Pulsed type bag dedusting device

A technology of bag dust removal and bag filter, which is applied in the direction of dispersed particle filtration, membrane filter, membrane technology, etc., can solve the problems of dust entering the factory building, the dust cannot be effectively discharged, and the dust emission concentration cannot meet the emission standard, so as to achieve the improvement effect effect on efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

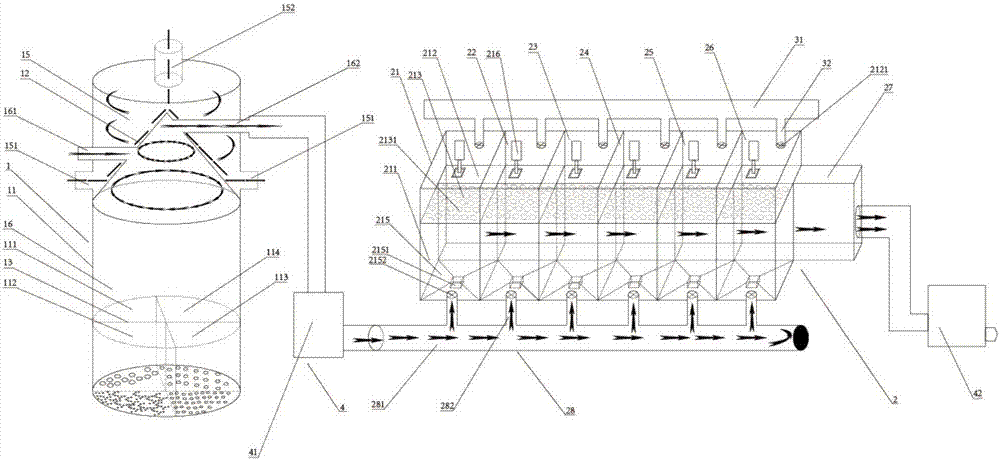

[0025] Below in conjunction with accompanying drawing, invention is further elaborated, and wherein, the direction of invention is with figure 1 as standard.

