Composite asphalt cooling pavement top layer and construction method thereof

A construction method and composite technology, applied to coatings, roads, roads, etc., can solve the problems of increased traffic accidents for drivers, poor anti-skid performance and wear-resistant performance, and reduce the function of the road surface, so as to alleviate the urban heat island effect , enhance the anti-wear performance, reduce the effect of road rutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

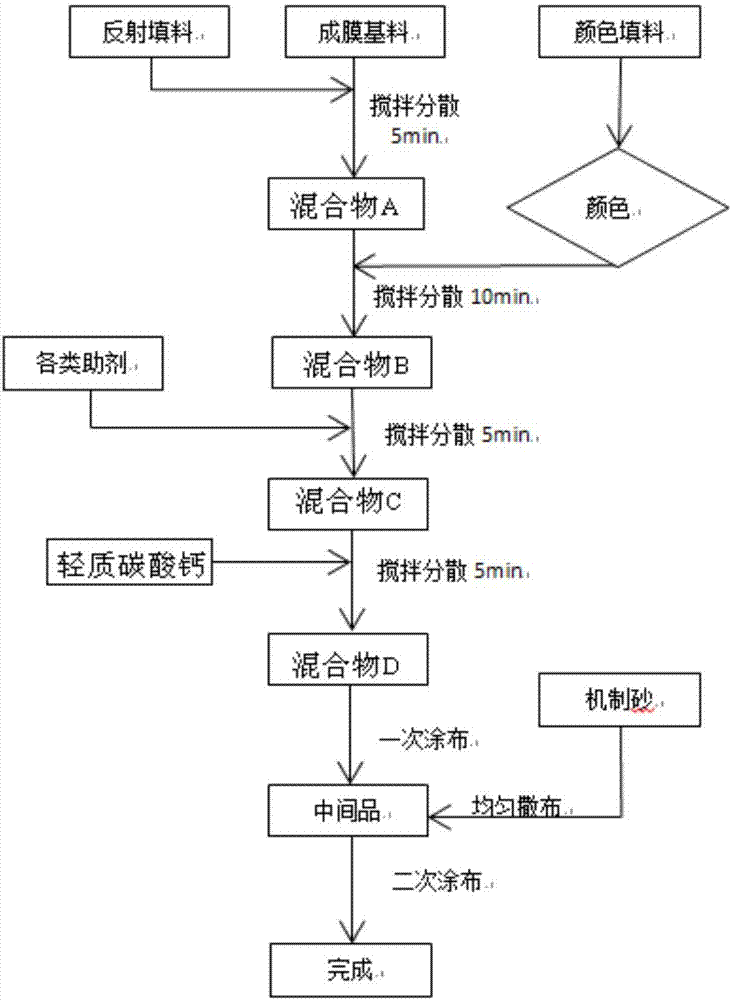

[0054] The construction method of the composite asphalt cooling pavement upper layer of the present embodiment comprises the following steps:

[0055] Step 1, in parts by weight, heating 100 parts of 70# road petroleum asphalt to 160°C-170°C;

