Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "To achieve the lubrication effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

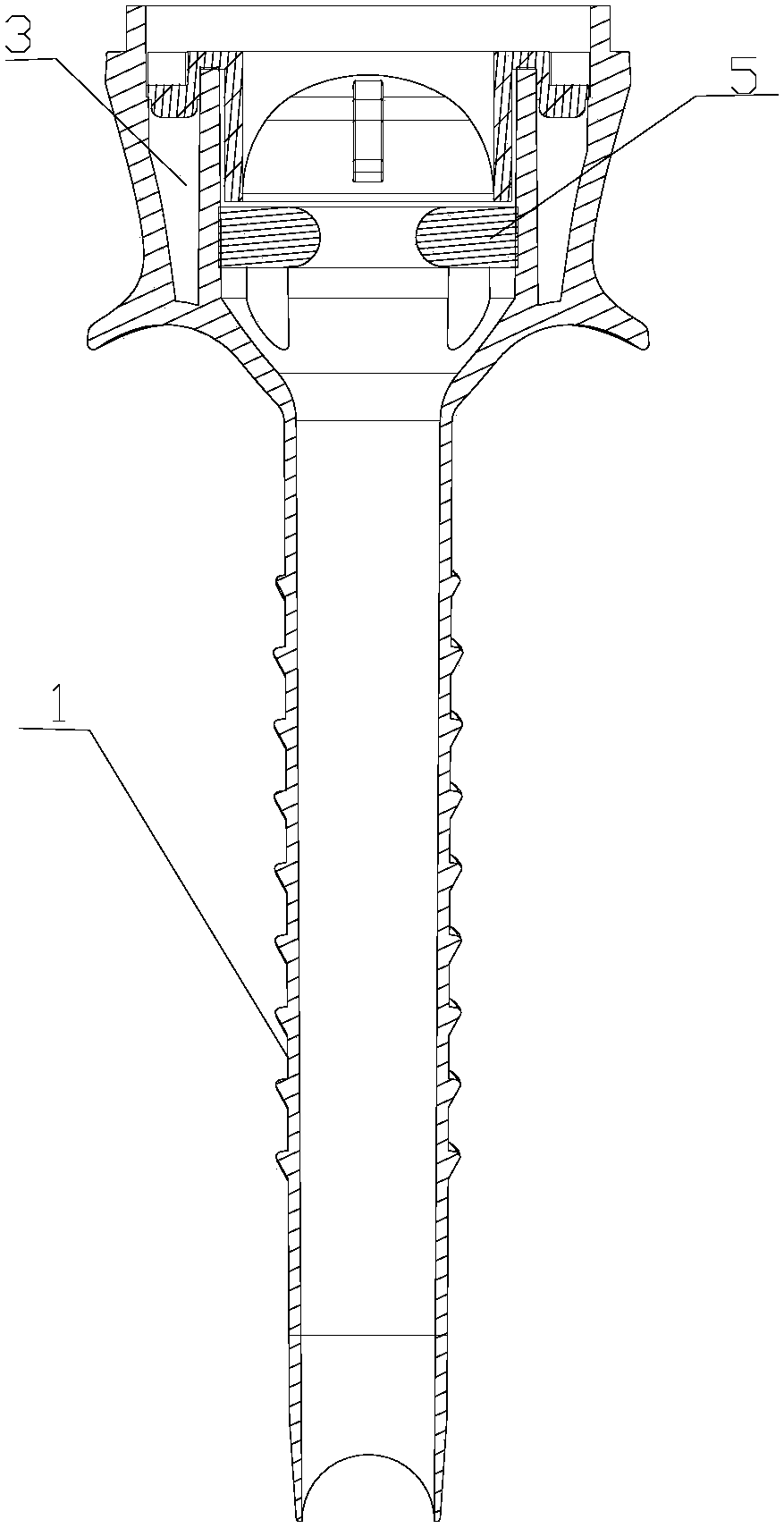

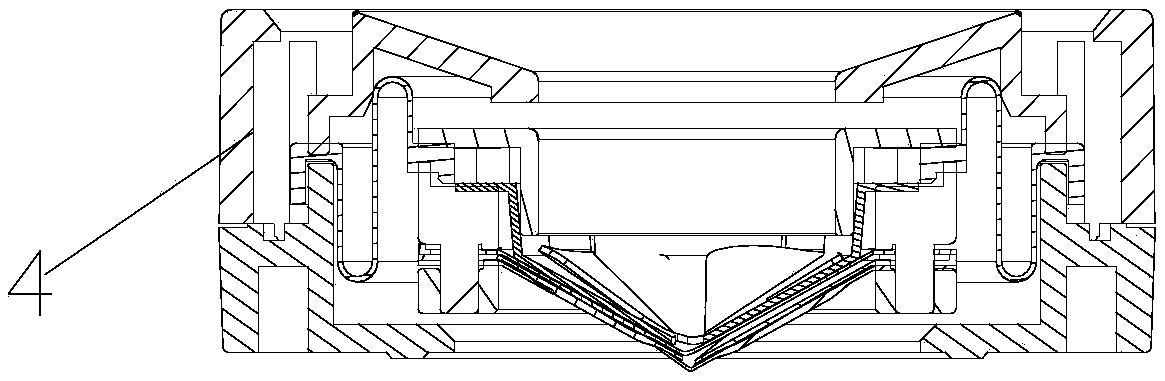

