Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Reduce rutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-modulus bituminous mixture additive and preparation method thereof

ActiveCN103773006AImprove dynamic stabilityImprove static modulusBuilding insulationsPolymer sciencePavement engineering

The invention discloses a high-modulus bituminous mixture additive and a preparation method thereof. The high-modulus bituminous mixture additive is composed of a modifying main agent, butadiene styrene rubber, polyethylene paraffin, a filling material, an anti-aging component, and a plasticizing component according to a mass percentage of 100:(10-30):(15-40):(40-80):(2-6):(5-20); wherein the modifying main agent consists of one or more components selected from waste PE, polypropylene, and EVA. The preparation method comprises the following steps: evenly mixing the modifying main agent, butadiene styrene rubber and polyethylene paraffin at a temperature of 160 to 190 DEG C, adding the filling material, anti-aging component and plasticizing component into the mixture, evenly mixing under a certain rotation speed, then extruding the mixture by a screw extruder, cooling at the room temperature, and finally cutting into particles. The high-modulus bituminous mixture additive is mainly applied to pavement projects such as new construction and reconstruction of high grade roads and heavy traffic roads, can improve the dynamic stability, static modulus, dynamic modulus and shearing resistant performance of bituminous mixture, thus prominently reduces the damages of rut, displacement, or the like, and can improve the low-temperature anti-cracking performance of high-modulus bituminous mixture at the same time.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Bitumen modifier

InactiveCN101041744AHigh softening pointImprove anti-aging propertiesBuilding insulationsEpoxyStearic acid

The invention discloses a modifier of pitch for road and water-proofing material, which comprises the following steps: allocating with mass percent as 20-30% polypropylene, 3-10% epoxide resin, 8-10% polyethylene, 8-10% geoceric acid and 40-60% ethylene distearamide; mixing; stirring for 10-15 min; getting the product. This product possesses good stability and predominant water resistance, which can be fit for all of asphalt.

Owner:上海诚鸿道路新材料有限公司

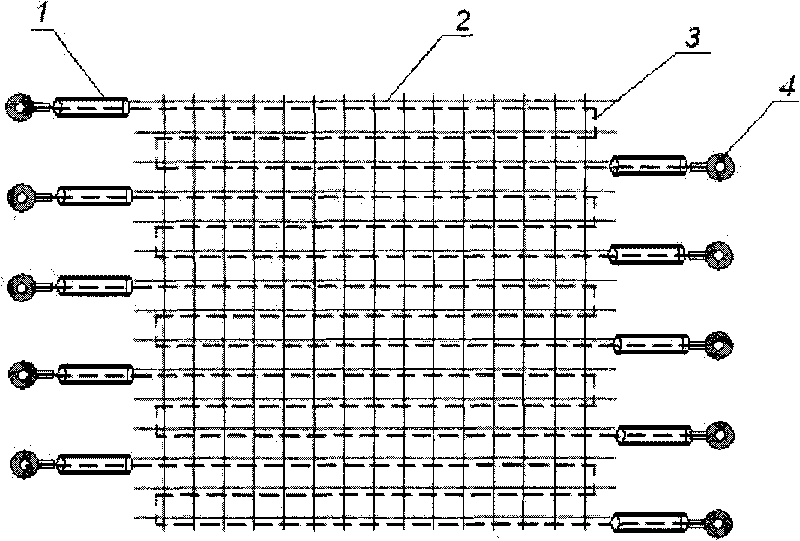

Basalt fiber and carbon fiber compound geogrid with electric heating function

The invention discloses a basalt fiber and carbon fiber compound geogrid with electric heating function, which is formed by compounding materials of basalt fiber, carbon fiber beams, modified asphalt, polyacrylic emulsion or high temperature resistant heat convertible resin and the like. The geogrid not only has the function of reinforcement, but also has the functional characteristic of electric heating effect, has simple construction, low manufacture cost, convenient construction, safety and reliability, and is mainly used for melting snow and ice on the concrete pavement and the airfield runway.

