A kind of air cooling device for heat treatment workpiece

A technology of air-cooling device and blowing device, which is applied in the field of cooling workpieces after heating in heat treatment furnaces. It can solve problems such as shaking, long time spent, and damage to workpieces, and achieve uniform cooling, easy left and right movement, and guaranteed effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings.

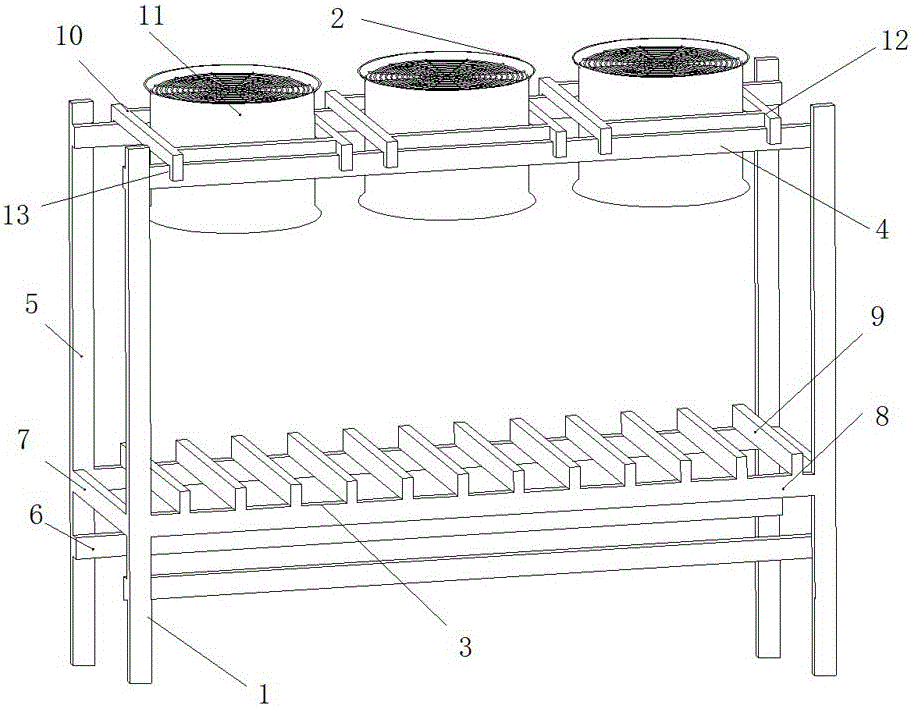

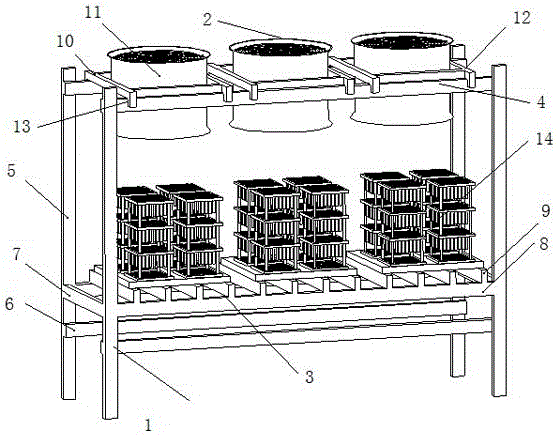

[0018] Such as figure 1 with figure 2 As shown, an air-cooling device for heat-treating workpieces includes a supporting device 1 and a blowing device 2 arranged on the supporting device 1. The supporting device 1 is used to support the fixed blowing device 2 to ensure the stability of the air-cooling process. The lower end is provided with a placing part 3 for placing the workpiece 14, and a blowing device 2 for cooling the workpiece 14 is provided above the placing portion 3. The blowing device 2 vertically faces the placing portion 3 to facilitate vertical blowing to cool the workpiece 14. Blowing air will not cause the workpiece 14 to sway and cause the risk of falling and damage. The cooling air uses air to take away the temperature of the workpiece 14 from top to bottom to achieve the cooling effect, and the cooling wind passes through the circumference of the workpiece 14 to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com