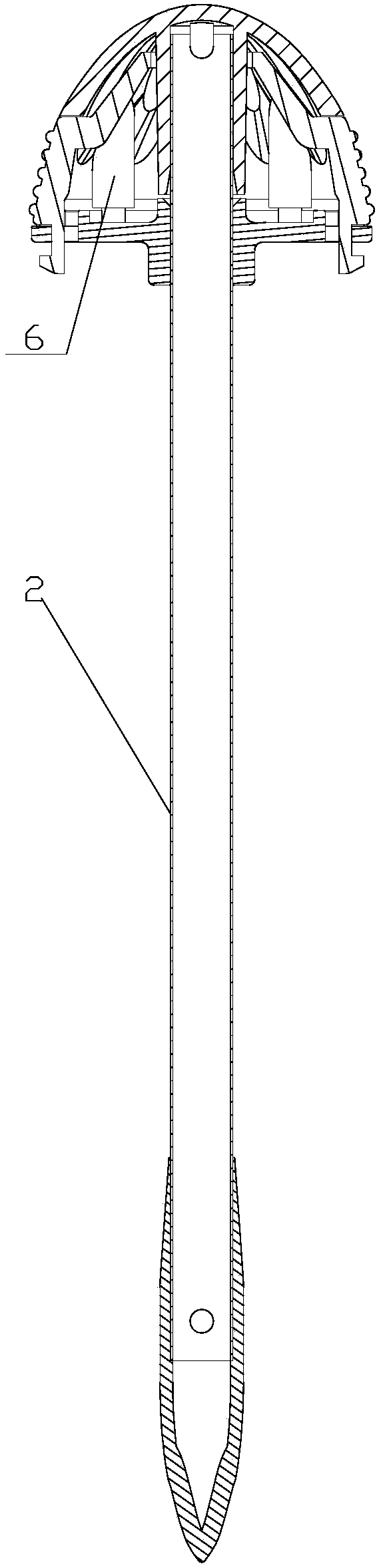

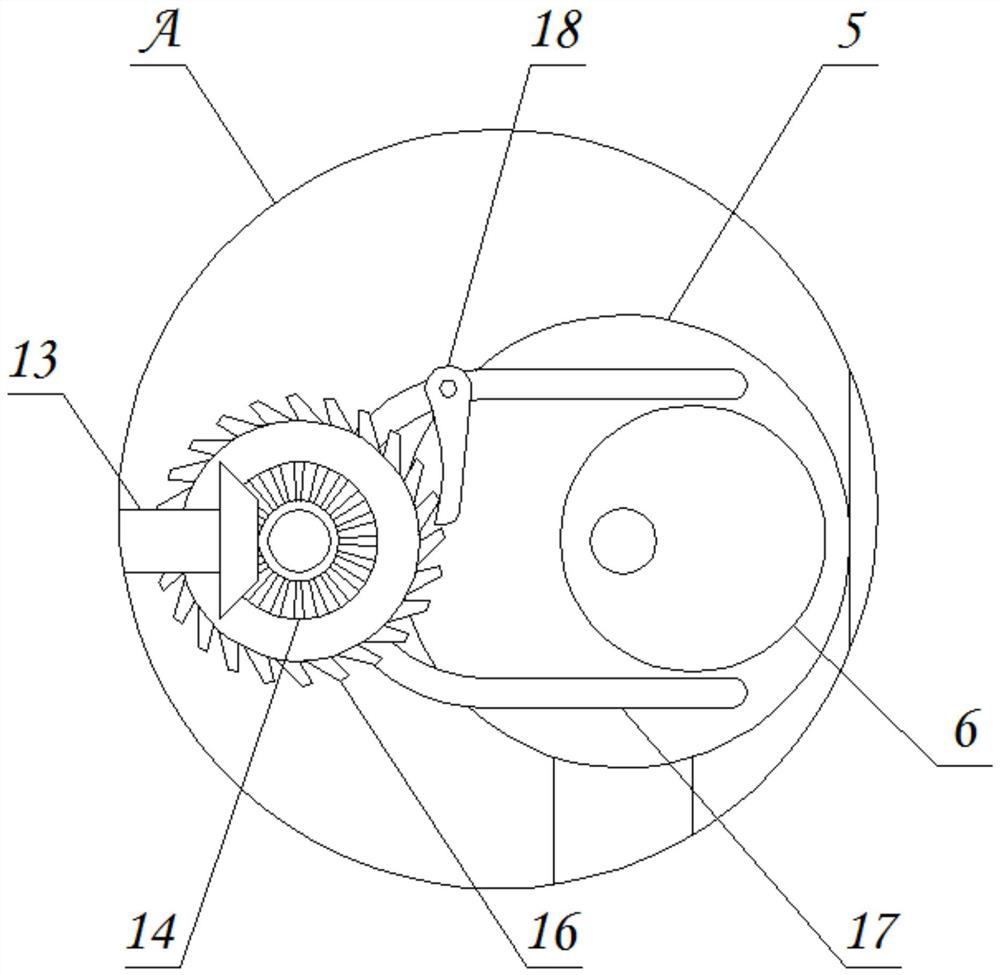

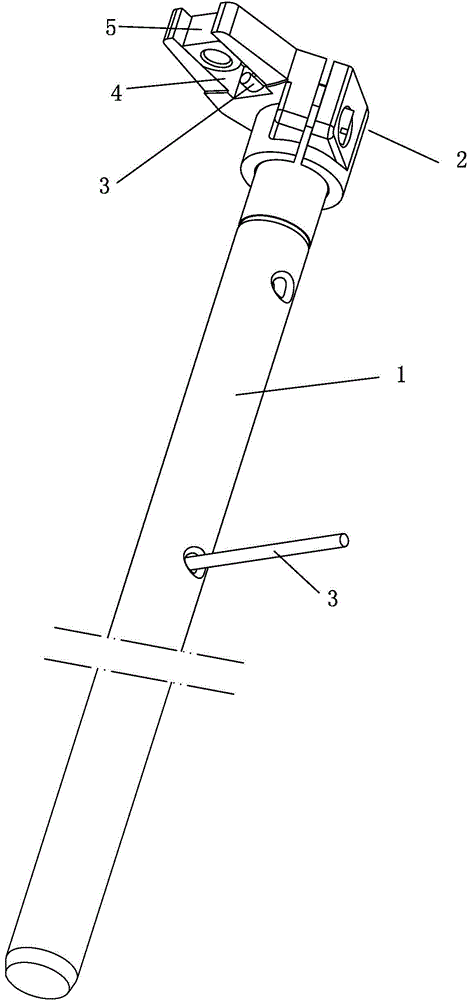

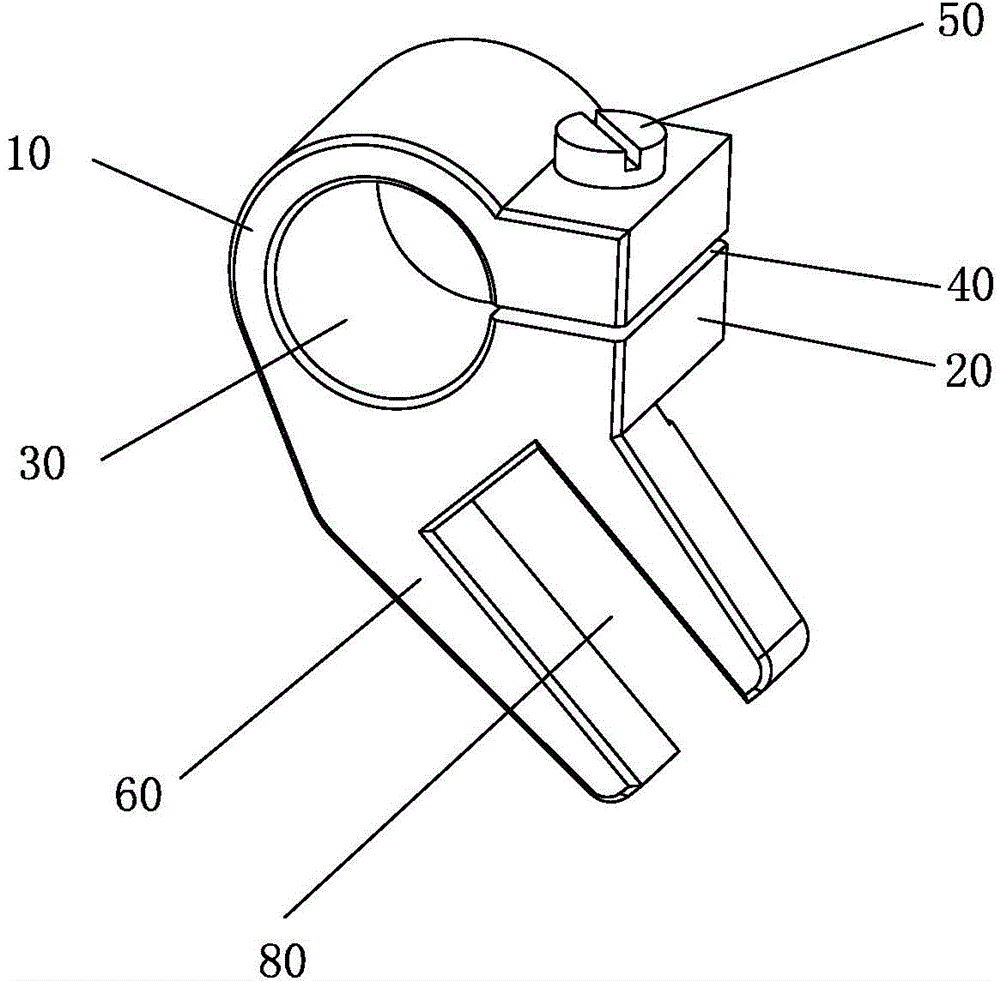

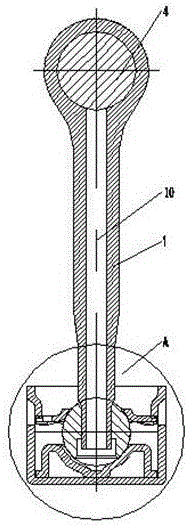

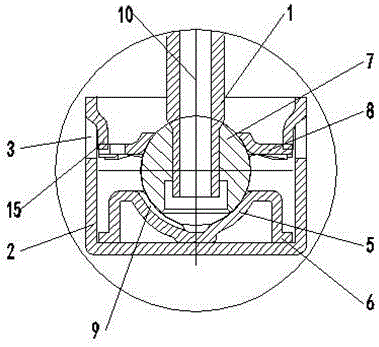

