Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "To achieve the purpose of cooling down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

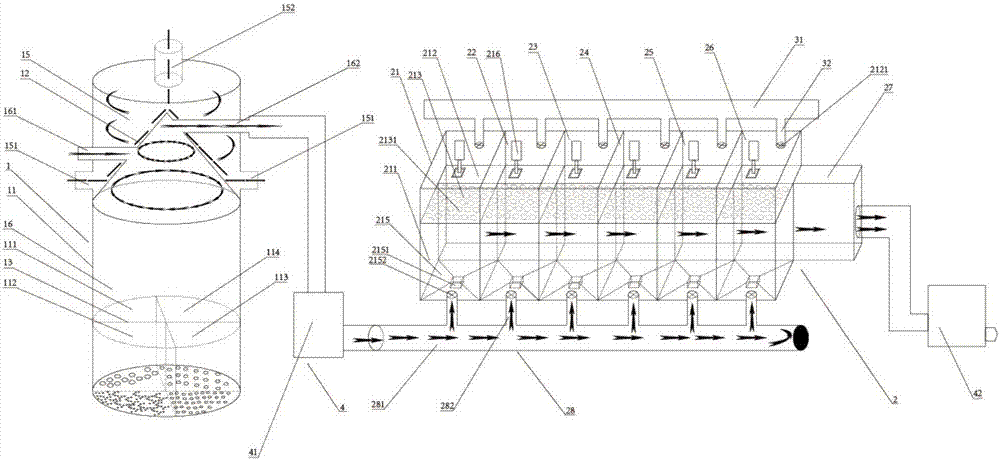

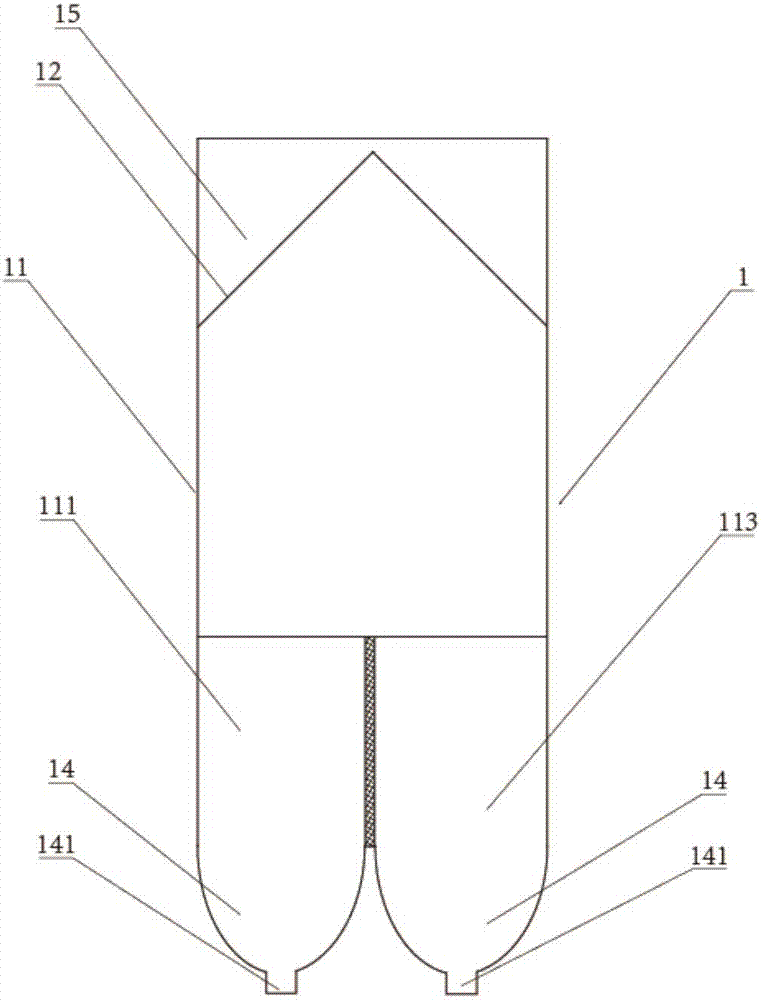

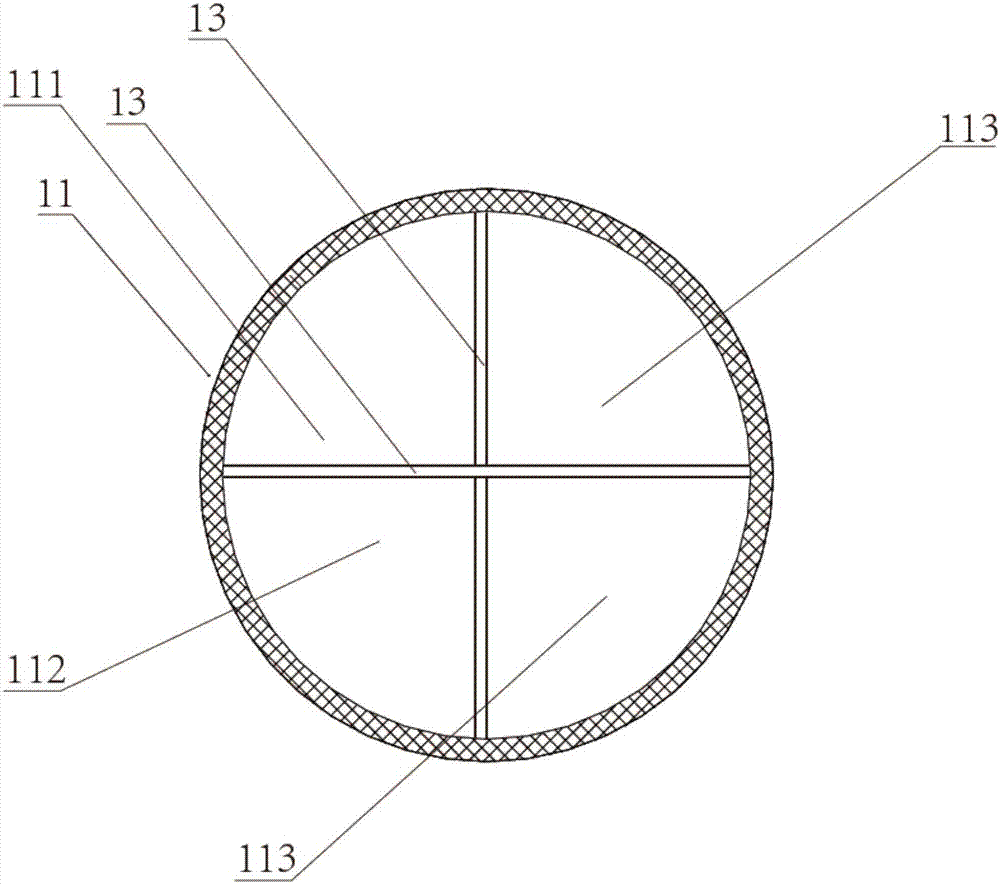

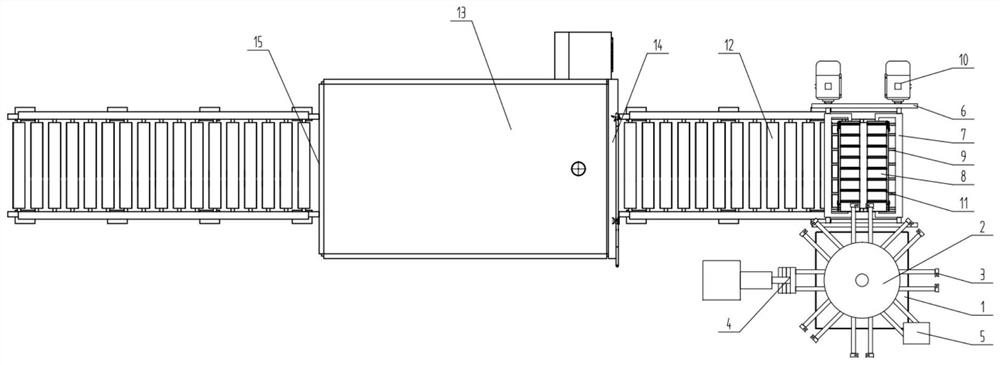

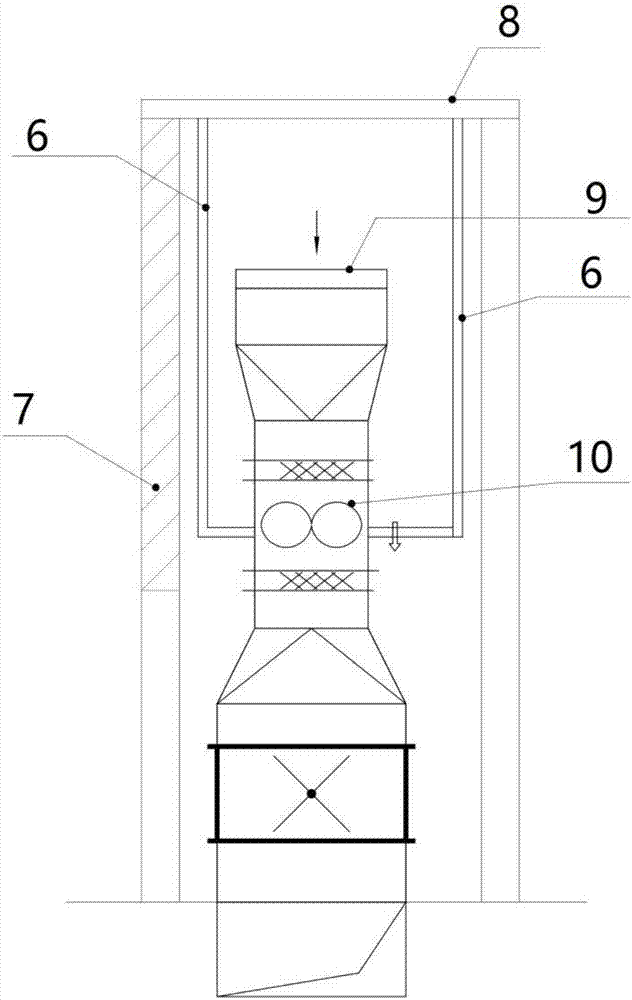

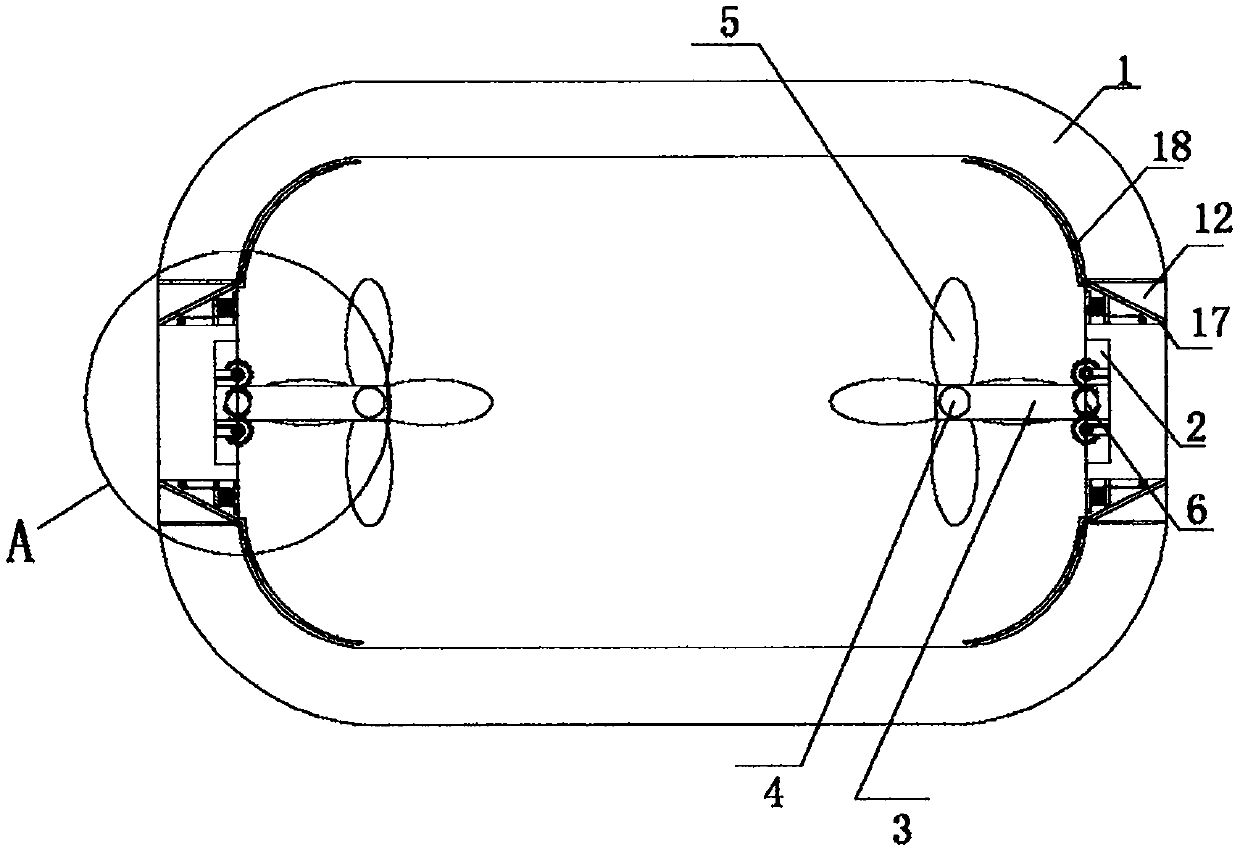

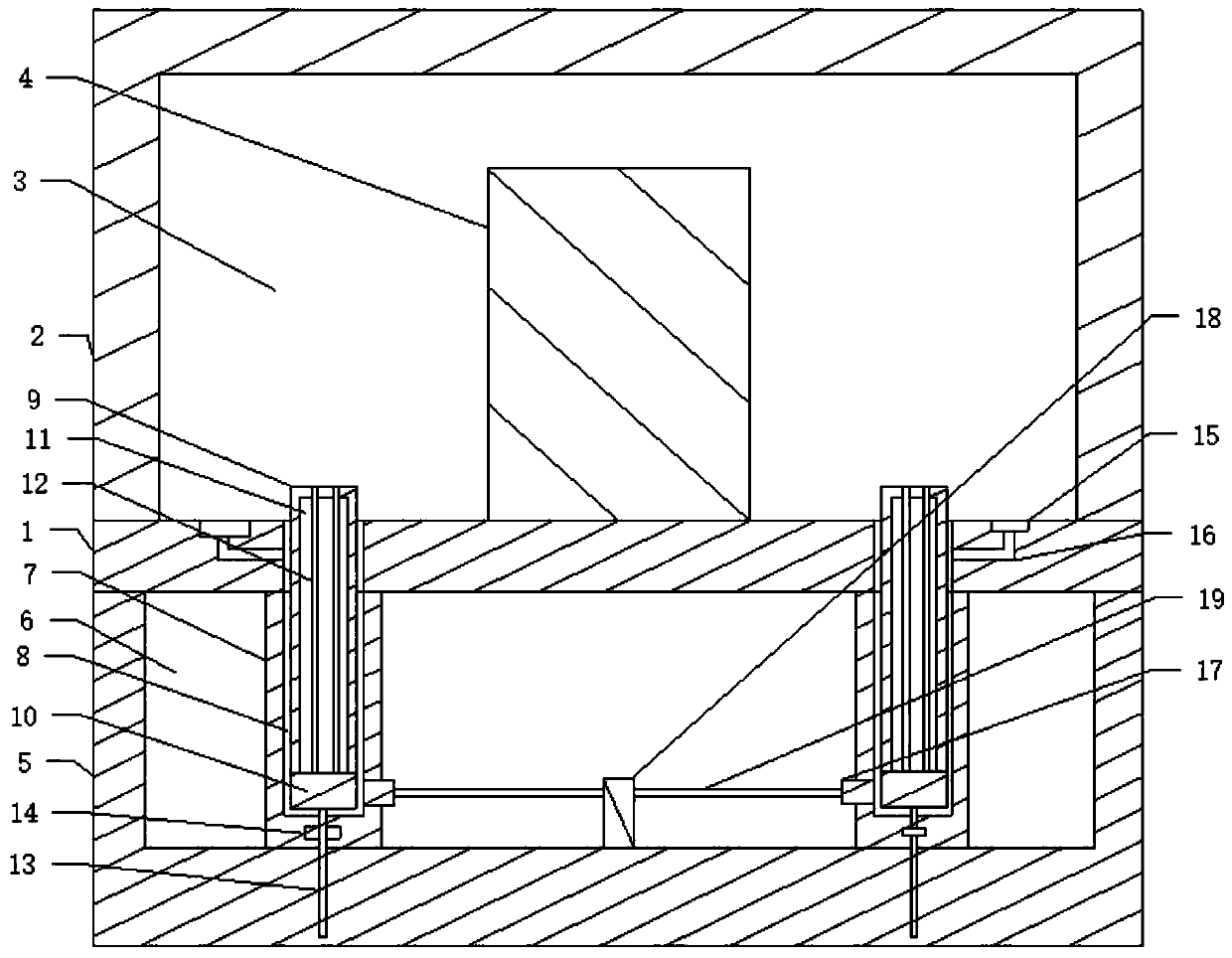

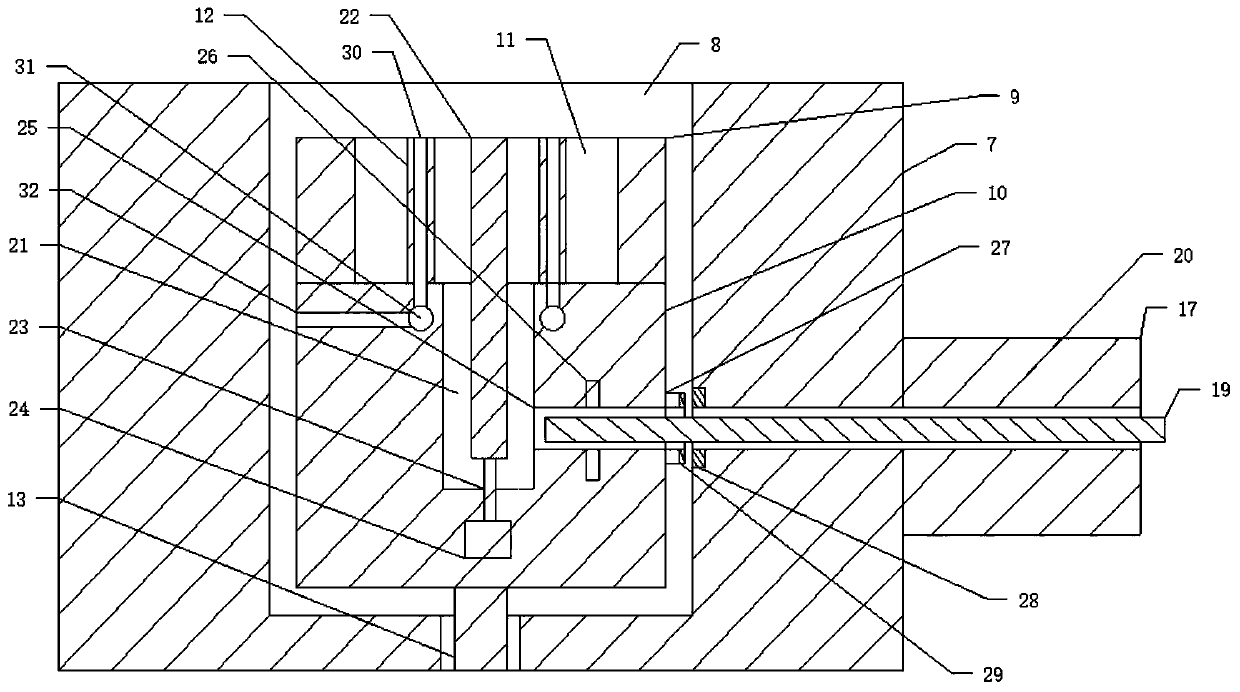

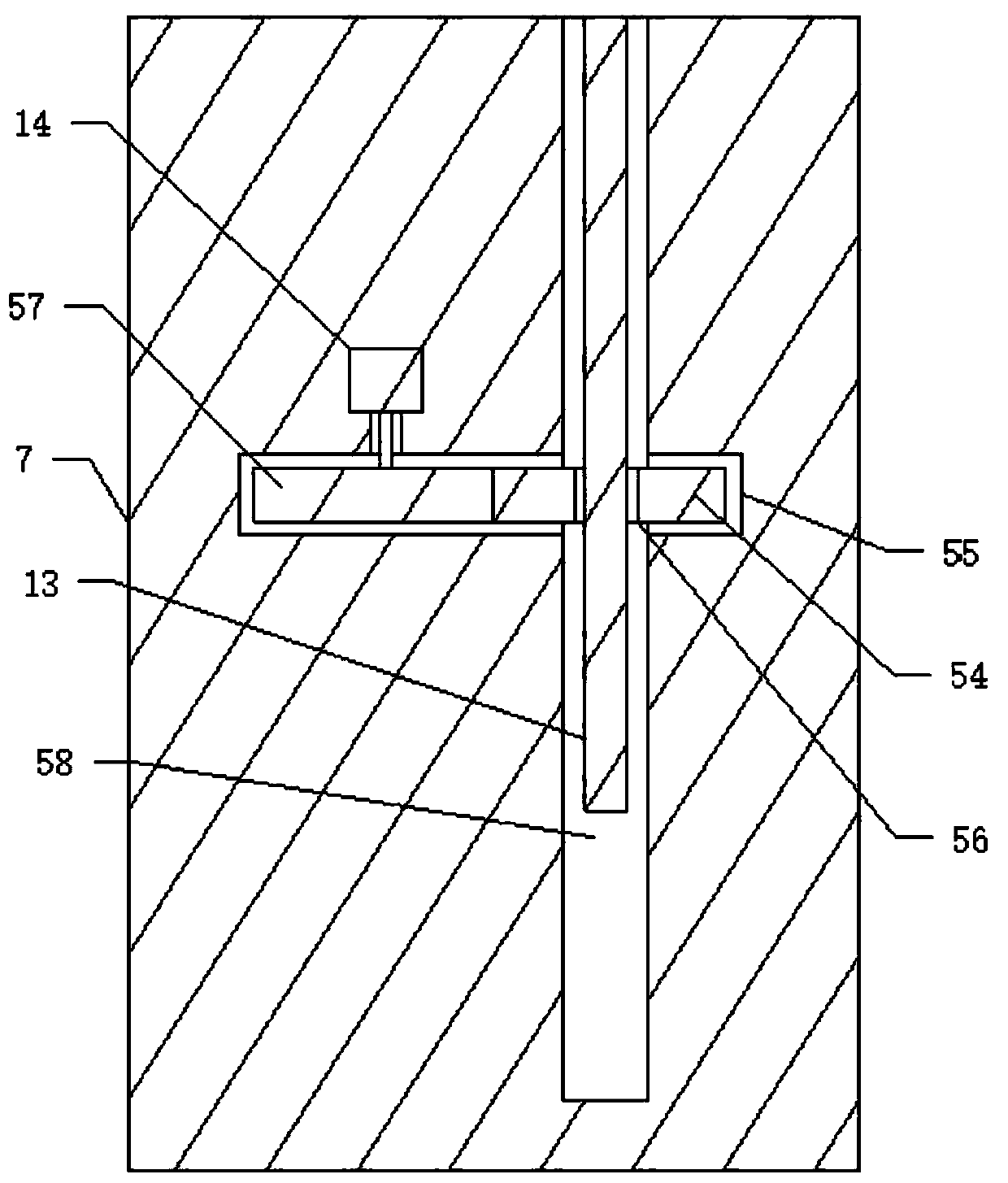

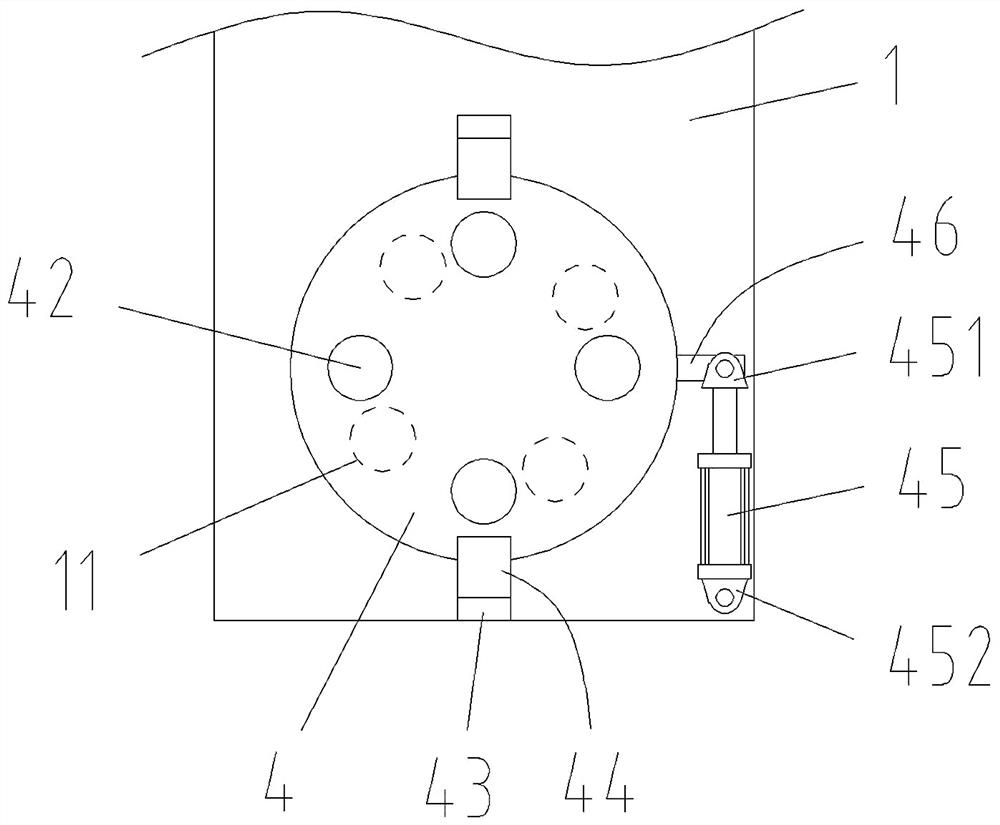

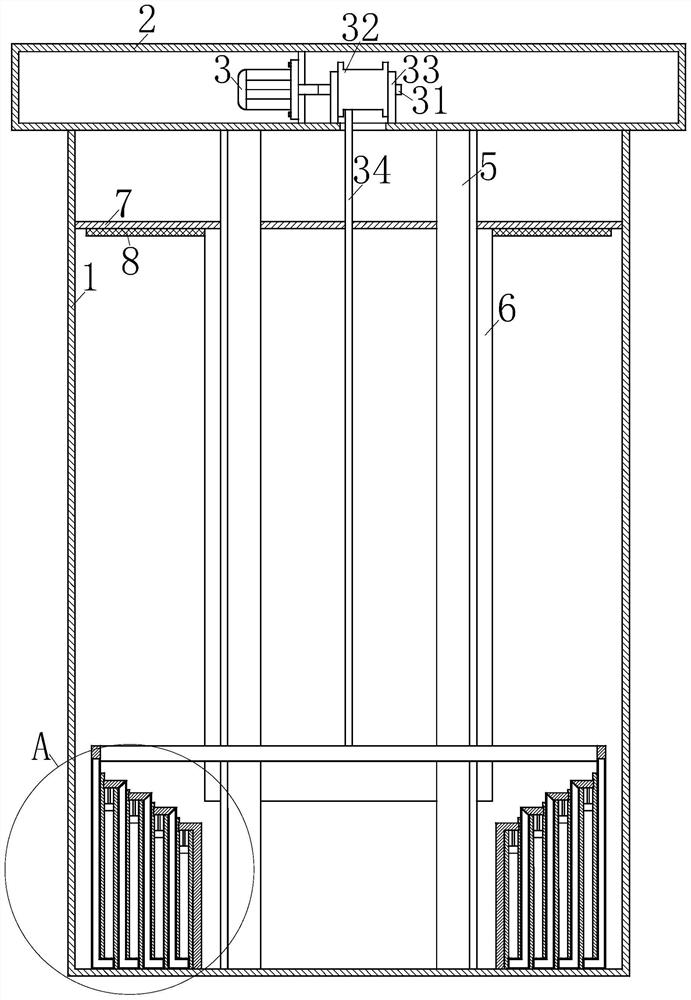

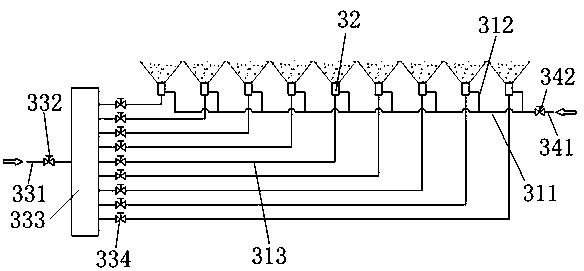

Pulsed type bag dedusting device

PendingCN107297107AImprove efficiency and effectivenessAchieving Recoil JitterDispersed particle filtrationTransportation and packagingEngineeringInlet channel

The invention discloses a pulsed type bag dedusting device which comprises a box combined type bag dust collector, a pulse airflow back-flushing cooling device and a second draught fan, wherein the pulse airflow back-flushing cooling device is arranged on the box combined type bag dust collector; the second draught fan is used for forming negative pressure suction in the pulse airflow back-flushing cooling device; the box combined type bag dust collector comprises at least two dedusting boxes, an exhausting channel, an air inlet channel and a dust collecting device; the dedusting boxes are successively arrayed from left to right; each dedusting box comprises a lower dust filtering chamber, an upper sealing air chamber, a sealing pattern plate, a cloth bag, a dust collecting hopper and a lifting valve device; the sealing pattern plate with a plurality of through holes is arranged between the lower dust filtering chamber and the upper sealing air chamber; the cloth bag is arranged on the position corresponding to the through holes on the sealing pattern plate; and an air inlet port of a second high temperature draught fan is communicated with an air outlet of the exhausting channel. The pulsed type bag dedusting device has the characteristics of reasonable structure design, complete function, high dedusting efficiency, safety, reliability, long service life and ultrahigh marketing value.