Owner:ZHEJIANG GBF BASALT FIBER

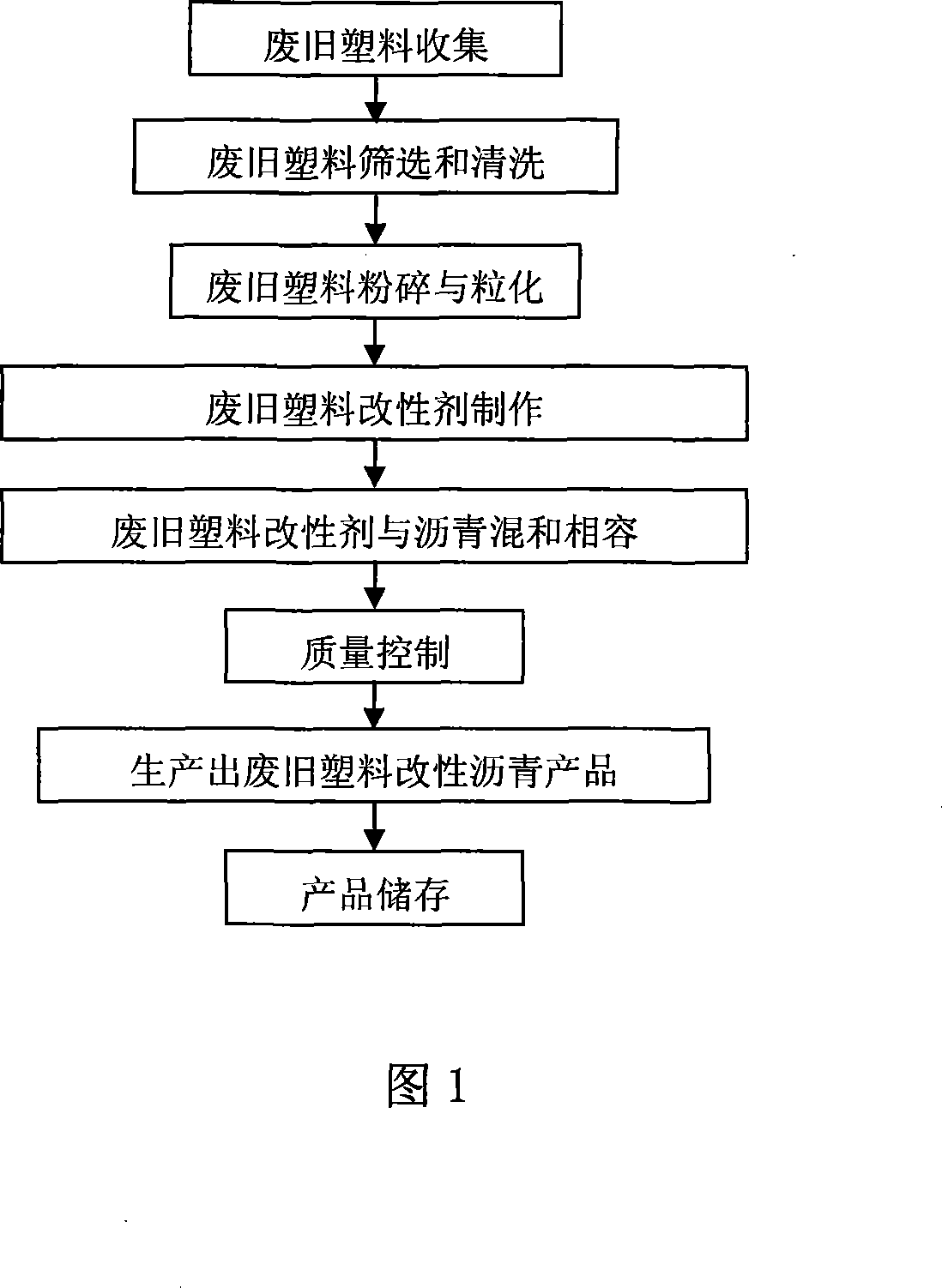

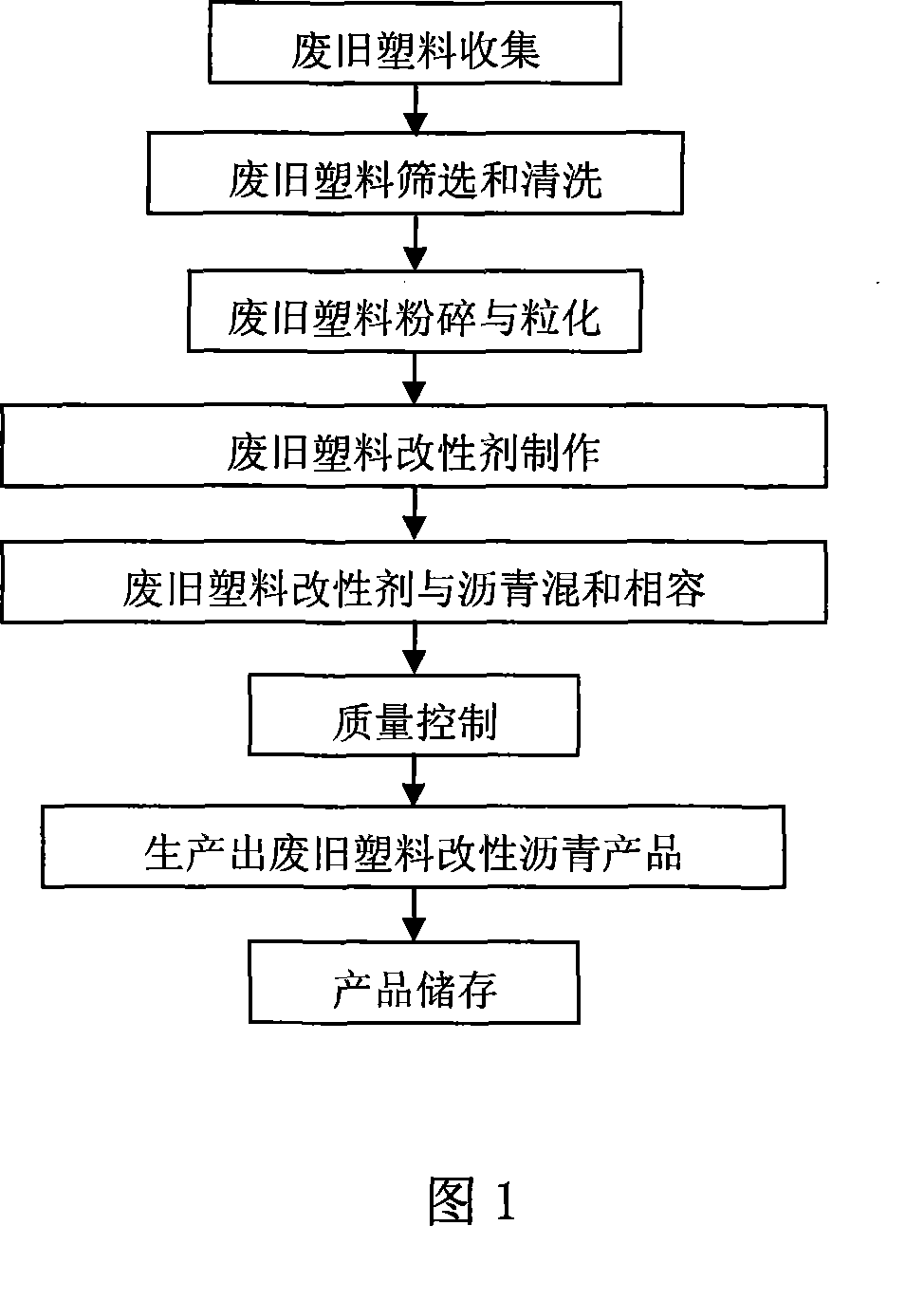

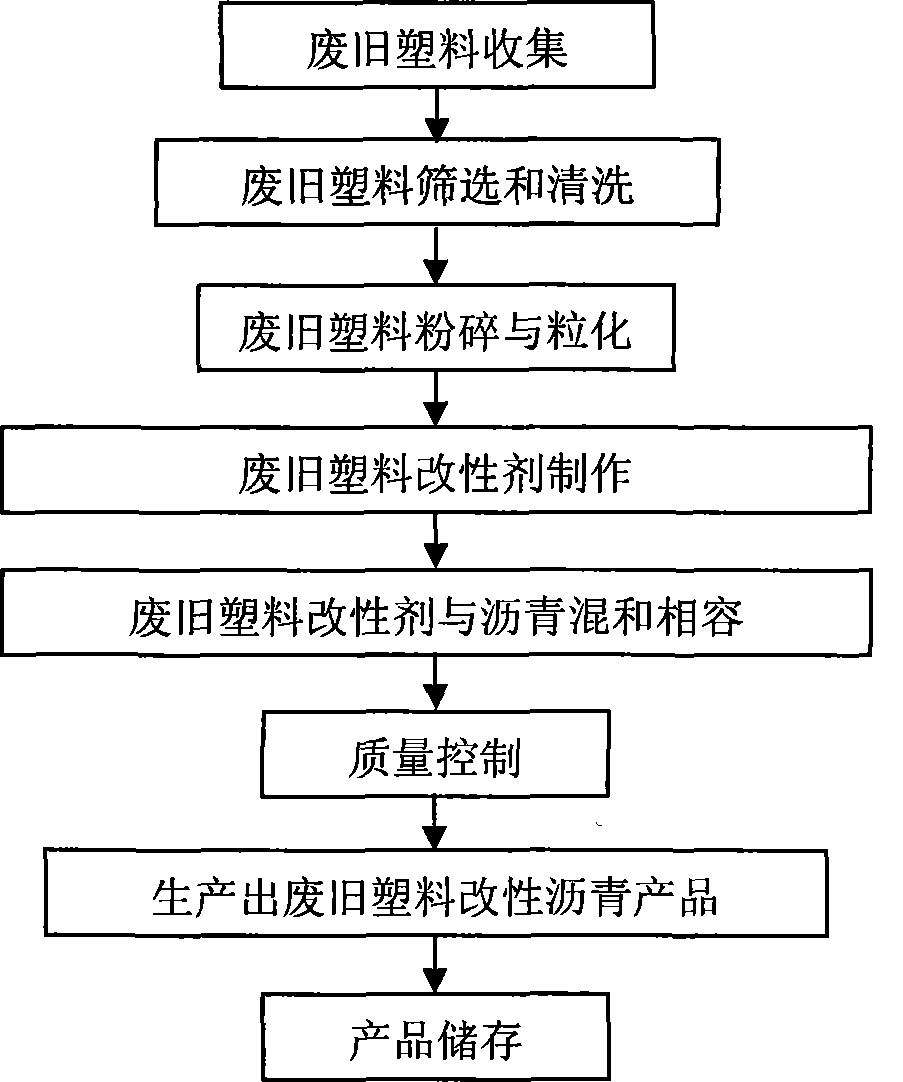

Method for preparing modified asphalt by using waste plastics

InactiveCN101225237AHigh softening pointImprove high temperature stabilityBuilding insulationsPulp and paper industryAsphalt

The invention discloses a method for making modified asphalt using waste plastics, comprising the following process steps: 1) various waste plastics are collected, sorted, washed and then dehydrated and grinded; 2) the grinded waste plastics are melted by heating up, and then processed into waste plastic grains after cooling; 3) the waste plastic grains are liquefied by high temperature heating and then cooled, the waste plastic modifying agent is obtained; 4) base asphalt is healed to be softened, then the waste plastic modifying agent obtained during step 3) and the base asphalt are melted to be immixed; 5) the mixture obtained during the step 4) is melted to expanded and sheared, the manufacture of the modified asphalt is finished; the method for making modified asphalt using waste plastics has the advantages that: the soften point of the asphalt is increased ten to fifteen DEG C, the price is low, the waste domestic plastic products are changed into valuables, and has the advantages of good technical performances and low price and other economic technique characterizes.

