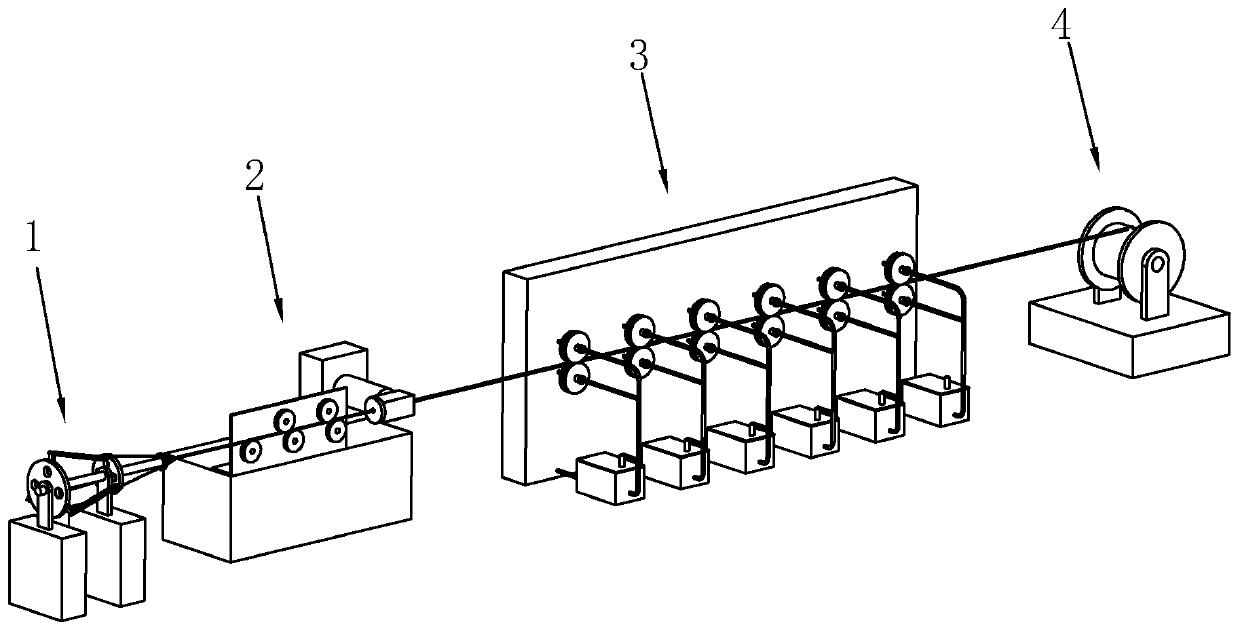

Bunchy optical cable sheath extrusion production line

A production line and optical cable technology, applied in the field of bundled optical cable sheath extrusion production line, can solve the problems of optical cable production speed block, optical cable surface is not easy to have water residue, optical cable with water, etc., to achieve the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