Owner:广东盛达穗南环保科技有限公司

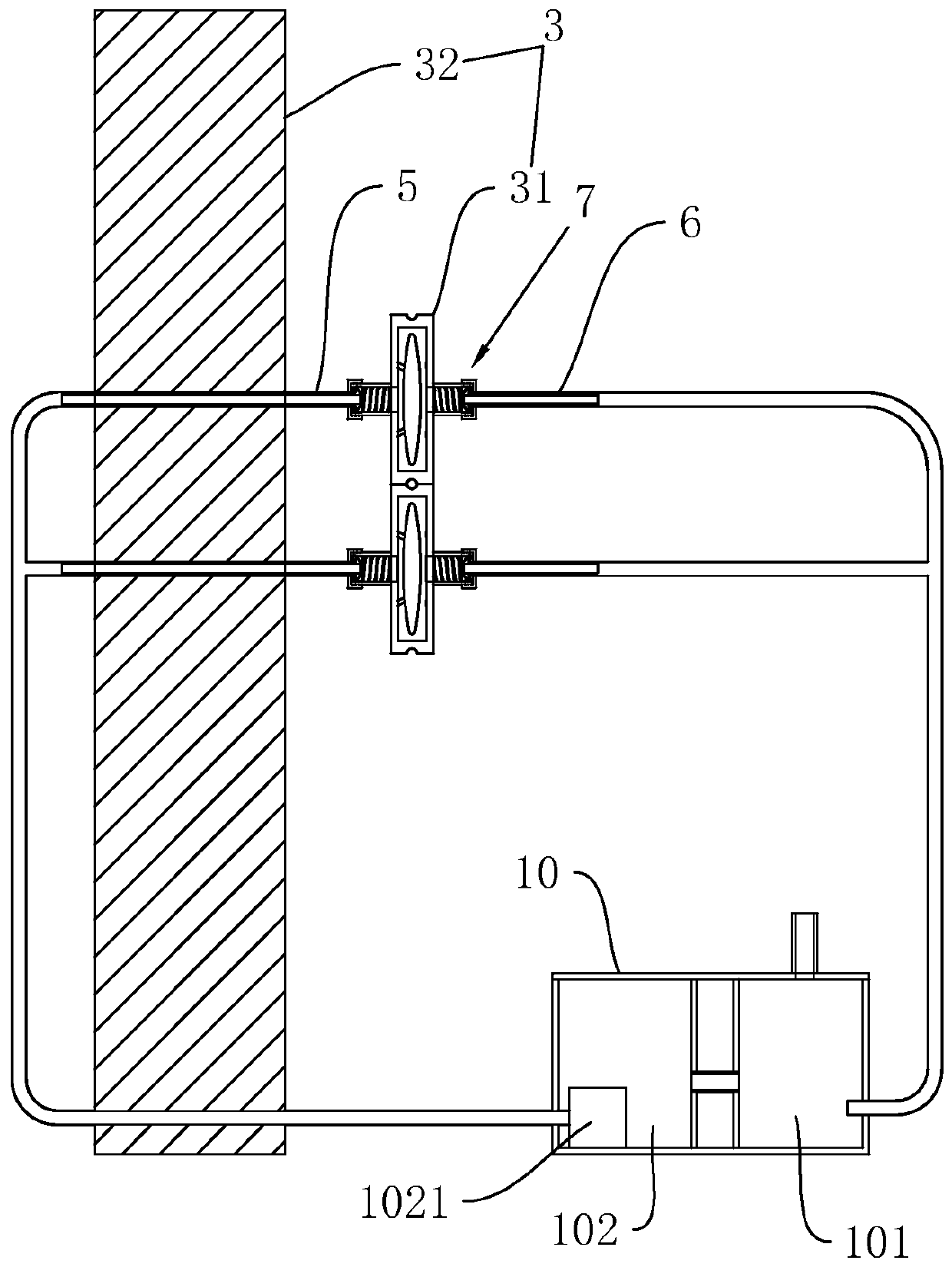

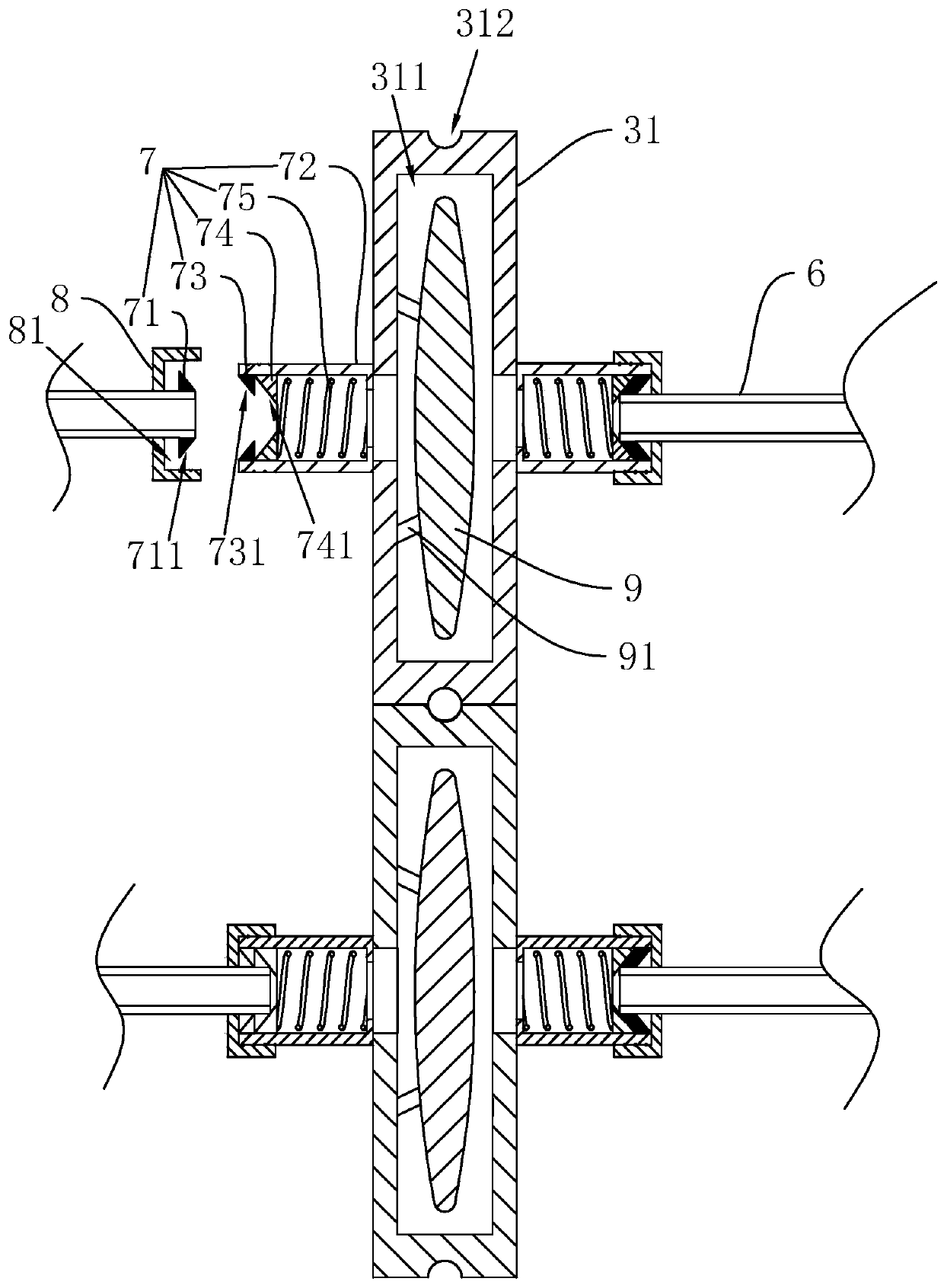

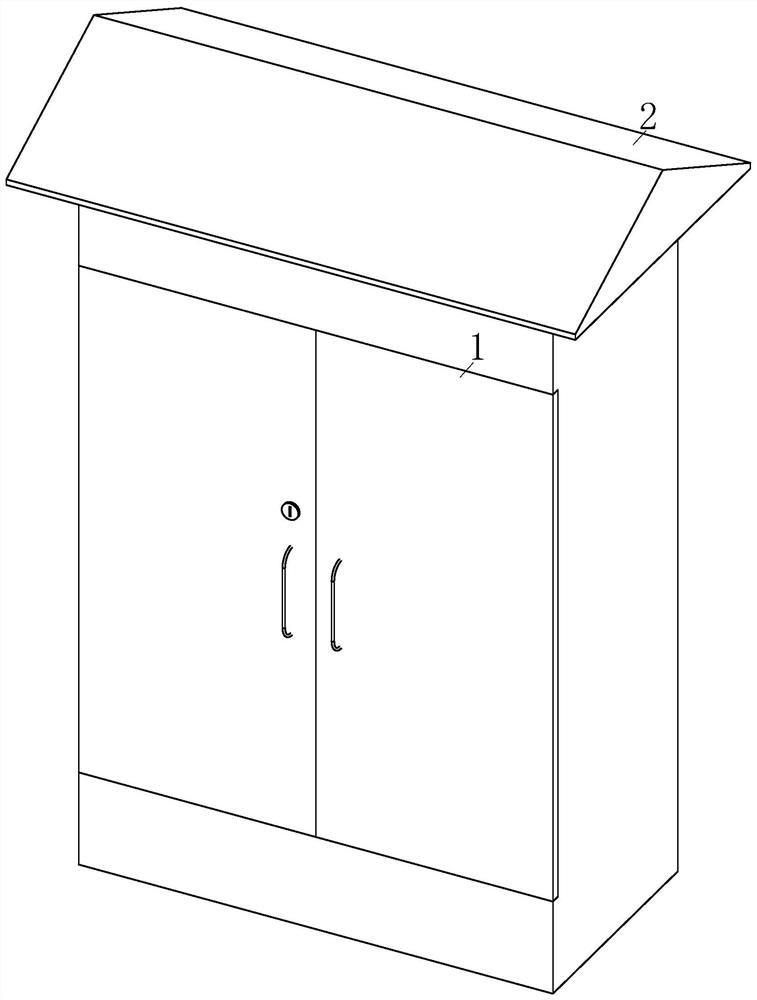

Positive pressure explosion-proof control cabinet

ActiveCN110461120ATo achieve the purpose of cooling downCasings/cabinets/drawers detailsHermetically-sealed casingsPositive pressureEngineering

The invention discloses a positive pressure explosion-proof control cabinet, which comprises a cabinet body. The inner side of the cabinet body is fixedly connected with a horizontally-disposed partition plate, and the partition plate divides the inner side of the cabinet body into an upper installation compartment and a lower exhaust compartment. The partition plate is provided with a communication hole, one side of the lower end of the communication hole is connected with a sealing plate in a rotary matching mode, a torsion spring for controlling reset of the sealing plate is disposed between the sealing plate and the partition plate, one side of the cabinet body is uniformly provided with a group of ventilation holes, and one side of the cabinet body is provided with an inflating device. The positive pressure explosion-proof control cabinet has the advantages that a cooling inert gas is supplied to the installation compartment; when the air pressure in the installation compartment can overcome the torsion force of the torsion spring, the air pressure in the installation compartment presses the sealing plate to rotate, and the air in the installation compartment is exhausted to the exhaust compartment; during the exhaust process, the heat in the installation compartment is also exhausted, and the purpose of cooling is achieved; and as the air pressure in the installation compartment is always greater than the external air pressure, the external air can not enter the installation compartment.