Owner:杨锡武 +1

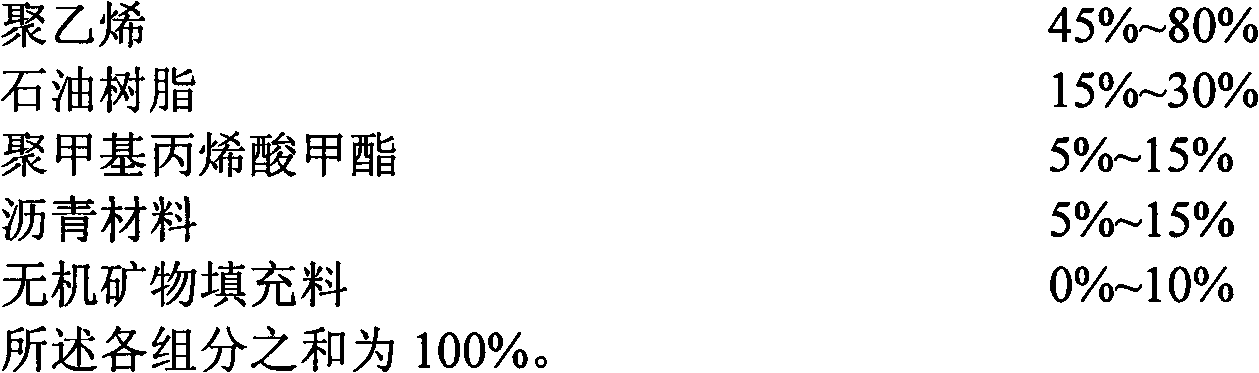

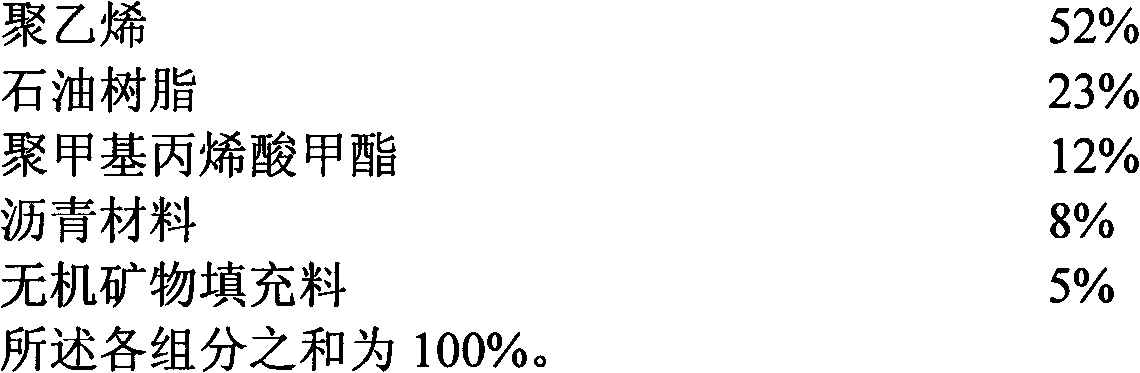

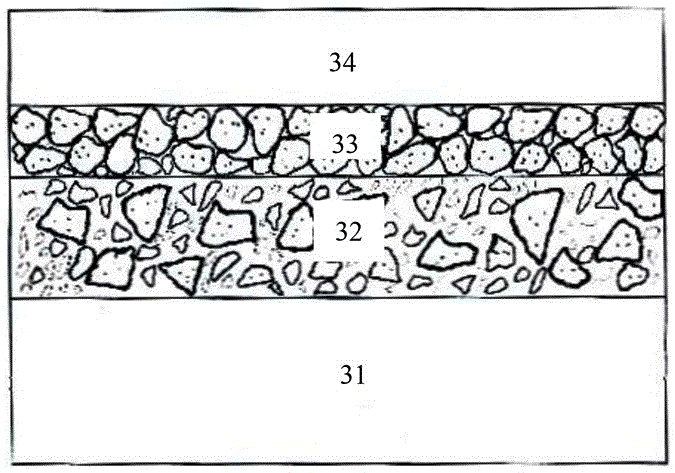

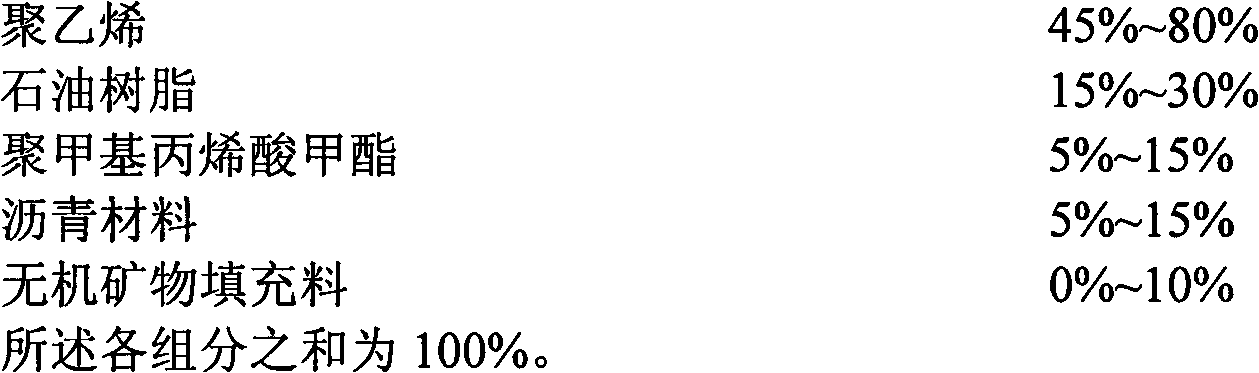

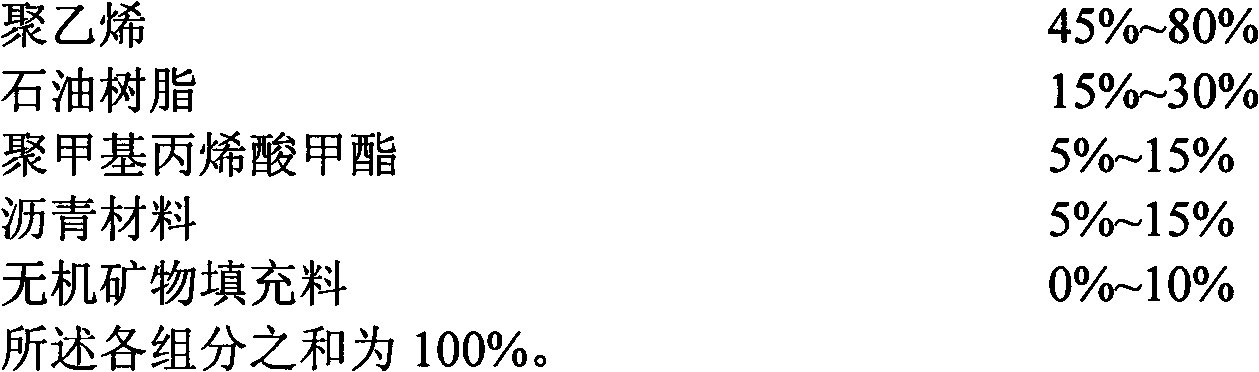

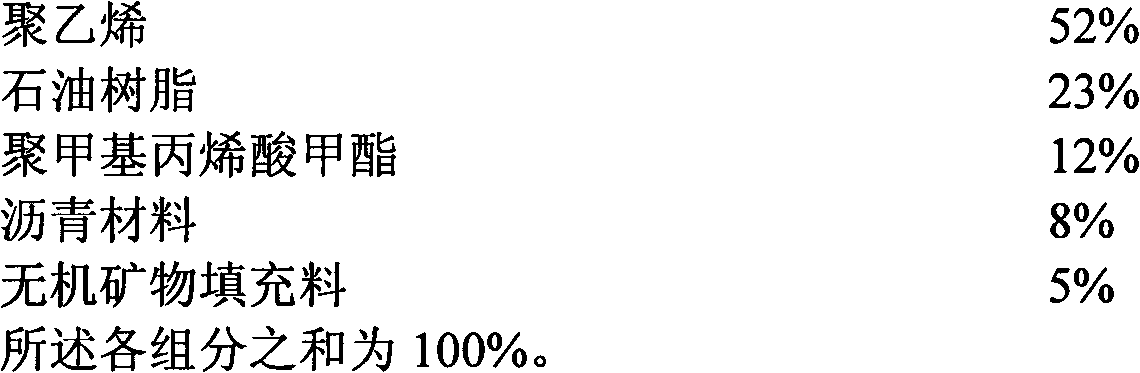

Environment-friendly asphalt pavement anti-rut agent and preparation method thereof

ActiveCN102702600AImprove protectionNo displacementBuilding insulationsLow-density polyethyleneMicrosphere

The invention discloses a preparation method of an environment-friendly asphalt pavement anti-rut agent and an application thereof. The method comprises the following steps of: mixing and stirring 45-80 percent of polyethylene and 15-30 percent of petroleum resin derived from 'plastic waste', 5-15 percent of polymethyl methacrylate, 5-15 percent of an asphalt material and 0-10 percent of an inorganic mineral filling material at a high speed; and extruding at a high temperature to prepare the environment-friendly asphalt pavement anti-rut agent. Due to the adoption of the environment-friendly asphalt pavement anti-rut agent, the performance of an asphalt pavement is enhanced, the service life of the pavement is prolonged, 'white waste' is recycled, and environmental pollution is lowered. Polyethylene serving as a major component is either or both of industrial production low-density polyethylene and industrial recycled waste polyethylene; the industrial recovered waste polyethylene is recovered polyethylene or regenerated low-pressure polyethylene or regenerated PE (Polyethylene); the molecular weight of the petroleum resin is 300-3,000; the molecular weight of the polymethyl methacrylate is 80,000-120,000; the asphalt material is one or more of natural asphalt, coal tar asphalt and petroleum asphalt; and the inorganic mineral filling material is one or over two of calcium carbonate of 500-800 meshes, talc powder, quartz sand, glass hollow microspheres and kaolin.

Owner:SHENZHEN KEZHONGDA POLYMER MATERIAL RES INST

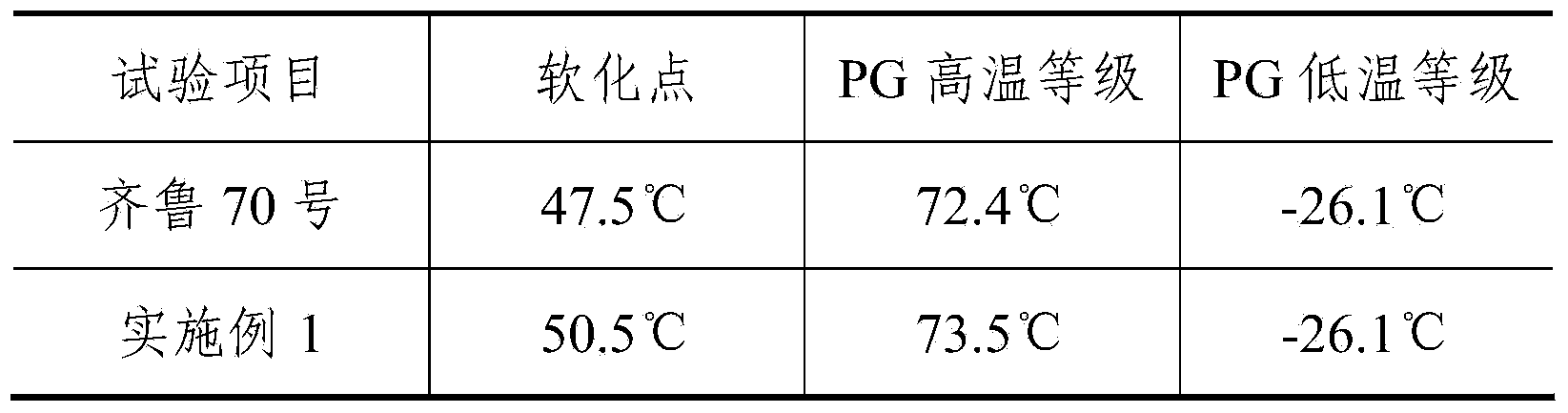

Modified asphalt composition and preparation method thereof

ActiveCN103102701AHigh softening pointHigh temperature viscosityBuilding insulationsPenetration indexAging resistance

The invention provides a modified asphalt composition and a preparation method thereof. The modified asphalt composition comprises, by weight, 87.5% to 98.9% of base asphalt, 1% to 10% of a modifier and 0.1% to 2.5% of a gelatinizing agent (a structure improver). The preparation method comprises the following steps: uniformly dispersing the modifier into the base asphalt at a temperature of 150 to 260 DEG C by using equipment like an ordinary agitator, a high speed shearing machine or a colloid mill to prepare the modified asphalt composition; and adding the gelatinizing agent to allow a sol-gel type colloid structure of asphalt to be converted into a gel type colloid structure and to allow a stable colloid structure of asphalt to be formed. According to the invention, the preparation method for the modified asphalt composition is simple; and the prepared modified asphalt composition has a high softening point, high viscosity, a high penetration index, excellent high and low temperature performance, excellent ageing resistance, small temperature sensitivity and the like, can reduce occurrence of damages like tracks and upheaval on a pavement and prolong a maintenance period of the pavement and is applicable to construction of high-grade highways.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cold-mix phase change type asphalt mixture for thermal energy storage

ActiveCN103508702AActively regulate temperatureMitigate the heat island effectThermal energy storageBitumen emulsion

The invention provides a cold-mix phase change type asphalt mixture for thermal energy storage, which is characterized in that: the asphalt mixture is prepared by normal-temperature mixing aggregates, porous base phase change particles for thermal energy storage, a filling material, water, and emulsified bitumen or modified emulsified bitumen with a mass ratio being 100:20-100:1-3:2-4:5-8. The porous base phase change particles for thermal energy storage are prepared by using porous fire rock aggregates as a matrix, absorbing an organic solid-liquid phase changing material in a pore structure of the matrix in a vacuum condition, coating a thermosetting resin film containing a heat conductive filling material on the surface by an immersion method, and solidifying the film for 2-4 days under normal temperature, wherein the phase change temperature is 40-70 DEG C, the phase change latent heat is 20-60j / g, and mechanical properties are good. The asphalt mixture has advantages of simple preparation technology, energy saving and environmental protection, and has good efficacy for reducing pavement temperature.

