Platform system for manufacturing tea set and wine set by using alkaline earth

A technology for tea set and wine set, which is applied in the field of alkaline soil for making tea set and wine set platform system, can solve problems such as uneven heating, and achieve the effects of avoiding heating dead ends, facilitating handling and ensuring firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

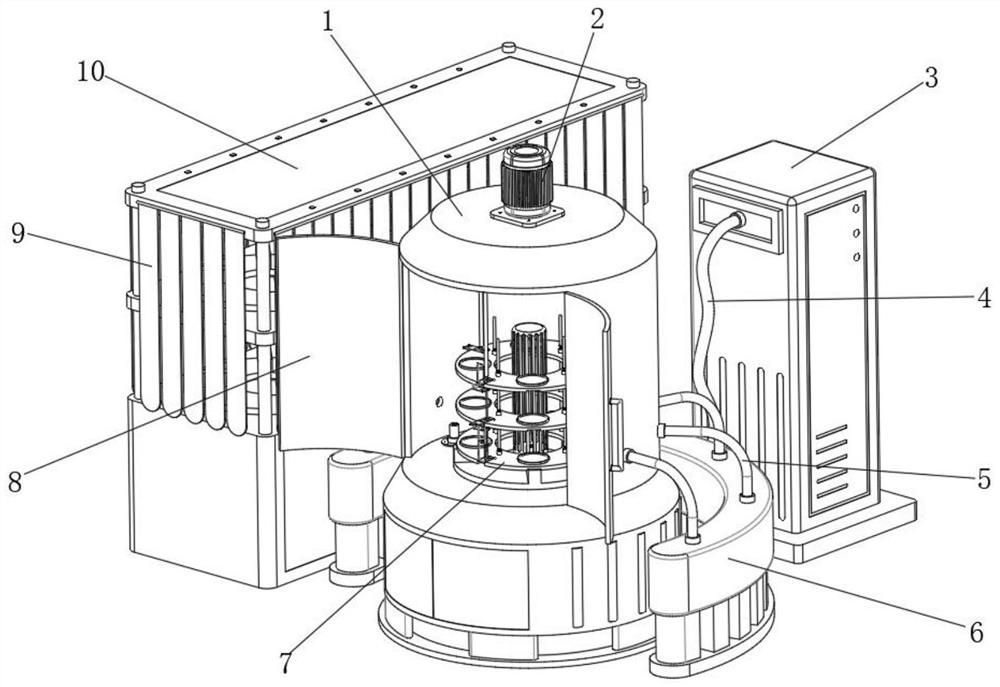

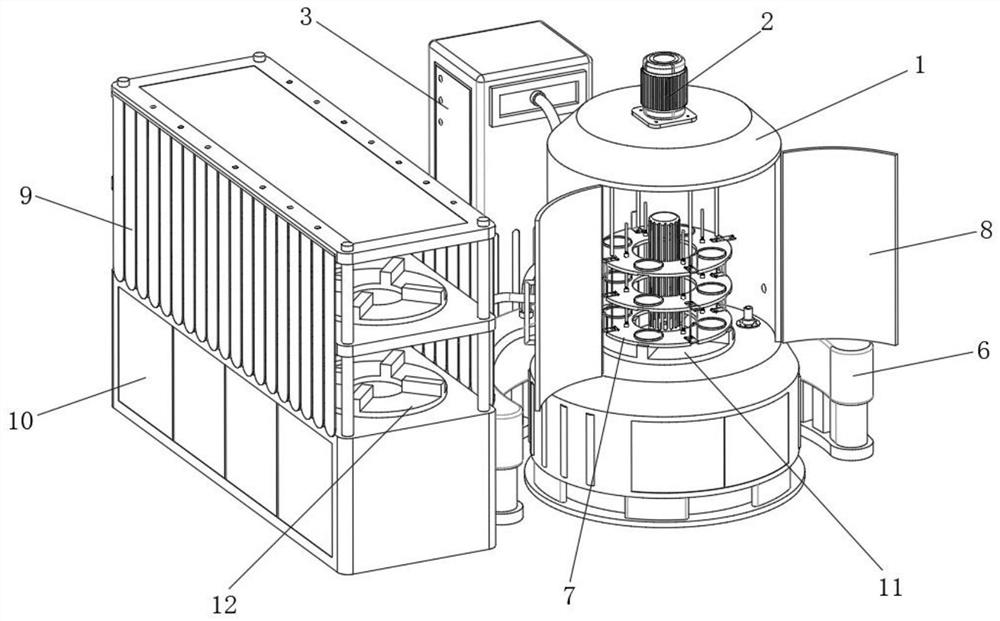

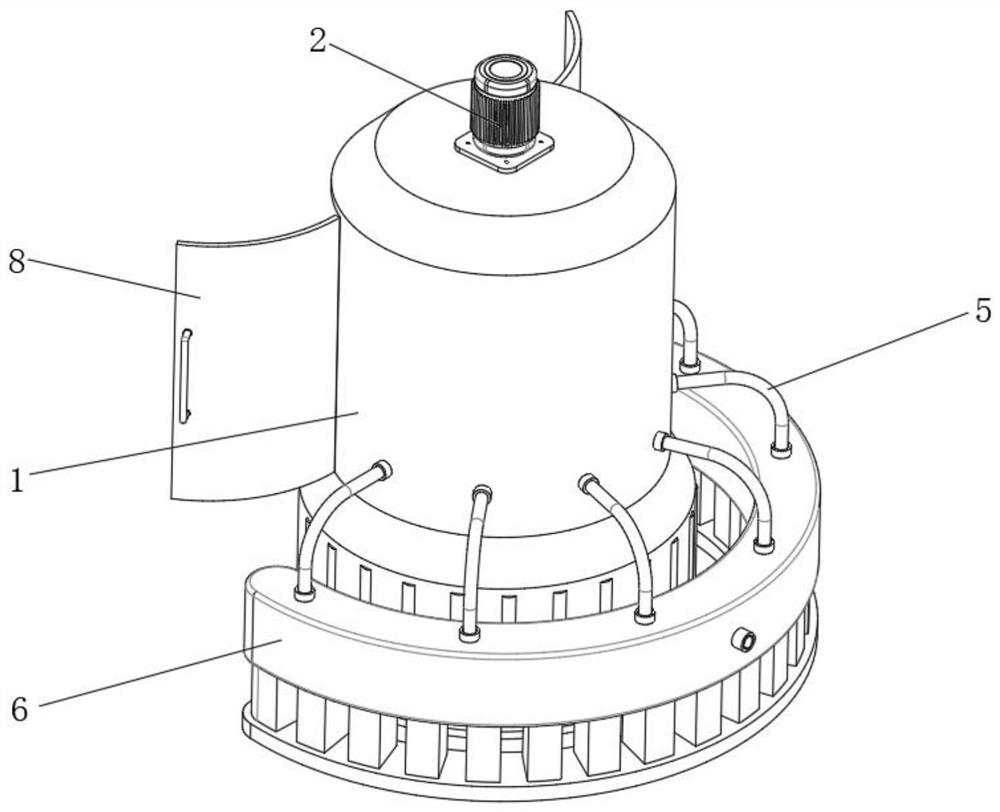

[0057] An alkaline earth making tea and wine platform system, such as Figure 1-9 As shown, it includes a firing furnace 1 and a ring-shaped support bracket 7. A motor 2 is installed on the top of the firing furnace 1 through a motor base, and the output end of the motor 2 is connected to a turret 13 in rotation. Connected with a first annular support seat 11, the first annular support seat 11 is concentric with the firing furnace 1, the center position of the firing furnace 1 and the outer side of the first annular support seat 11 are provided with a firing output head 19, the first annular support seat The firing output head 19 on the outer side of 11 is distributed in a semicircle, and the outer side of the firing output head 19 located in the center is covered with a protective cover 18. The outer wall of the top of the first annular support base 11 is integrally provided with positioning ribs 25. The outer wall of the bottom of the annular support bracket 7 is provided wi...

Embodiment 2