Owner:ERGONG EXPLOSION PROOF TECH CO LTD

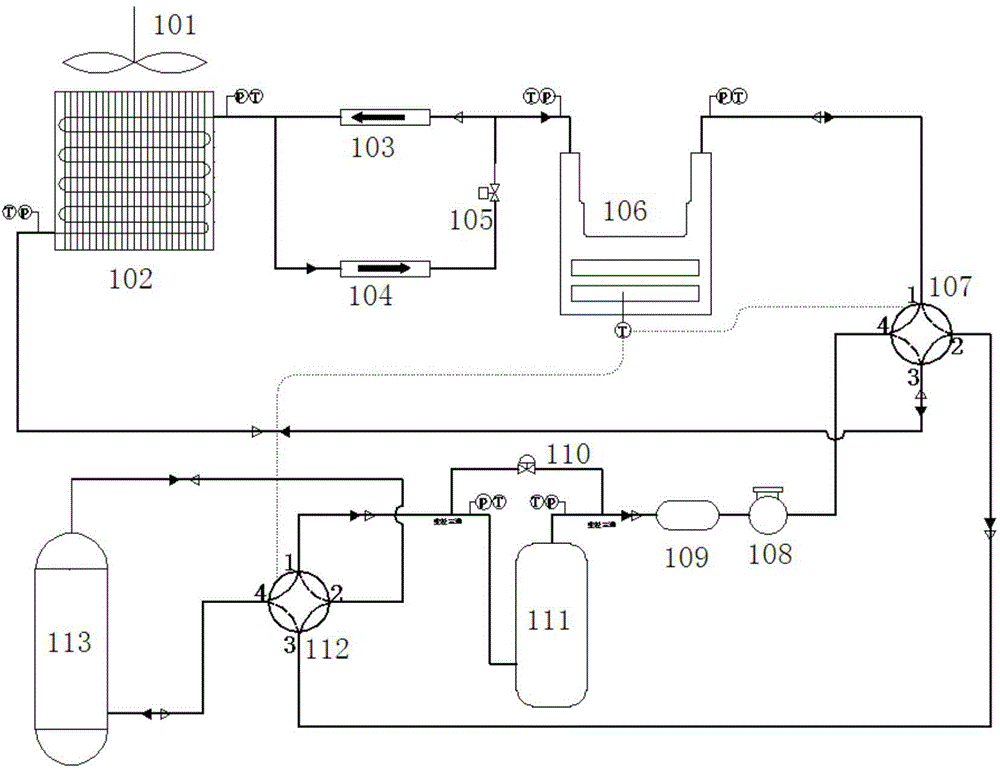

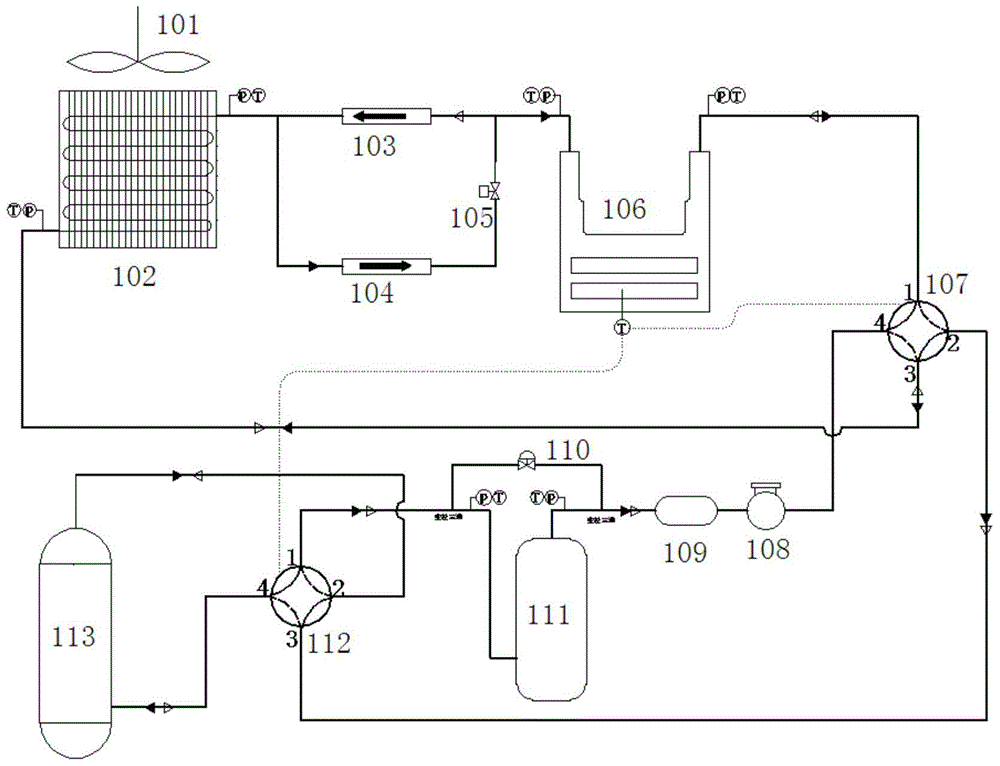

Two-phase refrigeration and gas compression integrated cooling system for electronic equipment

ActiveCN104864624AReduce usageDoes not affect space placementMechanical apparatusFluid circulation arrangementEngineeringCold plate

The invention discloses a two-phase refrigeration and gas compression integrated cooling system for electronic equipment. The two-phase refrigeration and gas compression integrated cooling system comprises a pump / compressor integrated dynamic core, a filter, a flowmeter, a first four-way reversing valve, an evaporator, a condenser, a second four-way reversing valve, a gas-liquid separator and a separation branch circuit comprising two check valves, one electronic expansion valve and one flow control valve. The electronic equipment to be cooled is adhered to a heat-transfer cold plate of the evaporator. The maximum temperature signal of the surface of the electronic equipment is used for controlling reversing motion of two four-way reversing valves. In the normal working condition, the system is used for cooling the electronic equipment by adopting the manner of boiling heat transfer in the two-phase cooling mode so that the characteristic of energy conservation is achieved. When surface temperature of the electronic equipment exceeds the set value with changes of ambient temperature or increase in thermal loads, control equipment takes an actuating signal for decreasing temperature of the electronic equipment in the mode of gas compression refrigeration and overcoming defects of two-phase cooling in the working condition with high ambient temperature in order to ensure normal operation of the electronic equipment.

Owner:XI AN JIAOTONG UNIV

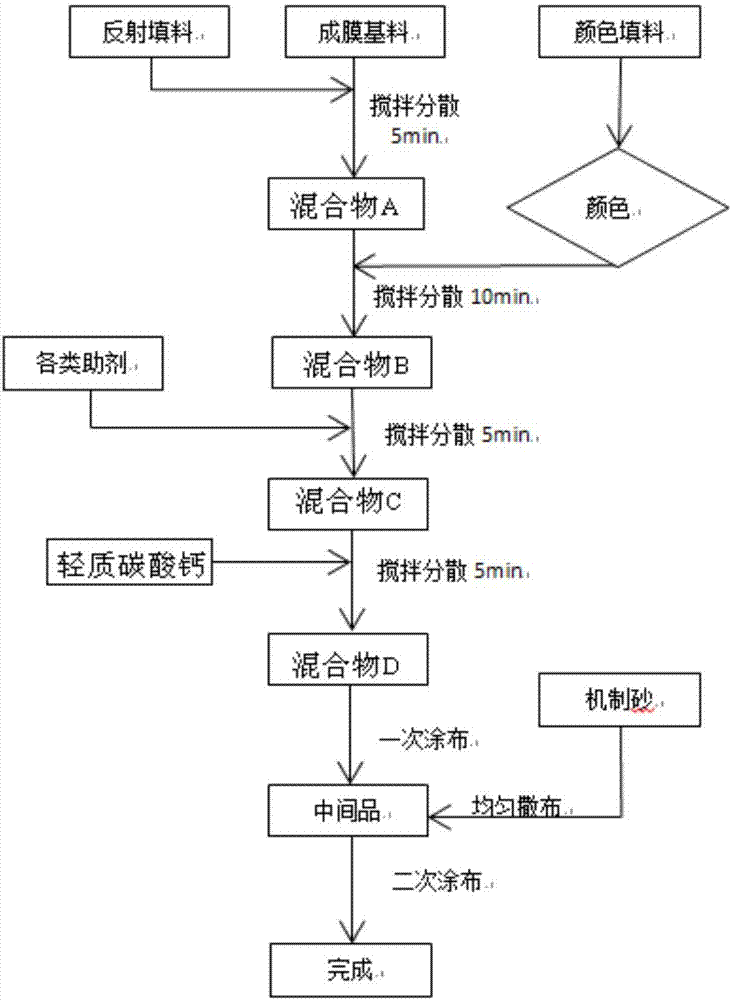

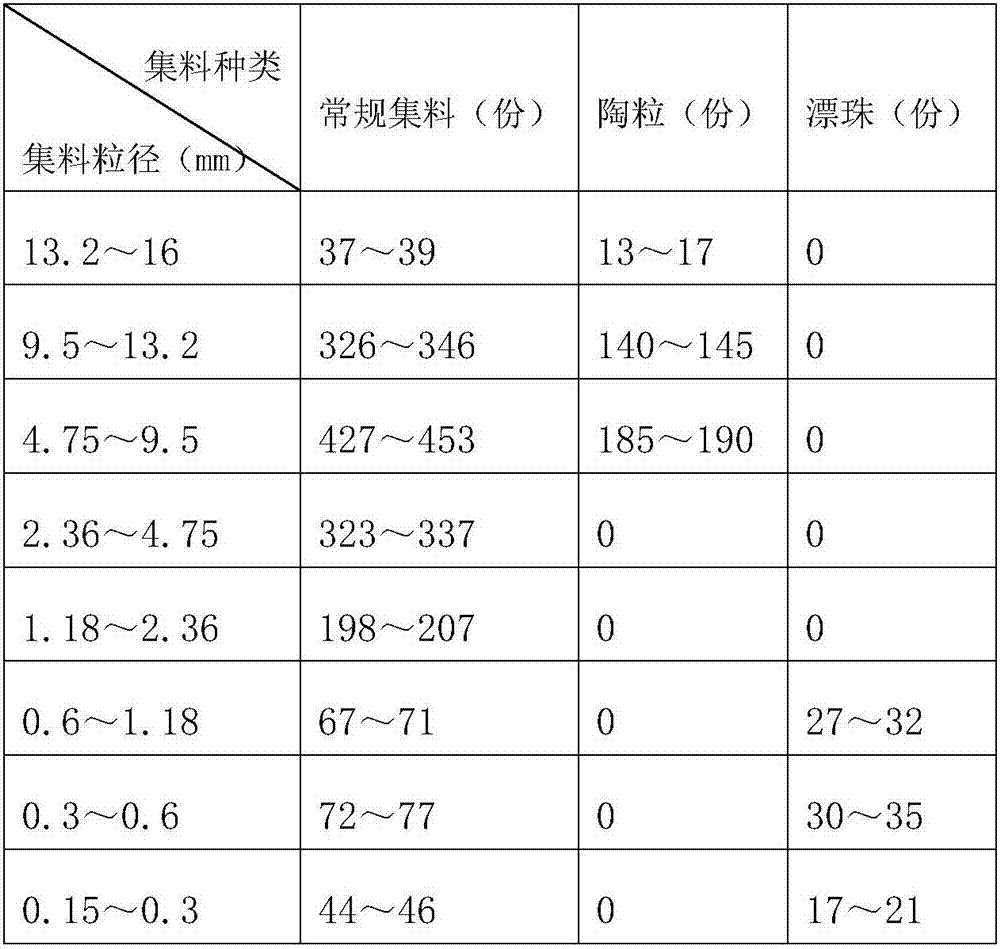

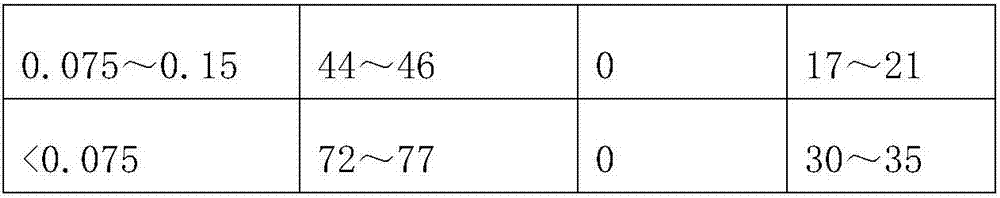

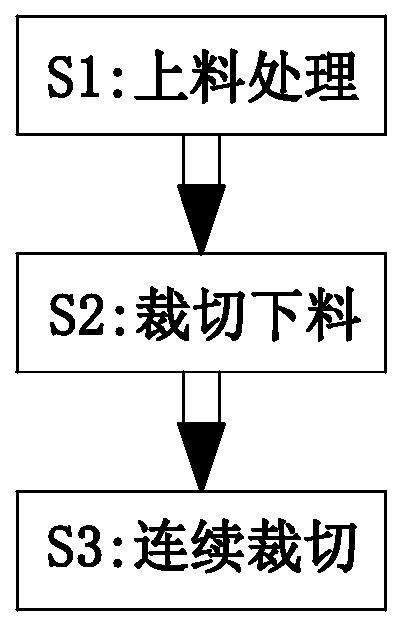

Composite asphalt cooling pavement top layer and construction method thereof

InactiveCN107503261AChange thermal conductivityChange specific heat capacityIn situ pavingsSolid waste managementPermafrostRoad surface

The invention belongs to the field of asphalt concrete pavements and relates to a composite asphalt cooling pavement top layer and a construction method thereof. The construction method comprises following steps: S1, a thermal-resistant asphalt mixture is spread on the top layer of a pavement and then rolled; S2, after the thermal-resistant asphalt mixture rolled in S1 is cured, the upper surface of the thermal-resistant asphalt mixture is coated with a coating; S3, after the thermal-resistant asphalt mixture and the coating are cured, the composite asphalt cooling pavement top layer is formed. Pavement ruts, the urban heat island effect and permafrost subgrade defects can be overcome.

Owner:CHANGAN UNIV

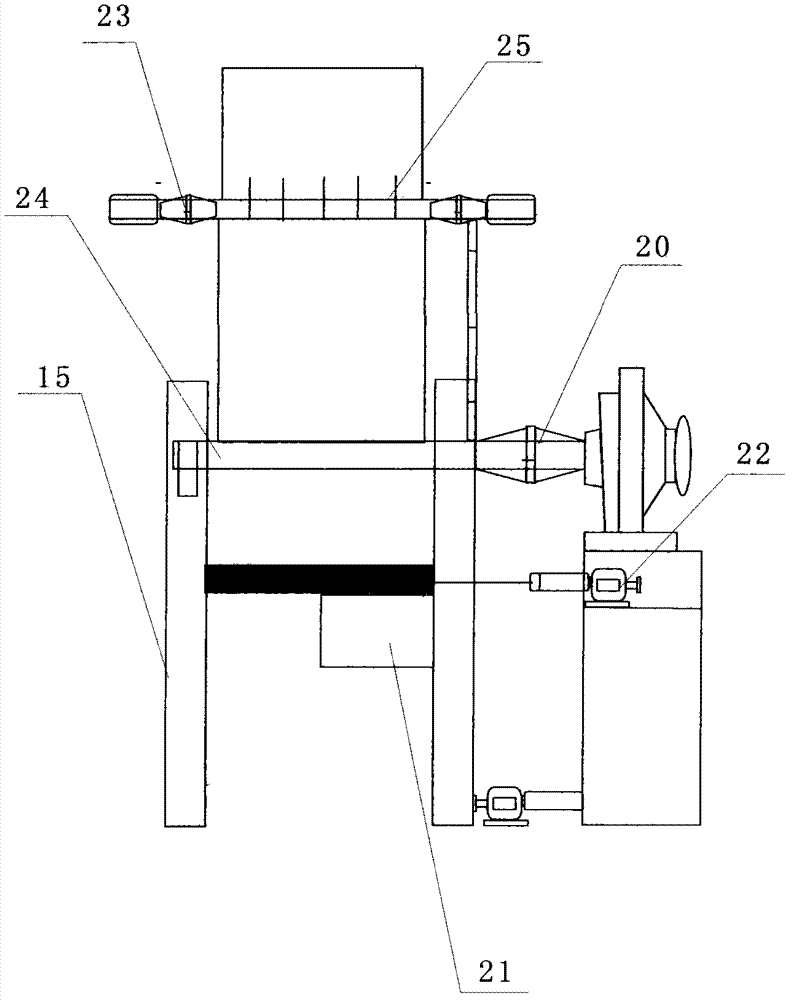

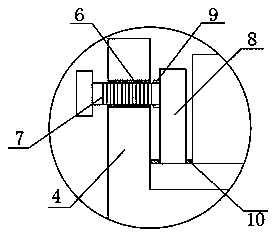

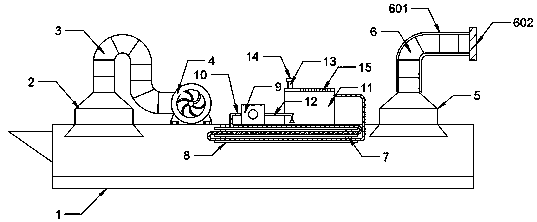

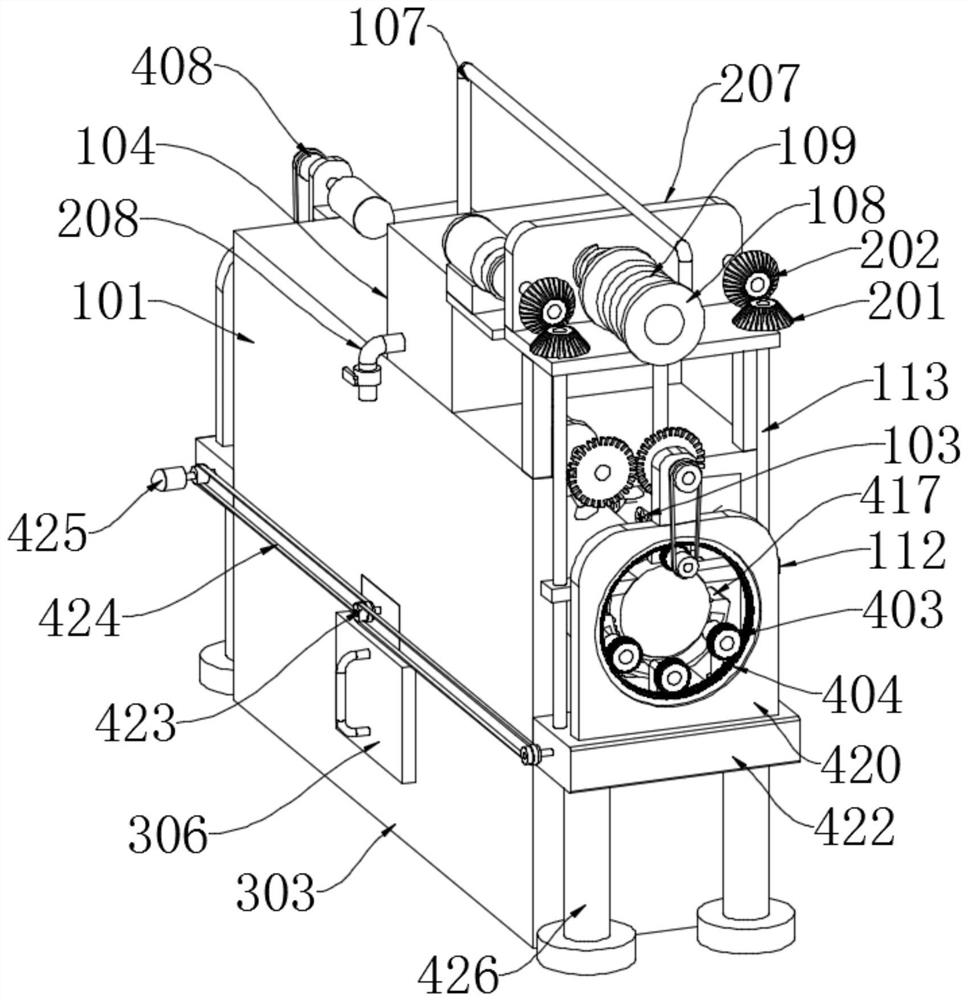

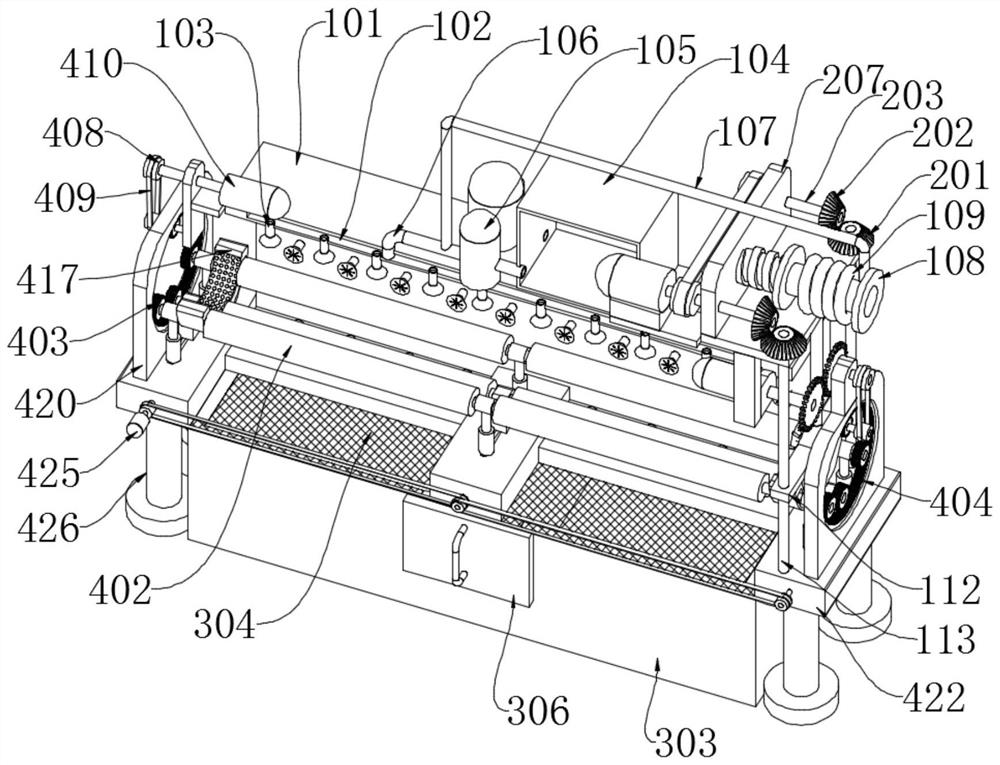

Automatic yeast stirring and cooling machine

InactiveCN103087868AReduce labor intensityTo achieve the purpose of cooling downAlcoholic beverage preparationYeastAutomatic control

The invention discloses an automatic yeast stirring and cooling machine which comprises a material feeding hopper, a yeast feeding box, a wall surface exhaust fan, a stainless steel sieve pore buckling plate conveying belt, a fan, a driving roller, a bracket and a main driving speed reducer, wherein the driving roller is arranged at one end of the bracket, and a driven roller is arranged at the other end of the bracket; the stainless steel sieve pore buckling plate conveying belt is arranged on the driving roller and the driven roller; a stirring rod is arranged on the upper plane of the upper part of the stainless steel sieve pore buckling plate conveying belt; a carrying roller is arranged at the bottom of the lower end of the lower part of the stainless steel sieve pore buckling plate conveying belt; the driving roller is arranged on a main rotating shaft; an adjusting rod is arranged on the driven roller; the fan is vertically arranged on the ground below the bracket; and a power distribution box is arranged on the inner side of the bracket. By adoption of a cooling method in which the fan is used for blowing air and the wall surface exhaust fan is used for exhausting air, the aim of cooling can be fulfilled in the conveying process; an automatic yeast feeding machine is fed in the process, the yeast can be uniformly fed; the temperature can be automatically controlled; the labor intensity of workers is reduced; and the production efficiency and the quality stability of a product are greatly improved.

