Asphalt pavement cooling device

A technology of cooling device and asphalt pavement, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems of low cooling efficiency and small cooling area, and achieve the effect of increasing coverage area, improving cooling efficiency and reducing rutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

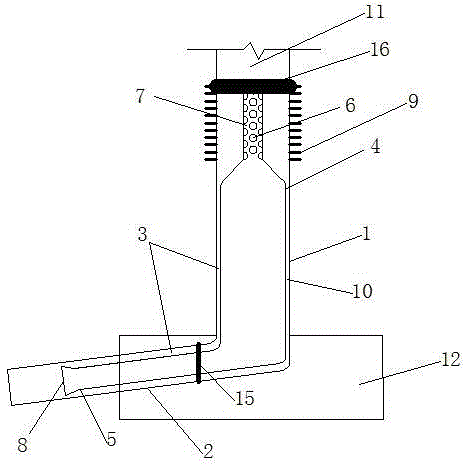

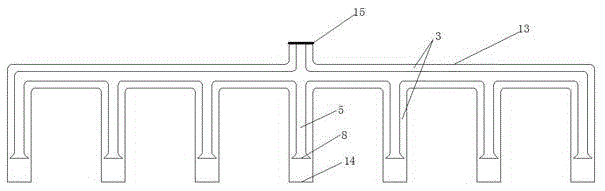

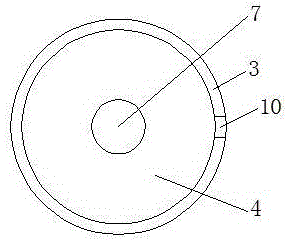

[0025] Embodiment 1: as figure 1 As shown, the base 12 is provided with an evaporation pipe section and a condensation pipe section, and the condensation pipe section includes an outer pipe 1 of the condensation pipe and an inner pipe 4 of the condensation pipe. In the shape of a wine bottle, the gas channel changes from wide to narrow, which will accelerate the airflow, thereby speeding up the speed of the gaseous working medium entering the outer tube from the inner tube, avoiding the early liquefaction of the gaseous working medium due to too slow gas outlet, and liquefaction in the outer tube The working medium can flow into the liquid working medium reflux tank along the outer contour of the wine bottle.

[0026] The top of the inner tube 4 of the condensation tube is provided with an air outlet 7, and the air outlet 7 is engraved with an air outlet 6 of the inner tube of the condensation tube with a diameter of 10 mm and a distance between centers of 15 mm, so that the g...

Embodiment 2

[0032] Embodiment 2: as figure 1 As shown, the base 12 is provided with an evaporation pipe section and a condensation pipe section, and the condensation pipe section includes an outer pipe 1 of the condensation pipe and an inner pipe 4 of the condensation pipe. In the shape of a wine bottle, the gas channel changes from wide to narrow, which will accelerate the airflow, thereby speeding up the speed of the gaseous working medium entering the outer tube from the inner tube, avoiding the early liquefaction of the gaseous working medium due to too slow gas outlet, and liquefaction in the outer tube The working medium can flow into the liquid working medium reflux tank along the outer contour of the wine bottle.

[0033] The top of the inner tube 4 of the condensation tube is provided with an air outlet 7, and the air outlet 7 is engraved with an air outlet 6 of the inner tube of the condensation tube with a diameter of 10 mm and a distance between centers of 15 mm, so that the g...

Embodiment 3

[0039] Embodiment 3: as figure 1 As shown, the base 12 is provided with an evaporation pipe section and a condensation pipe section, and the condensation pipe section includes an outer pipe 1 of the condensation pipe and an inner pipe 4 of the condensation pipe. In the shape of a wine bottle, the gas channel changes from wide to narrow, which will accelerate the airflow, thereby speeding up the speed of the gaseous working medium entering the outer tube from the inner tube, avoiding the early liquefaction of the gaseous working medium due to too slow gas outlet, and liquefaction in the outer tube The working medium can flow into the liquid working medium reflux tank along the outer contour of the wine bottle.

[0040] The top of the inner tube 4 of the condensation tube is provided with an air outlet 7, and the air outlet 7 is engraved with an air outlet 6 of the inner tube of the condensation tube with a diameter of 10 mm and a distance between centers of 15 mm, so that the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com