An automatic cooling sealed power cabinet

An automatic cooling and power cabinet technology, applied in the cooling/ventilation of substation/switchgear, electrical components, details of substation/switch layout, etc., can solve problems such as damage to electrical equipment, and achieve the effect of avoiding air humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

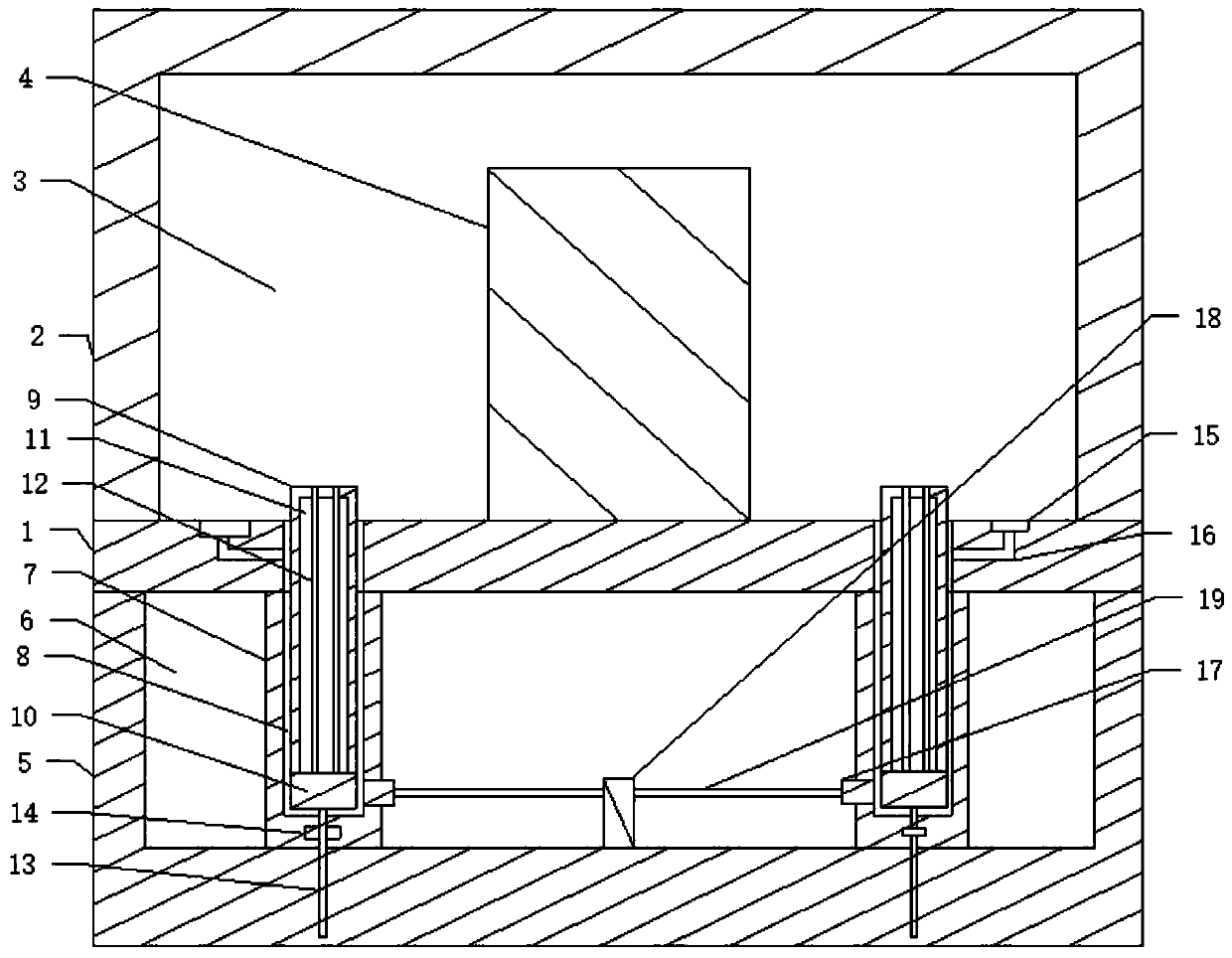

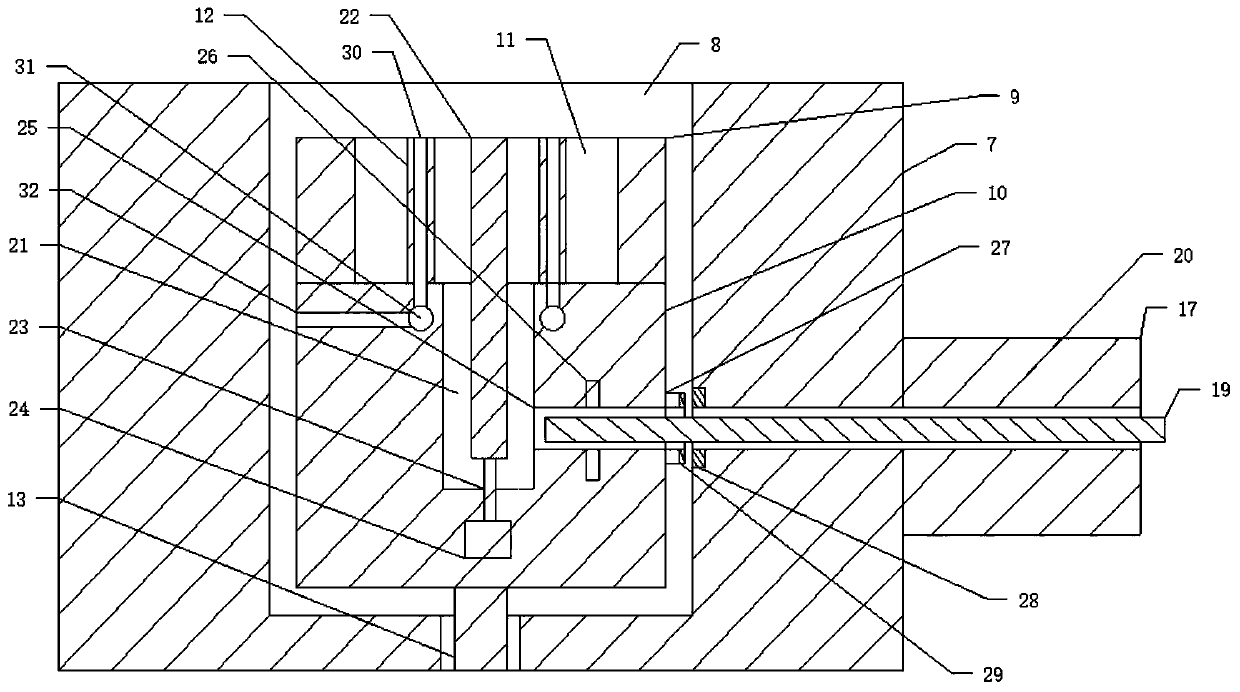

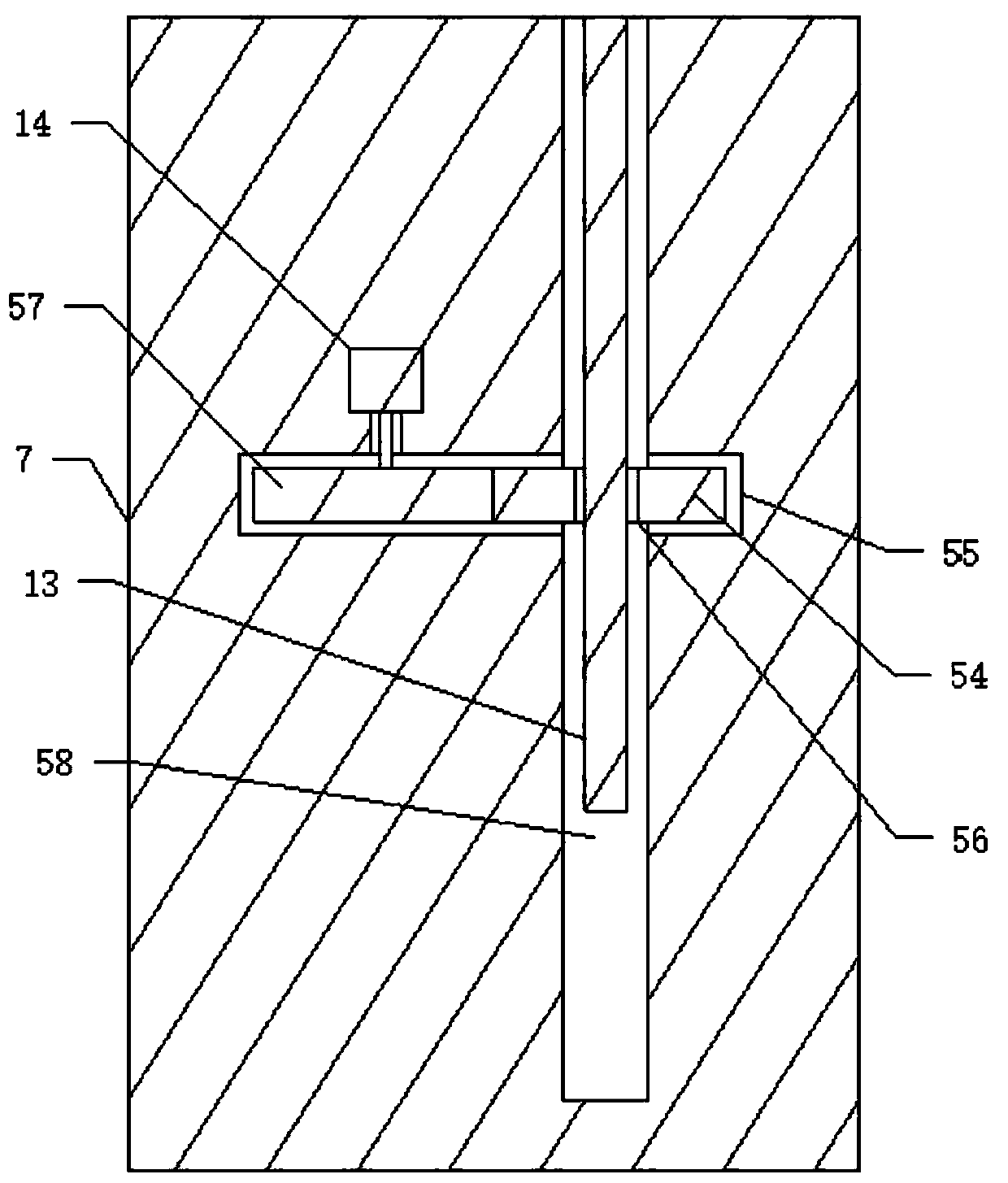

[0036] Such as Figure 1 to Figure 8 As shown, an automatic cooling sealed power cabinet includes a sealed cabinet body 2, a cabinet inner cavity 3 is arranged in the sealed cabinet body 2, a control cabinet 4 is arranged in the cabinet inner cavity 3, the The top of the sealed cabinet body 2 is provided with a fixed base 1, and the bottom of the fixed base 1 is provided with a cooling bottom box 5, and the cooling bottom box 5 is buried in the ground, and a cooling tank groove is arranged in the cooling bottom box 5 6. Fine sand is provided in the cooling tank tank 6, and a plurality of conveying cylinders 7 are provided in the cooling tank tank 6, and a conveying cylinder 7 is respectively provided with a corresponding communication with the inner cavity 3 of the cabinet. The first sliding chamber 8, a sliding cooling cylinder 9 is respectively arranged in the first sliding chamber 8, and a cooling cavity 11 is respectively arranged in the cooling cylinder 9, and a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com