Owner:湖北三麦酒业有限公司

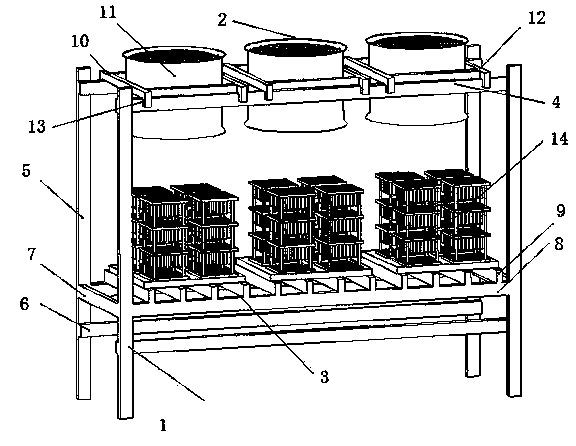

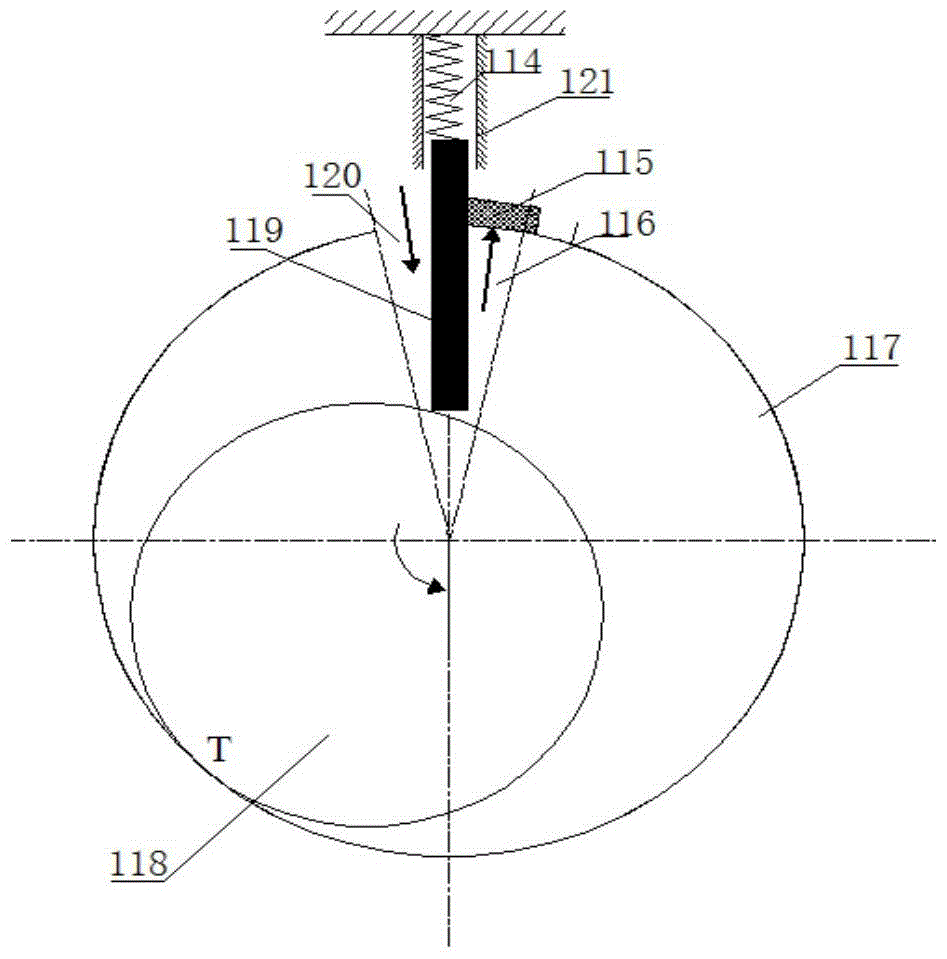

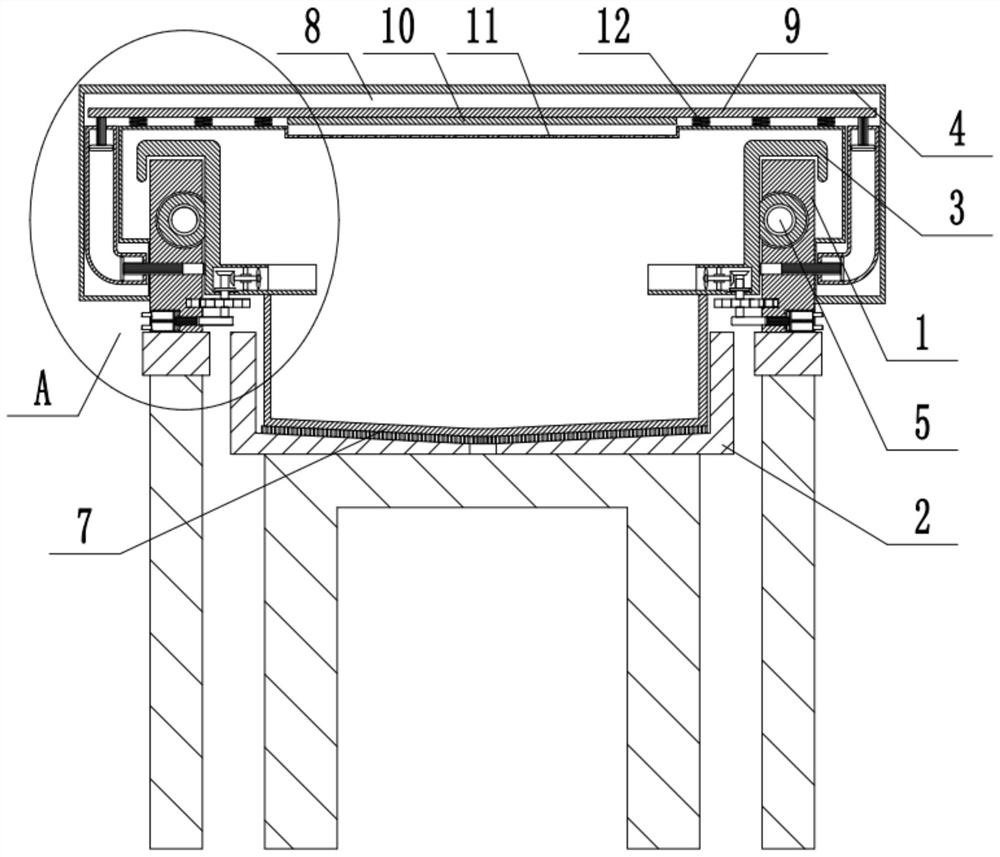

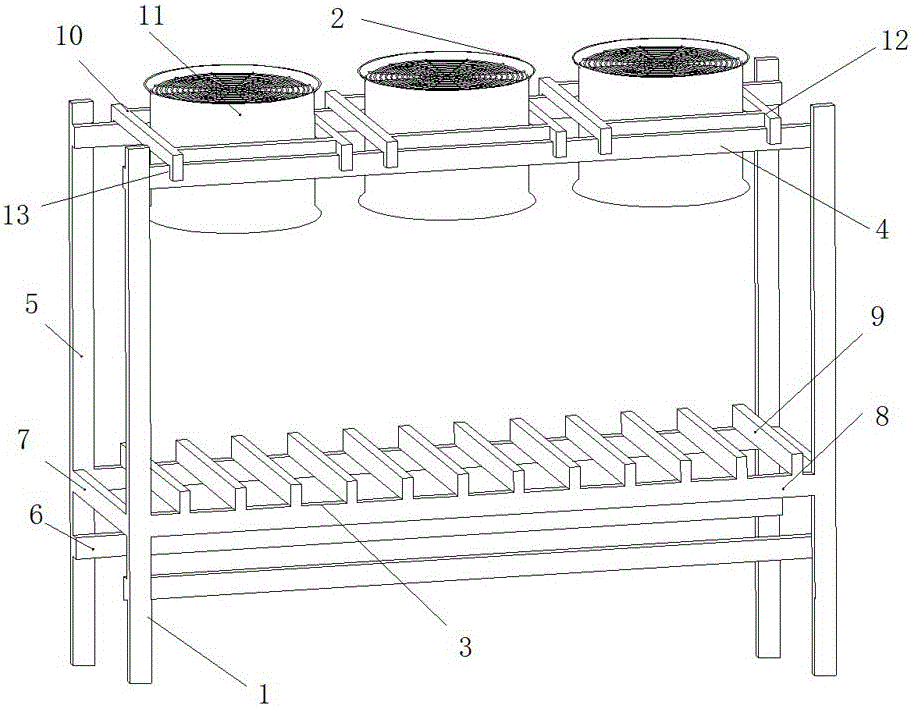

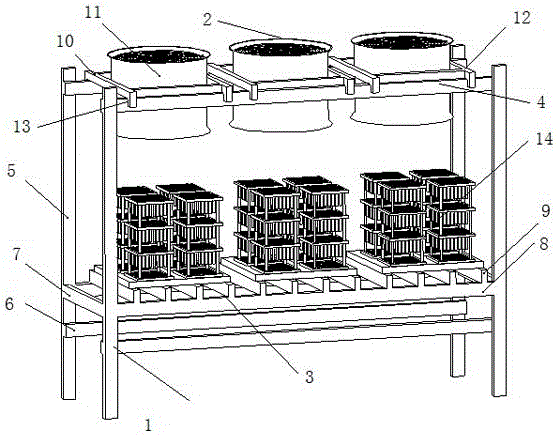

Air cooling device for heat treatment of workpiece

The invention discloses an air cooling device for heat treatment of a workpiece, which comprises a support device and a plurality of air blowing devices arranged on the support device, wherein the lower end of the support device is provided with a bearing part for bearing a workpiece; the air blowing devices for cooling the workpiece are arranged above the bearing part; the upper end of the support device is provided with a first cross beam; and the air blowing devices are arranged on the first cross beam in a movable manner. The air cooling device for heat treatment of a workpiece is simple in structure, convenient to manufacture and uniform in workpiece cooling, and enhances the cooling quality, thereby enhancing the quality of the workpiece, and reducing the deformation and rejection of the workpiece. Thus, the air cooling device has favorable popularization value.

Owner:JOUDER PRECISION INDAL KUSN

Molybdenum-rhenium-lanthanum-potassium big stick and preparation method thereof

The invention relates to a molybdenum-rhenium-lanthanum-potassium big stick and a preparation method thereof. The molybdenum-rhenium-lanthanum-potassium big stick is prepared from, by mass, 0.1-0.45% of rhenium, 0.1-0.25% of lanthanum, 0.1-0.55% of potassium and the balance molybdenum. The preparation method of the molybdenum-rhenium-lanthanum-potassium big stick comprises the following steps that 1, a lanthanum nitrate solution with the lanthanum oxide content being 30.5 g / L, a rhenium sulfide solution with the rhenium heptoxide content being 20.3 g / L, a potassium silicate solution with the potassium oxide content being 58.7 g / L and an ammonium rhenate solution with the amine oxide content being 28.6 g / L are prepared; 2, ammonium tetramolybdate (NH4)Mo4O13.2H2O is reduced to be molybdenum trioxide MoO3 under the temperature condition of 900-920 DEG C in the hydrogen protection state. According to the molybdenum-rhenium-lanthanum-potassium big stick and the preparation method thereof, the structure is simple, use is convenient, the production efficiency is high, and flying dust is effectively reduced.

Owner:JIANGSU DONGTAI FENGFENG TUNGSTEN & MOLYBDENUM MATERIAL

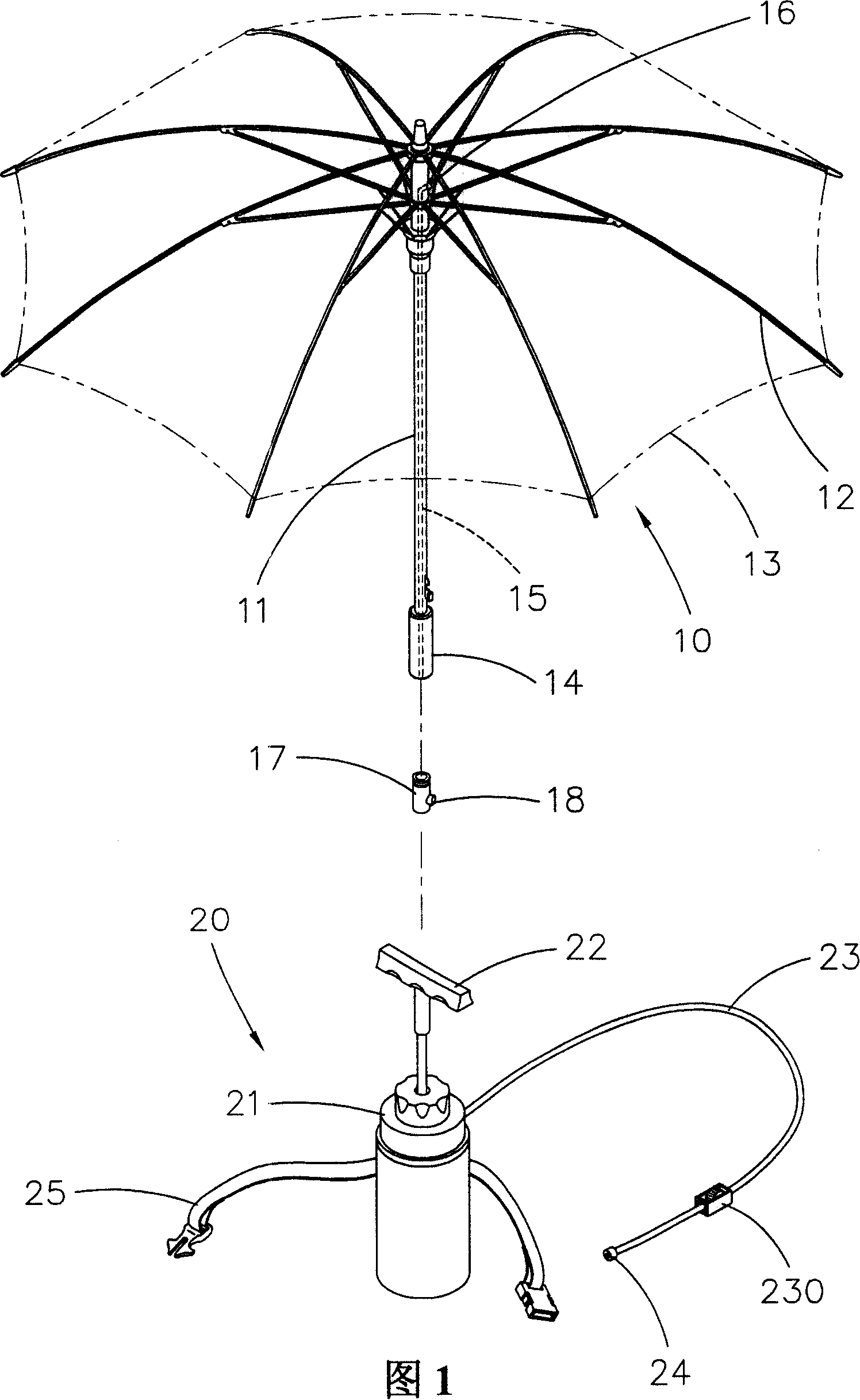

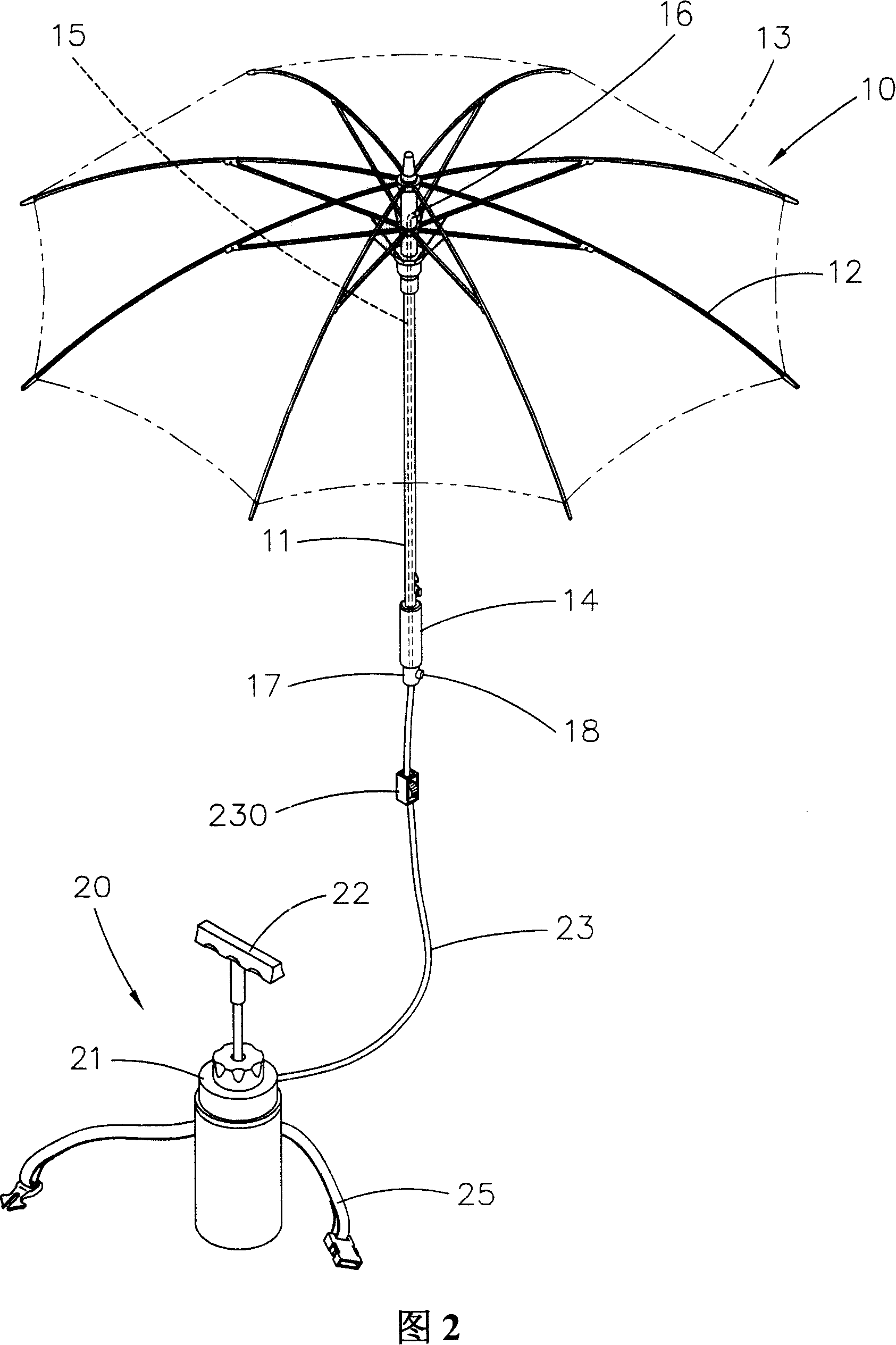

Spraying umbrella

The invention discloses a spraying umbrella, which particularly relates to a spraying umbrella capable of contentious spraying gas or atomizer liquid. The invention comprises an umbrella instrument which is provided with a duct in a hollow standing bar. At least one spraying mouth is provided in the outlet of the duct. A connector communicating with the duct is arranged in the other end of the standing bar facing the spraying mouth. A hydraulic unit is in tandem connection with the fast disassembled joint group of the umbrella, therefore the gas and the atomization liquid transferred to the umbrella duct will spray out through the spraying mouth using high pressure theory. The atomization liquid can be distributed evenly in area close to the operator head with the covering effect by the umbrella face of the umbrella instrument. The purpose of cooling air and avoiding sunstroke can be realized. Additional value can be further increased; also competitive power and economic benefit of the product are increased.

Owner:张宏任

Pig iron casting polishing device with cooling function

InactiveCN110712083AAvoid displacementEasy to fixGrinding carriagesGrinding work supportsEngineeringScrew thread

The invention discloses a pig iron casting polishing device with a cooling function. The pig iron casting polishing device comprises a lower support and an upper support, wherein the lower support andthe upper support are connected by utilizing four groups of stand columns; a clamping groove is formed in the middle position of the upper end face of the lower support; a casting is placed in the clamping groove; thread grooves are symmetrically formed in two side faces of the clamping groove; adjusting bolts are screwed and fixed in the thread grooves; clamping blocks are arranged in the threadgrooves and are positioned at two sides of the casting; bolt protection sleeves connected with the adjusting bolts are mounted on the outer side faces of the clamping blocks; a smooth surface for theclamping blocks to slide is arranged on the bottom surface of the clamping groove. According to the pig iron casting polishing device with the cooling function, disclosed by the invention, cooling water is provided by a water supply tank and the cooling water is changed into atomized liquid drops by utilizing an atomizing nozzle, so that the spraying area is enlarged and wastes of the water are also reduced; the cooling water is sprayed on the upper end face of the casting so that the aim of cooling is realized; the pig iron casting polishing device is suitable for different working conditions and brings a better application prospect.

Owner:安徽省含山县华平铸造厂(普通合伙)

Hotpot condiment filling and shaping system

InactiveCN112644788AImprove cooling efficiencyIncrease productivityWrapper twisting/gatheringLiquid materialEngineeringFood packaging

The invention belongs to the technical field of food packaging, and particularly discloses a hotpot condiment filling and shaping system. The hotpot condiment filling and shaping system is sequentially provided with a packaging device, an arrangement device and a freezing device, the arrangement device comprises a rack, two parallel supporting frames are rotationally connected to the rack, and first conveying belts are fixedly connected to the supporting frames respectively. The distance between the two first conveying belts meets the requirement for supporting a packaging bag in the horizontal state of the supporting frames, and the distance between the two first conveying belts cannot support the packaging bag in the vertical state of the supporting frames. Second conveying belts are arranged under the output ends of the first conveying belts, and the conveying direction of the second conveying belts is perpendicular to the conveying direction of the first conveying belts. The invention aims to provide the hotpot condiment filling and shaping system so as to solve the technical problem of low cooling efficiency of packaging bags.

