Processing technology of corrosion-resistant stainless steel seamless steel pipe

A technology of seamless steel pipe and processing technology, which is applied in the field of seamless steel pipe processing, can solve problems such as long time consumption, and achieve the effects of realizing reuse, accelerating cooling rate, and avoiding the outflow of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

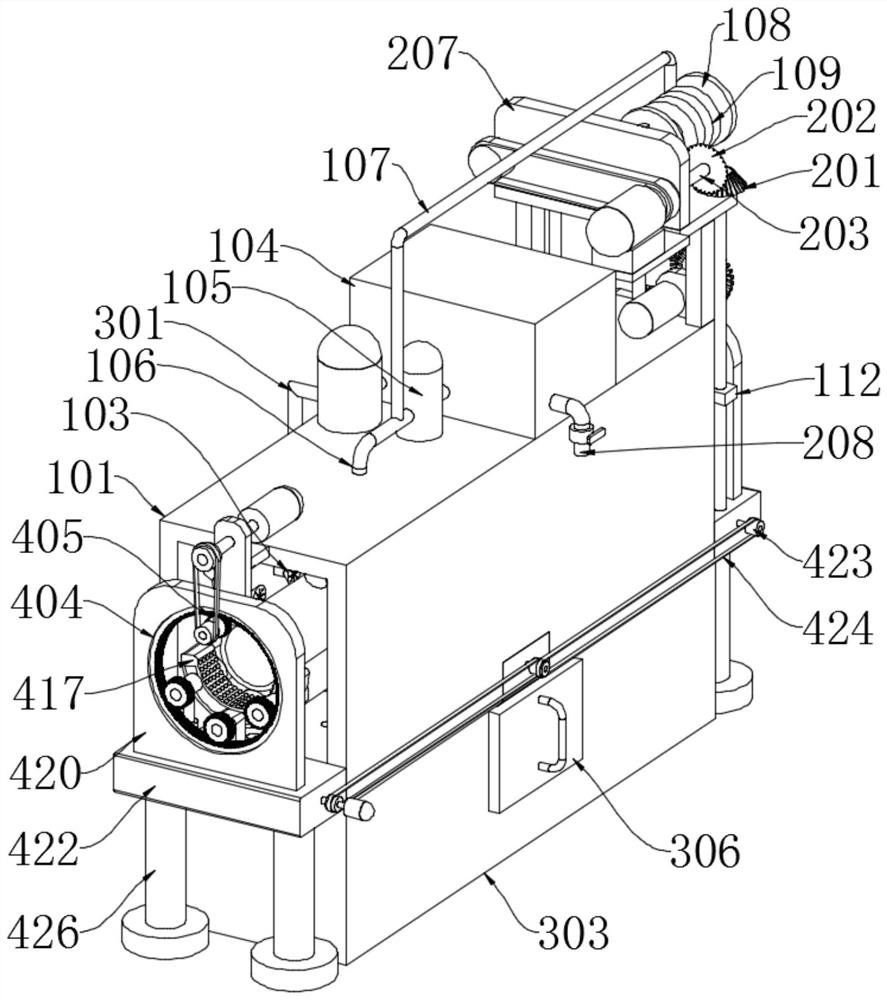

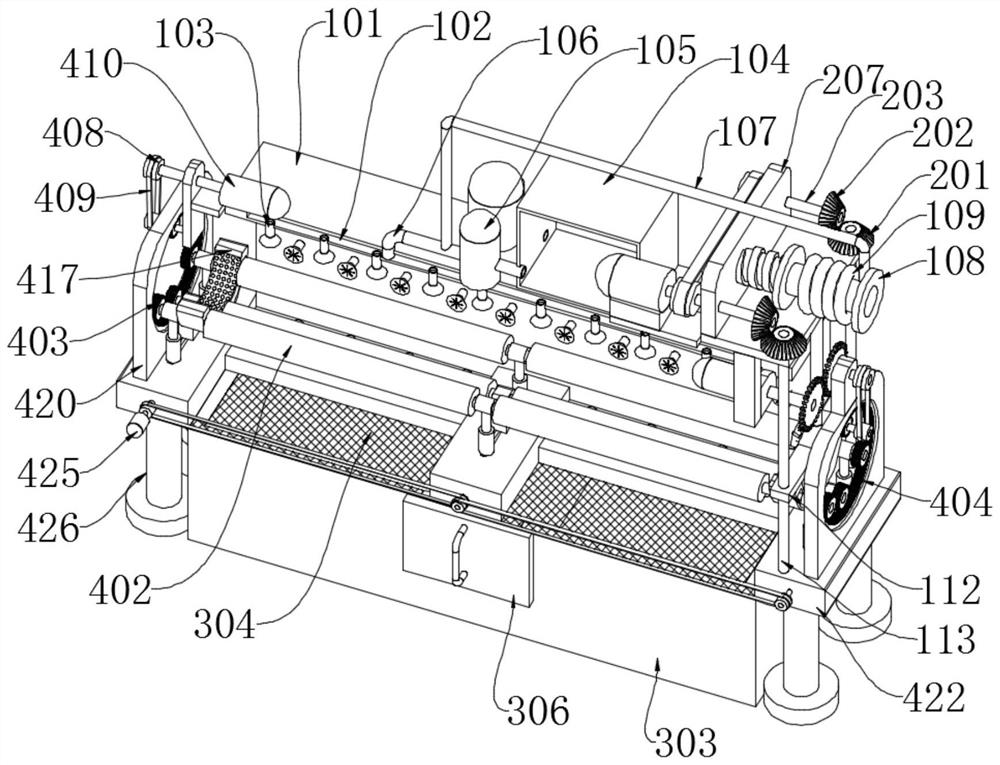

[0065] First of all, it is necessary to adjust the positions of the two second rotating shafts 401 located on the outside of the cooling device according to the specifications of the round tube blanks, so as to be suitable for stainless steel tubes of different sizes;