Owner:CHONGQING JIAOTONG UNIVERSITY

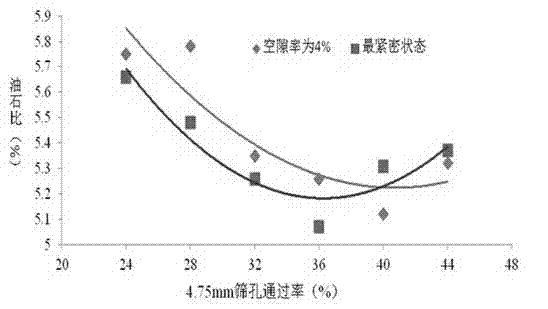

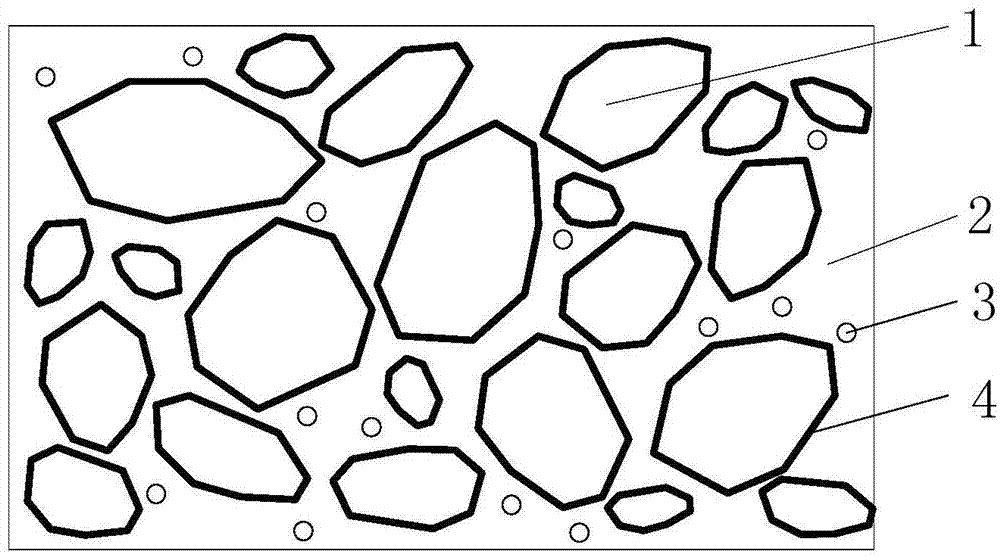

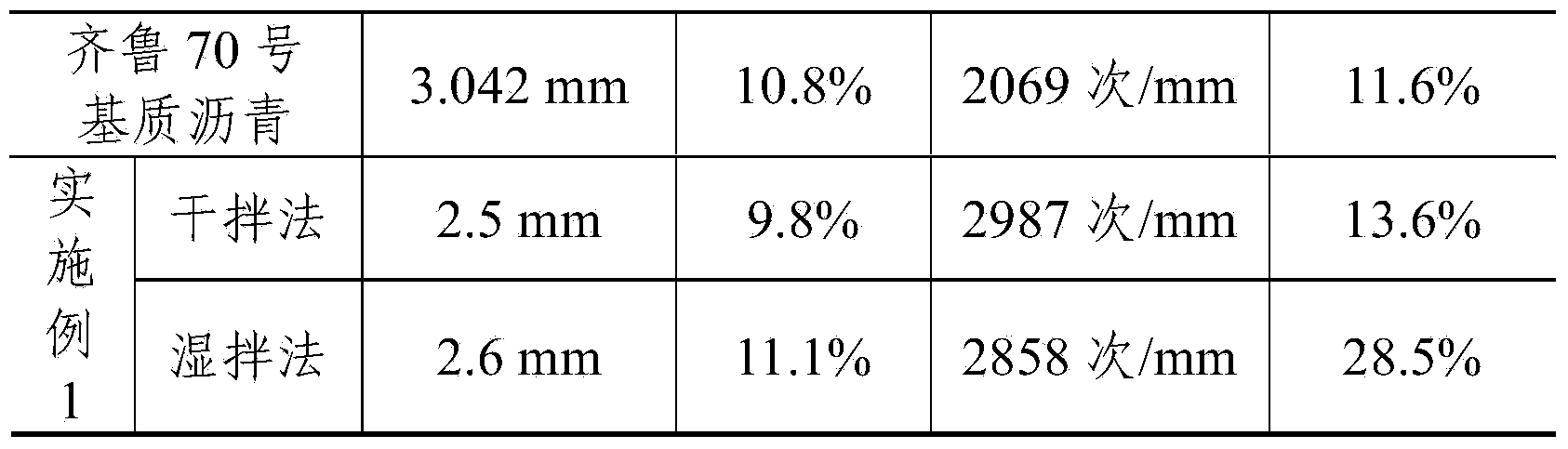

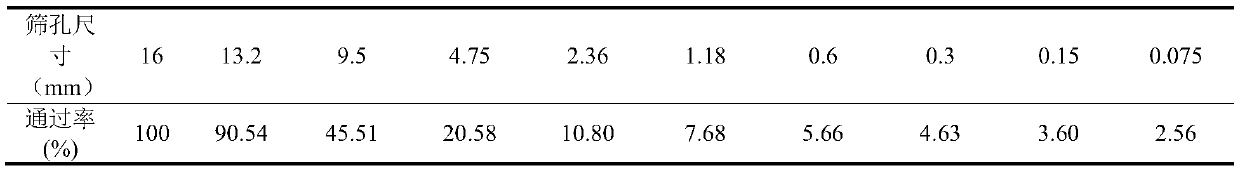

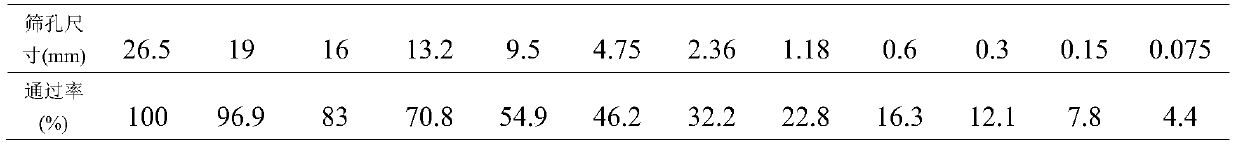

Determining method suitable for mix proportion of asphalt mixture of heavy traffic road surfaces

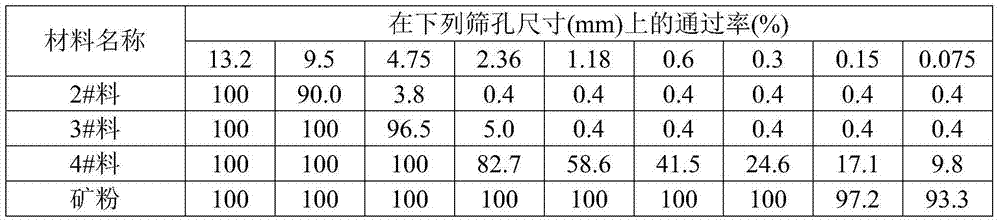

ActiveCN103526664AImprove high temperature stabilityReduce dosageIn situ pavingsStructural engineeringRoad surface

The invention discloses a determining method suitable for the mix proportion of asphalt mixture of heavy traffic road surfaces. The determining method comprises the following steps of preparing raw materials, using a coarse aggregate dry tamping VCA testing method to determine the mass relative proportion of coarse aggregate in the asphalt mixture, using a Marshall tamping testing method to determine the content of coarse aggregate and the content of fine aggregate in the asphalt mixture, and using the tightest framework embedding and extruding state to determine the optimal asphalt-aggregate ratio of the asphalt mixture. Compared with general asphalt mixture, the compactness of the asphalt mixture manufactured in the determining method is improved obviously, the water seepage situation of the road surfaces can be effectively reduced, and water breakage of the road surfaces is reduced. Furthermore, the asphalt mixture has better high temperature resistance, and harm of tracks, bleeding and the like are reduced. Meanwhile, the using amount of asphalt is reduced, engineering investment cost is obviously reduced, and positive effects are brought to wider application of asphalt road surfaces inland.

Owner:JIANGSU BAOLI INT INVESTMENT CO LTD +4

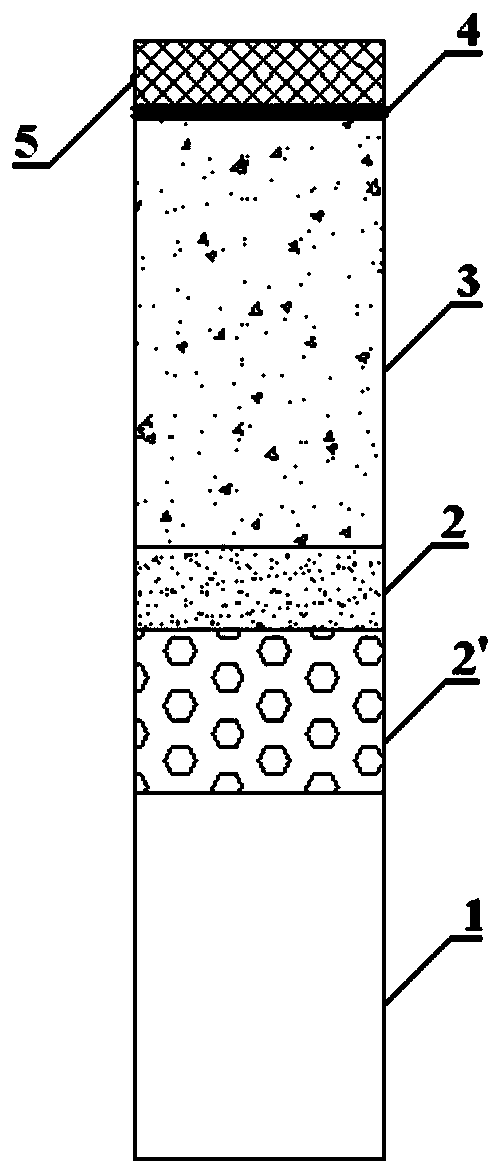

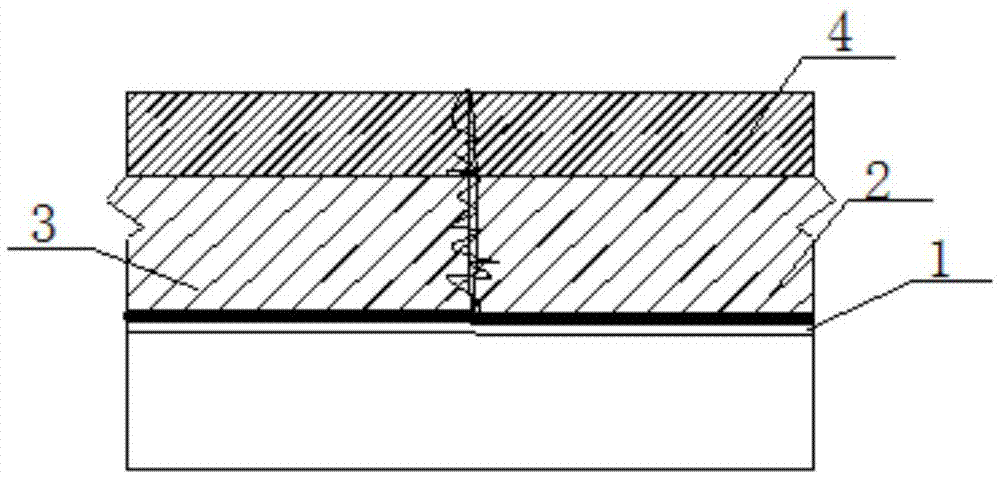

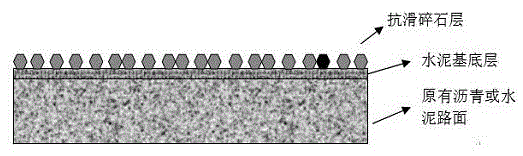

Composite fabricated cement concrete pavement structure and construction method thereof

The invention provides a composite fabricated cement concrete pavement structure. The composite fabricated cement concrete pavement structure comprises a base layer, a leveling layer laid on the baselayer, a fabricated prefabricated concrete slab laid on the leveling layer, a rubber modified asphalt synchronous gravel sealing layer laid on the fabricated prefabricated concrete slab, and rubber modified asphalt concrete laid on the rubber modified asphalt synchronous gravel sealing layer. Compared with the prior art, the composite fabricated cement concrete pavement structure is formed by combining specific functional layers under specific connection relationship, the functional layers have good interaction, and the cooperation of layer structures is realized, so that the whole composite fabricated cement concrete pavement structure has high strength and good driving comfort, and reflective cracks and rutting can be reduced, and the service life of the pavement is prolonged. The experimental results show that the pavement damage index PCI of the composite fabricated cement concrete pavement structure is 92.3-95.5, and the pavement service condition is excellent.