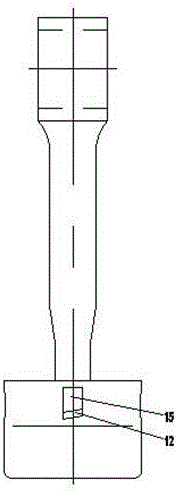

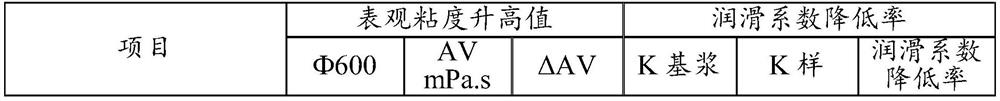

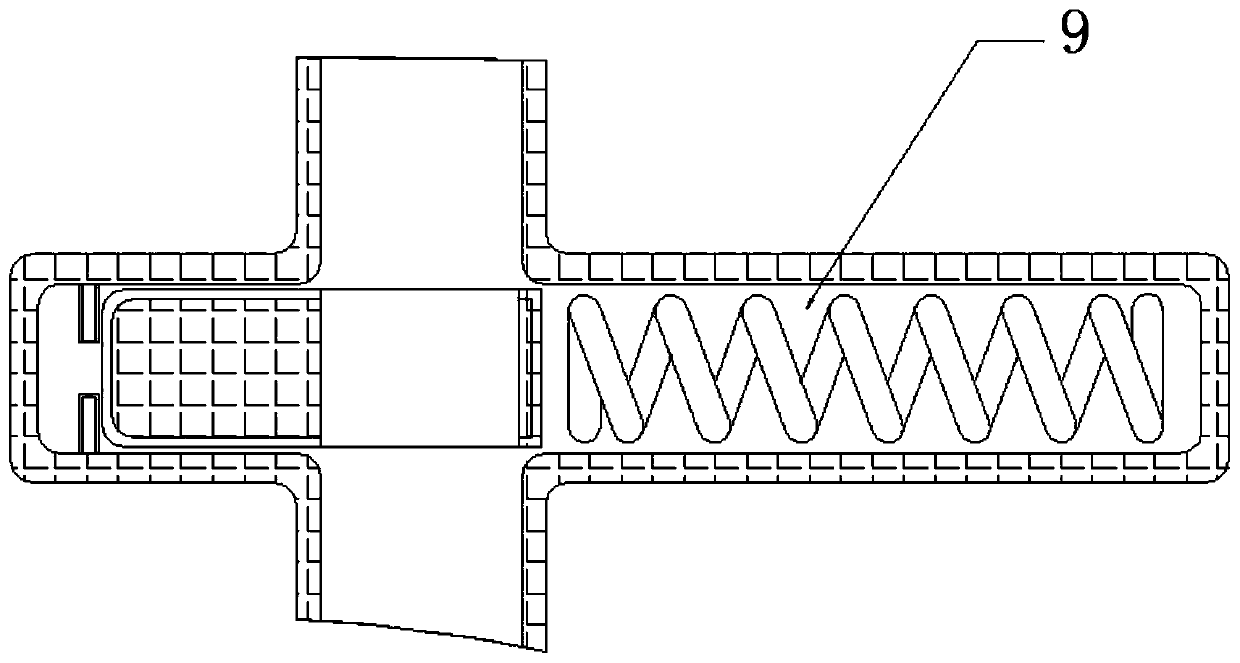

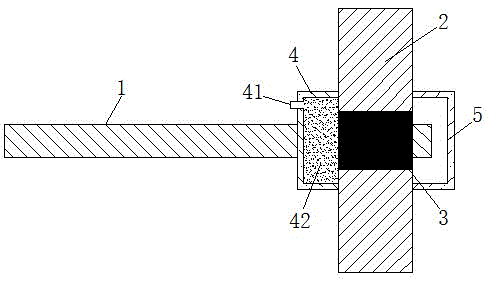

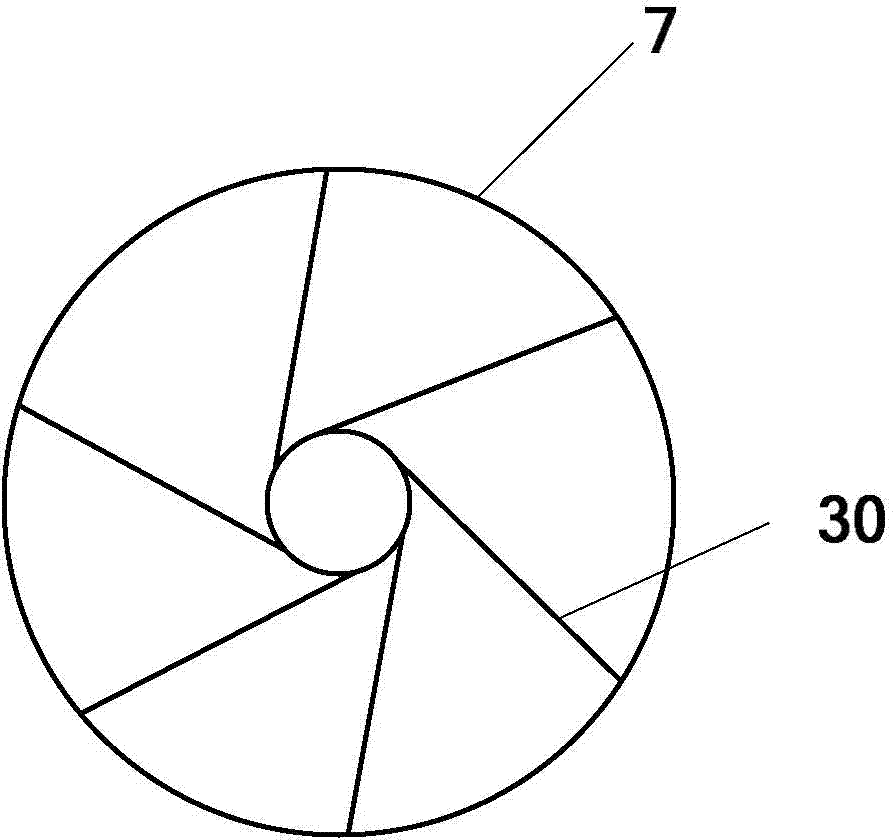