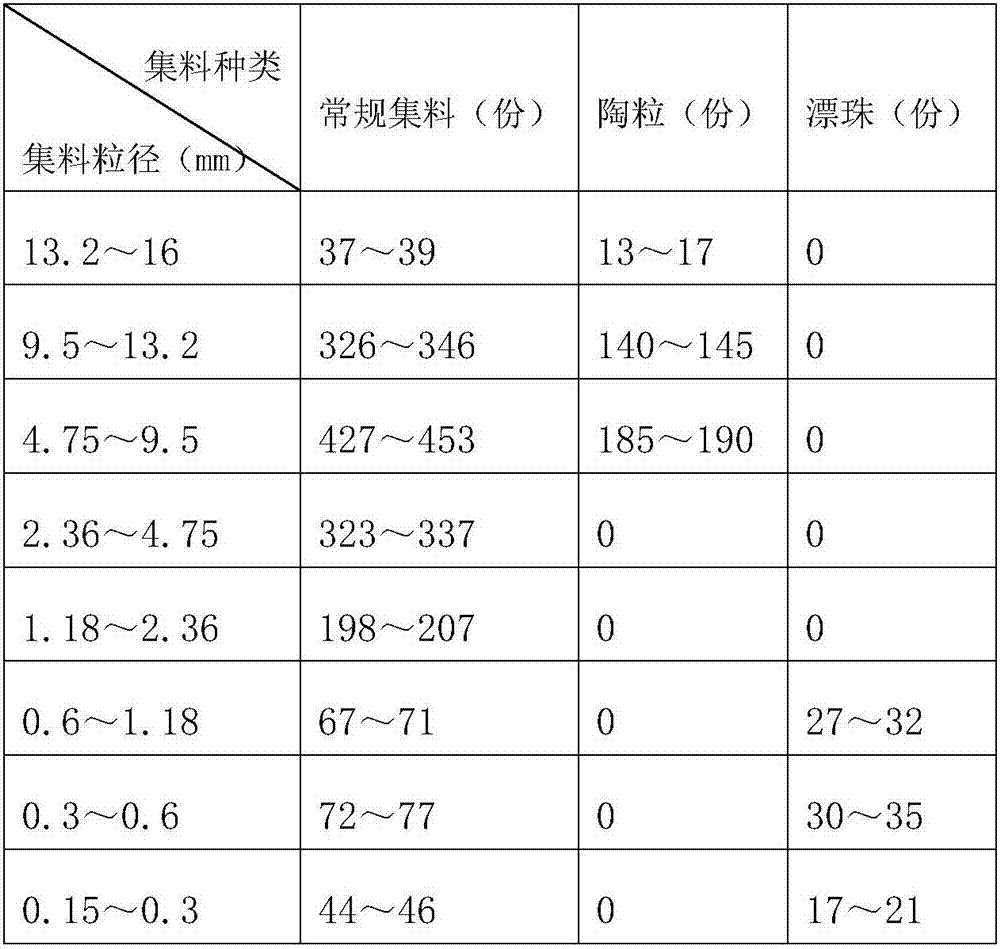

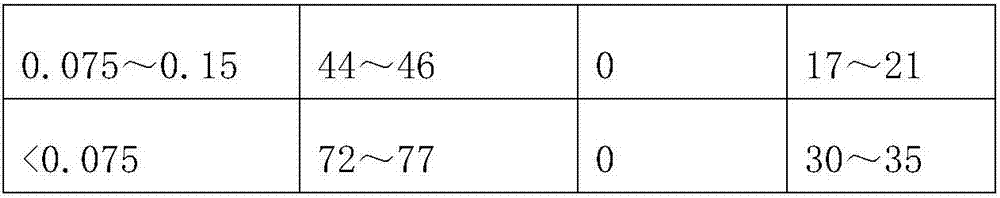

[0056] Step 2. 38 parts of limestone and 15 parts of ceramsite with a particle size of 13.2 to 16 mm, 335 parts of limestone and 143 parts of ceramsite with a particle size of 9.5 to 13.2 mm, 440 parts of limestone and 187 parts of ceramsite with a particle size of 4.75 to 9.5 mm Parts of ceramsite, 330 parts of limestone with a particle size of 2.36-4.75mm, 200 parts of limestone with a particle size of 1.18-2.36mm, 69 parts of limestone with a particle size of 0.6-1.18mm and 30 parts of floating beads with a particle size of 0.3-0.6mm 75 parts of limestone and 33 parts of floating beads, 45 parts of limestone and 19 parts of floating beads with a particle size of 0.15-0.3 mm, 45 parts of limestone with a particle size of 0.075-0.15 mm...

Embodiment 2

[0066] The construction method of the composite asphalt cooling pavement upper layer of the present embodiment comprises the following steps:

[0067] Step 1. Heat 100 parts of 90# road petroleum asphalt to 160°C to 170°C in parts by weight;

[0068] Step 2, 39 parts of basalt and 17 parts of ceramsite with a particle size of 13.2 to 16 mm, 346 parts of limestone and 145 parts of ceramsite with a particle size of 9.5 to 13.2 mm, 453 parts of basalt and 190 parts of ceramsite with a particle size of 4.75 to 9.5 mm Parts of ceramsite, 337 parts of basalt with a particle size of 2.36-4.75mm, 207 parts of basalt with a particle size of 1.18-2.36mm, 71 parts of basalt with a particle size of 0.6-1.18mm and 32 parts of floating beads with a particle size of 0.3-0.6mm 77 parts of basalt and 35 parts of floating beads, 46 parts of basalt and 21 parts of floating beads with a particle size of 0.15-0.3mm, 46 parts of basalt and 21 parts of floating beads with a particle size of 0.075-0....

Embodiment 3

[0078] The construction method of the composite asphalt cooling pavement upper layer of the present embodiment comprises the following steps:

[0079] Step 1, in parts by weight, heating 100 parts of 70# road petroleum asphalt to 160°C-170°C;

[0080] Step 2. 37 parts of limestone and 13 parts of ceramsite with a particle size of 13.2 to 16 mm, 326 parts of limestone and 140 parts of ceramsite with a particle size of 9.5 to 13.2 mm, and 427 parts of limestone and 185 parts of ceramsite with a particle size of 4.75 to 9.5 mm. Parts of ceramsite, 323 parts of limestone with a particle size of 2.36-4.75mm, 198 parts of basalt with a particle size of 1.18-2.36mm, 67 parts of limestone with a particle size of 0.6-1.18mm and 27 parts of floating beads with a particle size of 0.3-0.6mm 72 parts of basalt and 30 parts of floating beads, 44 parts of basalt and 17 parts of floating beads with a particle size of 0.15-0.3mm, 45 parts of basalt and 17 parts of floating beads with a particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com