Owner:CCCC THIRD HIGHWAY ENG

Road design method and mixing method

InactiveCN104844092AAvoid pitfalls that make perfusion quality difficult to controlReduce consumptionBitumen emulsionStructural engineering

The invention discloses a road design method. According to the spatial structure of a direct mixing type semi-flexible asphalt mixture, a mix proportion design method which determines the mineral aggregate gradation of a mixture matrix and optimal asphalt content and cement paste content is established. In combination with the demulsification and coagulation characteristics of modified emulsified asphalt, the invention puts forward a mixing method for the direct mixing type semi-flexible asphalt mixture which includes a sequence of adding various materials and mixing time. The invention can directly obtain the semi-flexible asphalt mixture by a mixing mode under the condition of normal temperature, and not only are the defects of conventional pouring type semi-flexible pavement materials, including high energy consumption, high pollution and complex construction process, effectively prevented, but also the defects of conventional asphalt mixture, including insufficient high-temperature stability and overhigh cement concrete pavement stiffness, are overcome.

Owner:陈素素

Modified asphalt and preparation method thereof

The invention provides modified asphalt, the modified asphalt comprises the following raw materials: a matrix asphalt, waste powdered carbon obtained from a printer or a copy, aluminic acid ester and stearic acid; a preparation method of the modified asphalt comprises the following steps: 1)respectively preheating the matrix asphalt and the waste powdered carbon; 2)mixing the preheated waste powdered carbon and the matrix asphalt to obtain a mixture; 3)simultaneously stirring or shearing the mixture while heating; 4)adding an aluminic acid ester coupling agent and continuously stirring or shearing; and 5)adding a stearic acid synergist and stirring or shearing to obtain the modified asphalt. The modified asphalt has the advantages of good technology performance and low price, the waste powdered carbon in a toner cartridge of the printer or a copy machine can be reused, the modified asphalt has good social, economic and environmental protection benefits; the softening point of the matrix asphalt can be increased by 3-8 DEG C, so that the high temperature stabilization performance of the asphalt mixture can be increased, pavement track is reduced, water stabilization performance is increased, and the low temperature performance grade of the modified asphalt can be kept or improved.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

Composite asphalt cooling pavement top layer and construction method thereof

InactiveCN107503261AChange thermal conductivityChange specific heat capacityIn situ pavingsSolid waste managementPermafrostRoad surface

The invention belongs to the field of asphalt concrete pavements and relates to a composite asphalt cooling pavement top layer and a construction method thereof. The construction method comprises following steps: S1, a thermal-resistant asphalt mixture is spread on the top layer of a pavement and then rolled; S2, after the thermal-resistant asphalt mixture rolled in S1 is cured, the upper surface of the thermal-resistant asphalt mixture is coated with a coating; S3, after the thermal-resistant asphalt mixture and the coating are cured, the composite asphalt cooling pavement top layer is formed. Pavement ruts, the urban heat island effect and permafrost subgrade defects can be overcome.

Owner:CHANGAN UNIV

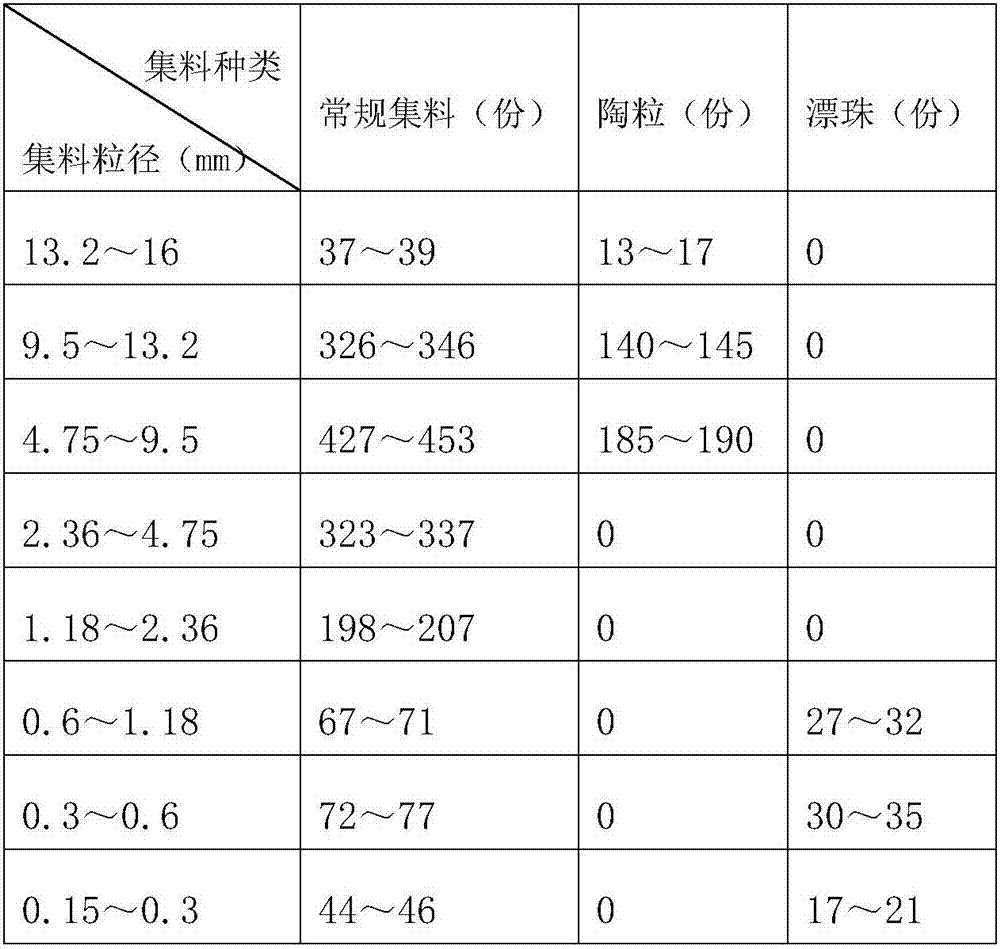

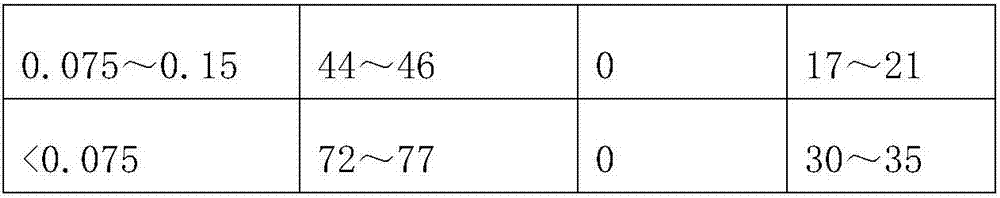

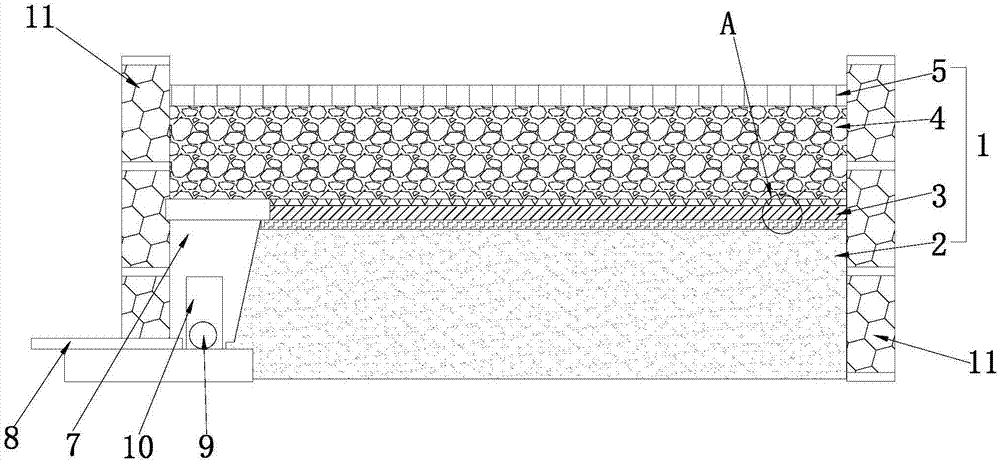

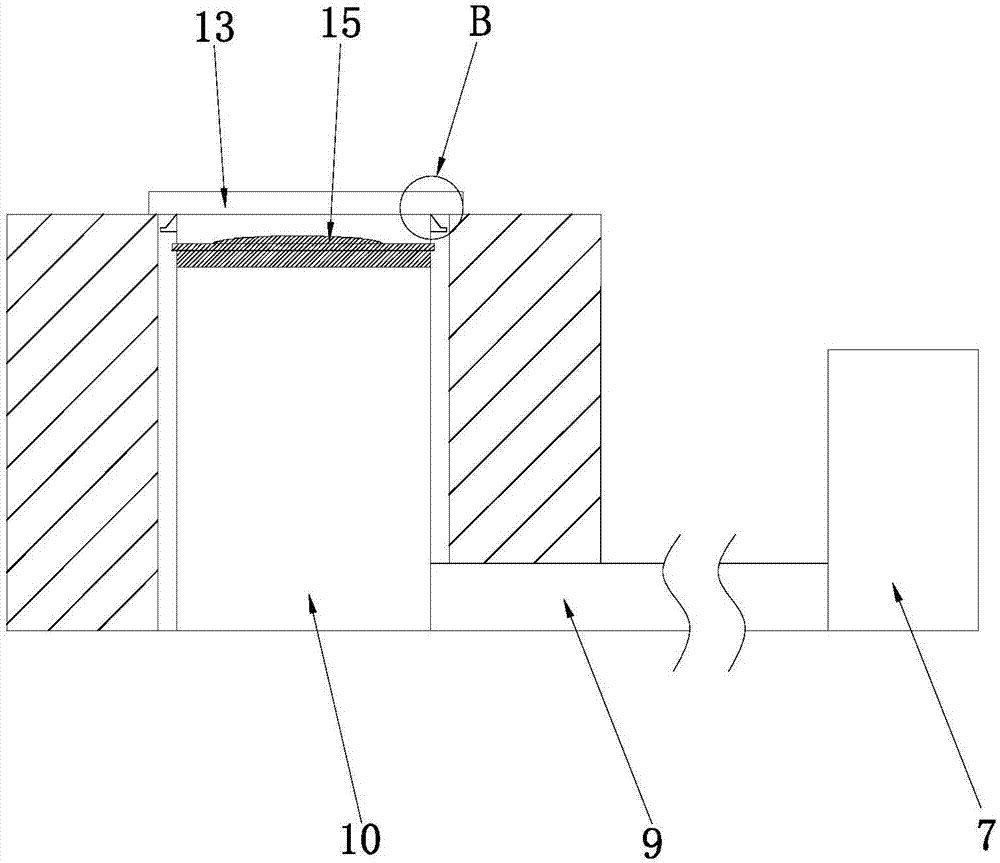

Emulsified bitumen concrete steady porcelain granule road surface base layer material and road surface base layer construction method thereof