Owner:重庆好点食品有限公司

Heat exchanger and bell-type furnace with same

PendingCN112710167ACompact structureLow costFurnace typesHeat exchanger casingsProcess engineeringHearth

The invention discloses a heat exchanger and a bell-type furnace with the same. The heat exchanger comprises a shell and a water cooling pipeline for allowing cooling water to pass through, the shell is provided with a heat exchange cavity for allowing gas to pass through, the heat exchange cavity is divided into a plurality of gas chambers, and the multiple gas chamber communicate with one another through communicating holes; the shell is provided with a gas inlet communicating with one gas chamber and a gas outlet communicating with the other gas chamber, and the water cooling pipeline penetrates through the at least two gas chamber. The heat exchanger has the advantages of compact structure, low cost, good heat exchange efficiency and heat exchange effect and the like. The bell-type furnace comprises a furnace body, a kiln car, a heating system, a gas inlet system and a cooling system, the cooling system comprises a fan, a water cooling machine and the heat exchanger, the gas inlet communicates with the hearth of the furnace body through the gas inlet pipeline, the gas outlet communicates with the hearth of the furnace body through a gas outlet pipeline, the two ends of the water cooling pipeline are connected with the water cooling machine, and the fan is arranged on the gas outlet pipeline. The bell-type furnace has the advantages of simple and compact structure, low cost, good heat exchange performance and the like.

Owner:HUNAN JINLU TECH CO LTD

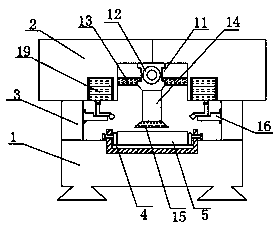

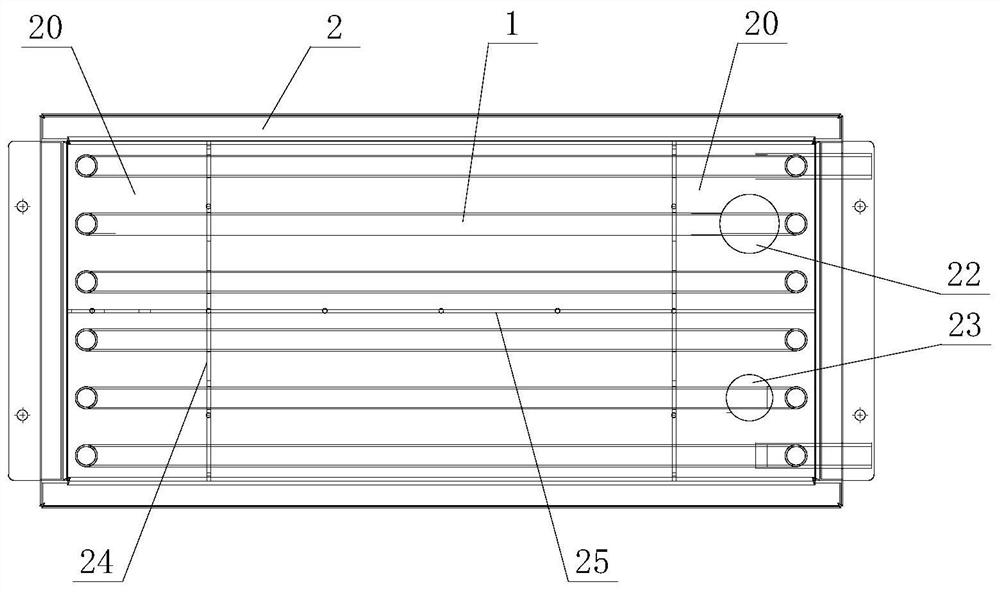

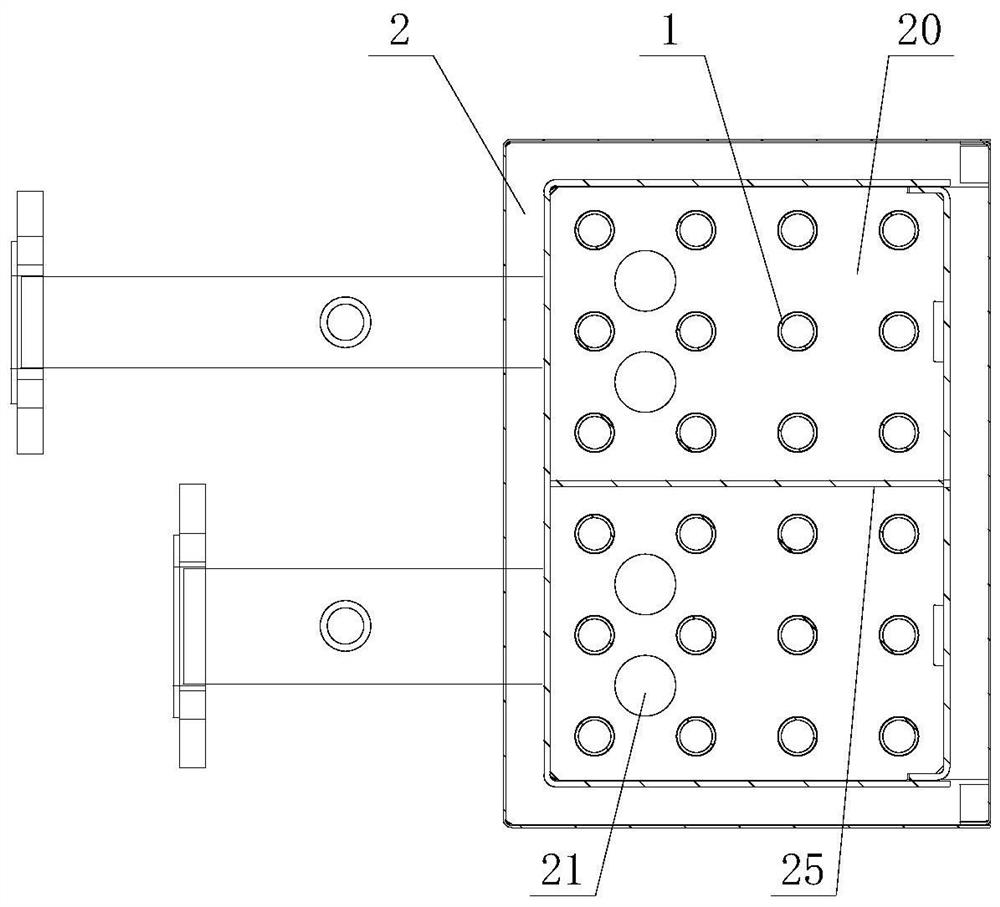

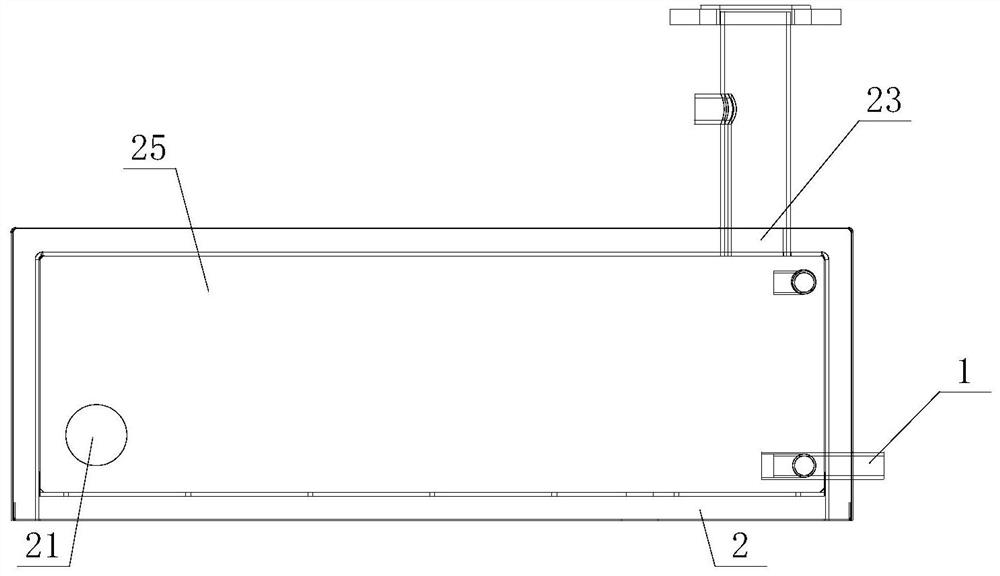

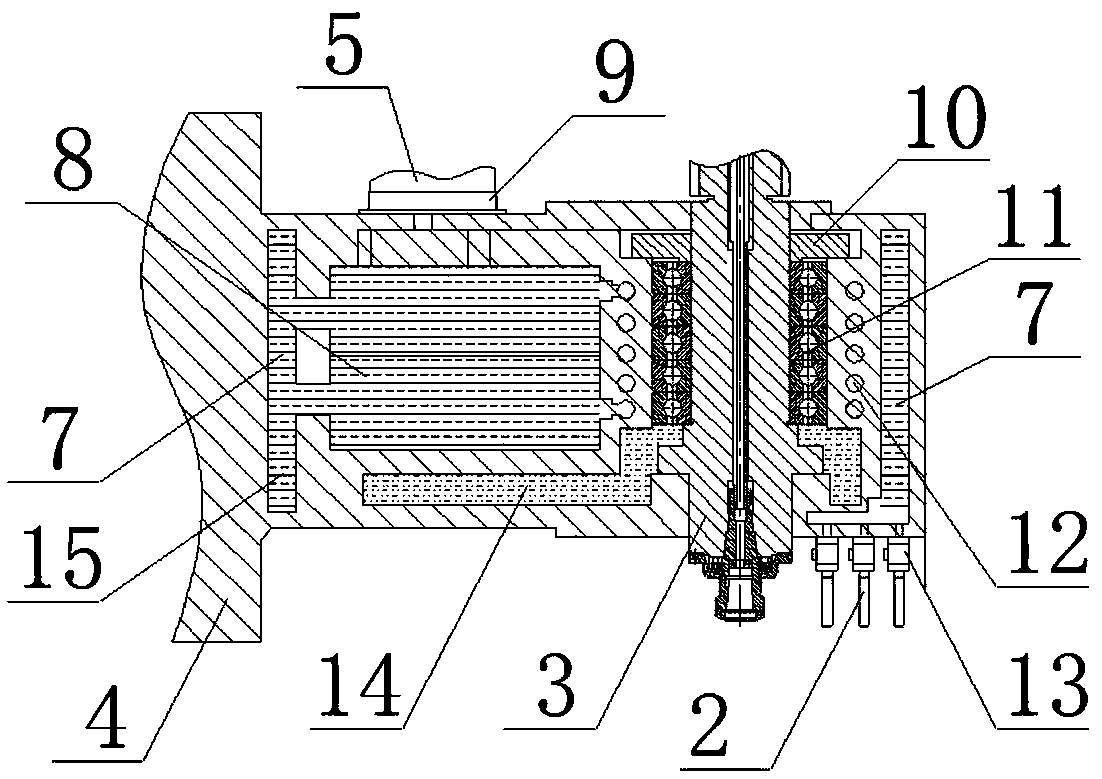

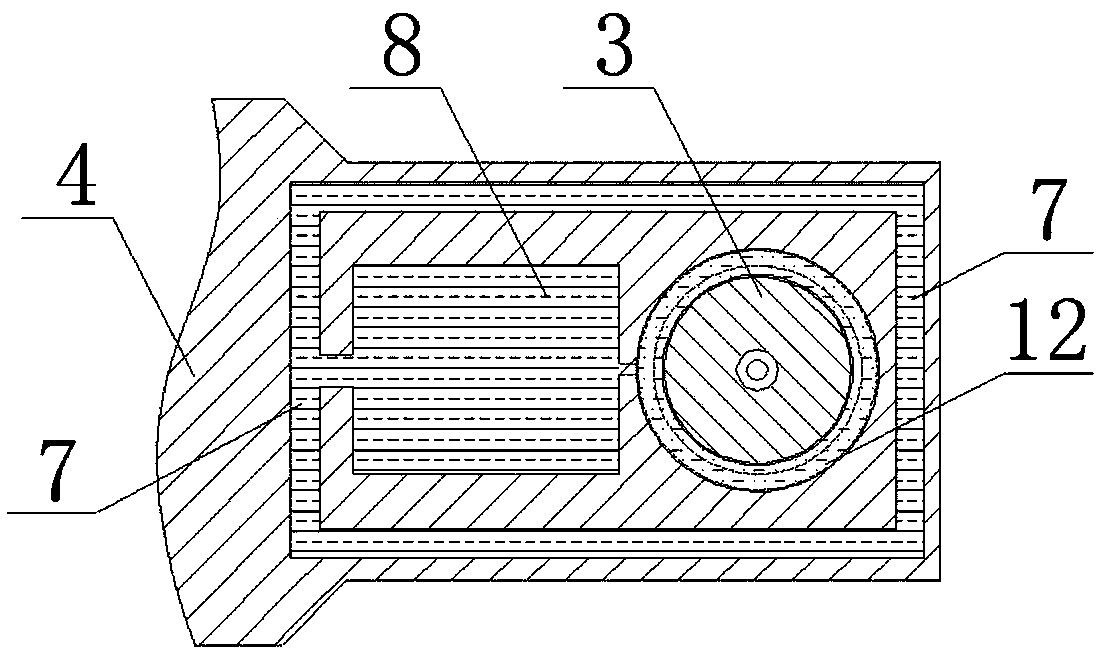

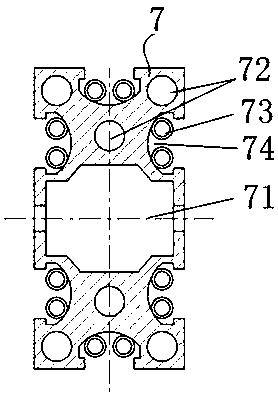

Cooling circulating main shaft box of numerical control machining center

InactiveCN109158949ATo achieve the purpose of cooling downPromote circulationLarge fixed membersMaintainance and safety accessoriesNumerical controlWater storage tank

The invention discloses a cooling circulating main shaft box of a numerical control machining center. The cooling circulating main shaft box of the numerical control machining center comprises a mainshaft box body, a main shaft, a bearing and a bearing cover; a circulating water way is formed around the main shaft box body; a water storage tank is arranged on one side in the main shaft box body;the circulating water way penetrates through the water storage tank; a spiral cooling water pipe is wound at the external of the bearing; the cooling water pipe communicates with the water storage tank; the circulating water way, the water storage tank and the cooling water pipe form a cooling channel; an electromagnetic switch is arranged at the lower part of one end of the main shaft box body, and communicates with the circulating water way; the lower end of the electromagnetic switch communicates a cooling nozzle; and the circulating water way, the electromagnetic switch and the cooling nozzle form another cooling channel. The cooling effect and the machining precision of a machine tool main shaft are improved; the service life of the main shaft and a cutter is prolonged; and the production and investment cost is reduced.

Owner:黄石市友嘉智能科技有限公司

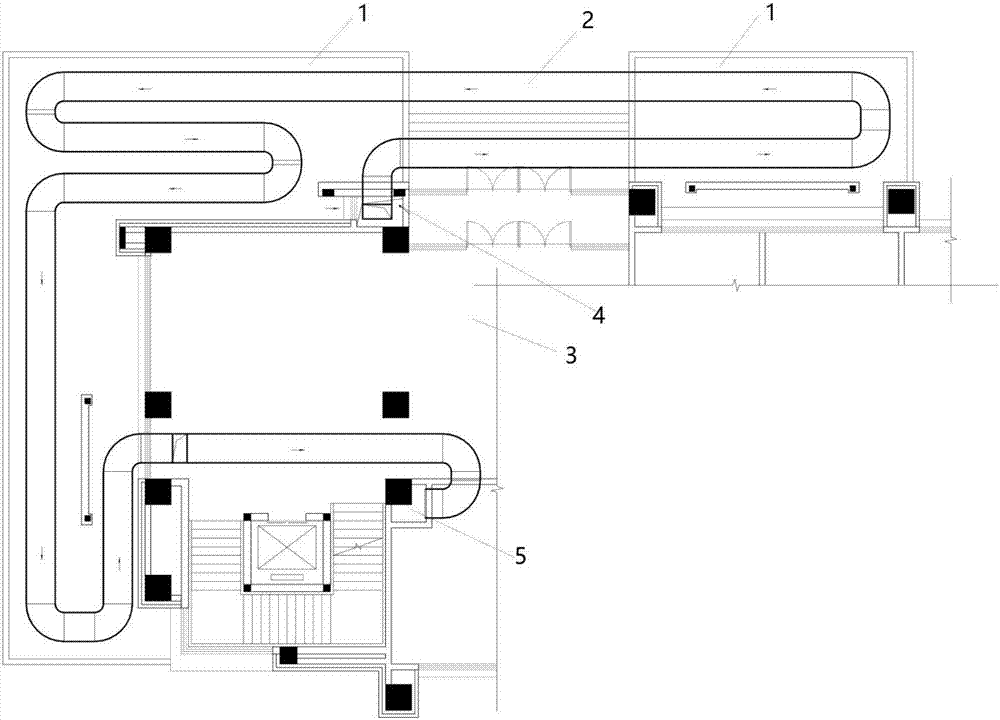

Building fresh air natural cooling system

InactiveCN106979571ATo achieve the purpose of cooling downReduce loadLighting and heating apparatusSpace heating and ventilation detailsBuilding energyFresh air

The invention discloses a building fresh air natural cooling system. By means of the method that finished cement pipe products are buried under an outdoor landscape pond by a certain depth, air exchanges heat with water in the pond through the pipe walls, and thus the cooling purpose is achieved. According to the building fresh air natural cooling system, underground buried pipes can be utilized to cool the air to achieve the purpose that the led-in outdoor air temperature is reduced, the fresh air air-conditioner load of a building is reduced through the storage effect of a stratum on cold and hot energy of the natural world, the indoor hot environment is improved, and the effect of building energy consumption reduction is achieved.

Owner:CHINA UNITED NORTHWEST INST FOR ENG DESIGN & RES

Cooling device for clinker in grate cooler

InactiveCN111156828ATo achieve the purpose of cooling downIncrease cooling rateHandling discharged materialHeat conductingCooling effect

The invention discloses a cooling device for clinker in a grate cooler. The cooling device comprises a grate cooler shell, wherein a blower nozzle is fixedly mounted on one side of the upper end of the grate cooler shell, an air inlet pipe is fixedly mounted at the upper end of the blower nozzle, a blower is fixedly mounted on the side, close to the blower nozzle, of the upper end of the grate cooler shell through a mounting seat, the air outlet of the blower is fixedly connected to the air inlet of the blower nozzle through an air inlet pipe, an air outlet is fixedly formed in the side, far away from the blower nozzle, of the upper end of the grate cooler shell, an air outlet pipe is fixedly mounted at the upper end of the air outlet, a plurality of heat conducting pipes are fixedly mounted in the middle of the upper end of the inner side of the grate cooler shell, and a plurality of heat conducting fin plates are fixedly mounted on the outer side surfaces of the heat conducting pipes. The cooling device is good in using effect, not only can cool clinker in the grater cooler by means of air cooling, but also can take away heat of the clinker in the grate cooler through a water flow quickly, and is good in cooling effect and high in cooling rate.

Owner:NANJING RUITAI CEMENT MFG EQUIP CO LTD

Two-phase refrigeration and gas compression integrated electronic equipment cooling system

ActiveCN104864624BGuaranteed temperatureReduce energy consumptionMechanical apparatusFluid circulation arrangementEvaporation heat transferSignal on

The invention discloses a cooling system for electronic equipment integrating two-phase refrigeration and gas compression, which comprises an integral power core of a pump / compressor, a filter, a flow meter, a first four-way reversing valve, an evaporator, and a condenser The device, the second four-way reversing valve, the gas-liquid separator and the separation branch contain two one-way valves, an electronic expansion valve and a flow regulating valve. The cooled electronic equipment is attached to the heat exchange cold plate of the evaporator, and the highest temperature signal on the surface of the electronic equipment controls the reversing action of the two four-way reversing valves. Under normal working conditions, the system uses a two-phase cooling method to cool electronic equipment by boiling heat exchange in the evaporator, which has the characteristics of energy saving. When the ambient temperature changes or the heat load increases, when the surface temperature of the electronic equipment exceeds the set value, the control equipment takes an action signal to reduce the temperature of the electronic equipment in the form of gas compression refrigeration, and overcomes the two-phase cooling under high ambient temperature conditions. Insufficient to ensure the normal operation of electronic equipment.

Owner:XI AN JIAOTONG UNIV

Cold supply system for village breeding plant

InactiveCN108224627AOptimize layoutTo achieve the purpose of cooling downWind energy with electric storageLighting and heating apparatusProcess engineeringElectricity

The invention discloses a cold supply system for a village breeding plant. The cold supply system for the village breeding plant comprises cold radiation modules arranged on the inner sides of two opposite lateral walls of a workshop and evaporation cooling systems arranged on the outer sides of the remaining two lateral walls of the workshop. The cold radiation modules and the evaporation coolingsystems are connected with a distribution type wind power system. According to the cold supply system, the radiation cold supply technology and the wind power generation technology are combined basedon the evaporation cooling technology, and the air inside the village breeding plant is cooled through natural cold sources such as deep phreatic water.