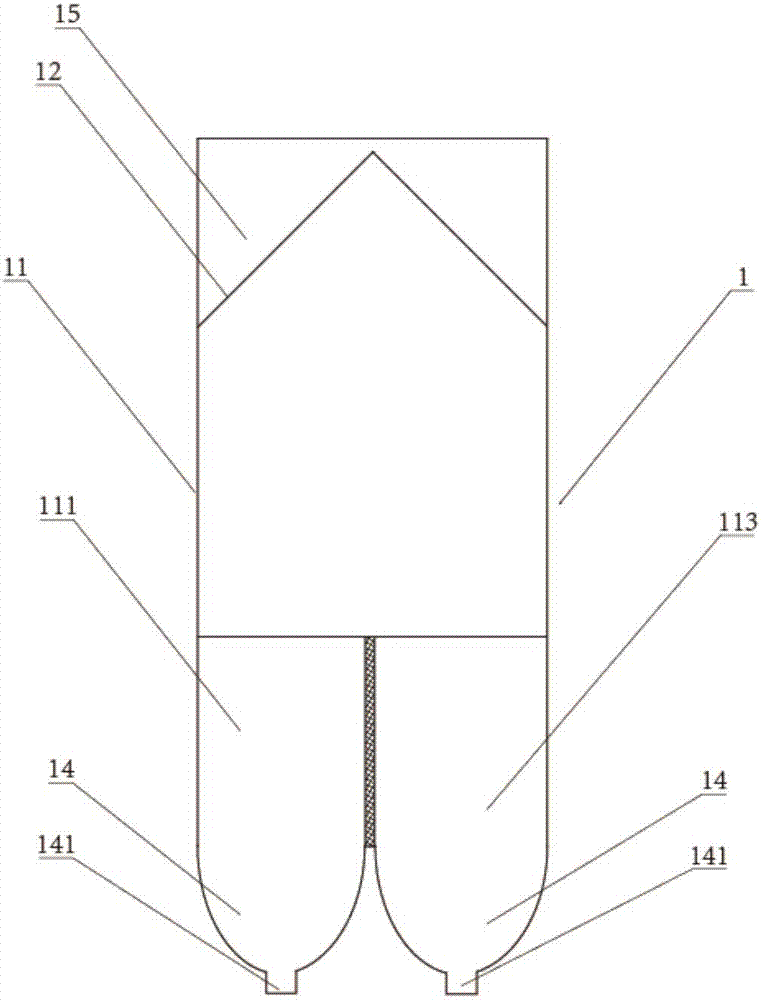

[0026] Such as Figure 1 to Figure 6 As shown, the pulse type bag dust removal equipment of the present invention includes a storage tank type grading material selection device 1, a box combined bag filter 2, a pulse airflow recoil cooling device 3 and a high temperature air induction device 4, wherein:

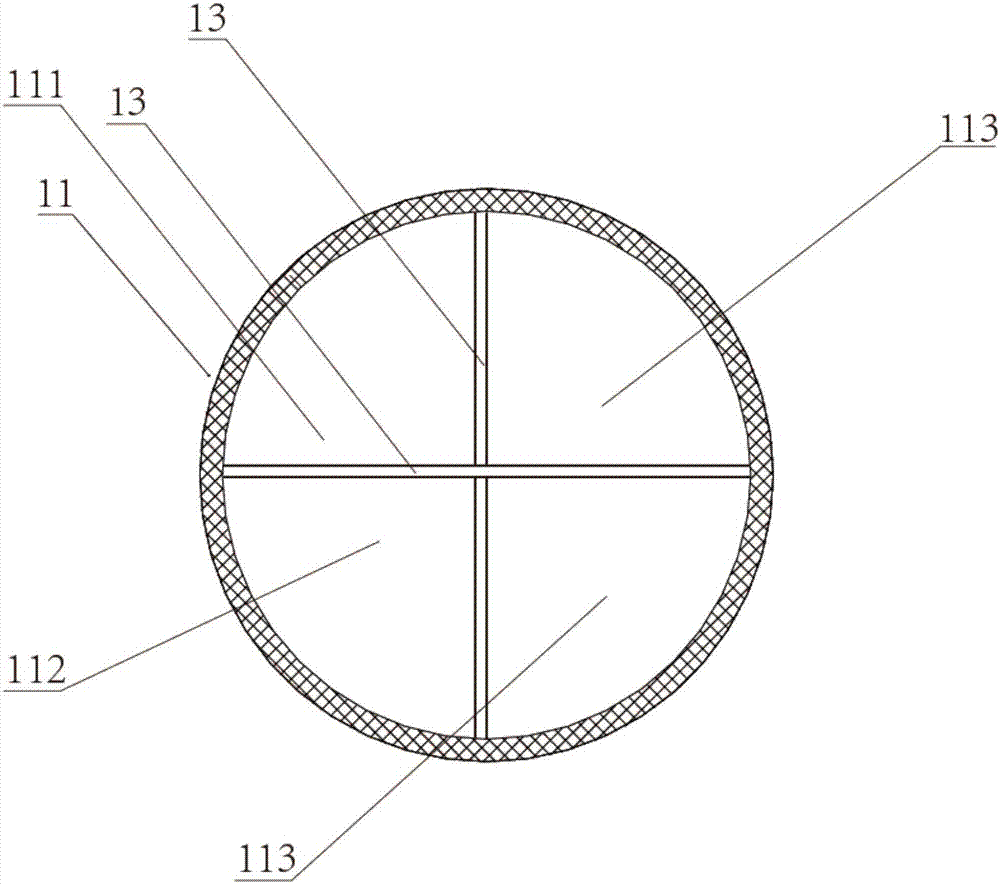

[0027] The storage tank type grading material selection device 1 includes a tank body 11, an inverted funnel-shaped cyclone part 12, four partitions 13 and four bottom hoppers 14, the tank body 11 and the inverted funnel-shaped cyclone part 12 are all made of high hardness, high It is made of white steel with high wear resistance, high heat resistance and good thermal conductivity, which overcomes the defects of the storage container made of traditional steel, which is easy to rust, easy to wear, poor heat resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com