InactiveCN101349037AReduce ruttingReduce reflective cracksIn situ pavingsCrushed stoneExpanded clay aggregate

The invention discloses an emulsified asphalt-cement stabilized porcelain granule base course material which eliminates waste and has good performance. Porcelain granules are utilized to substitute broken stones to prepare the base course material, the base course material mainly comprises cement, emulsified asphalt, the porcelain granules, stone chips and water, and further the porcelain granules are sintered porcelain granules produced by pelleting and roasting the waste. The base course material reduces rigidity, contributes to the reduction of ruts and reflective cracks on a road surface, improves the structural performance of the road surface, and has good impermeability, antifreezing performance and durability as well as convenient construction. The invention also provides a construction method for the emulsified asphalt-cement stabilized porcelain granule base course.

Owner:CHONGQING UNIV

Water permeable asphalt road surface and construction method thereof

InactiveCN107447620AImprove crack resistanceAvoid damageFatty/oily/floating substances removal devicesSewerage structuresInsulation layerEngineering

The invention discloses a water permeable asphalt road surface and a construction method thereof. The water permeable asphalt road surface comprises an asphalt road surface body, and the asphalt road surface body comprises an earth base, a cushion layer, a base layer and a face layer which are sequentially laid on the ground surface from bottom to top, a water insulation layer is arranged on the cushion layer, so that the water entering the interior of the asphalt road surface body is drained horizontally along the water insulation layer; a drainage ditch for collecting water is formed in one side of the earth base; a plurality of watering pipes which are connected with surrounding green belts are arranged in the drainage ditch; and water guiding pipes are arranged in the drainage ditch, and the water guiding pipes are connected to the gutter inlet. According to the water permeable asphalt road surface and the construction method thereof, water accumulating on the road surface is dispersed quickly, and the crack resistant ability of the road surface is improved by fully utilizing original discarded road surface materials, and the service life of road is prolonged.

Owner:无锡建设监理咨询有限公司

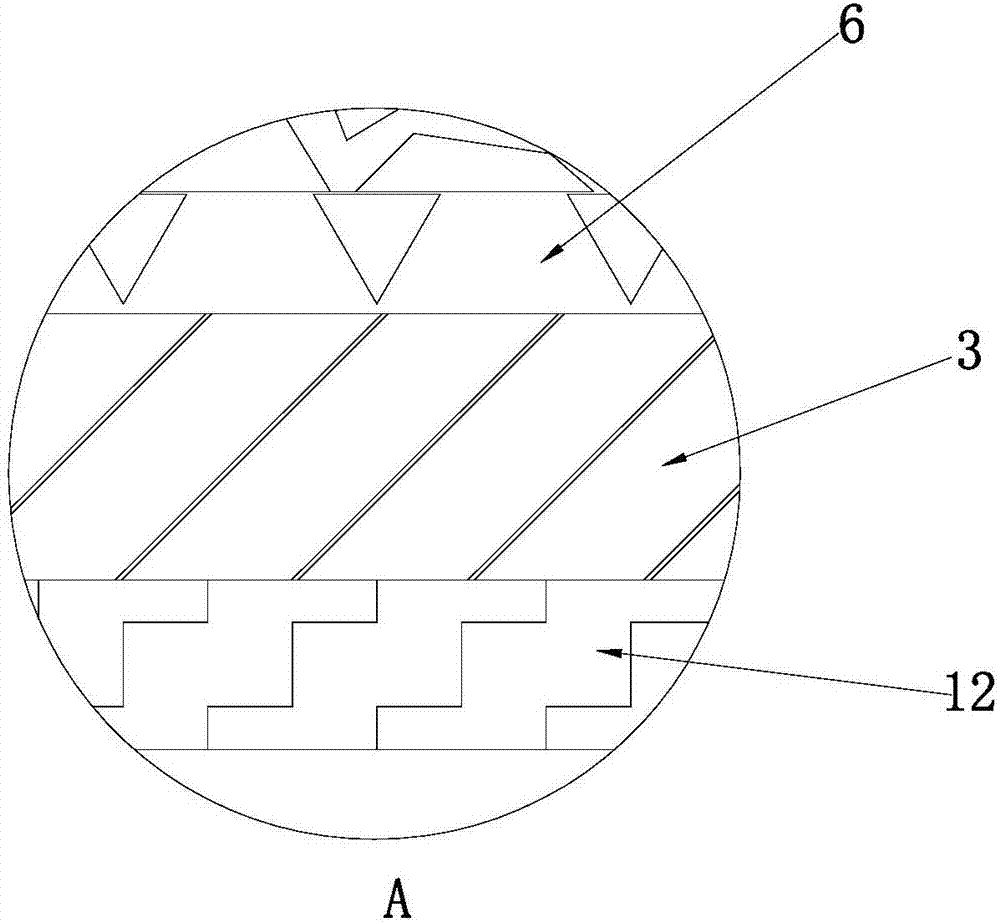

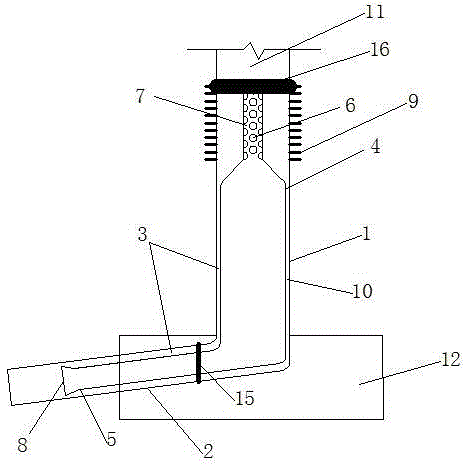

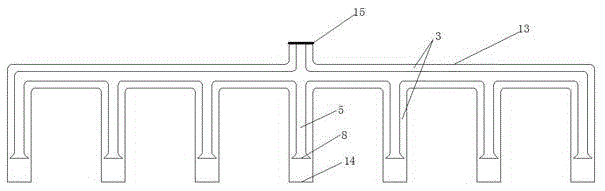

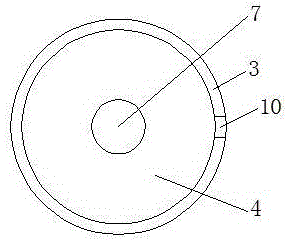

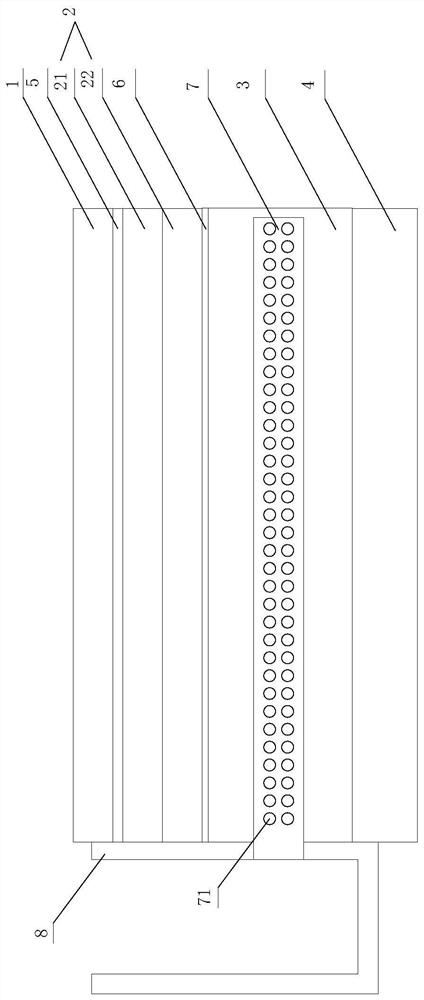

Asphalt pavement cooling device

The invention discloses an asphalt pavement cooling device, which comprises two main parts, i.e. an evaporation pipe section and a condensation pipe section. The condensation pipe section includes a condensation pipe outer pipe and a condensation pipe inner pipe, and the evaporation pipe section includes an evaporation pipe main pipe and evaporation pipe branch pipes. When the pavement temperature is higher than the air temperature, a working medium filling the device undergoes gas-liquid circulation spontaneously so as to dissipate the pavement heat into the air and reduce asphalt pavement rutting, flushing, translation and other diseases caused by temperature rise. Single condensation pipe is connected to a plurality of evaporation pipes, the cooling area of single condensation pipe is increased, and the cooling efficiency is greatly improved. Also, the condensation pipe can be combined with street lamps, advertising boards and other road affiliated facilities into a whole, thus having no influence to the appearance.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD

Anti-track bituminous pavement cooling structure and material composition of each layer thereof

PendingCN110499687AReduce road ruttingReduce road temperatureIn situ pavingsLower faceRoad surface temperature

The invention discloses an anti-track bituminous pavement cooling structure and a material composition of each layer thereof. The anti-track bituminous pavement cooling structure comprises a low-heatconduction upper face layer, a heat storage intermediate face layer and a high-heat-conduction lower face layer from top to bottom. During construction, layered paving and rolling are combined, and tack coat is scattered between the layers. According to the anti-track bituminous pavement cooling structure, a pavement structure actively carries out temperature control on a bituminous pavement, andpavement tracks are reduced by reducing the temperature of the intermediate face layer and the lower face layer of the bituminous pavement. According to the anti-track bituminous pavement cooling structure, the bituminous pavement structure with the low-heat conduction upper face layer, the heat storage intermediate face layer and the high-heat-conduction lower face layer is adopted, the pavementtemperature is reduced to the maximum degree through heat induction and phase change heat storage, and the cooling effect is remarkable. According to the anti-track bituminous pavement cooling structure, heat insulation fibers are added to the material of the low-heat conduction upper face layer, the high-temperature performance of a mixture can be improved while the heat conduction performance ofthe pavement, and the anti-track capacity of the upper face layer is improved.

