Heat exchanger and bell-type furnace with same

A heat exchanger and heat exchange cavity technology, applied in the field of bell jar furnaces, can solve the problems of raising the threshold for use of experimental bell jar furnaces, increasing the use cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

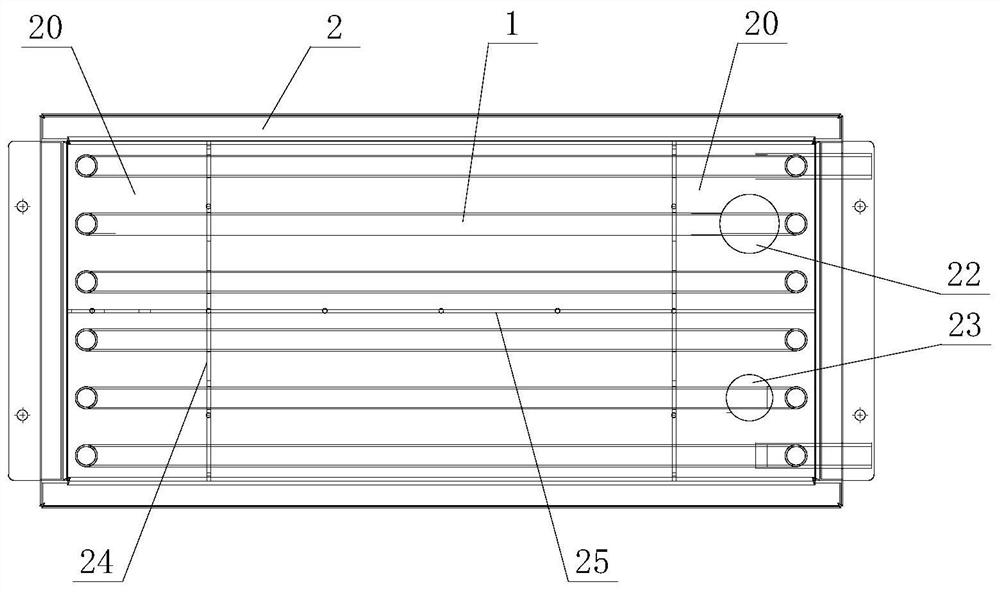

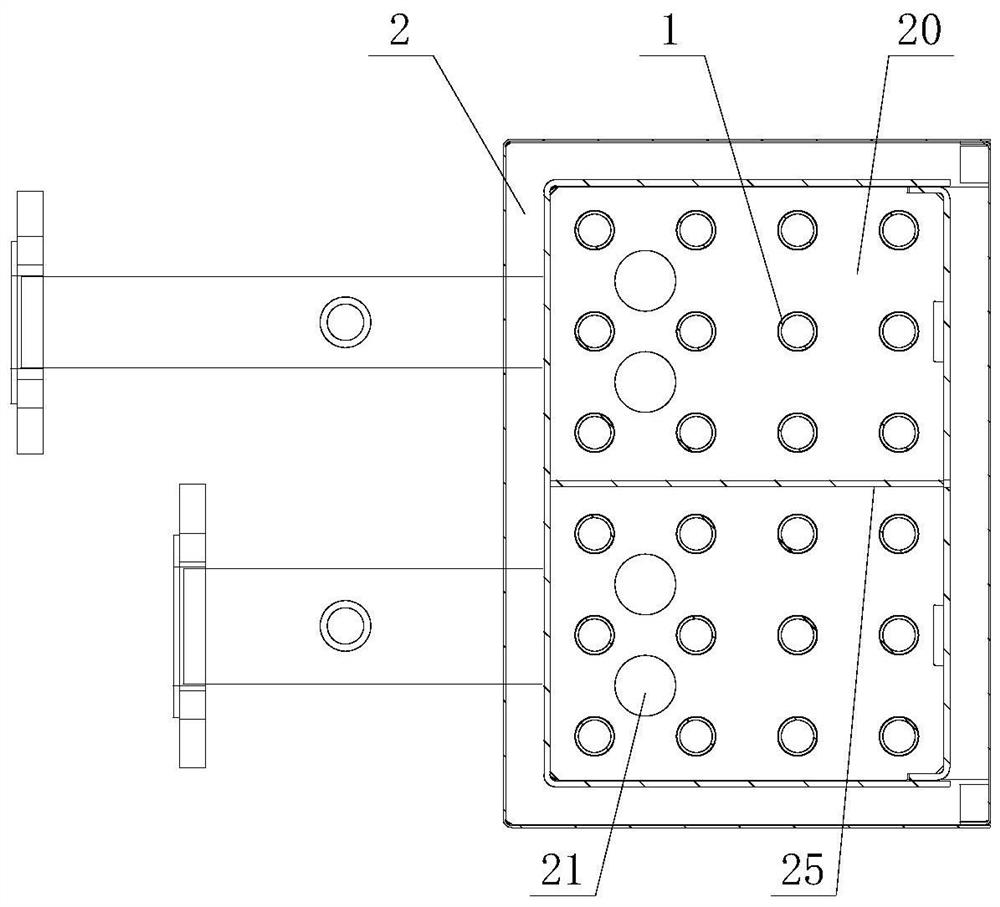

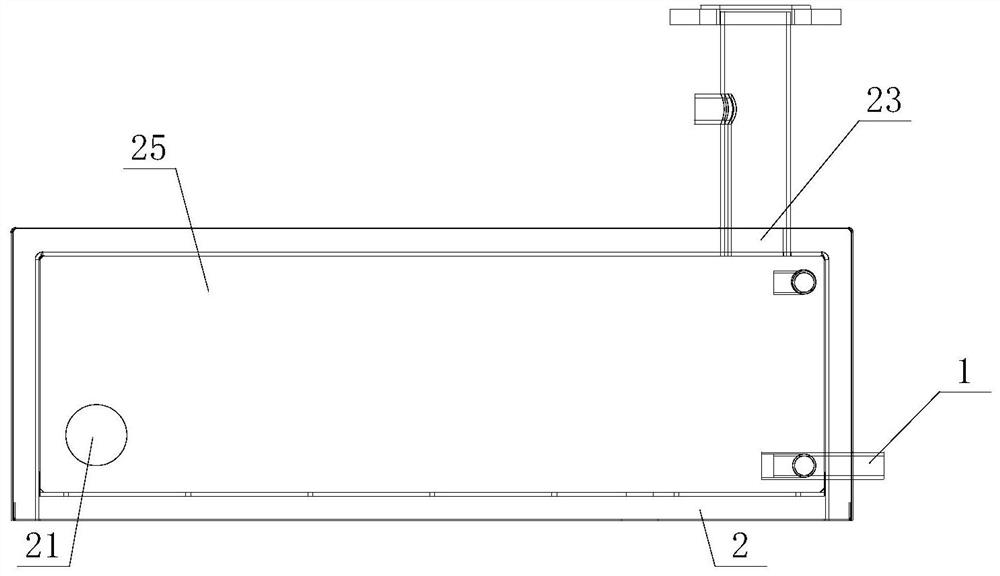

[0028] Such as Figure 1 to Figure 3 As shown, the heat exchanger of this embodiment includes a shell 2 and a water-cooled pipeline 1 for cooling water to pass through. The shell 2 has a heat exchange chamber for gas to pass through. The heat exchange chamber is divided into a plurality of air chambers 20. The two air chambers 20 communicate with each other through communication holes 21, and the housing 2 is provided with an air inlet 22 communicating with one of the air chambers 20 and an air outlet 23 communicating with the other air chamber 20, through which the water cooling pipe 1 passes. At least two air chambers 20 . When the heat exchanger works, the cooling water passes through the water-cooling pipeline 1, and the gas to be cooled is passed into the heat exchange chamber from the air inlet 22, and the gas to be cooled is discharged from the gas outlet 23 through the heat exchange chamber. The pipes 1 are in contact with each other for heat exchange, so as to achiev...

Embodiment 2

[0037] Such as Figure 4 and Figure 5 As shown, a bell furnace includes a furnace body 3, a kiln car 4, a heating system, an air intake system and a cooling system 5, and the cooling system 5 includes a fan 51, a water cooler 52 and the heat exchanger in Embodiment 1, and further The gas port 22 communicates with the hearth of the furnace body 3 through the air inlet pipeline 53, the gas outlet 23 communicates with the furnace hearth of the furnace body 3 through the gas outlet pipeline 54, the two ends of the water cooling pipeline 1 are connected with the water cooler 52, and the fan 51 is arranged on the gas outlet on road 54. When the blower fan 51 starts, the gas in the furnace is allowed to enter the heat exchange chamber of the heat exchanger through the inlet pipeline 53 and the air inlet 22 for cooling, and then returns to the furnace through the gas outlet 23, the blower fan 51 and the gas outlet pipeline 54 after cooling. The cooling system 5 of the bell furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com