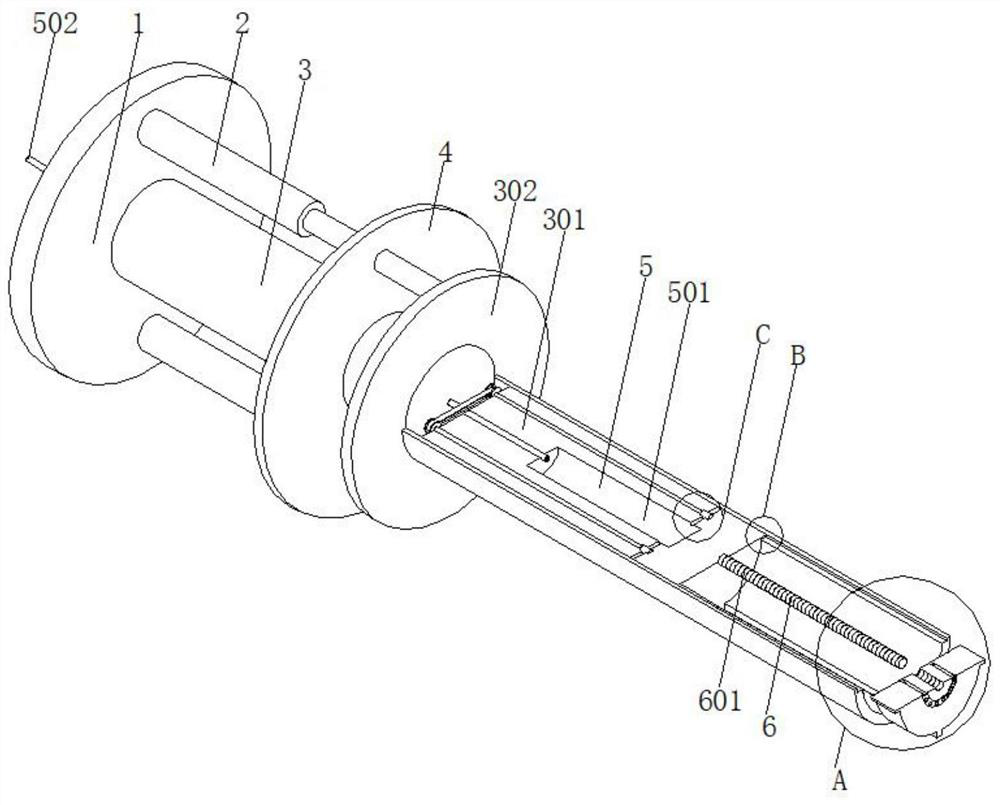

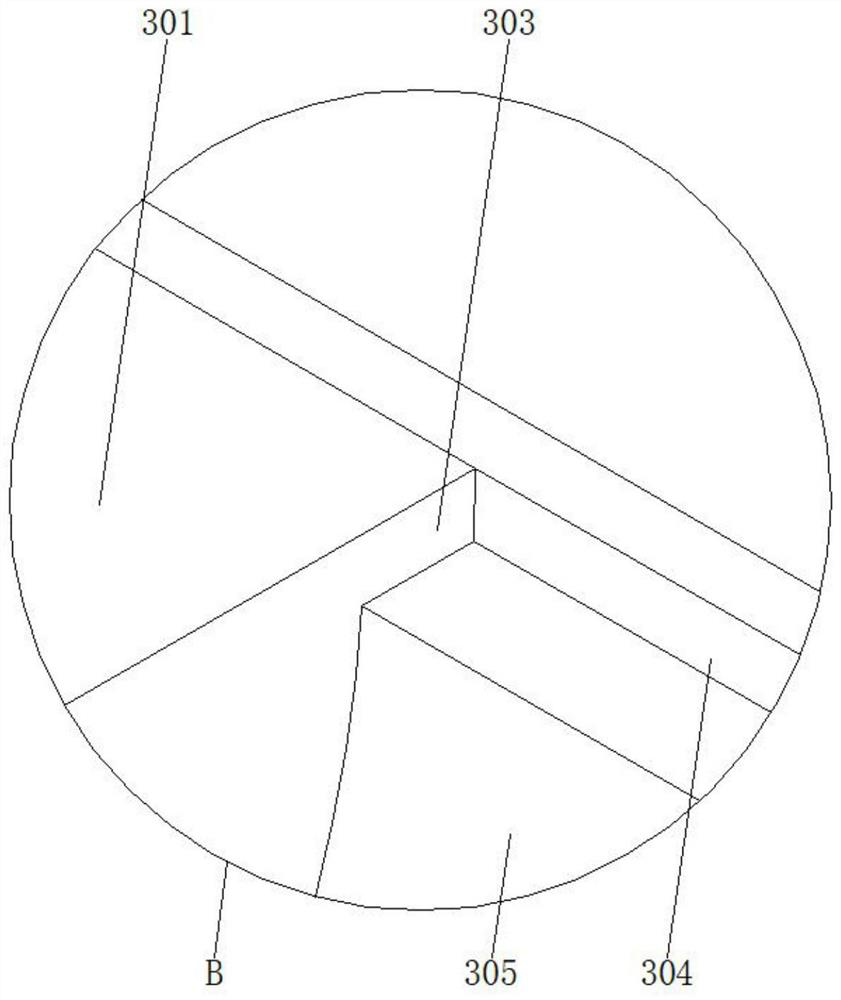

Self-lubricating disposable puncture device

InactiveCN105943131ATo achieve the lubrication effectRelieve painCannulasSurgical needlesSurgical instrumentEngineering

