Cooling device for automobile part machining

A technology for cooling devices and spare parts, which is applied in cooling fluid circulation devices, household refrigeration devices, lighting and heating equipment, etc. It can solve the problems of cumbersome work and manual control of the opening and closing of cooling nozzles, so as to improve the effect of finished products and reduce work content, effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

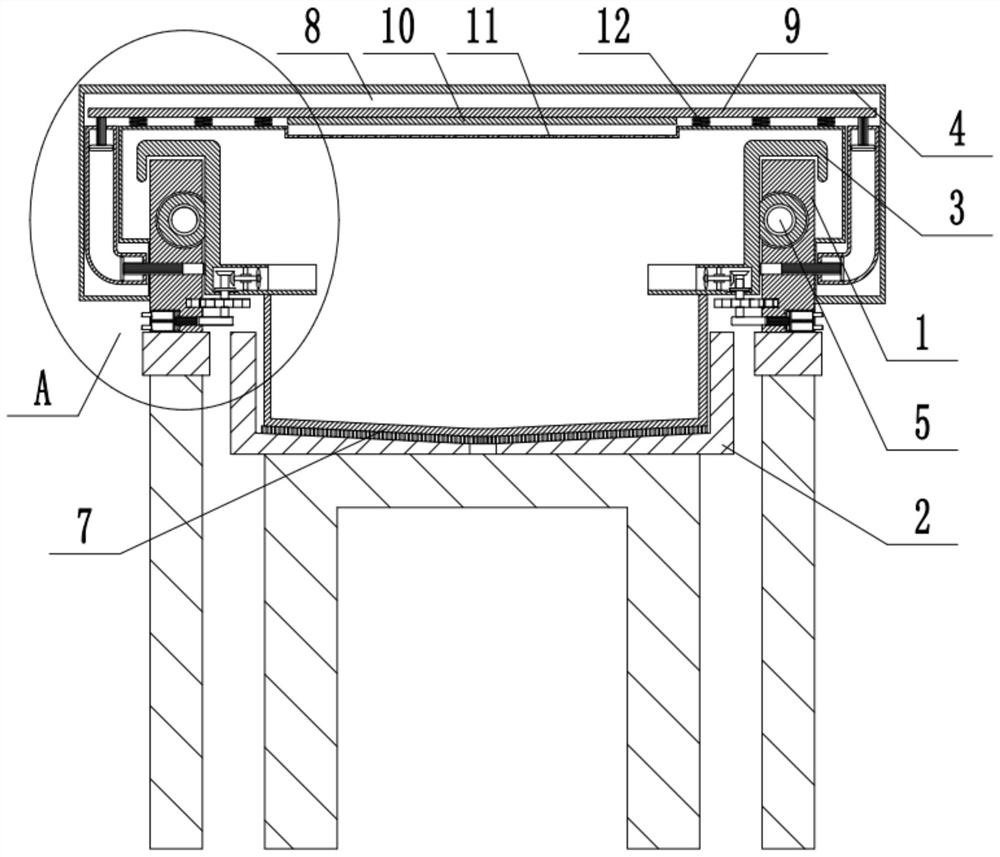

[0026] The reference signs in the drawings of the description include: guide rail 1, slag discharge tank 2, sliding seat 3, sprinkler table 4, lead screw 5, timing belt 6, connecting rod 7, sprinkler chamber 8, sealing plate 9, sealing plug 10, Outlet plate 11, second return spring 12, transmission shaft 13, rack 14, gear 15, cam 16, first piston rod 17, piston chamber 18, connecting block 19, second piston rod 20, L-shaped air bag 21, the first Three piston rods 22, fan 23.

[0027] Auto parts processing cooling device, for example figure 1 and figure 2 As shown: it includes a symmetrically arranged guide rail 1, a bearing mechanism that is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com