[0064] An alkaline earth making tea and wine platform system, such as Figure 1-4As shown, in order to facilitate cooling; this embodiment makes the following improvements on the basis of embodiment 1: a communication chamber 6 and a gas pressure generating device 3 are provided on the outside of the firing furnace 1, and the outer wall of one side of the communication chamber 6 is connected with a main Delivery pipe 4, one end of the main delivery pipe 4 is detachably installed on the output end of the air pressure generating device 3; the communication chamber 6 is a C-shaped structure, and the outer wall of the top of the communication chamber 6 is connected to the bottom of the firing furnace 1 through the auxiliary delivery pipe 5 On the outer wall of the circumference; by setting up structures such as the air pressure generating device 3, the communication chamber 6 and the auxiliary conveying pipe 5, the air pressure generating device 3 can be used to work, and the firin...

Embodiment 3

[0067] A platform system for making tea sets and wine sets with alkaline earth. In order to ensure the preparation quality of tea sets and wine sets, the raw material formula includes 50-60 parts of kaolin, 20-30 parts of red shale, and 20-30 parts of clay in parts by weight. , 2-18 parts of alkaline soil, 8-10 parts of dolomite, and 4-6 parts of bentonite; the alkaline soil is saline-alkali soil planted with Suaeda salsa.

[0068] The method for making tea set and wine set by using said formula comprises the following steps:

[0069] S1: Take each raw material according to weight for later use;

[0070] S2: adding the raw materials into a ball mill, and then adding water with 60-90% of the total weight of the raw materials for ball milling to obtain a slurry;

[0071] S3: Pass the obtained slurry through a 260-300 mesh sieve;

[0072] S4: Process the sieved slurry into the required pottery blank in the shape of tea set or wine set;

[0073] S5: Then the pottery base is nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com