Low-temperature cover plate ink and preparation method thereof

A technology of ink and cover plate, applied in the field of low temperature cover plate ink and its preparation, can solve the problems of low dyne value and high temperature of curing and film formation of cover plate ink, and achieve the advantages of improving volatilization speed, increasing roughness and increasing contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In the low-temperature cover plate ink of the present embodiment, the first component comprises the following components (in mass percentage):

[0050] components Specification percentage content High molecular weight saturated polyester resin Molecular weight 10000-30000 20.5% Small molecular weight hydroxyl saturated polyester resin Molecular weight 2000-7000 20% carbon black powder 13% Isophorone —— 16% Ethylene glycol butyl ether —— 10% Silica for matting powder 8% SiO2 for thickening powder 2% SDBS —— 7.5% cellulose acetate —— 0.5% BYK-066N Commercial specification 0.5% A silane coupling agent Commercial KH560 2%

[0051] The preparation steps of the first component are as follows:

[0052] (1) Put the carbon black into a high-speed stirred tank at 80°C, the stirring speed is 400rpm, and the stirring time is 10h.

[0053] (2) Add isophorone, ethylene glycol butyl et...

Embodiment 2

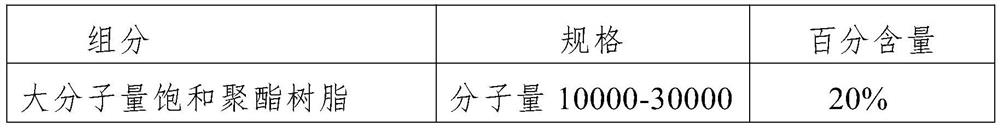

[0067] In the low-temperature cover plate ink of the present embodiment, the first component comprises the following components (in mass percentage):

[0068]

[0069]

[0070] The first component is prepared according to the method of Example 1, and the first component is mixed with 8% isocyanate curing agent (BASF Lupranate M 20S), and is respectively applied to the surface of the PET base plate and the surface of the CPI base plate (preliminary Remove oil and dust), bake at 60±5°C for 60 minutes, the ink is completely dry and cured into a paint film.

[0071] The PET / CPI substrate plate of embodiment 2 is carried out hundred grid test (dyne value adopts dyne pen to test), and the result is as follows:

[0072] Adhesion boiled Dyne value Bending properties Substrate 5B 5B 34 200,000 times, no change in appearance PET, CPI

[0073] Note: The boil test is boiled at 80°C for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com