Collet type cutter structure

A tool and collet technology, which is applied in the field of collet tool structure, can solve the problems that the tool spindle 7 cannot be used to automatically load and retract the tool, does not have the function of changing the tool, and manually loads the tool, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

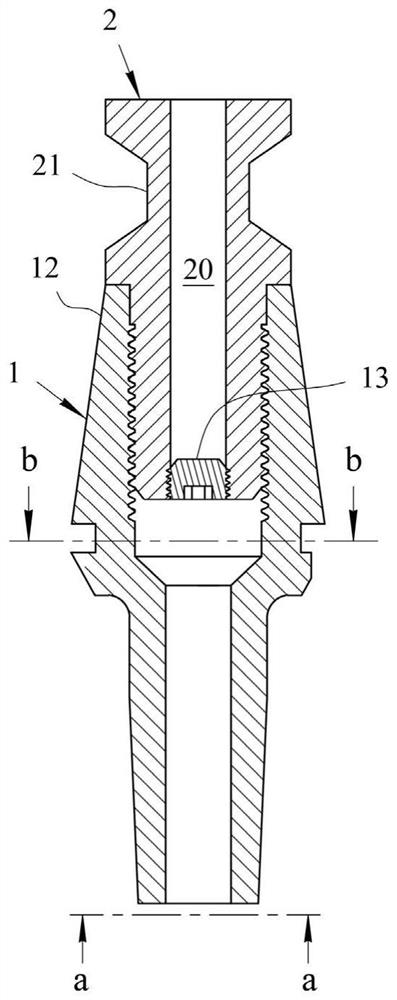

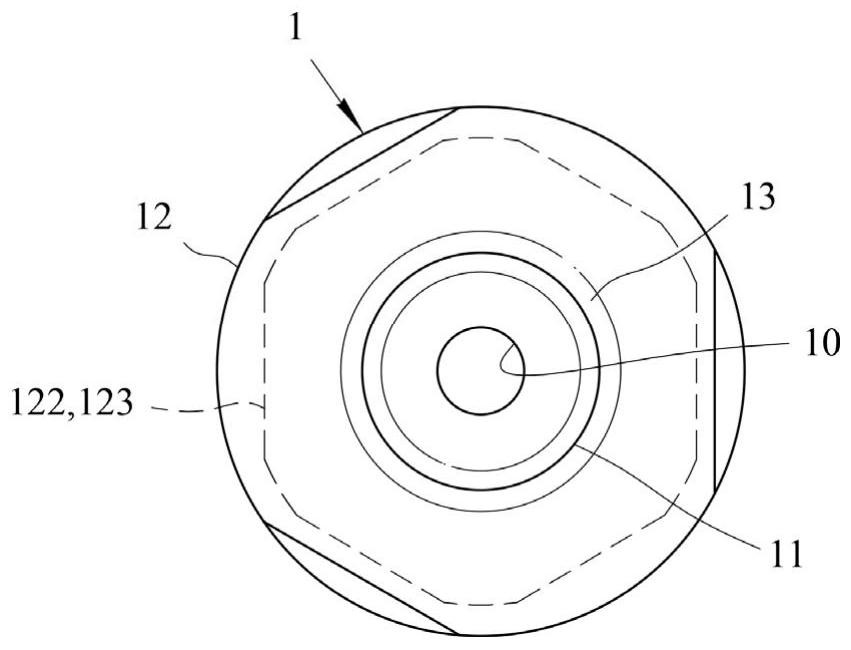

[0043] Such as Figure 1-Figure 7 As shown, a collet-type tool structure includes a stepped rod 1 and a buckle rod 2. The stepped rod 1 includes a first rod body 11 and a second rod body 12. The first channel 10, the second rod body is provided with a tapered structure suitable for the inner taper hole of the tool spindle, the second rod body is provided with a threaded hole, and the upper part of the buckle rod 2 is provided with a There is a fastening groove 21 matched with the inner retracting claw, and the fastening rod is provided with an external thread matching the threaded hole.

[0044] A hollow second channel 20 for supplying cooling liquid is provided in the fastening rod. Coolant can enter the tool structure through the second channel for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com