Automatic yeast stirring and cooling machine

A koji cooling machine and automatic technology, which is applied in the field of brewing production equipment, can solve the problems of troublesome cleaning work, heavy water treatment burden, and high labor intensity, so as to achieve the improvement of production efficiency and product quality stability, production efficiency and The stability of product quality is enhanced and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following examples illustrate the present invention in more detail, but are not limited to the following examples as long as it falls within the scope of the present invention.

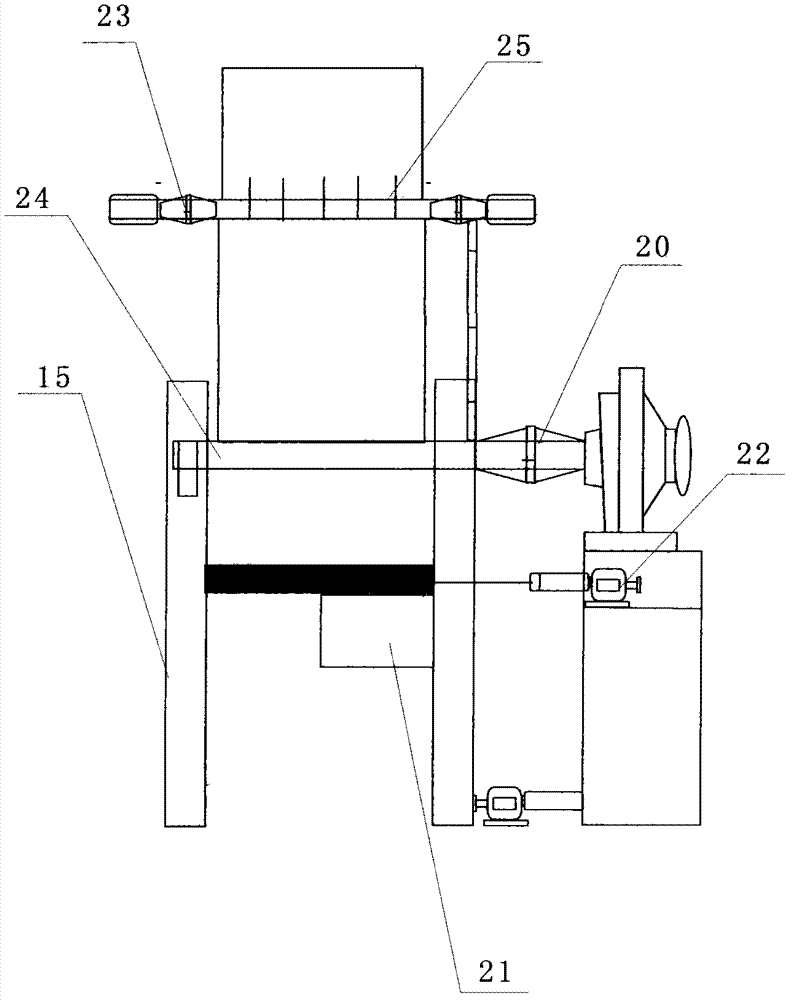

[0015] like figure 1 , 2 The shown automatic mixing and cooling machine includes a feed hopper (1), a regulating plate (2), stirring rods (3a), (3b), (3c), (3d), and a water temperature air-conditioning interface (4) , fan interface (5), automatic temperature gauge (6), exhaust chimney (7), bent box (8), wall exhaust fan (9), support roller (10a), (10b), (10c) , (10d), (10e), observation port (11), stainless steel sieve gusset plate conveyor belt (12), fan (13a), (13b), drive roller (14), bracket (15), discharge port ( 16), stainless steel shell (17), adjusting rod (18), passive roller (19), main drive reducer (20), distribution box (21), speed-regulating motor (22), crankcase infinitely variable speed reducer ( 23), the main rotating shaft (24), the cross stirring stick (25), the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com