Method for modifying lithium battery diaphragm by temperature-resistant macromolecules and corresponding lithium battery diaphragm

A lithium battery diaphragm and polymer technology, applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problem of not being able to prevent lithium dendrites from the mechanism, no diaphragm modification technology, and lack of performance of traditional diaphragms, etc. problem, to achieve the effect of preventing internal short circuit of the battery, uniform distribution of lithium ions, and inhibiting the growth of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] First prepare a polyimide solution with a mass fraction of 10%, and weigh the required mass of soluble polyimide precursor material and organic solvent N, N to dimethylformamide according to the proportion; mix the organic solvent N, N ~ Dimethylformamide was slowly added to the polyimide, heated and stirred at 100° C. for 7 hours, and ultrasonicated for 1 hour.

[0062] Select a commercial polyethylene lithium battery separator, cut it into a suitable size, and fix it on the roller collector of the electrospinning spraying device.

[0063] Transfer the prepared polyimide solution to the syringe of the electrospinning spraying device, and remove excess air bubbles; adjust the device parameters, the voltage is 20kV, the drum collector speed is 500r / min, and the injection pump injection speed is 1mL / h , the distance between the high pressure needle and the roller collector is 20cm.

[0064] Turn on the switch of the device and carry out high-pressure spraying for 3 hours...

Embodiment 2

[0068] First configure 10% polyimide solution, and the configuration process is the same as in Example 1.

[0069] Select a commercial polyethylene lithium battery separator, cut it into a suitable size, and fix it on the roller collector of the electrospinning spraying device.

[0070] Transfer the prepared polyimide solution to the syringe of the electrospinning spraying device, and remove excess air bubbles; adjust the device parameters, the voltage is 25kV, the drum collector speed is 100r / min, and the injection pump injection speed is 1mL / h , the distance between the high pressure needle and the roller collector is 25cm.

[0071] Turn on the switch of the device and carry out high-pressure spraying for 2 hours.

[0072] Close the device, take out the modified diaphragm, put it into a vacuum oven, adjust the temperature to 100°C, and dry it for 1 hour to obtain a polyethylene diaphragm modified with polyimide.

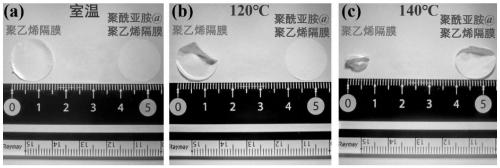

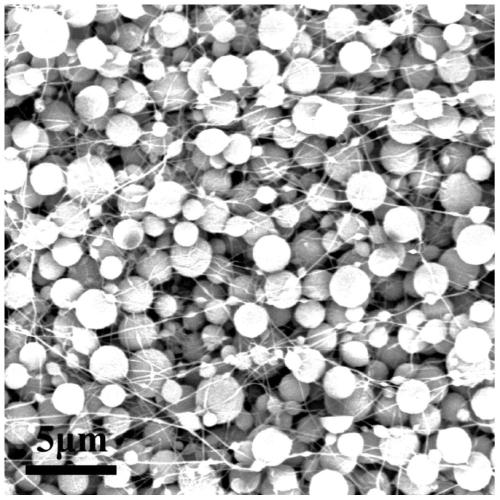

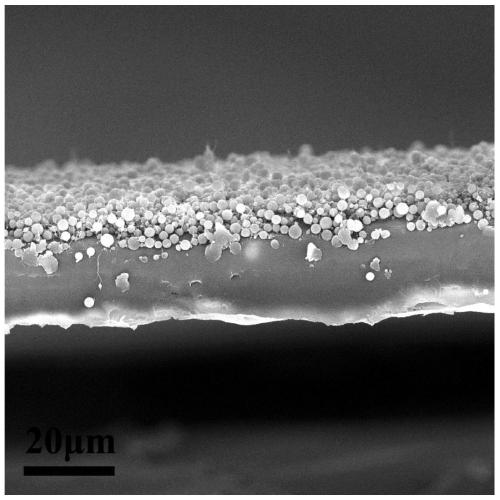

[0073] Scanning electron microscope analysis was carried ou...

Embodiment 3

[0075] First prepare a polyimide solution with a mass fraction of 5%, and weigh the required mass of soluble polyimide precursor material and organic solvent dimethylacetamide according to the ratio; slowly add the organic solvent dimethylacetamide into polyimide, heated and stirred at 120° C. for 7 h, and ultrasonicated for 0.5 h.

[0076] Select a commercial polyethylene lithium battery separator, cut it into a suitable size, and fix it on the roller collector of the electrospinning spraying device.

[0077] Transfer the prepared polyimide solution to the syringe of the electrospinning spraying device, and remove excess air bubbles; adjust the parameters of the device, the voltage is 25kV, the rotation speed of the drum collector is 1000r / min, and the injection speed of the syringe pump is 0.5mL / h, the distance between the high pressure needle and the roller collector is 20cm.

[0078] Turn on the switch of the device and carry out high-pressure spraying for 0.5h.

[0079...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com