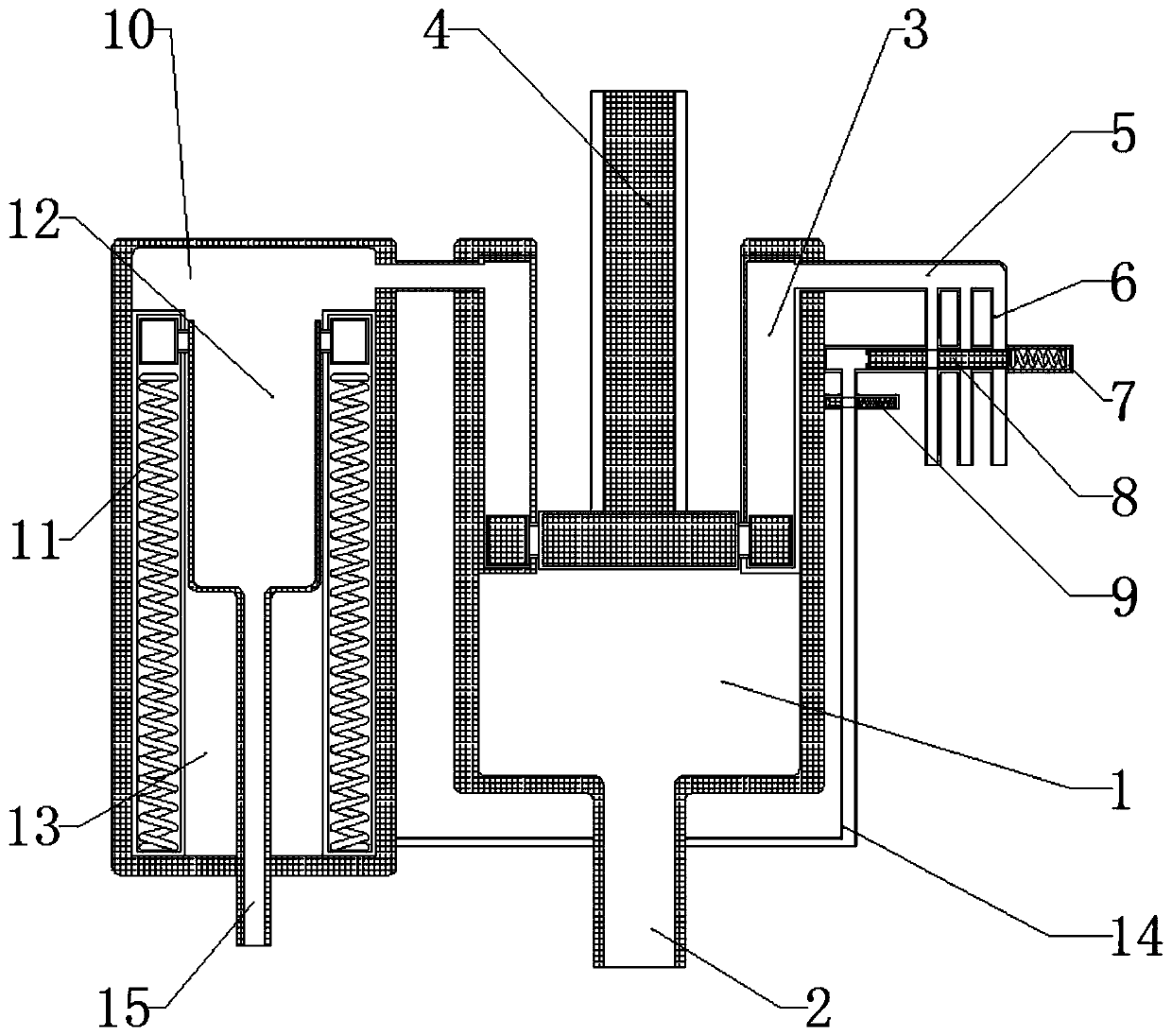

The invention relates to a self-lubricating disposable puncture device. The self-lubricating disposable puncture device comprises a puncture sleeve, a shell and a core rod, wherein the shell is connected with the upper end of the puncture sleeve, and the core rod is provided with a core rod seat at the upper end; the shell sequentially comprises a switching cap and a sleeve seat from top to bottom, the switching cap is matched with the sleeve seat in a sealed manner, the sleeve seat is arranged at the upper end of the puncture sleeve and integrally connected with the puncture sleeve, and the central axis of the puncture sleeve, the sleeve seat and the switching cap is provided with a working channel allowing a surgical instrument or the core rod to penetrate. The self-lubricating disposable puncture device further comprises a lubricating component arranged on the working channel. The lubricating component contacts with the surgical instrument or the core rod to lubricate the surgical instrument or the core rod. The self-lubricating disposable puncture device is simple in structure, convenient to operate and capable of fast lubricating the instrument.

Owner:SURGAID MEDICAL XIAMEN CO LTD

Water-based lubricant for metal stamping

InactiveCN104498168AGood wettability and adsorptionImprove performanceLubricant compositionSodium polyacrylatePolypropylene

The invention discloses a water-based lubricant for metal stamping, belonging to the technical field of a lubricant for metal stamping. The water-based lubricant for metal stamping comprises the following components: polyethylene glycol, sodium polyacrylate, fatty acid amide, guar gum, sodium pyrophosphate, silica sol, polyacrylamide, dipotassium hydrogen phosphate, naphthalene sulfonate and water. According to the water-based lubricant for metal stamping and through the creative component proportion, the lubricant has good antirust performance while the good lubrication can be guaranteed; and in addition, the lubricant is convenient to clean, not only the cleaning labor intensity be greatly reduced, but also a workpiece has favorable smooth finish.

Owner:芜湖华金冲压加工件厂

Preparation method of clopidogrel bisulfate solid preparation

ActiveCN110339178AReduce the probability of stickingIncrease dissolution rateOrganic active ingredientsDrageesSulfateDissolution

The invention relates to a preparation method of a clopidogrel bisulfate solid preparation. The method discloses a two-step granulation process of melt-granulating and then dry-pressing granulating for clopidogrel bisulfate, and the obtained granules have good compressibility and fluidity, and are not easy to stick to a die, so that the problems of tablet sticking, easy revealing or splitting which are common in the preparation of oral tablets of clopidogrel bisulfate is solved. The preparation method can ensure the rapid dissolution of the drug in the preparation, and the long-term retentionof the sample does not increase the impurities. The preparation process of the present invention is highly practical and can be used for large-scale preparation of clopidogrel sulfate bulk drugs withdifferent physical properties.

Owner:GUANGZHOU BAIYUSN TIANXIN PHARMA

Precision stamping process for sheet metal parts

ActiveCN108555105AGuaranteed accuracyImprove the lubrication effectShaping toolsVehicle componentsSulfonatePunching

The invention provides a precision stamping process for sheet metal parts. The precision stamping process comprises the following steps that boards are cut into sheets by a plate shearing machine, flattening is carried out, deburring is carried out, and a positioning holes is formed; graphite, ethylene glycol, ethyl alcohol, ethyl acrylate, sodium dodecyl sulfonate and water are mixed to obtain suspension liquid; a stamping die is heated to 110DEG C to 120 DEG C,and the stamping die is sprayed with the suspension liquid; and a suction device is arranged on the lower portion of the stamping die, and then the stamping die is used for punching. According to the precision stamping process for the sheet metal parts, the graphite, the ethylene glycol, the ethyl alcohol and the sodium dodecyl sulfonate are used for preparing the suspension liquid, the graphite can achieve a lubrication effect, the sodium dodecyl sulfonate can disperse the graphite, the ethyl alcohol can accelerate the evaporation rate of the suspension liquid, and the ethylene glycol can enable the graphite to become uniformly distributed graphite films. Therefore, in the process of precision stamping of the sheet metal parts, the die plays a very good lubrication role, the precision of the sheet metal parts is ensured, and the qualified rate of a product is high.

Owner:宁波诚泰汽车部件有限公司

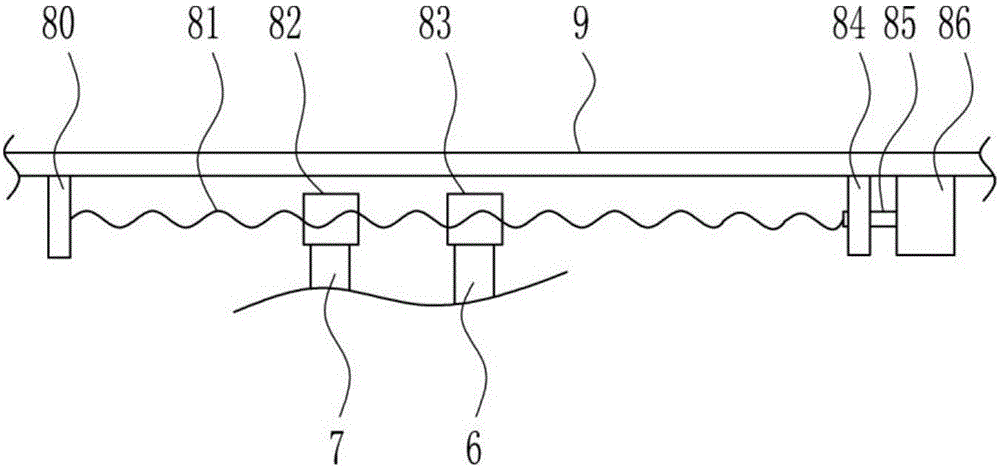

Steel wire rope lubricating device used for crane and capable of automatically carrying out lubricating during working

InactiveCN113294674ATo achieve the lubrication effectEvenly lubricatedEngine lubricationDrive wheelMarine engineering

The invention relates to the technical field of cranes, and discloses a steel wire rope lubricating device used for a crane and capable of automatically carrying out lubricating during working. The steel wire rope lubricating device comprises a lubricating box; an oil absorption brush is fixedly connected between the inner bottom wall and inner top wall of the lubricating box; a steel wire rope body is arranged inside the oil absorption brush; an oil outlet pipe is fixedly connected to the left side of the lubricating box; an oil inlet box is fixedly connected to the top of the oil outlet pipe; a first driven wheel, a driving wheel and a second driven wheel are arranged inside the oil inlet box; a rotating rod is fixedly connected to the top of the driving wheel; a first rotating shaft is fixedly connected to the right side of the top of the rotating rod; an oil inlet pipe is fixedly connected to the left side of the top of the oil inlet box; and an oil storage tank is fixedly connected to the left side of the oil inlet pipe. According to the steel wire rope lubricating device, lubricating oil in the oil storage tank intermittently enters the lubricating box, and the oil absorption brush in the lubricating box absorbs the lubricating oil and smears the lubricating oil on the steel wire rope body, so that the lubricating effect is achieved while the steel wire rope body works, the lubricating is uniform, and the working efficiency is improved.

