Lithium molybdate serving as secondary battery electrode material

An electrode material, secondary battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of no electrochemical activity, low first cycle efficiency, battery safety hazards, etc., to achieve good compatibility, high volume energy The effect of high density and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

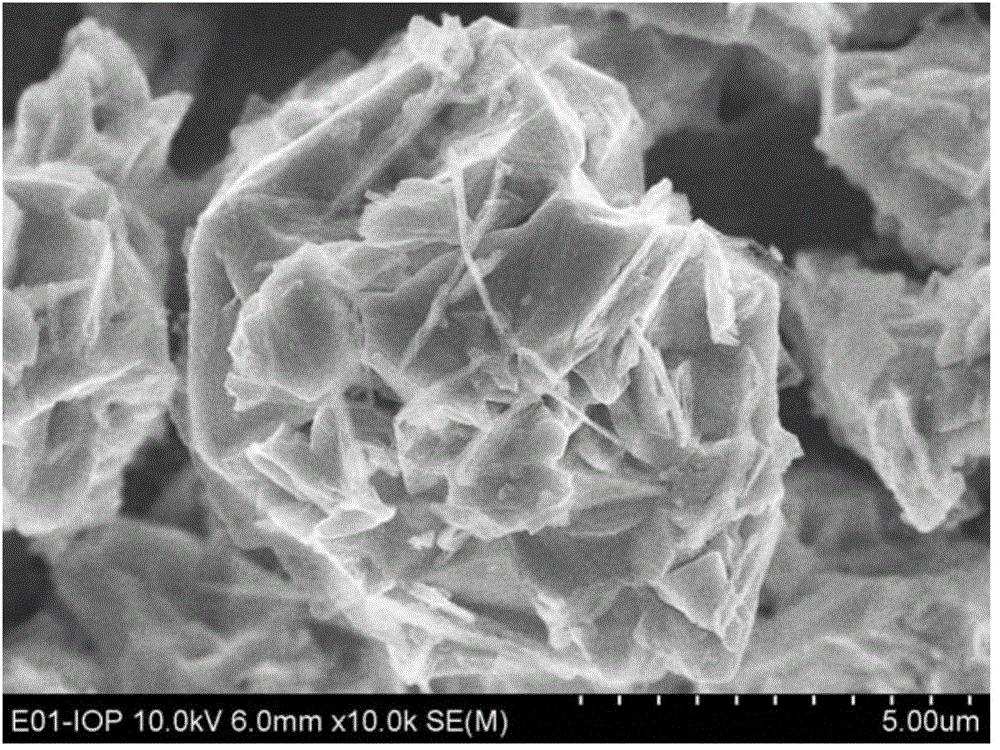

[0039] Synthesis of Li by a solid-state method 2 MoO 3 . Li 2 CO 3 and MoO 3 Mix according to the ratio of 1.05:1, and heat at 600°C for 10h to obtain Li 2 MoO 4 . will get Li 2 MoO 4 Placed in a tube furnace with Ar / H 2 Mixed gas, heat treatment at 600°C for 24h to obtain Li 2 MoO 3 powder. The typical XRD and SEM results of the obtained material are as follows figure 1 and 2 shown.

[0040] With the obtained Li 2 MoO 3 The powder is used as the electrode active material to prepare the positive electrode sheet and assemble the battery. The electrode sheet preparation, battery components and battery assembly processes are as described above. After the battery was left to stand for 4 hours, the battery was charged and discharged with a constant current (10mA / g) using a LAND tester. Li in Example 2 2 MoO 3 The charge-discharge curve of the first week is as follows image 3 shown. The charging and discharging conditions and cycle results are listed in Table...

Embodiment 5

[0042] Synthesis of Li by sol-gel method 2 MoO 3 . According to the ratio of 1.05:1 Li 2 CO 3 and MoO 3 Mix the powder evenly and add to 1mol / L citric acid aqueous solution. Stir for 12h. Then the mixed solution was heated to 80° C., stirred and dried for 24 hours to obtain a dry gel, which was placed in a muffle furnace for calcination at 450° C. for 2 hours to obtain a precursor. Finally, the precursor is placed in a tube furnace and passed through Ar / H 2 Mixed gas, heat treatment at 600°C for 24h to obtain Li 2 MoO 3 powder.

[0043] With the obtained Li 2 MoO 3 The powder is used as the electrode active material to prepare the positive electrode sheet and assemble the battery. Electrode sheet preparation, battery components and battery assembly are the same as above. After the battery was left to stand for 4 hours, the battery was charged and discharged with a constant current (10mA / g) using a LAND tester. The charging and discharging conditions and cycle res...

Embodiment 6

[0045] Synthesis of Li by co-precipitation method 2 MoO 3 . First put (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in an appropriate amount of deionized water and stirred, then Li 2 CO 3 solution and adjust its pH value to about 8 with ammonia water. The obtained precipitate was filtered, washed with deionized water, dried at 80° C. for 12 hours, and then calcined at 500° C. for 5 hours in a muffle furnace. The calcined product was ground and mixed with Li 2 CO 3 Mix evenly according to the ratio of 7.35:1, place in a tube furnace, pass Ar / H 2 Mixed gas, heat treatment at 600°C for 24h to obtain Li 2 MoO 3 powder.

[0046] With the obtained Li 2 MoO 3 The powder is used as the electrode active material to prepare the positive electrode sheet and assemble the battery. Electrode sheet preparation, battery components and battery assembly are the same as above. After the battery was left to stand for 4 hours, the battery was charged and discharged with a constant cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com