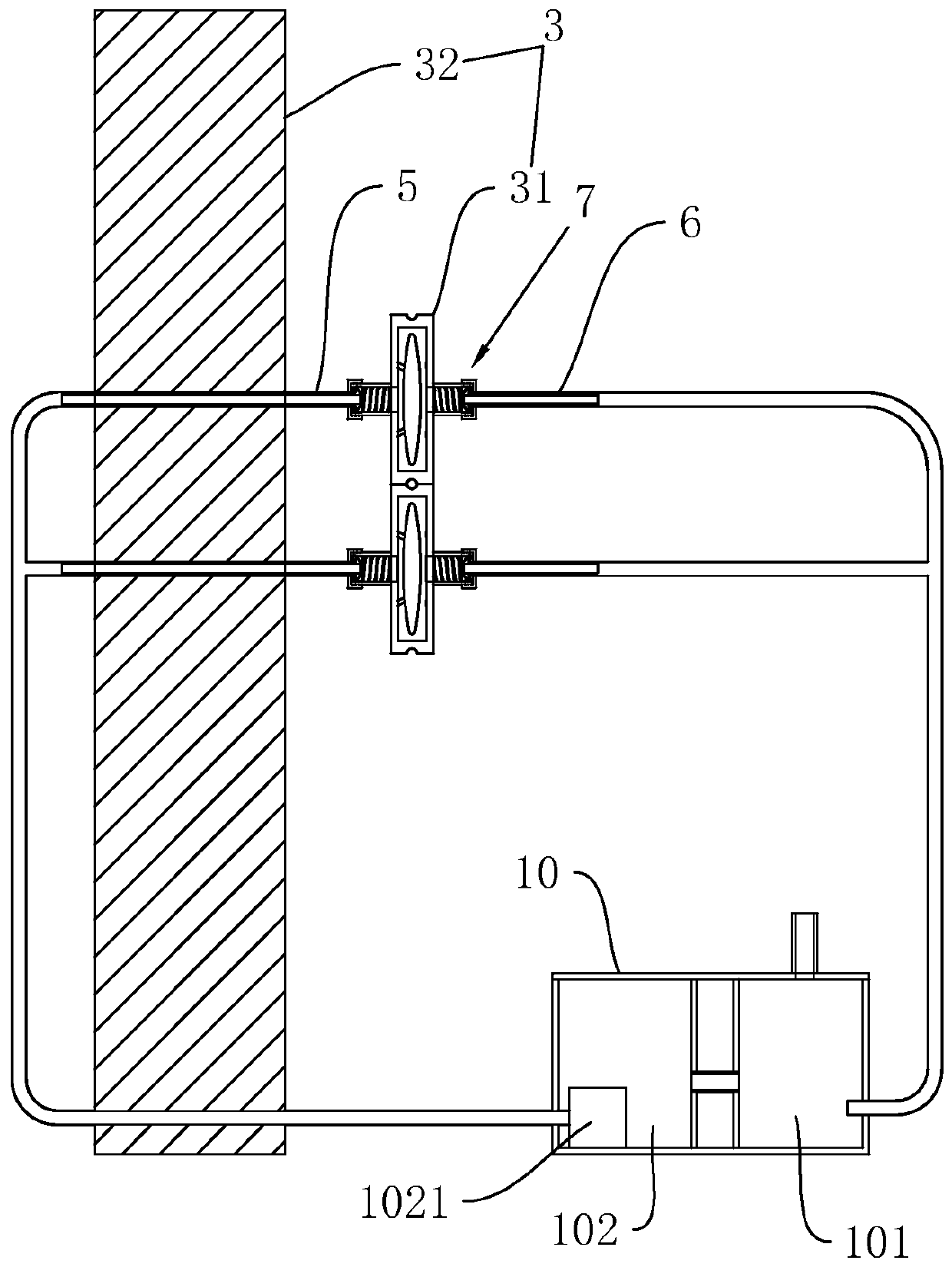

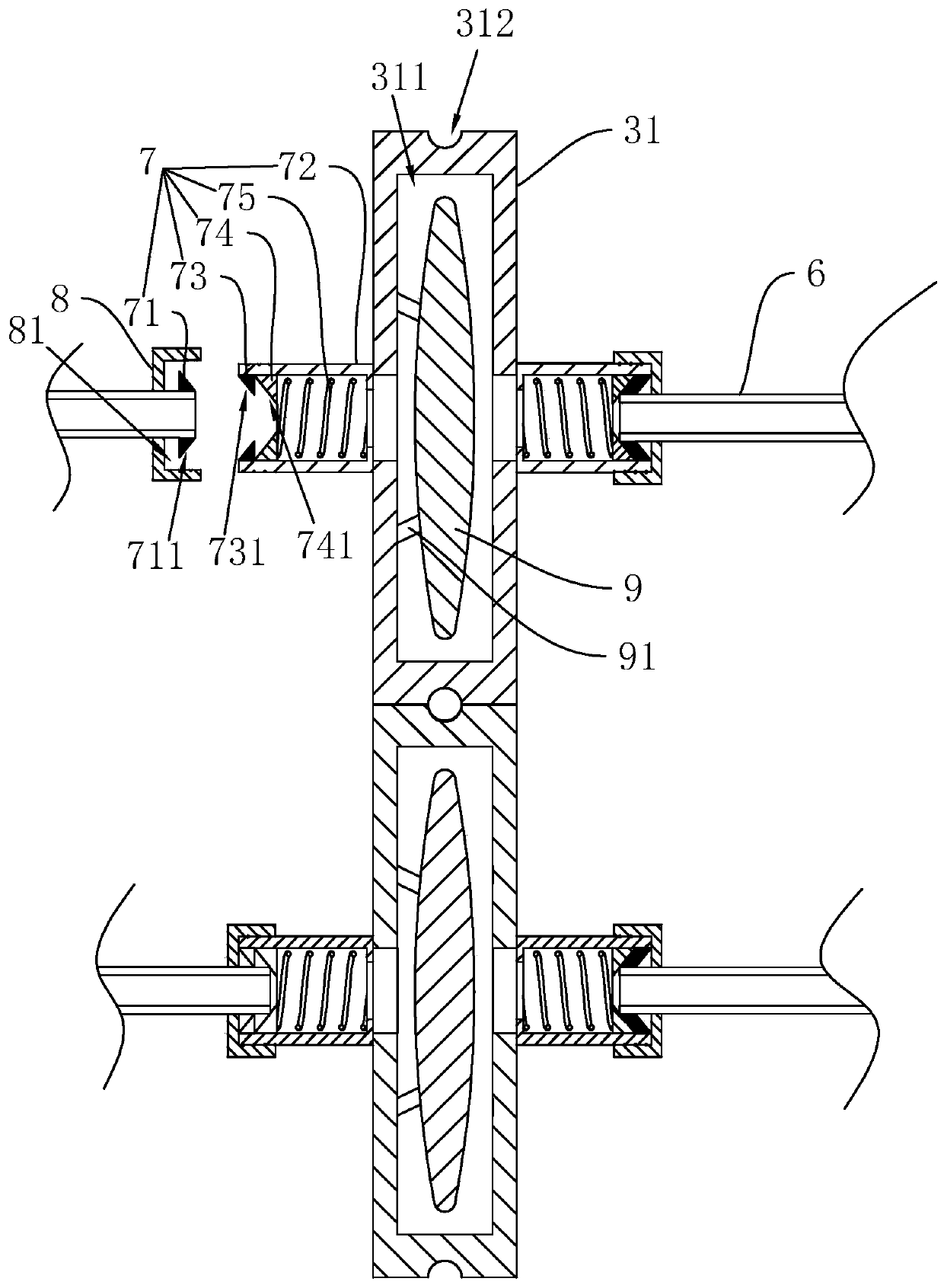

[0056] Embodiment two, refer to Figure 4 , the difference from Embodiment 1 is that a liquid collection tank 51 is arranged below the junction of the liquid inlet pipe 5 and or the liquid outlet pipe 6 and the connecting pipe 72. The liquid collection tank 51 is in the shape of a rectangular parallelepiped and is made of stainless steel. The upper end of the liquid tank 51 is open, and the liquid collecting tank 51 is welded to the lower surface of the liquid inlet pipe 5 and or the axial side of the liquid outlet pipe 6. Once the cooling liquid seeps out, the cooling liquid is not easy to drop directly on the ground.

Embodiment 3

[0057] Embodiment three, refer to figure 1 and Figure 5 The difference from Embodiment 1 is that a plurality of driving parts 321 are fixed on the mounting table 32 by bolts, the driving parts 321 are servo motors, and a driving part 321 is arranged under each liquid inlet pipe 5, A pinion 3211 is sheathed on the output shaft of the driver 321, and the pinion 3211 is keyed to the output shaft of the driver 321, and a pinion 3211 is sleeved on the outer surface of each connecting pipe 72 connected to the liquid inlet pipe 5. The big gear 721, the big gear 721 is keyed to the connecting pipe 72, and a big gear 721 is correspondingly meshed with a small gear 3211, so that when the output shaft of a driver 321 rotates, it can drive a connecting pipe 72 to rotate, and then drive a The cooling wheel 31 rotates. In a cooling mechanism 3, the upper and lower cooling wheels 31 turn in the opposite direction, and when the two cooling wheels 31 rotate, they will not hinder the movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com