Core-sheath nano-fiber three-stage coaxial electrospinning preparation method and device

A nanofiber, coaxial electrospinning technology, used in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of easy independent injection of sheath liquid, low fiber quality, and easy clogging of the spinning head. Clear structure, uniform diameter distribution and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

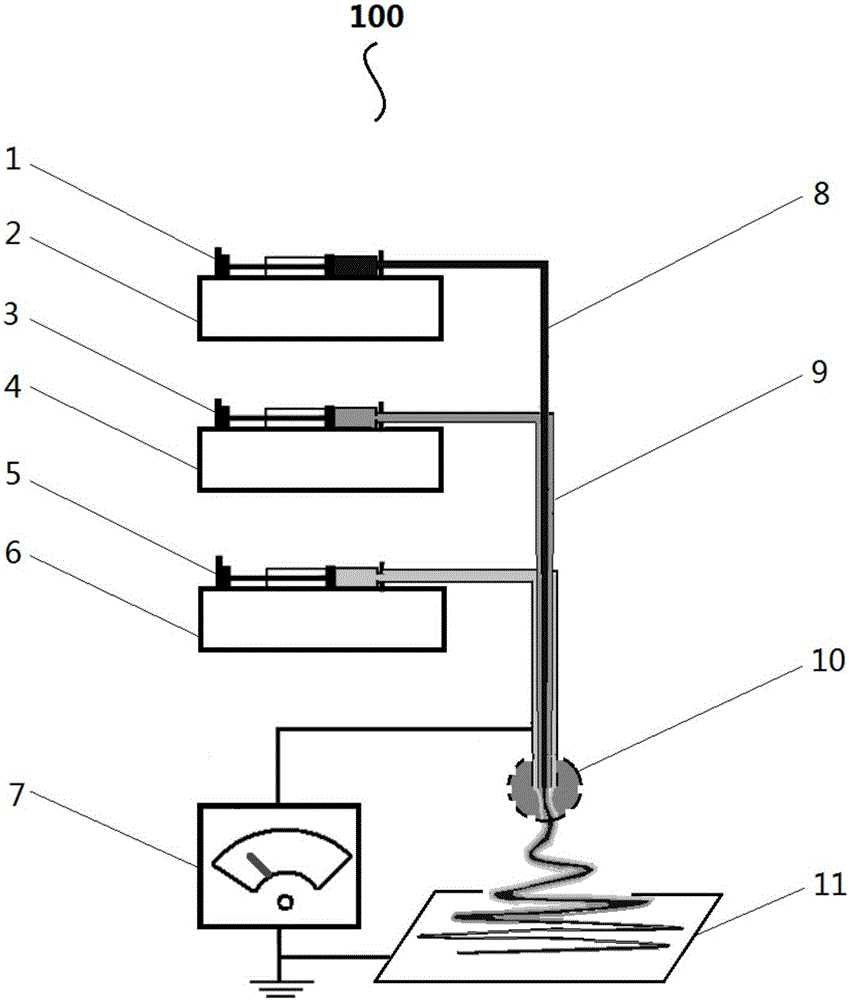

[0022] figure 1 is a schematic diagram of the three-stage coaxial electrospinning preparation device of the present invention.

[0023] like figure 1 As shown, the three-stage coaxial electrospinning preparation device 100 of the present invention includes a high-voltage generator 7, a three-stage coaxial spinning head 10, a fiber receiving plate 11, and a fluid injection pump.

[0024] The three-stage coaxial spinning head 10 is connected with the high-voltage generator 7; the fiber receiving plate 11 is a cardboard wrapped in aluminum foil, which is arranged under the three-stage coaxial spinning head 10 and is grounded for receiving the core-sheath nanofiber; the fluid The syringe pump is connected to the three-stage coaxial spinning head 10, and has an outer fluid injection pump 6, a middle fluid injection pump 4, and an inner fluid injection pump 2, and an outer fluid injection pump 6, a middle fluid injection pump 4, and an inner fluid injection pump. The syringe pumps...

Embodiment 2

[0039] This embodiment provides a common two-stage coaxial electrospinning preparation method of core-sheath nanofibers, the preparation method is the same as that of Embodiment 1, and the outer fluid is closed.

[0040] Figure 6 is a field emission scanning electron microscope image of the core-sheath nanofiber prepared in Example 2 of the present invention.

[0041] like Figure 6 As shown, the morphology and structure of the core-sheath nanofibers prepared in this example were analyzed using a field emission scanning electron microscope, and it was found that a large number of forked fibrils appeared in the core-sheath nanofibers prepared in this example.

[0042] Figure 7is a transmission electron microscope image of the core-sheath nanofiber prepared in Example 2 of the present invention.

[0043] like Figure 7 As shown, the core-sheath nanofiber prepared in this example has obvious inner core liquid leakage phenomenon.

[0044] Function and effect of embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com