Owner:XI'AN POLYTECHNIC UNIVERSITY

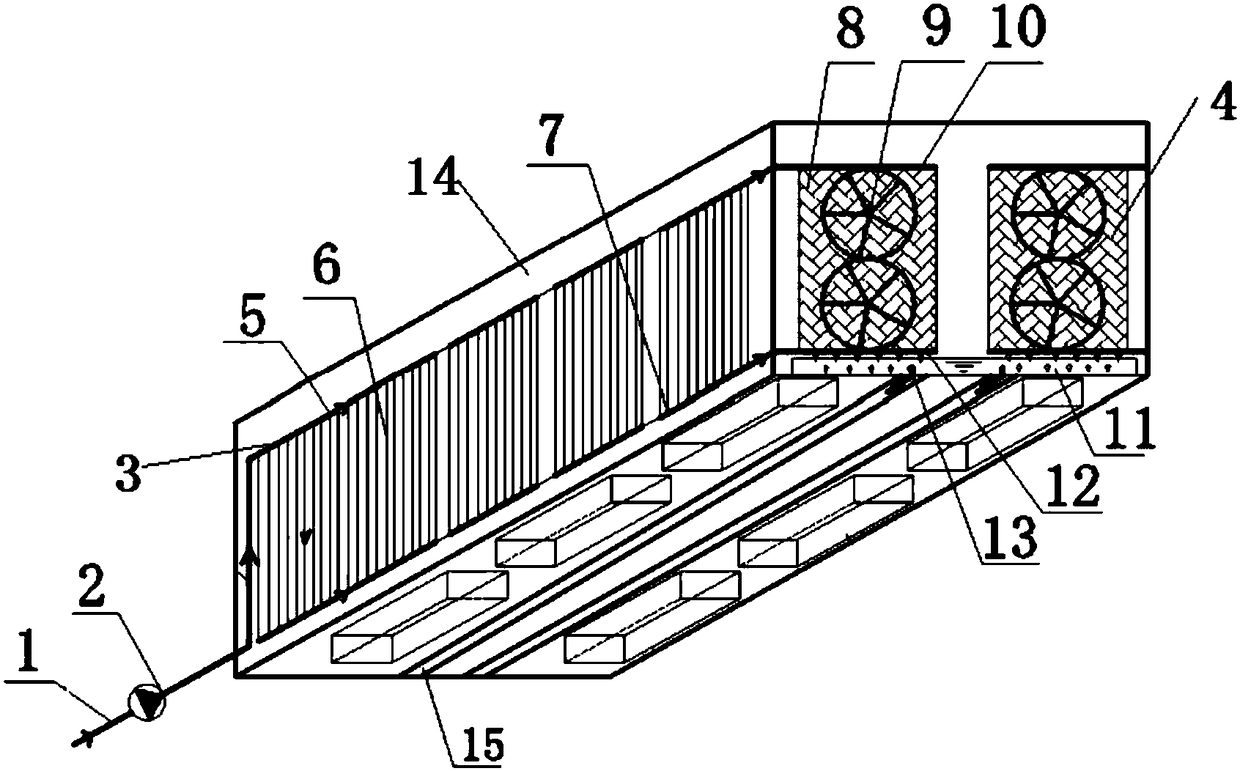

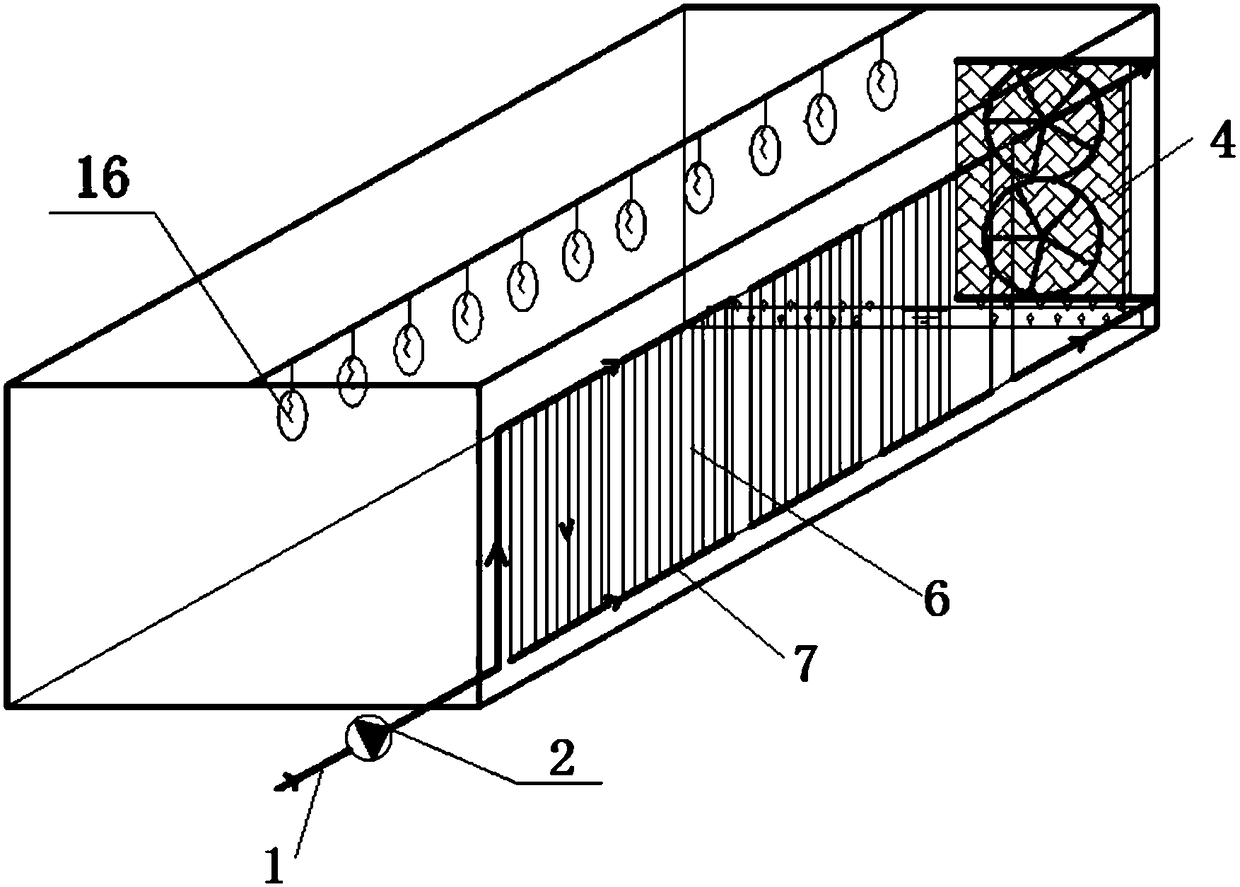

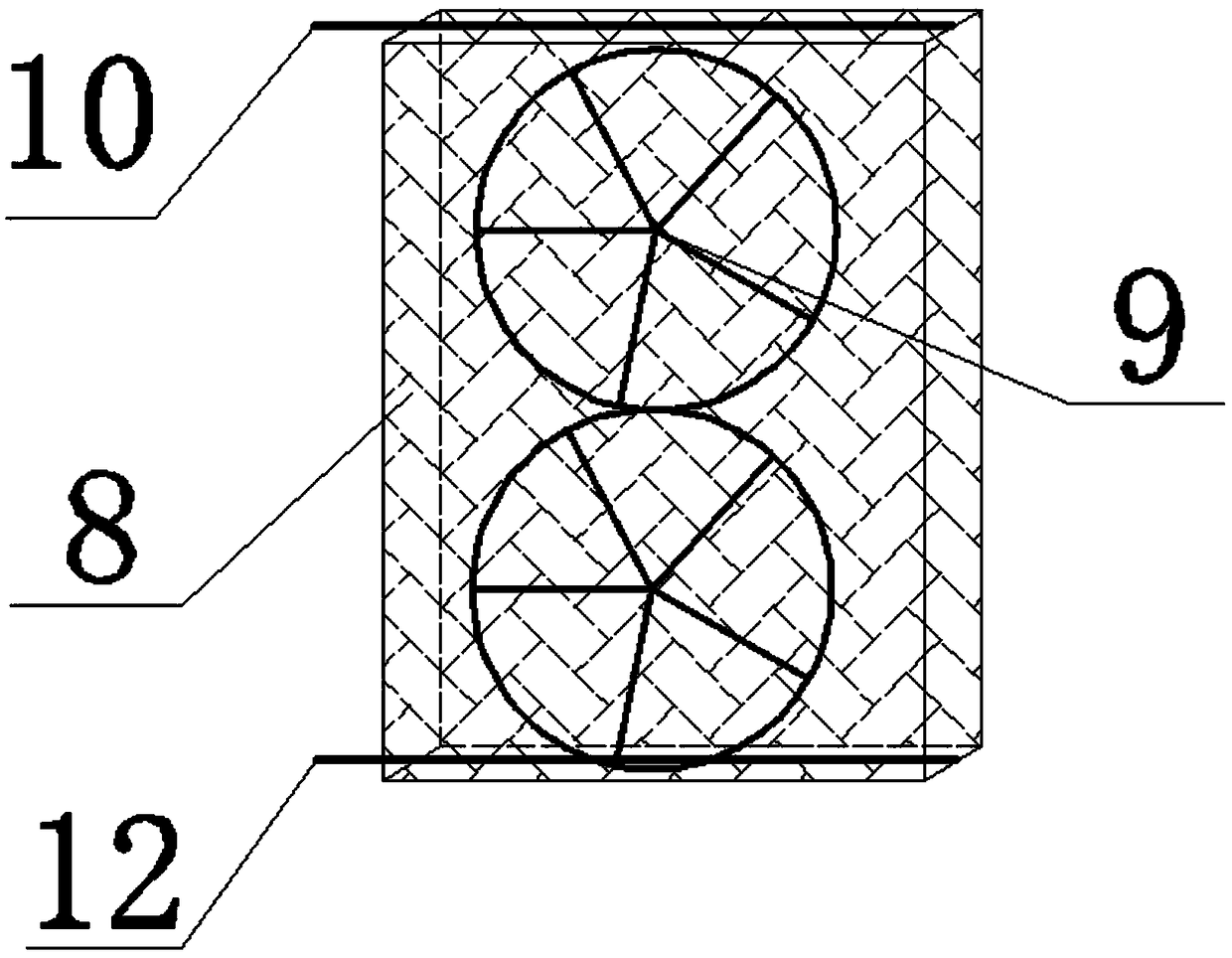

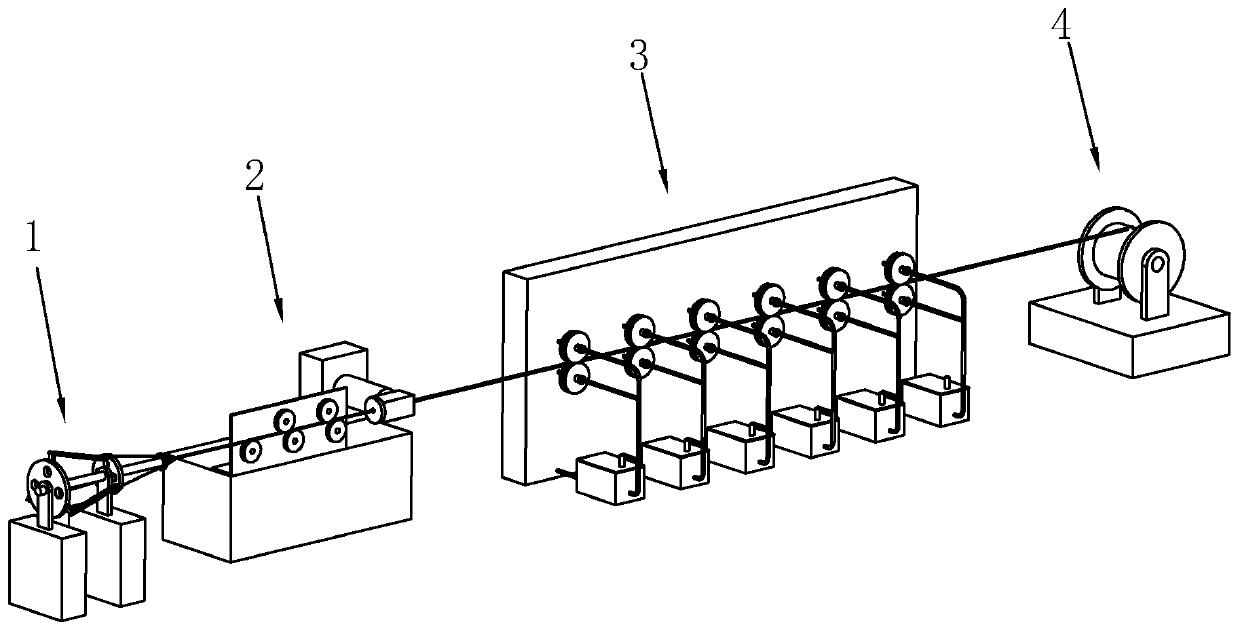

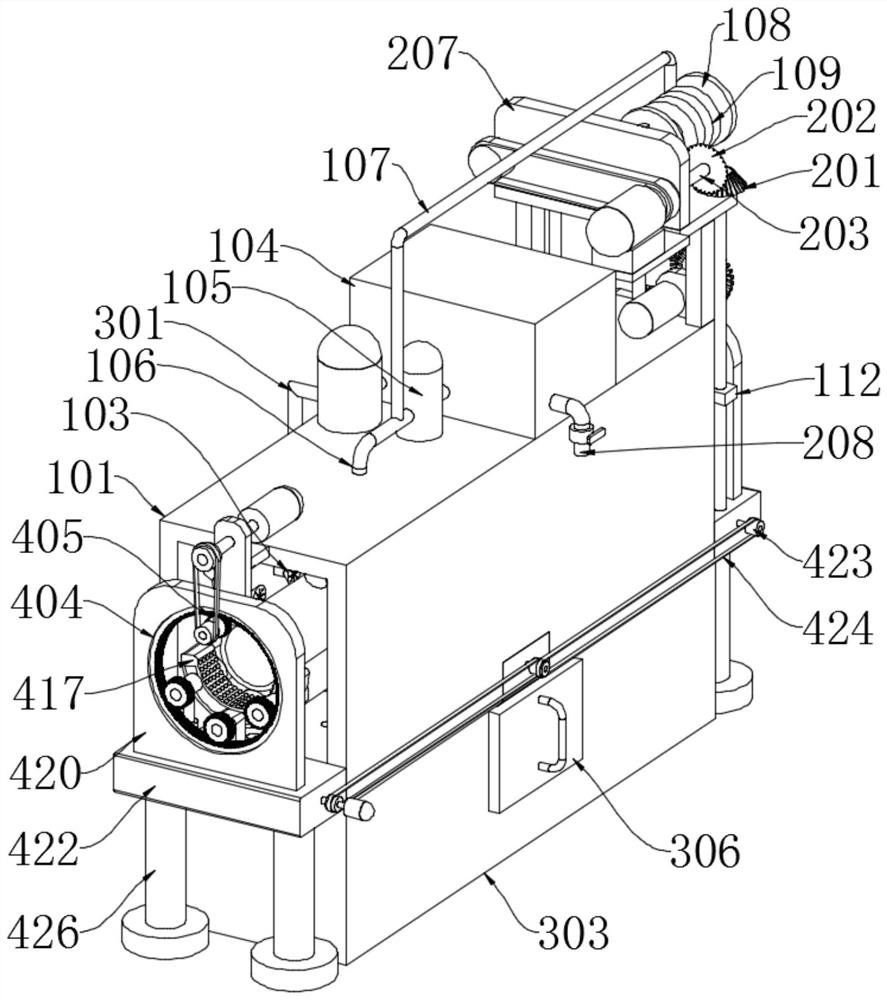

Bunchy optical cable sheath extrusion production line

ActiveCN111487737AImprove cooling effectTo achieve the purpose of cooling downFibre mechanical structuresProduction lineEngineering

The invention relates to a bunchy optical cable sheath extrusion production line, which comprises a cooling mechanism. The cooling mechanism comprises two cooling wheels arranged up and down and a mounting table, wherein the two cooling wheels are rotationally arranged on the mounting table, and the axes of the two cooling wheels are parallel; an optical cable passes through the space between thetwo cooling wheels, and the surface of the optical cable abuts against the ends, close to each other, of the axis side surfaces of the two cooling wheels; a cavity is formed in each cooling wheel andused for containing cooling liquid for cooling the optical cable; a liquid inlet pipe is arranged on the surface at one side of the cooling wheel, and one end of the liquid inlet pipe communicates with the cavity; a liquid outlet pipe is arranged on the surface of the other side of the cooling wheel, and one end of the liquid outlet pipe is also communicated with the cavity; and sealing assembliesare arranged at the joint of the liquid inlet pipe and the cooling wheel and the joint of the liquid outlet pipe and the cooling wheel. According to the invention, the optical cable is not contactedwith water during water cooling, so that cooling water is effectively prevented from being attached to the surface of the optical cable, and the optical cable can be continuously processed after beingcooled and shaped.

Owner:TAKFLY COMM

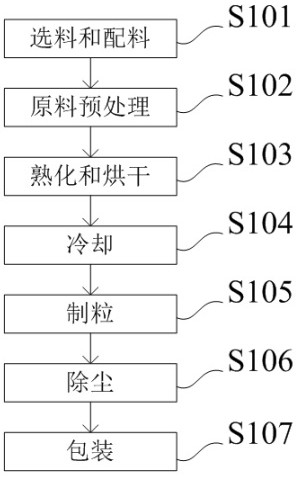

Concentrated feed for suckling pigs and production method of concentrated feed

InactiveCN111642643AHelp secretionPromote digestion and absorptionFood processingAnimal feeding stuffBiotechnologySophocarpidine

The invention provides a concentrated feed for suckling pigs and a production method of the concentrated feed. The formula of the concentrated feed for the suckling pigs comprises the following components in parts by weight: 10-20 parts of wheat bran, 20-30 parts of rice bran, 2-5 parts of rapeseed meal, 5-8 parts of puffed soybeans, 7-10 parts of fish meal, 3-5 parts of blood powder, 10-20 partsof premix, and 3-5 parts of plant additive, wherein the rapeseed meal is 200 type rapeseed meal; the invention belongs to the technical field of concentrated feed for suckling pigs. The plant additiveis added in the concentrated feed, radix sophorae flavescentis contains sophocarpidine, secretion of gastric juice of the suckling pigs is facilitated, the digestive absorption capacity of the suckling pigs is improved, the purposes of relieving summer heat and cooling are achieved in cooperation with wrinkled giant hyssop leaves, the phenomenon that the suckling pigs get sick in summer is avoided, the appetite of the suckling pigs is promoted through hawthorn, the feed intake of the suckling pigs is increased, and growth and development of the suckling pigs are facilitated; according to themethod, the curing step is set, the feed raw materials are cured, so that the feed raw materials are fully cured, the taste of the concentrated feed is improved, and meanwhile, the diarrhea probability of suckling pigs is reduced.

Owner:安徽牧仕达饲料科技有限公司

Processing technology of corrosion-resistant stainless steel seamless steel pipe

ActiveCN114769354AIncrease cooling rateTo achieve the purpose of cooling downWork cooling devicesMetal rolling arrangementsSteel tubeElectric machinery

The invention discloses a processing technology of a corrosion-resistant stainless steel seamless steel tube, and particularly relates to the technical field of seamless steel tube processing, and the processing technology comprises the following specific steps: S1, selecting a lossless round tube blank which has good corrosion resistance so as to ensure that a prepared stainless steel tube is relatively high in corrosion resistance; then cutting a round tube blank according to the required steel tube specification; s2, heating the selected round tube blank to enable the round tube blank to reach a plastic deformation state; according to the steel pipe cooling device, water is sprayed to the outer end and the inner wall of a steel pipe through a spray head and a water outlet pipe in the cooling mechanism, and the purpose of cooling the interior and the exterior of the steel pipe at the same time is achieved; and the rotating rollers can be used for driving the steel pipes placed at the outer ends of the rotating rollers to rotate, so that the spray heads can spray the steel pipes from the outer ends in all directions, dead angles are avoided, and the cooling rate of the steel pipes is increased.