Owner:谢柏红

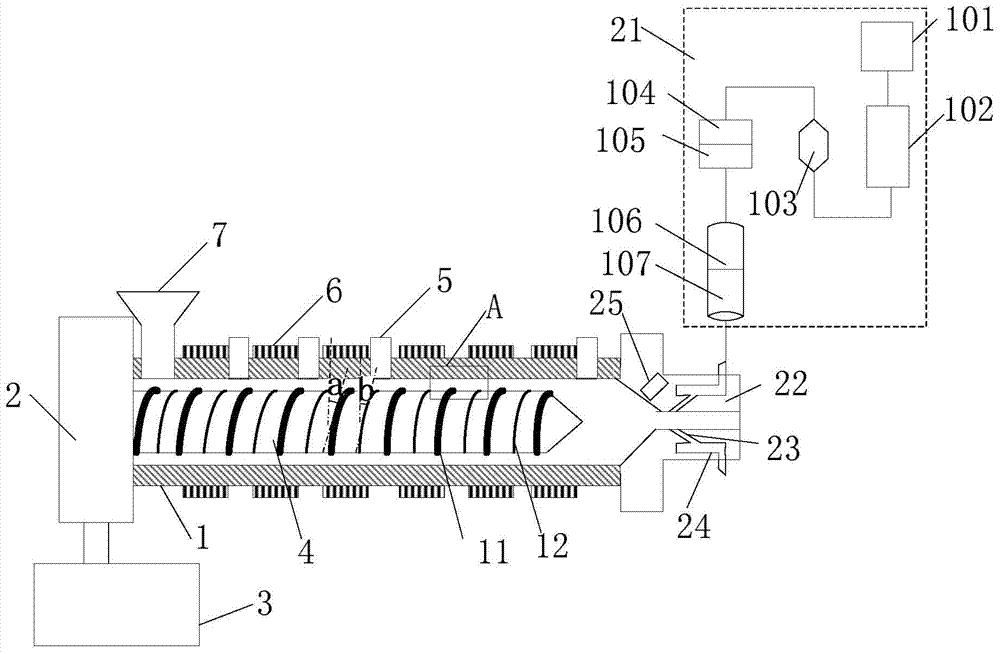

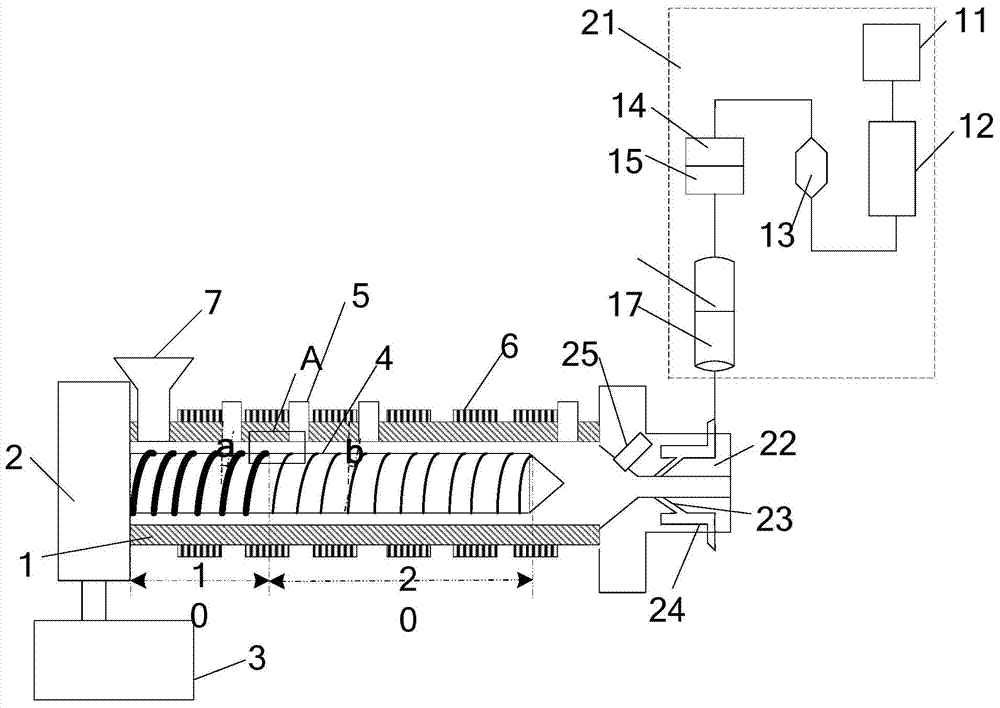

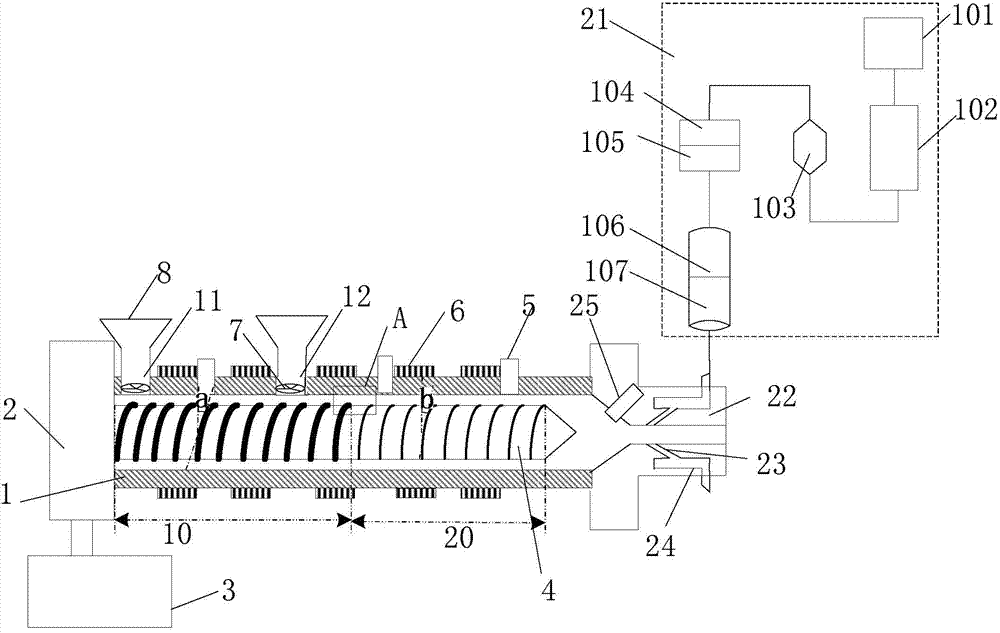

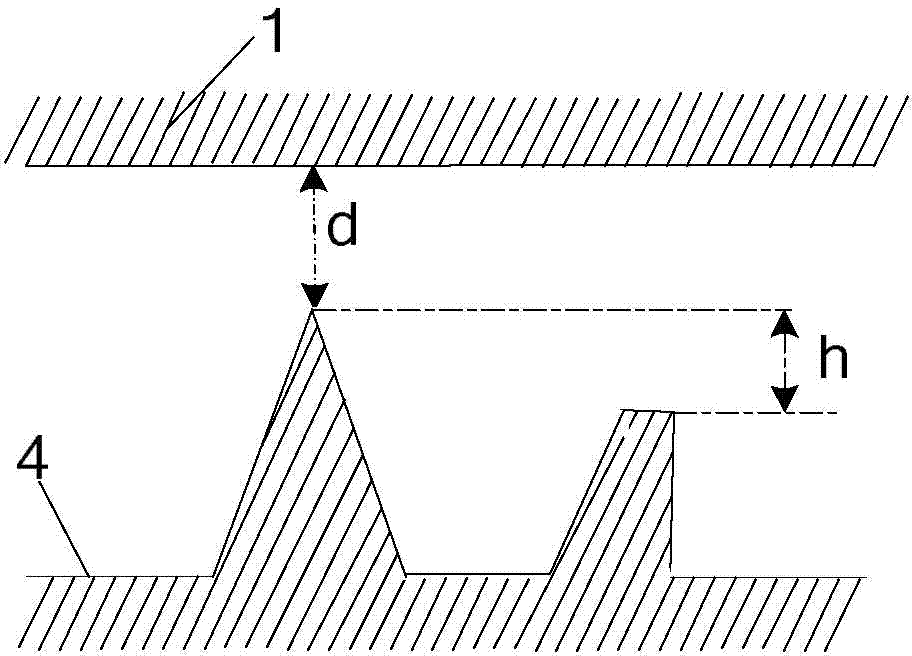

Gas-assisted extrusion equipment

InactiveCN103496145AImprove machine lifeReduce frictional resistanceInput controlMechanical engineering