Owner:CENT SOUTH UNIV

Reflection crack repairing structure and reflection crack repairing process

InactiveCN105442407AImprove high temperature stabilityImprove stabilityIn situ pavingsPaving detailsPolyesterFiltration

The invention discloses a reflection crack repairing structure and a reflection crack repairing process. The reflection crack repairing structure comprises a waterproof adhesive layer, a fiberglass-polyester paving mat anti-crack layer, a first backfill layer and a second backfill layer, wherein the waterproof adhesive layer is arranged on a grooved bottom surface of a reflection crack; the fiberglass-polyester paving mat anti-crack layer is arranged on the upper surface of the waterproof adhesive layer; the first backfill layer is arranged on the upper surface of the fiberglass-polyester paving mat anti-crack layer; and the second backfill layer is arranged on the upper surface of the first backfill layer. By milling materials around the crack and backfilling the fiberglass-polyester paving mat anti-crack layer and backfill, the reflection crack repairing structure disclosed by the invention has favorable integrity, continuity and durability. When the reflection crack repairing structure is applied to a pavement structure, the reflection crack repairing structure has the functions of isolation, seepage prevention, filtration, drainage and the like, can improve the resistance to fatigue cracking of an asphalt surface course, can prevent the reflection crack and deformation resistance, and can improve the use quality of a semi-rigid base asphalt pavement with obviously insufficient old road intensity, large traffic flow, frequent heavy overload vehicles and severe cracking, thereby prolonging the service life of the pavement structure.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

Soilbag roadbed and method

A soilbag roadbed and a method. The soilbag roadbed comprises soilbags, a roadbed substrate, a soilbag roadbed, a pavement and a surface protection. Soilbags are staggered vertically and horizontally and stacked up layer by layer from the roadbed substrate to be tightly combined with asphalt, concrete or broken stone paved on the pavement. The invention is simple, practical, thrift and economical and has substantial social and economic benefits.

Owner:刘斯宏 +1

Waterproof asphalt pavement structure and construction method thereof

PendingCN112746542AImprove waterproof performanceIncreased durabilityIn situ pavingsPaving gutters/kerbsBitumen emulsionStructural engineering

A waterproof asphalt pavement structure comprises an asphalt wearing surface layer, an asphalt middle-lower surface layer, a roadbed surface layer and a roadbed; a waterproof adhesive layer is arranged between the asphalt wearing surface layer and the asphalt middle-lower surface layer; a waterproof permeable sealing layer is arranged between the asphalt middle-lower surface layer and the roadbed surface layer; a drainage pipe is arranged in the roadbed surface layer, and drainage holes are formed in the circumference of the drainage pipe; and one side of the road width direction is provided with a drainage ditch, the lower side of the drainage ditch extends to the roadbed, and the side, close to the drainage ditch, of the drainage pipe is communicated with the drainage ditch. The construction method comprises the following steps: firstly, building a roadbed, then paving the roadbed surface layer on the roadbed, burying the drainage pipe in the paving process of the roadbed surface layer, cleaning waste materials in the drainage pipe, and then paving the asphalt middle-lower surface layer and the permeable sealing layer; then uniformly spraying the waterproof adhesive layer on the asphalt middle-lower surface layer, and after demulsification and evaporation of emulsified asphalt are completed, paving the asphalt wearing surface layer and properly rolling; and building the drainage ditch at a reserved position on one side of the road surface in the width direction, and enabling the drainage pipe to be communicated with the drainage ditch.

Owner:安徽水利嘉和建筑工程有限公司 +1

Lightweight heat-insulating semi-flexible anti-cracking pavement and preparation method thereof

ActiveCN113186772ALight weightRelieve pressureIn situ pavingsSolid waste managementThermal insulationRoad surface

The invention discloses a lightweight heat-insulating semi-flexible anti-cracking pavement which comprises large-gap asphalt concrete and foaming cement glue filled in gaps of the large-gap asphalt concrete, wherein the macropore asphalt concrete is prepared from aggregate, filler and high-viscosity modified asphalt as main raw materials, and the high-viscosity modified asphalt is prepared by adding high-viscosity modified anti-crack particles into SBS modified asphalt or matrix asphalt for modification; the foamed cement mucilage is prepared from cement, quick lime, fly ash, gypsum, carboxylated styrene-butadiene emulsion, sodium sulfate, sodium polyacrylate, aluminum powder paste and water as raw materials. The lightweight flexible pavement has the advantages of light self-weight, good thermal insulation performance, high interface bonding performance and the like, can effectively reduce the low-temperature cracking property of the pavement, is suitable for middle and upper surface layers of the pavement, solves the problems of easy surface cracking and fatigue aging of the existing semi-flexible pavement, prolongs the service life of the pavement, and is suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

Surface layer structure of bus lane and paving method

The invention provides a surface layer structure of a bus lane and a paving method, and relates to the technical field of road surface pavement. Diseases such as wheel rut, pushing upheaval, cracks and pit slots of general asphalt concrete pavement can be solved. The surface layer structure of the bus lane comprises a general road segment and a platform road segment, and a layer surface structureof the general road segment and the platform road segment sequentially comprises a cement concrete layer, a bonding layer and an asphalt concrete thin layer from bottom to top; the bonding layer of the general road segment is an asphalt bonding layer, and the bonding layer of the platform road segment is a polyurethane bonding layer or an epoxy resin bonding layer; the thickness of the cement concrete layer is not less than 20cm; the thicknesses of the polyurethane bonding layer and the epoxy resin bonding layer are not less than 3mm; and the thickness of the asphalt concrete thin layer is 1.5cm-2.5cm. The technical scheme of the surface layer structure of the bus lane and the paving method is suitable for the process of bus lane road pavement.

Owner:BEIJING ZHIHUATONG TECH CO LTD

Asphalt pavement structure

InactiveCN106702846AWith drainage functionWith temperature control functionIn situ pavingsPaving detailsTemperature controlPorosity

The invention discloses an asphalt pavement structure comprising an asphalt surface layer which comprises a lower layer, an intermediate layer, a drainage insulation layer and an upper layer arranged in order from bottom to top, wherein the drainage insulation layer is an asphalt mixture layer with a porosity of 8% to 20%. The asphalt pavement structure disclosed by the invention has the functions of drainage and temperature control, and has the advantages of reducing water damage and ruts of asphalt pavements.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Environment-friendly asphalt pavement anti-rut agent and preparation method thereof

ActiveCN102702600BImprove protectionNo displacementBuilding insulationsLow-density polyethyleneMicrosphere

The invention discloses a preparation method of an environment-friendly asphalt pavement anti-rut agent and an application thereof. The method comprises the following steps of: mixing and stirring 45-80 percent of polyethylene and 15-30 percent of petroleum resin derived from 'plastic waste', 5-15 percent of polymethyl methacrylate, 5-15 percent of an asphalt material and 0-10 percent of an inorganic mineral filling material at a high speed; and extruding at a high temperature to prepare the environment-friendly asphalt pavement anti-rut agent. Due to the adoption of the environment-friendly asphalt pavement anti-rut agent, the performance of an asphalt pavement is enhanced, the service life of the pavement is prolonged, 'white waste' is recycled, and environmental pollution is lowered. Polyethylene serving as a major component is either or both of industrial production low-density polyethylene and industrial recycled waste polyethylene; the industrial recovered waste polyethylene is recovered polyethylene or regenerated low-pressure polyethylene or regenerated PE (Polyethylene); the molecular weight of the petroleum resin is 300-3,000; the molecular weight of the polymethyl methacrylate is 80,000-120,000; the asphalt material is one or more of natural asphalt, coal tar asphalt and petroleum asphalt; and the inorganic mineral filling material is one or over two of calcium carbonate of 500-800 meshes, talc powder, quartz sand, glass hollow microspheres and kaolin.

Owner:SHENZHEN KEZHONGDA POLYMER MATERIAL RES INST

A cold-mix phase-change heat-storage asphalt mixture

ActiveCN103508702BActively regulate temperatureMitigate the heat island effectPhysical chemistryBitumen emulsion

The present invention proposes a cold-mix phase-change heat-storage asphalt mixture, which is characterized in that it is mixed at room temperature by aggregates, porous base phase-change heat-storage particles, fillers, water, emulsified asphalt or modified emulsified asphalt, each Mass ratio of raw materials Aggregate: porous base phase change heat storage particles: filler: water: emulsified asphalt or modified emulsified asphalt = 100: 20~100: 1~3: 2~4: 5~8. Porous-based phase-change heat storage particles are based on porous igneous rock aggregates. Under vacuum conditions, organic solid-liquid phase-change materials are adsorbed in the pore structure of the matrix, and the surface is coated with a thermosetting resin film layer containing thermally conductive fillers by immersion method. , It is obtained by curing at room temperature for 2-4 days, its phase transition temperature is 40-70°C, its latent heat of phase transition is 20-60J / g, and its mechanical properties are good. The preparation process of the invention is simple, energy-saving and environment-friendly, and has a good effect of reducing road surface temperature.