Owner:JIANGSU ZHENGTAI STAINLESS STEEL IND CO LTD

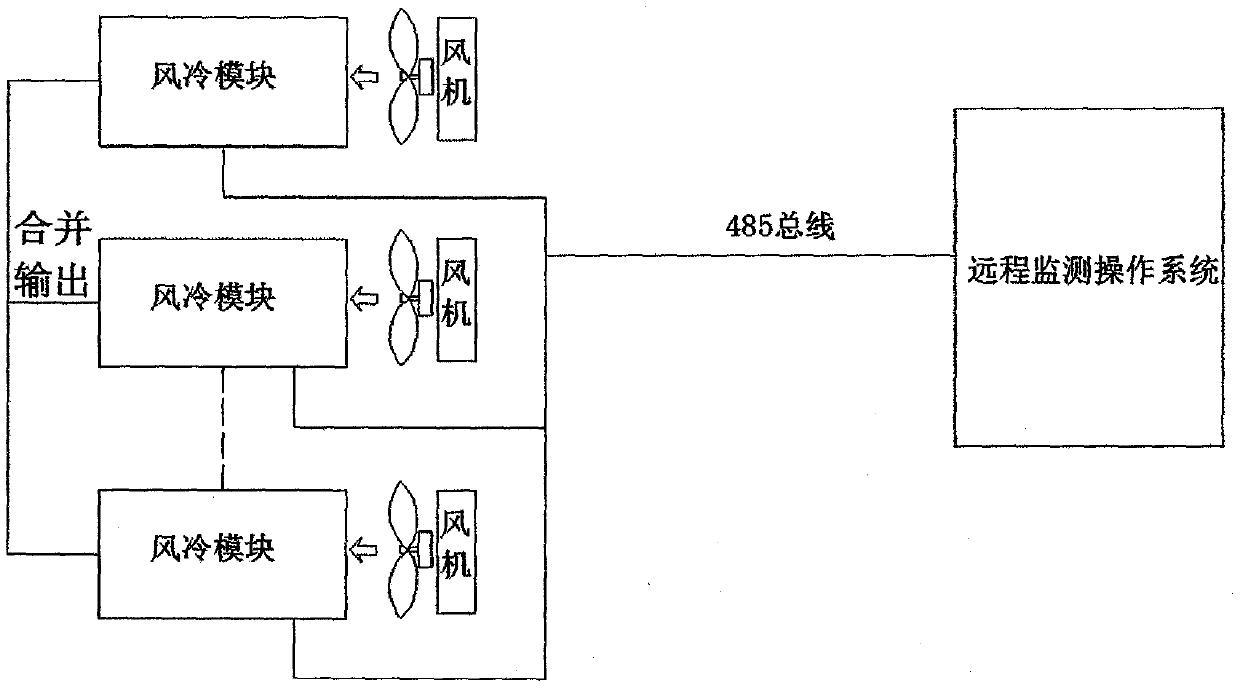

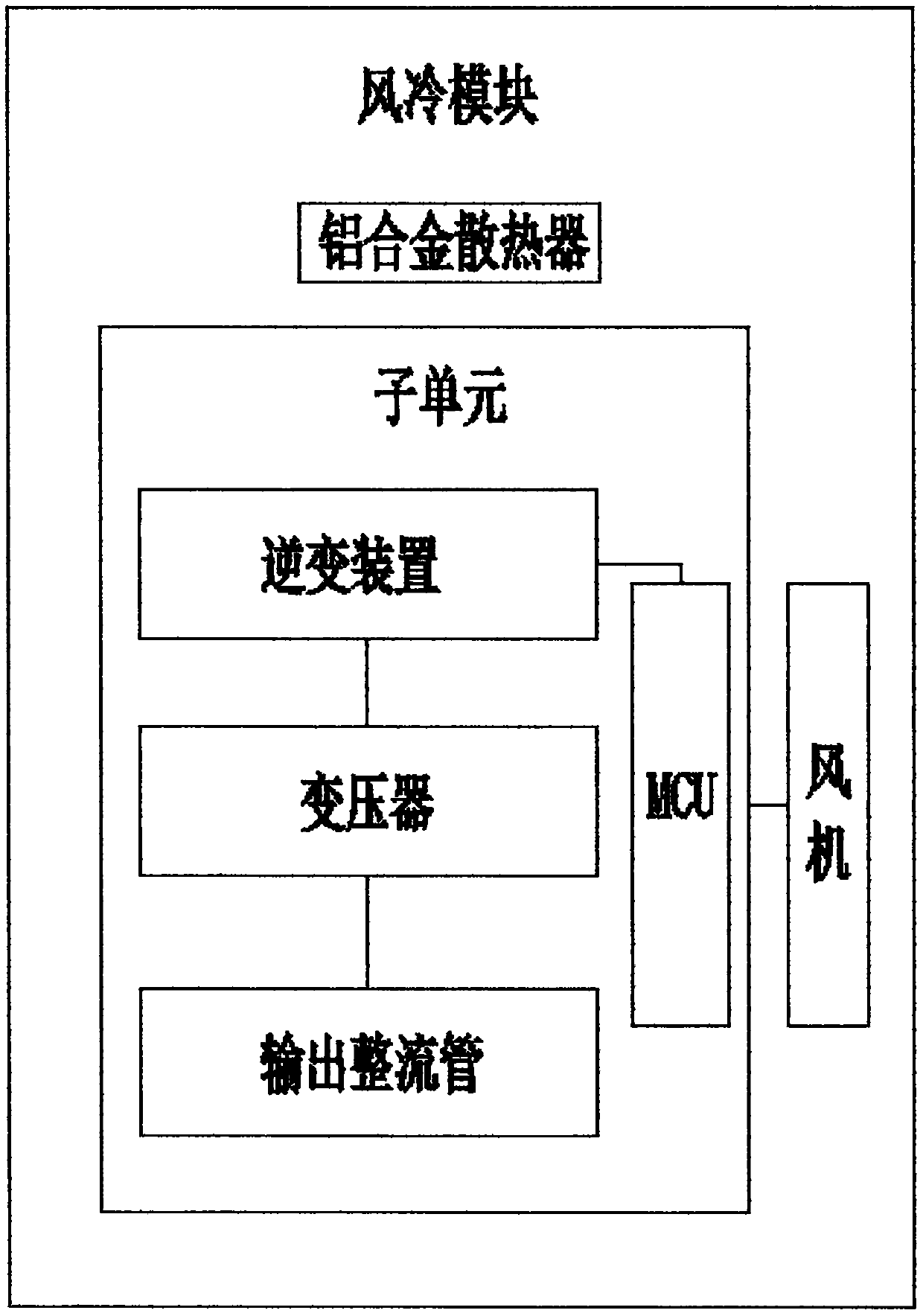

1000A air-cooled oxidation high-frequency power supply

ActiveCN110572009AReduce flow rateAvoid damageModifications for power electronicsPower conversion systemsHigh frequency powerHigh energy

The invention belongs to the technical field of high-frequency power supplies and in particular to a 1000A air-cooled oxidation high-frequency power supply. In view of the problem that a conventionalwater-cooled high-frequency oxidation power supply requires an additional water cooling system such as a refrigerator, a spray tower, a circulating water pump and the like which are difficult to install, have high energy consumption, and cause water pollution by the discharged cooling water, the 1000A air-cooled oxidation high-frequency power supply includes a remote monitoring operating system, a485 bus and multiple air cooling modules, wherein the remote monitoring operating system is connected with the multiple air cooling modules through the 485 bus; the multiple air cooling modules are connected in parallel to jointly output a current of more than 10000A; each air cooling module includes an aluminum alloy radiator, a sub-unit, and a fan. The heat generated by heat-generating components is forcibly discharged in an air-cooling manner to achieve a cooling purpose, and the structure greatly enhances a heat dissipation effect without consuming more energy. The 1000A air-cooled oxidation high-frequency power supply has a simple structure and low cost.

Owner:张家港克林特电源科技有限公司

An automatic cooling sealed power cabinet

ActiveCN109449800BPrevent moistureGuaranteed normal operationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsMechanical engineeringCooling pipe

The invention discloses an automatic cooling and sealing power cabinet, which comprises a sealed cabinet body, a fixed base is arranged on the top of the sealed cabinet, and a cooling bottom box is arranged on the bottom of the fixed base, inside the cooling bottom box A cooling tank groove is provided, and fine sand is arranged in the cooling tank groove, and a plurality of conveying cylinders are arranged in the cooling tank groove, and a first sliding chamber is respectively arranged in the conveying cylinders, and the first sliding chambers A sliding cooling cylinder is respectively arranged in the cavity, and a cooling chamber is respectively arranged in the cooling cylinder, and a plurality of cooling pipes are arranged in the cooling chamber, and a Corresponding to the connected cooling air holes, the fine sand in the cooling tank can be further cooled by the underground temperature, so that the cooling pipe can be further lowered, so that the air in the cabinet cavity can be circulated to the cooling air. In the process of holes, the purpose of cooling the inner cavity of the cabinet is further achieved.

Owner:江苏楚能电控设备有限公司

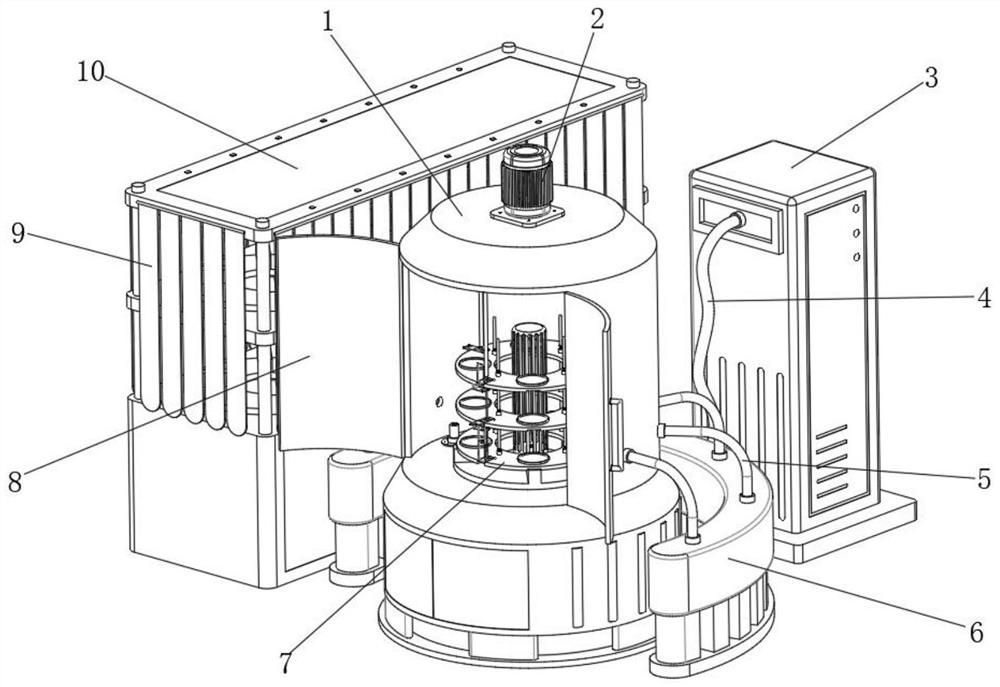

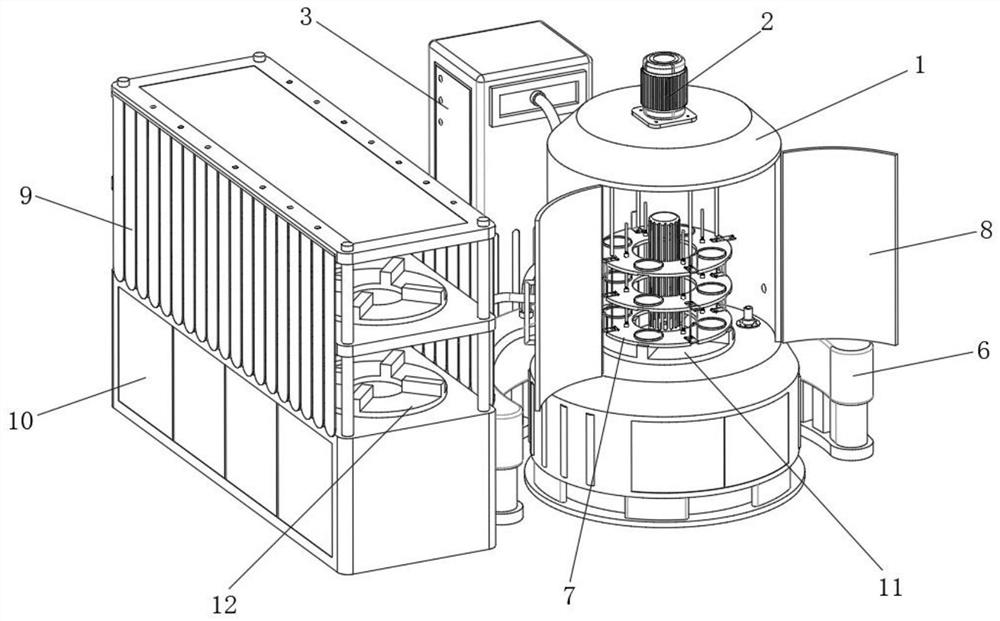

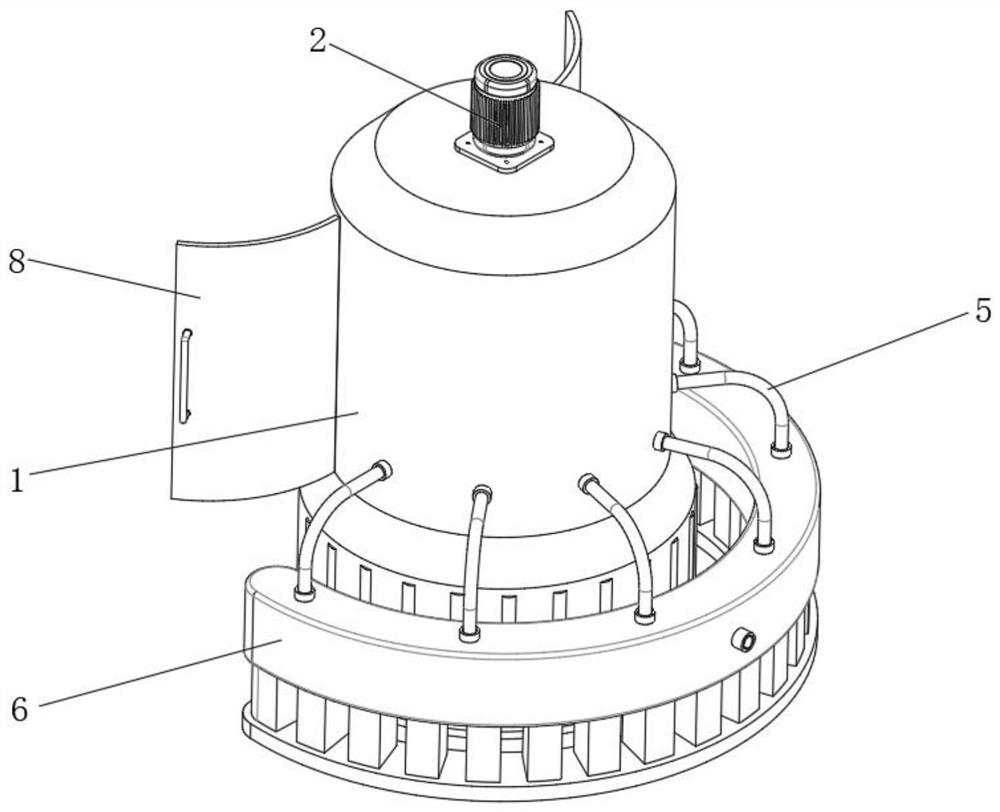

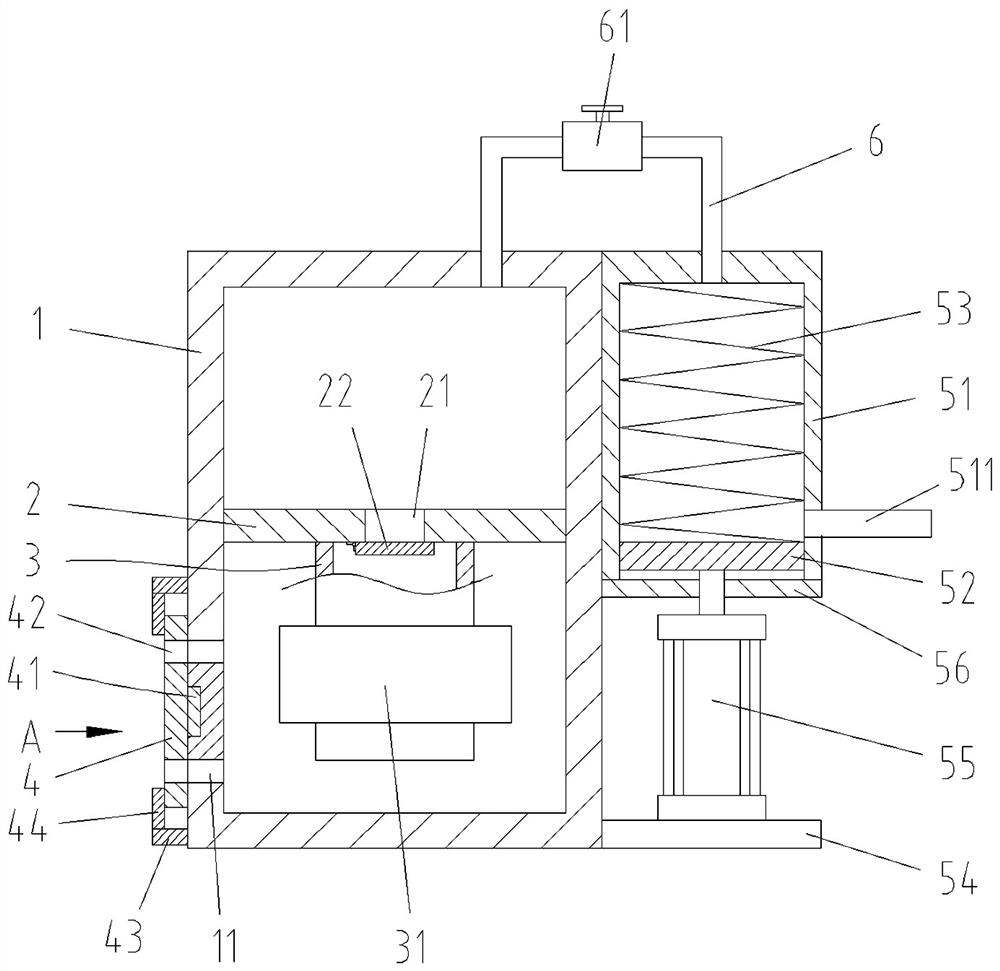

Platform system for manufacturing tea set and wine set by using alkaline earth

PendingCN114111341AEvenly heatedAvoid the problem of heating dead endsCharge composition/stateCharge manipulationThermodynamicsElectric machine

The invention discloses a platform system for manufacturing tea sets and wine sets from alkaline earth, and relates to the technical field of tea set and wine set manufacturing. The firing effect is improved; the platform system comprises a firing furnace and an annular bearing frame, a motor is installed on the top of the firing furnace through a motor base, and the output end of the motor is rotationally connected with a rotating frame; the safety management method comprises the following steps: carrying out safety inspection on a firing furnace before firing; water is injected into the communicating chamber, and the liquid level is controlled to be lower than one end of the main conveying pipe. By arranging the motor and the linkage mechanism, a user can make a strip-shaped rotating block at one end of a linkage telescopic rod penetrate through a first strip-shaped hole of the annular bearing frame and then rotate by 90 degrees, the strip-shaped rotating block is clamped in a clamping groove under the acting force of a spring, and therefore the annular bearing frame and the rotating frame are connected through the linkage mechanism; and the annular bearing frame is driven to rotate, so that the tea set and the wine set can be uniformly heated in the firing process.

Owner:碱蓬先创科技(盘锦)有限公司

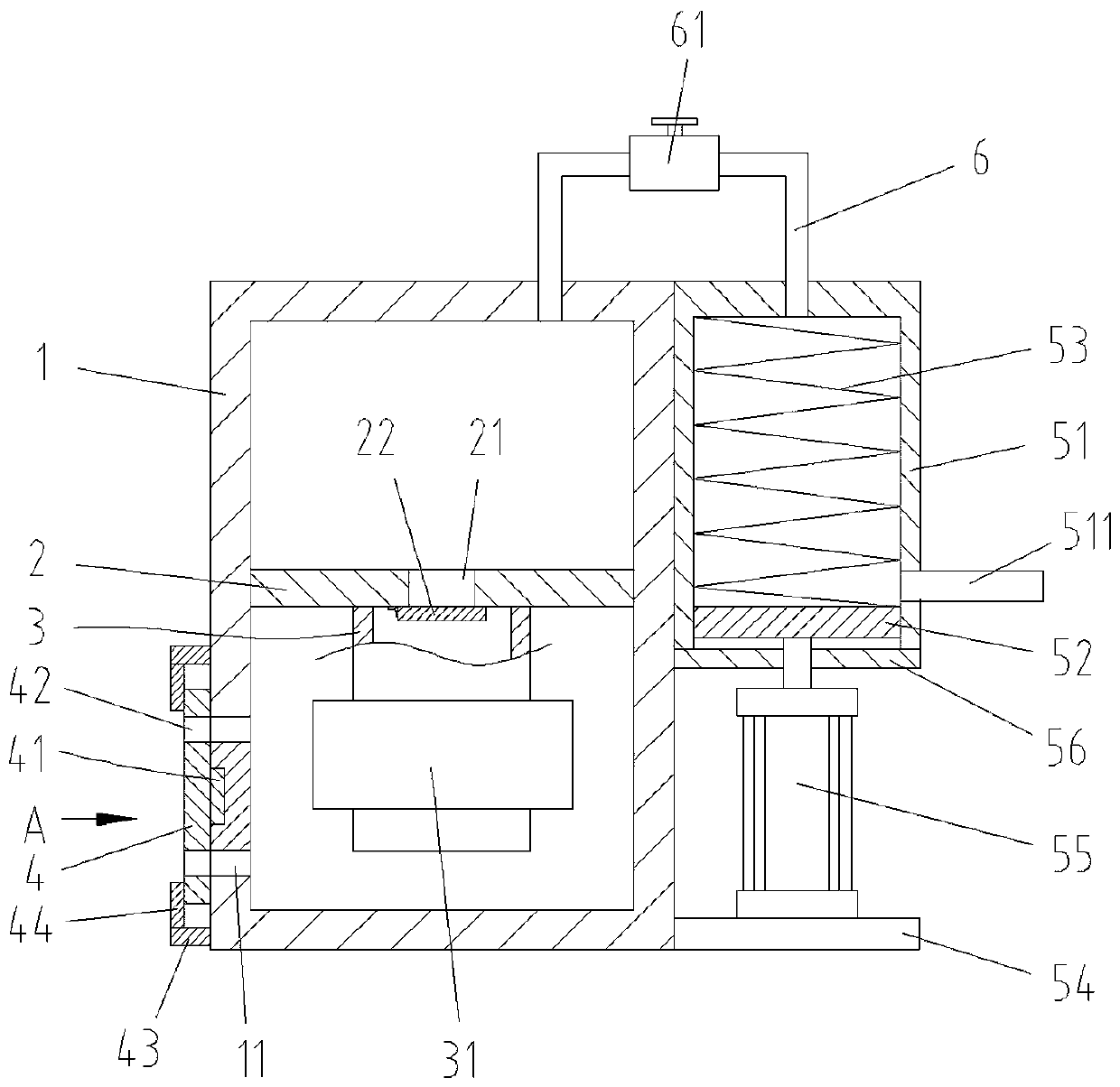

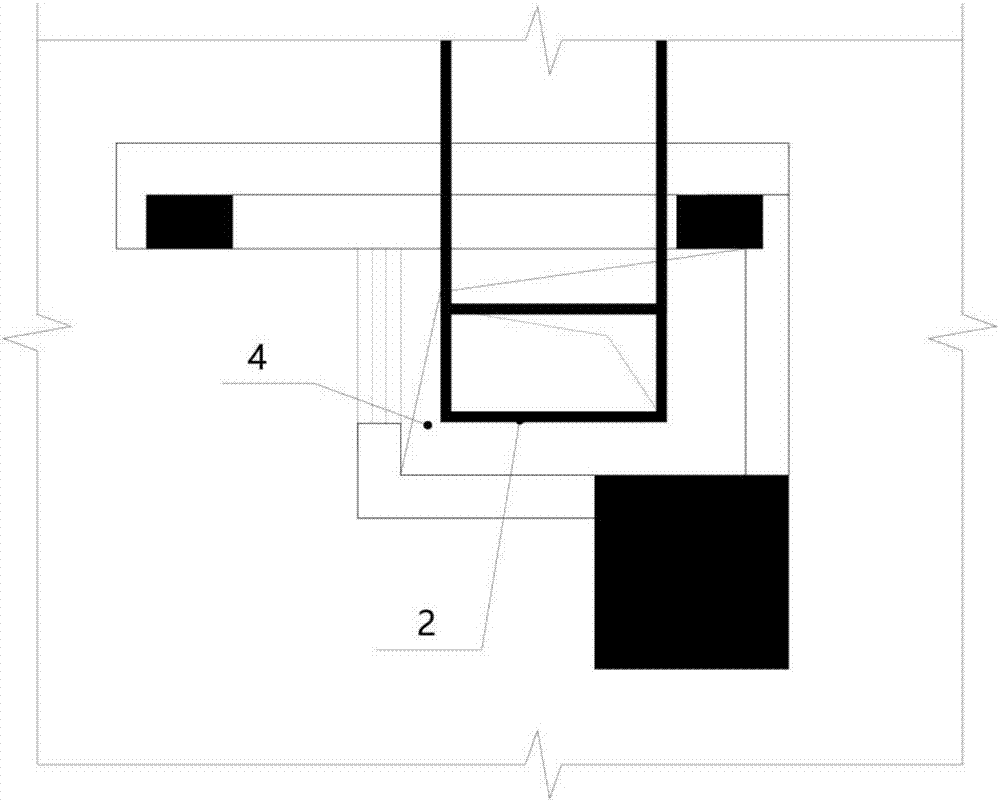

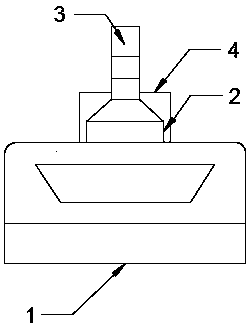

A positive pressure explosion-proof control cabinet

ActiveCN110461120BTo achieve the purpose of cooling downCasings/cabinets/drawers detailsHermetically-sealed casingsEngineeringTorsion spring

