A metal cylinder electrofusion additive manufacturing system

An additive manufacturing and metal cylinder technology, which is applied in the field of metal cylinder electrofusion additive manufacturing system, can solve the problems of complex manufacturing process, low material utilization rate, long production cycle, etc. Good performance and chemical properties, ensuring the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0038] [Implementation case] Production of rotating cylinder

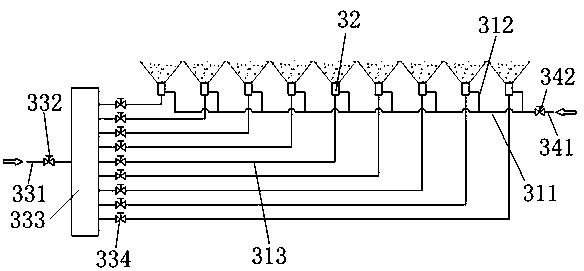

[0039] This case describes the process of making a metal cylinder by electrofusion forming. The material is ordinary low carbon steel. For the equipment used, see the attached figure 1 .

[0040] Attached figure 1 This is a schematic explanatory diagram of this embodiment, in which the cooling device only draws 9 nozzles 32 in this schematic diagram, and the number that meets the requirements can be selected according to specific needs during implementation, and the power supply, automatic wire feeding and other devices are omitted in the figure.

[0041] Specifically, ordinary low-carbon steel is selected as the raw material wire, the diameter of the raw wire is 4mm, the electrofusion head assembly 2 includes 9 electrofusion heads, the electrofusion power source is a DC power source, and the electrofusion head is connected to the negative electrode of the power source. Connect the positive pole of the power supply (when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com