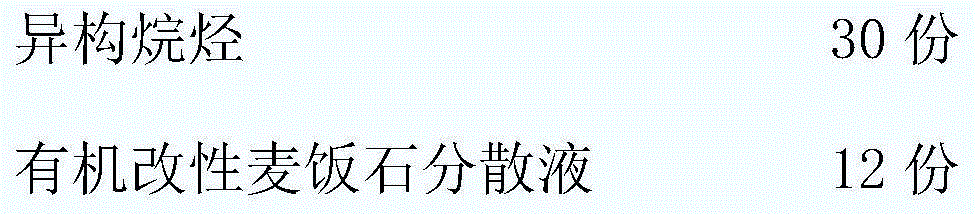

Detergent for soldering tin and preparation method of detergent

The invention discloses detergent for soldering tin and a preparation method of the detergent. The detergent is prepared from the following components in parts by weight: 30-40 parts of isoparaffin, 6-12 parts of an organic modified medical stone dispersion liquid, 15-25 parts of a surfactant, 5-10 parts of a stabilizing agent, 3-10 parts of a saponifier, 20-30 parts of water as well as 3-5 parts of carboxymethyl chitosan oligosaccharide, 7-9 parts of water-soluble phosphorylated chitosan and / or 2-4 parts of an organosilicon quaternary ammonium salt, 3-8 parts of an epoxy quaternary ammonium salt, and 4-6 parts of an epoxy organosilicon quaternary ammonium salt. The invention further discloses a preparation method of the detergent for soldering tin. The detergent disclosed by the invention is rapid to volatilize, rapid to seep, free of corrosion on substrates and high in cleaning property, and can be applied to fields such as headset plug lines and plastic; the surface of a substrate cleaned by using the detergent is bright, the connection strength of soldering tin is not influenced, and the sound quality of a headset line is not affected; a semi-water washing process is adopted, soldering tin is washed with the detergent firstly and water secondly, an outstanding washing effect can be achieved, and the detergent is reasonable in process, low in cost and can be produced in a large scale.

Owner:浦北瀛通智能电子有限公司

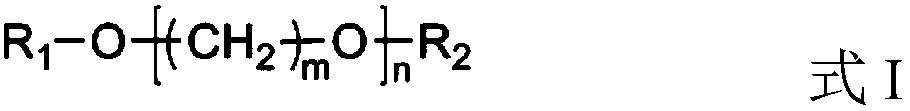

Inorganic nanometer material printing ink, preparation method and applications thereof

The invention provides an inorganic nanometer material printing ink, wherein the solvent in the inorganic nanometer material printing ink is an organic solvent, the inorganic nanometer material printing ink comprises at least an inorganic nanometer material and at least a long carbon chain alcohol ether organic solvent, the long carbon chain alcohol ether organic solvent has a structure represented by a structure general formula I, and in the formula I, R1 and R2 are independently selected from C8-40 aliphatic groups and C8-40 aromatic groups, m and n are positive integers, m is 2 or 3, and nis more than or equal to 1 and is less than or equal to 8.

Owner:TCL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com