Owner:CHONGQING JIAOTONG UNIVERSITY

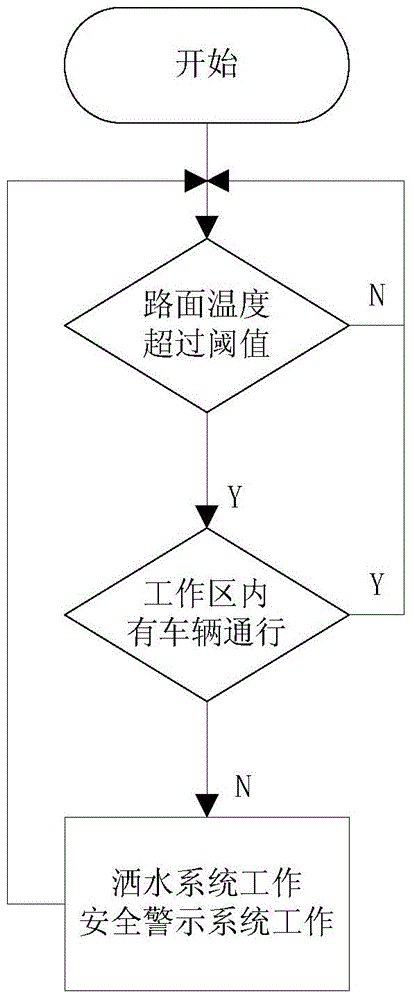

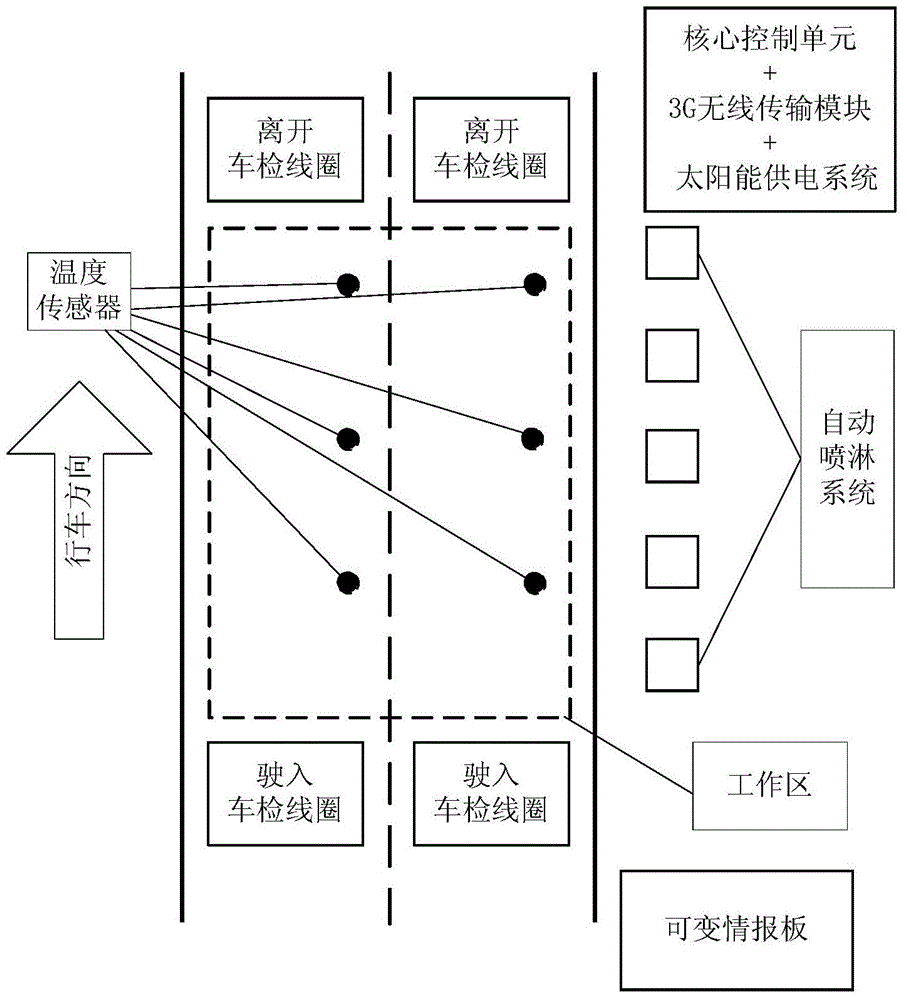

Rut preventing device and method for long uphill section of asphalt pavement

InactiveCN104963260ASimple methodThe method is efficient and fastArrangements for variable traffic instructionsRoads maintainencePavement maintenanceWireless transmission

The invention provides a rut preventing device and method for the long uphill section of an asphalt pavement. The rut preventing device comprises a central control unit, a pavement temperature acquiring system, an automatic spraying system and a running safety warning system, wherein the central control unit analyzes and judges the received real-time temperature data and the received real-time traffic information, and controls the automatic spraying system and the running safety warning system to work; besides, the central control unit transmits the working state of the systems to a server in a remote manner through a 3G wireless transmission module; besides, the central control unit receives commands from the server. The rut preventing method disclosed by the invention is simple, rapid and highly efficient, and is low in cost; both of running safety and pavement maintenance are taken into consideration; the temperature of the asphalt pavement can be effectively lowered, so that the generation of ruts on the asphalt pavement can be effectively relieved, and the running safety and running comfort on the asphalt pavement under high-temperature conditions in summer are improved.

Owner:CHANGAN UNIV +2

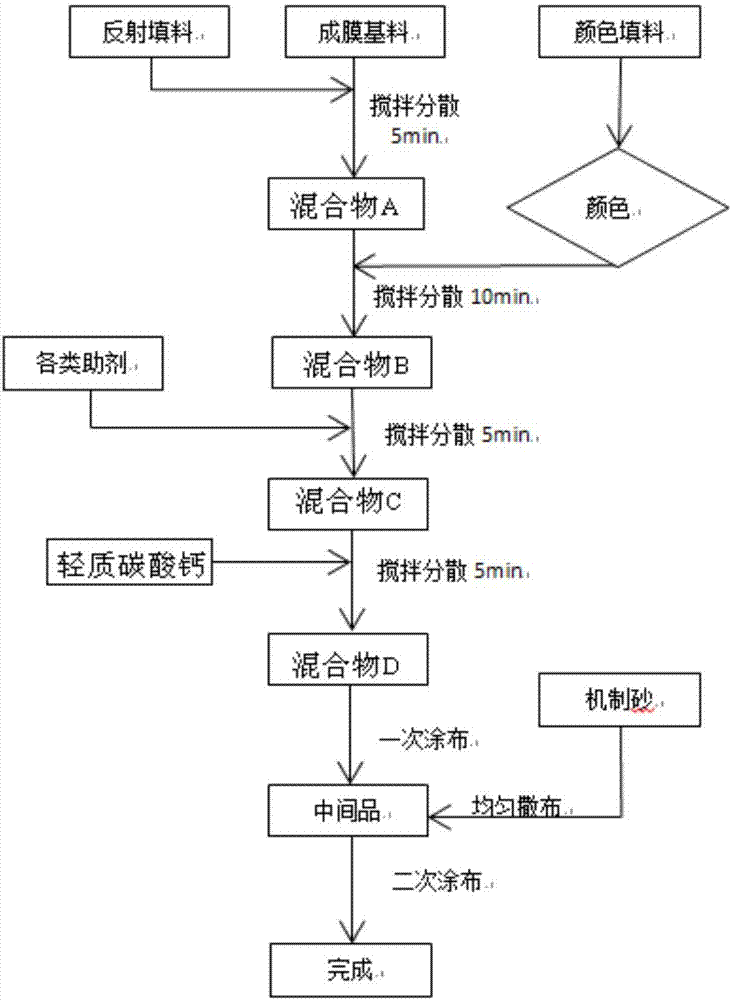

Cement-base colored microsurface and construction method thereof

The invention discloses a cement-base colored microsurface, belonging to the technical field of road engineering. The microsurface pavement comprises a cement-base layer, wherein the cement-base layer comprises the following components in parts by mass: 100 parts of cement, 150-170 parts of colored quartz sand, 50 parts of water, 7 parts of waterproofing agent and 10 parts of pigment; and the cement-base layer also comprises 0.1 vol% of polyvinyl alcohol fiber and a right amount of modifier. The modifier is composed of a water-based epoxy resin (the mass ratio of the water-based epoxy resin to the cement is (8-12):100) and a curing agent (the mass ratio of the curing agent to the water-based epoxy resin is 1.3:1), or hydroxy cellulose (the mass ratio of the hydroxy cellulose to the water is 3:100), or a water-based organic silicon resin (the mass ratio of the water-based organic silicon resin to the cement is 2.5:100). The color of the colored quartz sand has the same color system as the color of the pigment. The invention also discloses a construction method of the cement-base colored microsurface. The cement-base colored microsurface has the advantages of higher water resistance, higher crack resistance, higher wear resistance, higher color distinction degree and high color durability, and is easy for construction.

Owner:SOUTHEAST UNIV

Method for preparing modified asphalt by using waste plastics

InactiveCN101225237BHigh softening pointImprove high temperature stabilityBuilding insulationsPulp and paper industryAsphalt

The invention discloses a method for making modified asphalt using waste plastics, comprising the following process steps: 1) various waste plastics are collected, sorted, washed and then dehydrated and grinded; 2) the grinded waste plastics are melted by heating up, and then processed into waste plastic grains after cooling; 3) the waste plastic grains are liquefied by high temperature heating and then cooled, the waste plastic modifying agent is obtained; 4) base asphalt is healed to be softened, then the waste plastic modifying agent obtained during step 3) and the base asphalt are melted to be immixed; 5) the mixture obtained during the step 4) is melted to expanded and sheared, the manufacture of the modified asphalt is finished; the method for making modified asphalt using waste plastics has the advantages that: the soften point of the asphalt is increased ten to fifteen DEG C, the price is low, the waste domestic plastic products are changed into valuables, and has the advantages of good technical performances and low price and other economic technique characterizes.

Owner:杨锡武 +1

Modified asphalt composition and preparation method thereof

ActiveCN103102701BHigh softening pointBig aging indexBuilding insulationsPenetration indexAging resistance

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano-composite natural rock modified asphalt mixture additive

The invention belongs to the technical field of engineering materials, and particularly relates to a nano-composite natural rock modified asphalt mixture additive. The additive is prepared from natural rock asphalt as a main raw material and waste tire rubber powder, a polymer, nano-diatomite, lignin fibers, nano-zinc oxide and other raw materials as auxiliary materials, so the elasticity, adhesiveness and rigidity of an asphalt mixture are effectively improved, and the high-temperature deformation resistance, the low-temperature crack resistance and the water damage resistance of the compound rock modified asphalt mixture are remarkably improved.

Owner:广西路冠科技投资发展有限责任公司

Shape memory epoxy resin modified asphalt mixture and preparation method thereof

The invention provides a shape memory epoxy resin modified asphalt mixture and a preparation method thereof. The preparation method comprises the following steps: taking 4-6 parts of asphalt, 100 parts of aggregate, 1-20 parts of shape memory epoxy resin and 1-6 parts of mineral powder according to parts by mass; mixing the aggregate and the shape memory epoxy resin, and then blending uniformly atthe temperature of 140 DEG C to 180 DEG C to obtain a blending mixture a; mixing the asphalt and the blending mixture a, and then blending uniformly at the temperature of 140 DEG C to 180 DEG C to obtain a mixing mixture b; and mixing the mineral powder and the blending mixture b, then blending uniformly at the temperature of 140 DEG C-180 DEG C, cooling to a room temperature, and thus obtainingthe shape memory epoxy resin modified asphalt mixture. The shape memory epoxy resin modified asphalt mixture has an excellent pavement performance and a remarkable improvement effect on the deformation recovery performance of the asphalt mixture; and the preparation method is simple in operation and low in cost and has low requirements on equipment and the characteristics of environmental protection.

Owner:XIAN UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com