The invention discloses gas-assisted extrusion equipment. The gas-assisted extrusion equipment comprises an extruder and an extruder head which is matched and connected with the extruder, wherein the extruder comprises a material cylinder; the inside of the material cylinder is provided with a screw rod; the screw rod is capable of rotating in the material cylinder and comprises main threads and accessory threads which are arranged in intervals with the main threads; the height of each main thread is greater than that of each accessory thread; the extruder head comprises a gas input controlling device and an extrusion opening die; a gas inlet hole is formed in the extrusion opening die; the gas inlet hole is connected with the gas input controlling device; the gas in the gas input controlling device enters the extrusion opening die through the gas inlet hole; a gas layer is formed between the inner wall side of the extrusion opening die and a molten plastic body. Through the gas-assisted extrusion equipment, the molten plastic body can be fully stirred and pushed to a discharging die opening, the requirement on the rotation torsion of the screw rod can be reduced, the whole life of the gas-assisted extrusion equipment is prolonged, and the production efficiency is improved.

Owner:昆山市华浦塑业有限公司

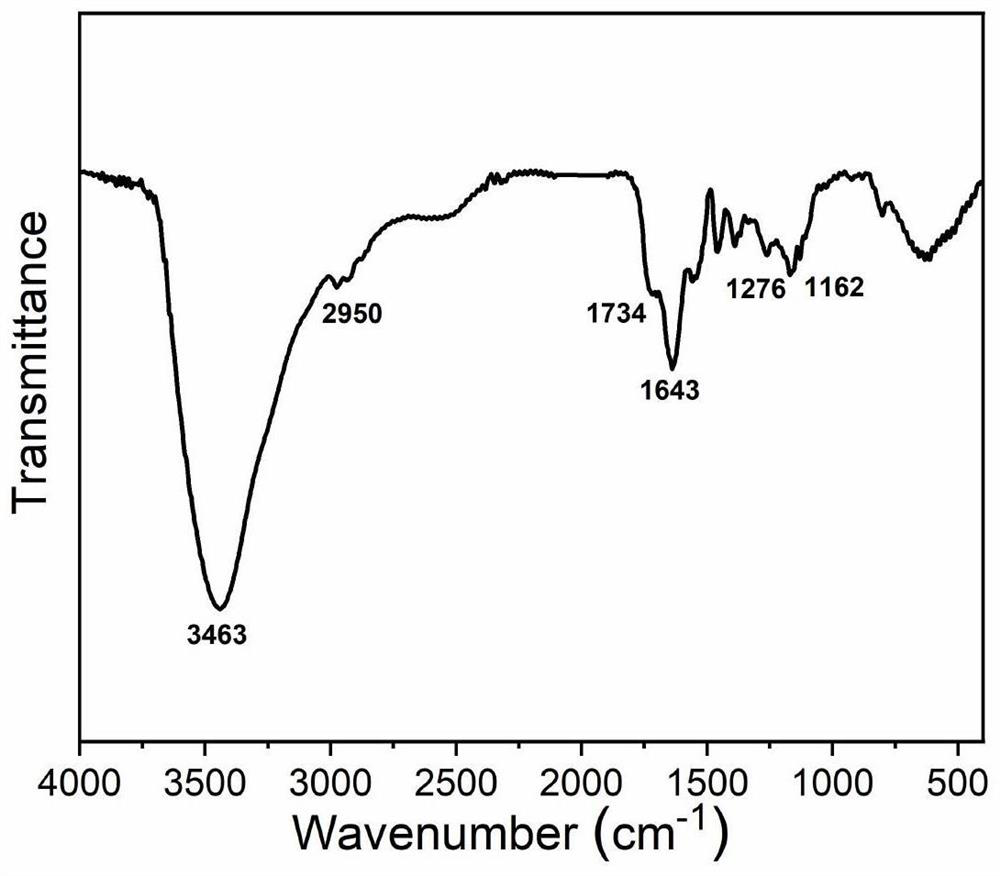

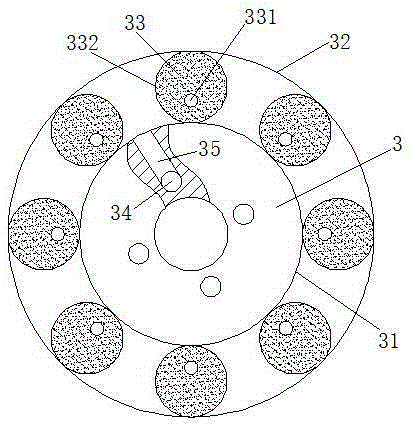

Modified forked feed lifting rock shaft crank

InactiveCN104153131AWear-resistantImprove the lubrication effectWork-feeding meansPorosityEngineering

The invention belongs to the technical field of accessories of sewing machines, and particularly relates to a modified forked feed lifting rock shaft crank. A protruding block is axially arranged on one side of the outer cylindrical surface of a barrel, an opening communicated with a central hole of the barrel is formed in the protruding block, a fastening screw penetrating through the opening is arranged on the protruding block, a forked plate is radially arranged on the side, with the protruding block, of the barrel, the forked plate comprises a fork opening used for arranging a sliding block, the bottom of the fork opening is solid, the barrel, the protruding block and the forked plate are made of powder containing oil in a metallurgical mode. The modified forked feed lifting rock shaft crank is made to have the advantages of being resistant to abrasion, good in lubricating property by controlling the matching of certain powder components and oil content; porosity is controlled by controlling the density degree of the powder, a certain amount of lubricating oil can ooze out of holes in crank materials along with changes of rotating speed and temperature, and therefore a lubricating effect is achieved; material cost is low, processing technic is simple, the modified forked feed lifting rock shaft crank is pressed, sintered and formed once through powder in the metallurgical mode, and the structure is simplified.

