Two-phase refrigeration and gas compression integrated electronic equipment cooling system

A technology of electronic equipment and cooling system, which is applied in the field of electronic equipment cooling system integrating two-phase refrigeration and gas compression, which can solve the problems of low temperature, rising temperature and energy waste of electronic equipment, and reduce the use of pipelines and accessories , Pipeline simplification and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

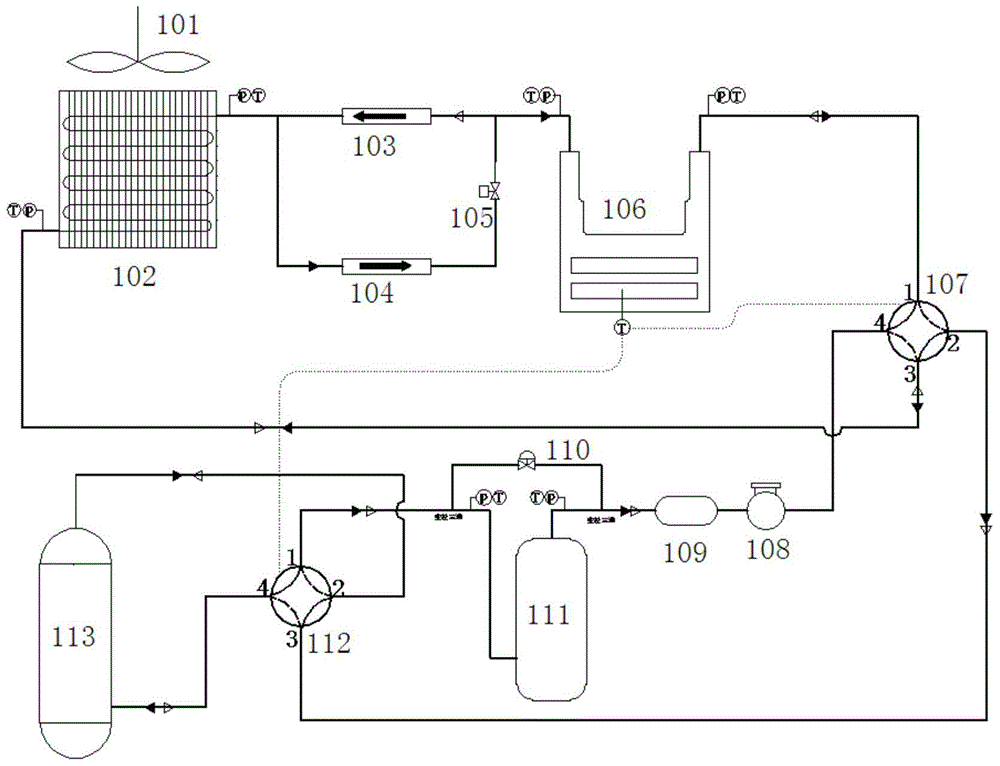

[0020] see figure 1 , a two-phase refrigeration and gas compression integrated electronic equipment cooling system, the power core integrated machine 111 inlet (suction / liquid port) is respectively connected to the gas phase of the gas-liquid separator 113 through the first four-way reversing valve 112 channel and liquid phase channel; the outlet of the compressor (exhaust / liquid port) is connected to the filter 109, which is mainly used to protect the flowmeter 108, evaporator 106, electronic expansion valve 105 and other components to prevent impurities from damaging the flowmeter or causing flow Inaccurate meter test and blockage of electronic expansion valve, or damage to special heat exchange cold plate with electronic equipment attached. The outlet of the filter is connected to a flow meter, which mainly measures the system flow, and gives a flow signal to the control equipment to adjust the opening of the flow regulating valve 110, so as to reduce the power consumption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com