Hotpot condiment filling and shaping system

A hot pot bottom material and filling technology, which is applied in the field of food packaging, can solve the problems of low cooling efficiency of packaging bags, achieve the effects of improving freezing production efficiency, reducing the time required for freezing, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

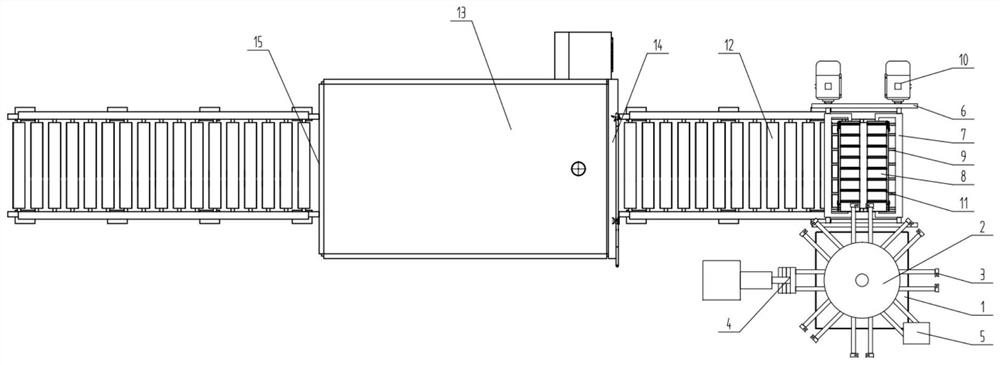

[0023] The reference signs in the drawings of the description include: base 1, turntable 2, clamping mechanism 3, plastic sealing mechanism 4, injection mechanism 5, frame 6, support frame 7, first conveyor belt 8, driven roller 9, The second drive motor 10, the dividing plate 11, the second conveyor belt 12, the freezer 13, the material inlet 14, and the material outlet 15.

[0024] The embodiment is basically as attached figure 1 Shown: The hot pot base material filling and shaping system is equipped with a packing device, an arranging device and a freezing device in sequence. Packing device comprises base 1, and base 1 is fixedly connected with first drive motor, and the output shaft of first drive motor vertically faces upwards, and the output shaft key connection of first drive motor is fixed with the turntable 2 of disc-shaped structure. The turntable 2 is provided with eight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com