The invention discloses a positive pressure explosion-proof control cabinet, which comprises a cabinet body. The inner side of the cabinet body is fixedly connected with a horizontally-disposed partition plate, and the partition plate divides the inner side of the cabinet body into an upper installation compartment and a lower exhaust compartment. The partition plate is provided with a communication hole, one side of the lower end of the communication hole is connected with a sealing plate in a rotary matching mode, a torsion spring for controlling reset of the sealing plate is disposed between the sealing plate and the partition plate, one side of the cabinet body is uniformly provided with a group of ventilation holes, and one side of the cabinet body is provided with an inflating device. The positive pressure explosion-proof control cabinet has the advantages that a cooling inert gas is supplied to the installation compartment; when the air pressure in the installation compartment can overcome the torsion force of the torsion spring, the air pressure in the installation compartment presses the sealing plate to rotate, and the air in the installation compartment is exhausted to the exhaust compartment; during the exhaust process, the heat in the installation compartment is also exhausted, and the purpose of cooling is achieved; and as the air pressure in the installation compartment is always greater than the external air pressure, the external air can not enter the installation compartment.

Owner:ERGONG EXPLOSION PROOF TECH CO LTD

Novel power distribution box

PendingCN113964691ATo achieve the purpose of cooling downSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsThermodynamicsEngineering

The invention relates to the technical field of electrical equipment, in particular to a novel power distribution box which comprises a power distribution box body, the top surface of the power distribution box body is fixedly connected with a power distribution box top, a driving mechanism is arranged in the power distribution box top, the driving mechanism is connected with a waterproof assembly, two fixing plates are arranged in the power distribution box, the top ends of the two fixing plates are fixedly connected with the bottom face of the top of the distribution box and fixedly connected with the bottom face of the distribution box body, and the side faces of the fixing plates are fixedly connected with mounting panels. By adopting a water level sensor, the driving mechanism and the waterproof assembly, the waterproof assembly can be driven to be in a waterproof working state when the water level is too high in rainy days, so that the purpose of protecting internal electric appliance elements when the water level is too high in rainy days is achieved; and by adopting the temperature sensor, the driving mechanism and the waterproof assembly, when the temperature of the internal assembly is too high, the waterproof assembly is driven to be in a cooling working state, so that the purpose of cooling the internal electrical components is achieved.

Owner:盛缪钰

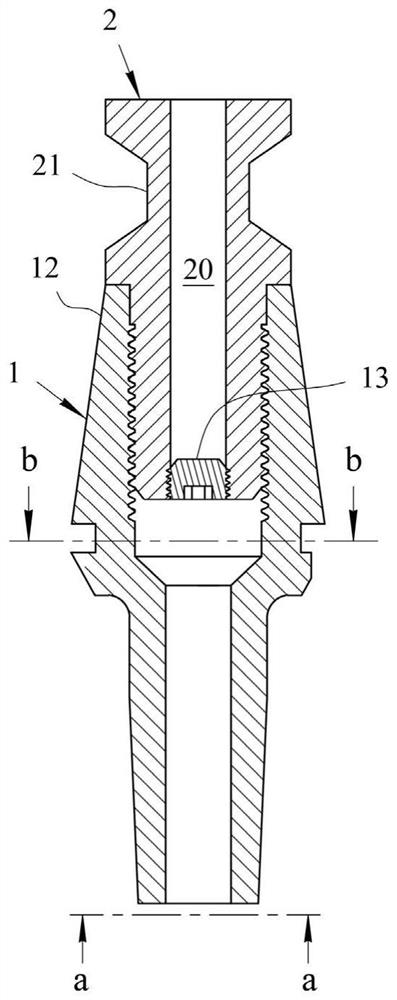

Collet type cutter structure

ActiveCN112894437ASimple structureEasy to operateMilling cuttersPositioning apparatusWrenchKnife handles

The invention discloses a collet chuck type cutter structure which comprises a step rod and a buckling rod, the step rod comprises a first rod body and a second rod body, the first rod body is provided with a first channel used for installing a cutter rod, the second rod body is provided with a conical structure matched with an inner conical hole of a cutter main shaft, a threaded hole is formed in the second rod body, and the buckling rod is connected with the threaded hole. The upper portion of the buckling rod is provided with a buckling groove matched with a tool retracting buckling claw in a tool spindle, and the buckling rod is provided with an external thread matched with the threaded hole. And a second channel is arranged in the buckling rod. And a water stop screw is arranged on the buckling rod and is arranged at the lower end of the second channel. And a groove part convenient for a wrench tool to operate is arranged on the step rod. The collet chuck type tool is simple in structure and convenient to operate, and can be matched with an ATC tool magazine of a CNC machine tool to achieve the purposes of metal cutting machining and automatic tool changing without using a tool handle, so that the working efficiency of metal machining is improved.

Owner:YAMAKEN TOOL

Cooling device for automobile part machining

PendingCN114294900AReduce work contentHigh degree of intelligenceLighting and heating apparatusCleaning using toolsGear wheelCam

The invention relates to the technical field of automobile part machining, and particularly discloses an automobile part machining cooling device which comprises symmetrically-arranged guide rails, a bearing mechanism slidably connected with the guide rails and a driving mechanism driving the bearing mechanism to slide, the bearing mechanism comprises a sliding seat, a mounting groove and a gear, the mounting groove and the gear are arranged on the sliding seat, and racks are arranged on the side walls of the guide rails. A piston cavity is formed in the guide rail and communicates with a water inlet pipe and a water outlet pipe, a first piston rod is slidably connected into the piston cavity in a sealed mode, a first reset spring is arranged between the first piston rod and the piston cavity, and the free end of the first piston rod extends out of the piston cavity and the side wall of the guide rail. A water spraying table is arranged above the guide rail, a water spraying cavity communicated with the free end of the water outlet pipe is formed in the water spraying table, a plurality of water spraying holes communicated with the water spraying cavity are formed in the lower surface of the water spraying cavity, and the problems that in the traditional automobile part cooling process, technicians need to manually control opening and closing of cooling spray heads, and work is tedious are solved.

Owner:重庆乐迪龙鑫科技股份有限公司

A kind of air cooling device for heat treatment workpiece

Owner:JOUDER PRECISION INDAL KUSN

Heat pipe type instant-heating water dispenser

A heat pipe type instant-heating water dispenser comprises a cold water pipe, a cooler, a water inlet valve, a heating channel, a high temperature water bucket, a low temperature water bucket, heat pipes and a box body; the heating channel is composed of four serially-connected sealed vertical pipes; electric heaters are arranged in each vertical pipe; both the high temperature water bucket and the low temperature water bucket are sealed tank bodies, and temperature controllers are arranged in the tank bodies respectively; a hot water outlet pipe and a water outlet valve are arranged at the top of the high temperature water bucket; the heat pipes are two sealed vertical pipes, wherein the upper ends extend into the cooler, and the lower ends extend into the low temperature water bucket; the cooler and other components are connected in series through pipelines and are all arranged in the box body; and the water outlet valve is arranged outside the box body. The heat pipe type instant-heating water dispenser has the advantages that tap water is directly taken as a water source, so that the use cost is low; due to the instant-heating design, hot water can be supplied continuously; the volumes of the water buckets are small, so that electric energy wasted for heat preservation can be reduced greatly; and a hot water bucket adopts a full-capacity design, and the pressure of tap water is utilized to realize continuous water supply to avoid dry heating, so that safe and reliable operation can be ensured.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

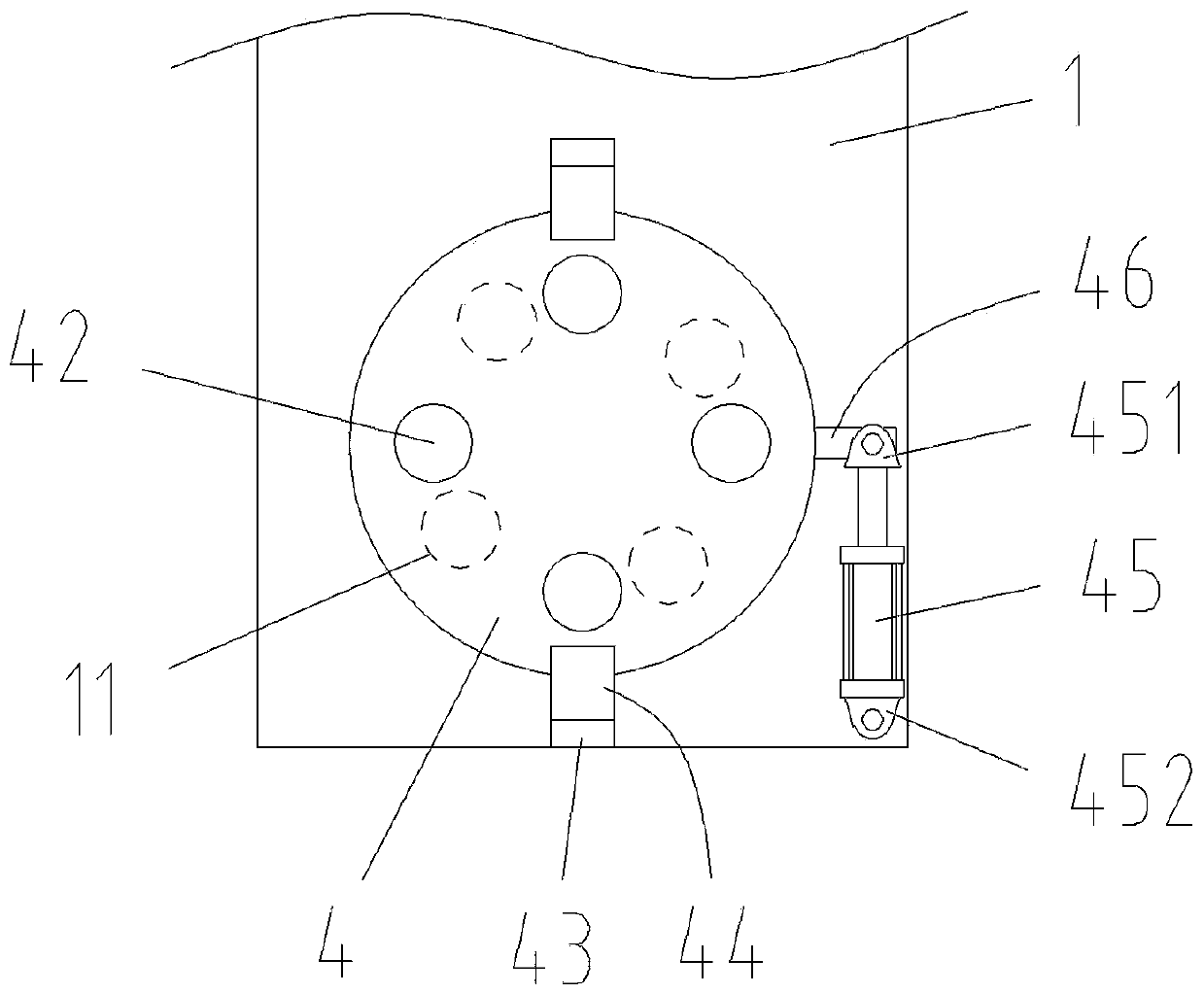

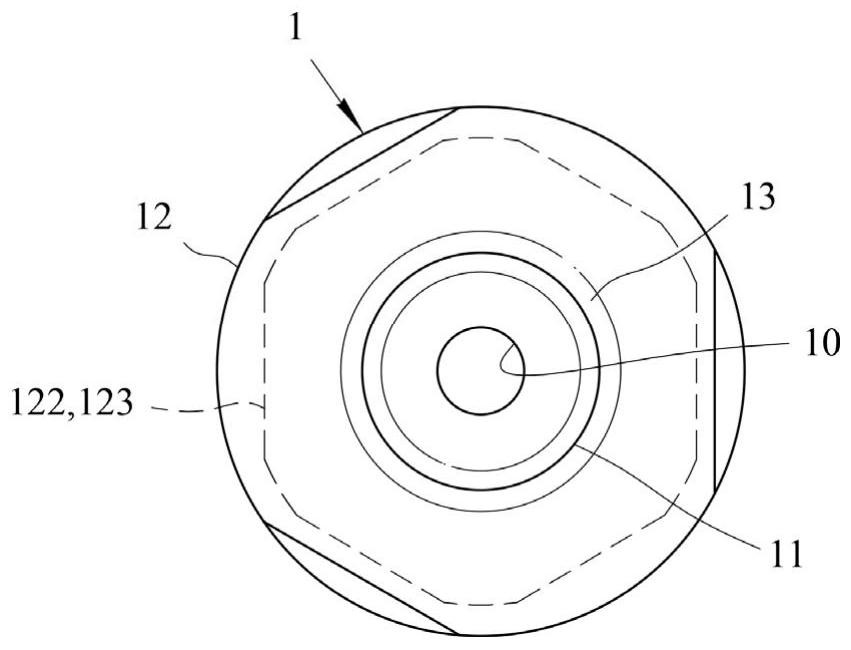

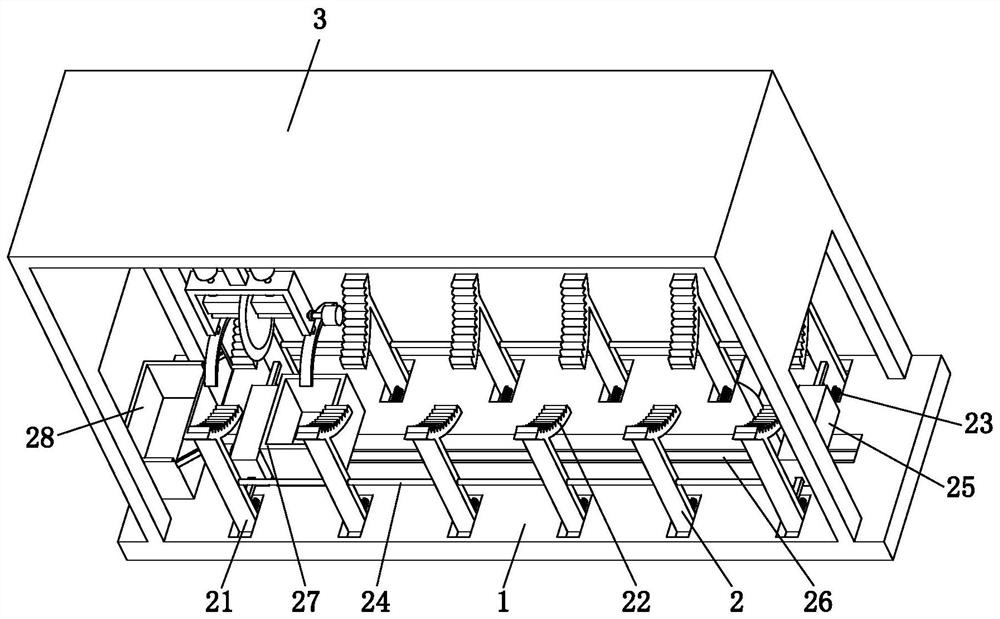

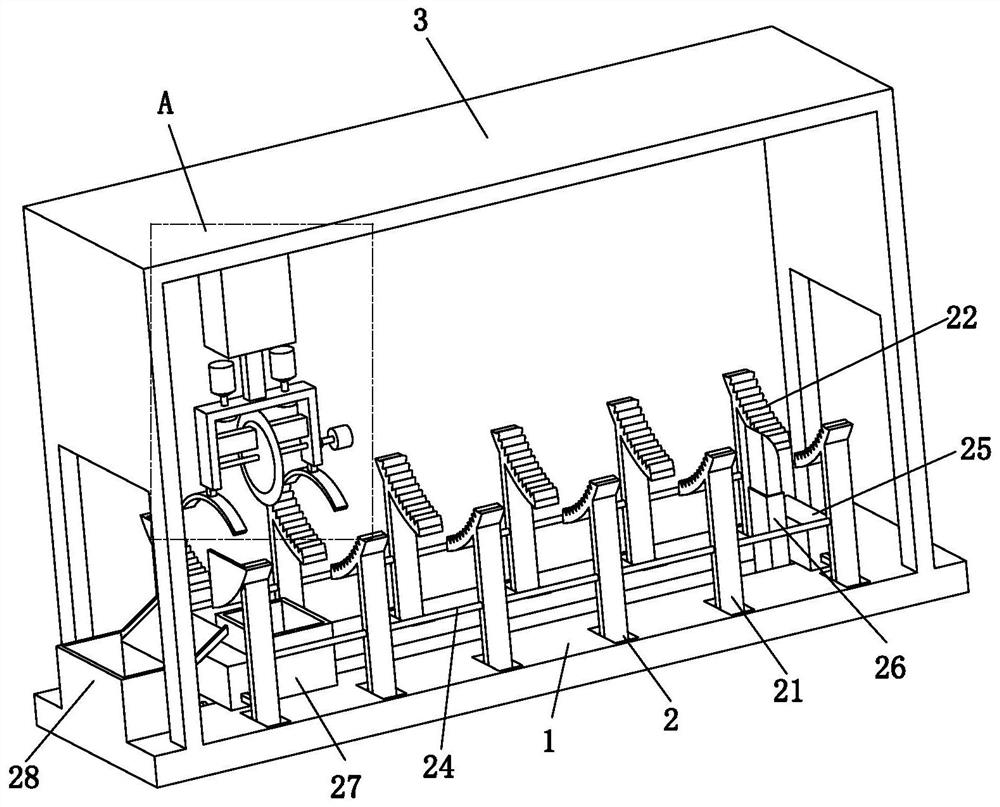

Manufacturing and forming process for oil pump rotor

InactiveCN113510303AQuick breakGuaranteed stabilityMetal sawing devicesMetal sawing accessoriesWorking environmentEngineering

The invention relates to a manufacturing and forming process for an oil pump rotor, which comprises a bottom plate, a supporting device and a cutting device. The manufacturing and forming process can solve the problems that in the cutting process of an existing oil pump outer rotor blank, a, the cylindrical outer rotor blank is manually clamped and fixed through a clamp so that the outer rotor blank can be cut, the clamp needs to be disassembled again after cutting every time, then cutting can be conducted again, time and labor are wasted, the cutting efficiency is low, and the production efficiency of the oil pump outer rotor is reduced; and b, during cutting, conventional cutting equipment generally adopts a mode of spraying cooling liquid to a cutting tool for cooling, so that a large amount of cooling liquid and cutting chips are attached to the surface of cut small-section blanks, the cutting quality is reduced, and meanwhile, the working environment is polluted due to outflow of the cooling liquid, and inconvenience is caused to subsequent cleaning.

Owner:李宜宜

A metal cylinder electrofusion additive manufacturing system

The invention discloses a metal cylinder electric smelting additive manufacturing system. The metal cylinder electric smelting additive manufacturing system comprises a cylindrical base body, an electric smelting head component, a cooling device and a horizontal moving drive device; the cooling device comprises an integration part arranged in the base body, a plurality of nozzles sequentially arranged in the length direction of the integration part, a water inlet part arranged at one end of the integration part and an air inlet part arranged at the other end of the integration part; the integration part is internally provided with a ventilation main pipe, ventilation branch pipes communicated with the ventilation main pipe with the nozzles, and a plurality of independent water passing ways in one-to-one correspondence connection with the nozzles, and the water inlet part comprises a water inlet main pipe, a stop valve used for controlling the water inlet main pipe to be on and off, a distributor used for distributing water of the water inlet main pipe to the independent water passing ways, and water amount adjusting valves arranged on the independent water passing ways. The air inlet part comprises an air inlet pipe communicated with the ventilation main pipe and an air amount adjusting valve arranged on the air inlet pipe. The metal cylinder electric smelting additive manufacturing system can achieve rapid precise cooling.

Owner:NANFANG ADDITIVE MFG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com