[0066] Specifically, as Figure 1-7 As shown in 9-11, by starting the third motor 425 installed on the outer end of the second threaded rod 416 in the transmission mechanism, the third motor 425 is used to drive one of the second threaded rods 416 to rotate, because the outer end of each second threaded rod 416 is used. A third pulley 423 is installed on both, and a third belt 424 is installed between the two adjacent third pulleys 423 that can drive the third pulley 423 to rotate, so the third motor 425 can drive the three second threaded rods 416 to rotate at the same time ;

[0067] Second, if Image 6 As shown, the sliding seat 415 threadedly connected with the outer end of the second threaded rod 416 can...

Embodiment 2

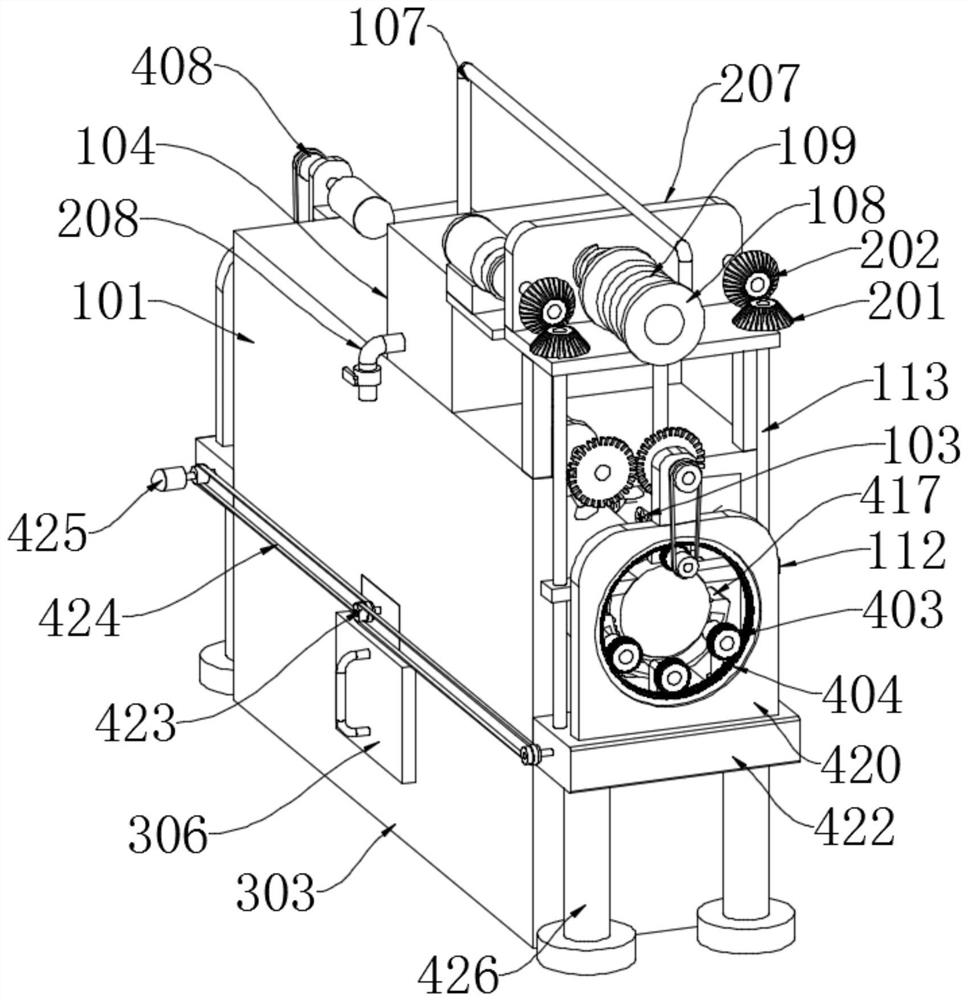

[0070] After the position between the three rotating rollers 402 is adjusted, the heated steel pipe can be moved between the three rotating rollers 402 under the transmission of the conveying machine, so as to use the three rotating rollers 402 to support the steel pipe, and then Then spray water through the cooling mechanism to cool down;

[0071] Specifically, after the steel pipe is moved into the cooling box 101, the first water pump 105 installed on the top of the cooling box 101 is activated, and the first water pump 105 is used to pump the water stored in the cooling water tank 104 through the first water outlet pipe 106. In the water storage tank 102 in the inner wall of the cooling tank 101, the water is sprayed through the nozzle 103 communicated with the inside of the water storage tank 102, and the sprayed water can contact the outer wall of the steel pipe, so that the steel pipe can be cooled and cooled;

[0072] When the steel pipe enters and leaves the cooling b...

Embodiment 3

[0078] In the process of spraying, in order to avoid the waste of water resources, such as figure 1 , 4 As shown in , 7, 8, the recovery mechanism in the present invention can recover the water flow ejected from the cooling box 101, so as to facilitate the subsequent reuse of water resources;

[0079] Specifically, the water sprayed by the spray head 103 and the water outlet pipe 111 can enter the collection box 303 installed at the bottom of the cooling box 101 through the water outlet hole 305 opened at the bottom of the cooling box 101 , and the water flow will flow into the collection box 303 after entering the collection box 303 . Pass through the filter screen 304 installed inside and move to the bottom of the filter screen 304, and when the water flows through the filter screen 304, it will filter out the solid debris in the water flow, thereby preventing the pipeline from being blocked;

[0080] In order to facilitate the transfer of the water collected at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com