Owner:JACK SEWING MASCH CO LTD

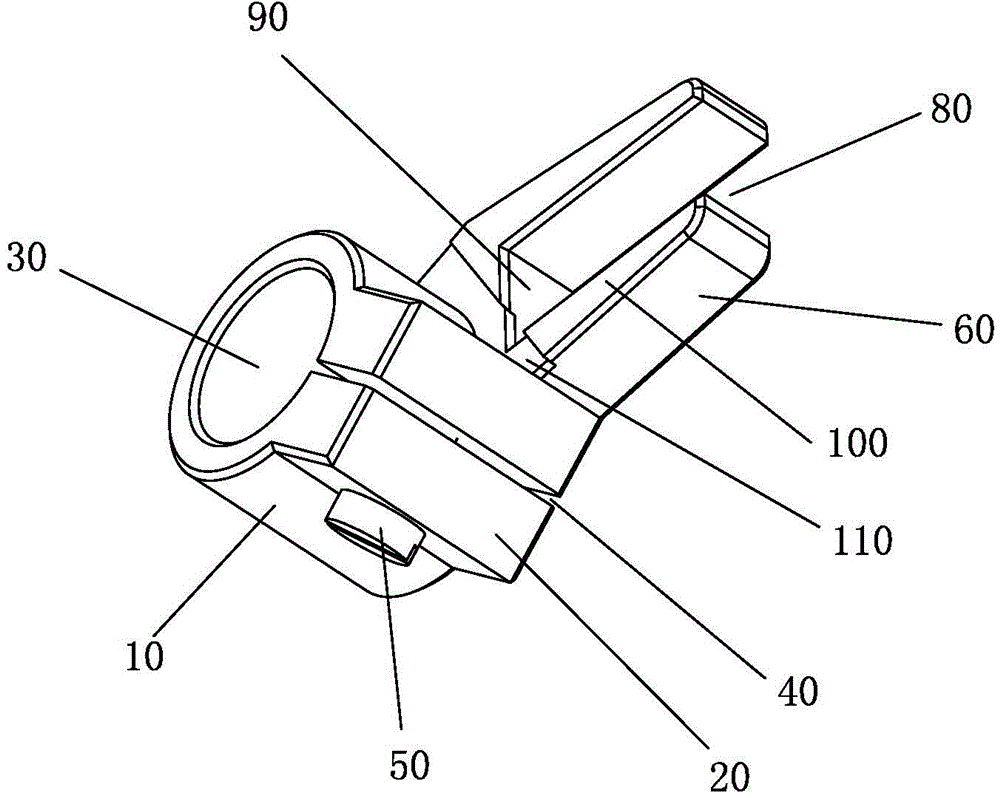

Nano lubricating additive for regulating and controlling interface friction as well as preparation method and application of nano lubricating additive

The invention belongs to the technical field of functional materials and preparation thereof, and provides a nano lubricating additive for regulating and controlling interface friction, a preparation method and application, the nano lubricating additive comprises core-shell structure nanospheres formed by taking gold nanoparticles as a core and taking a temperature-sensitive polymer cross-linked network as a shell; the manufacturing method comprises the following steps that s1, reducing gold ions into gold nanoparticles, and preparing a gold nanoparticle solution; s2, synthesizing a composite microgel ball dispersion liquid by adopting a soap-free emulsion polymerization method; s3, purifying the composite microgel ball dispersion liquid synthesized in the step S2; wherein composite microgel balls are dispersed in water, are used as a hydrated lubricating additive, can respond to near-infrared light stimulation, and are used for preparing a friction force switching agent for realizing rapid switching between low friction and high friction. The nano lubricating additive prepared by adopting soap-free emulsion polymerization can respond to near-infrared light stimulation, so that rapid switching between low friction and high friction is realized, and the friction performance of microgel is remotely regulated and controlled.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

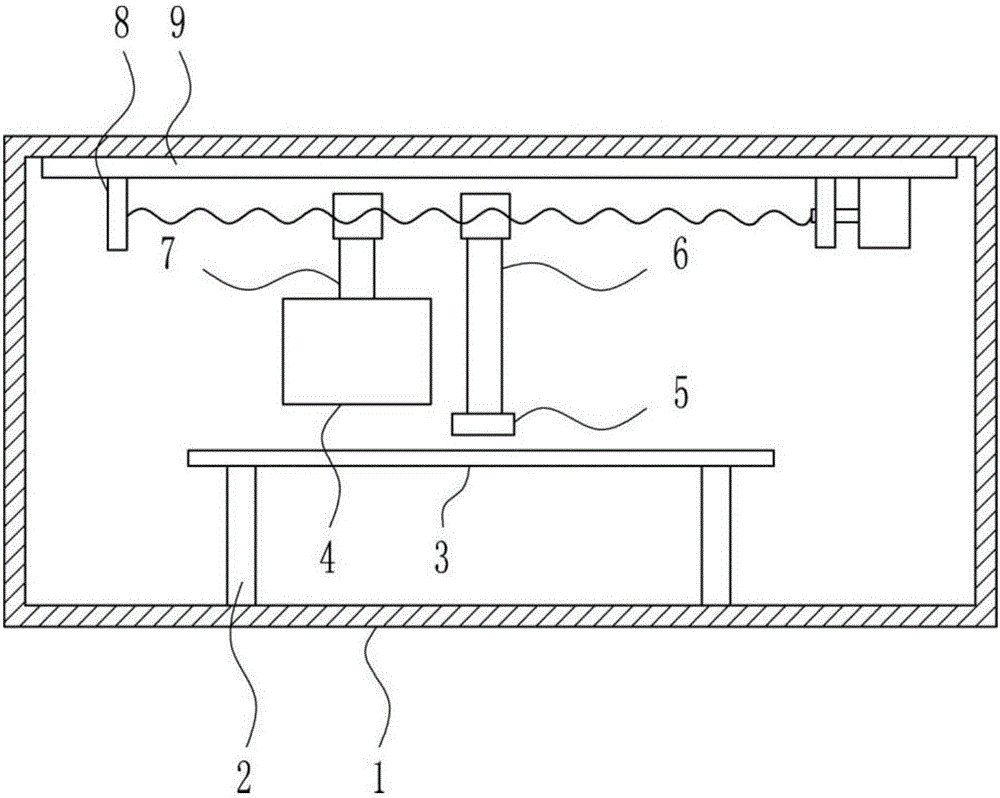

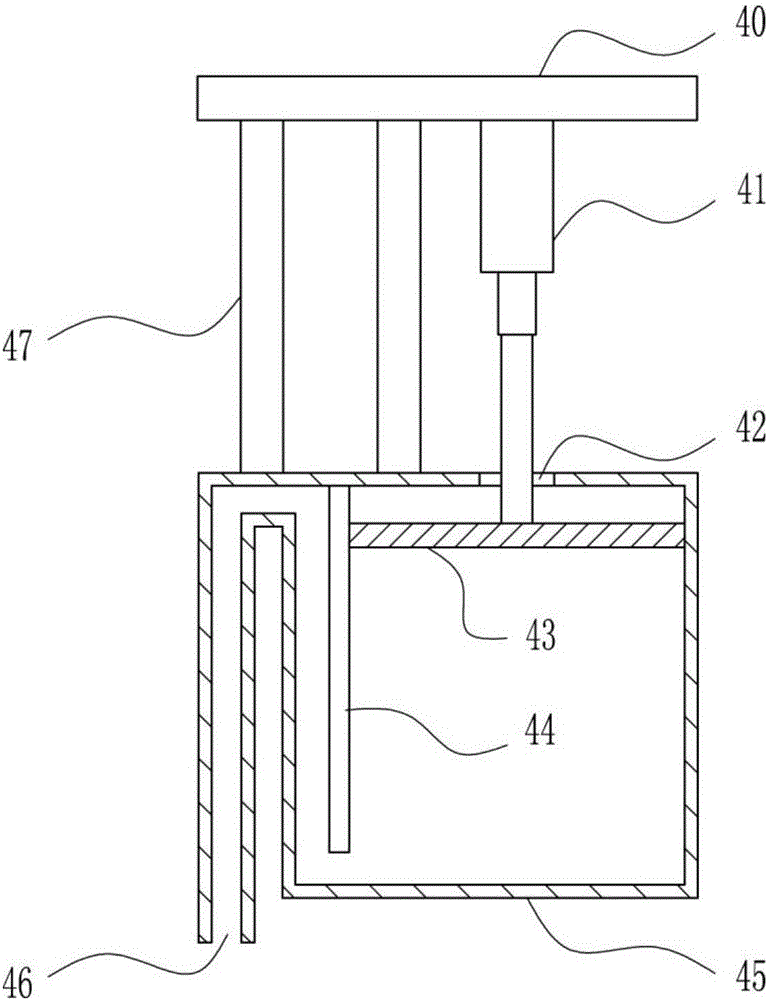

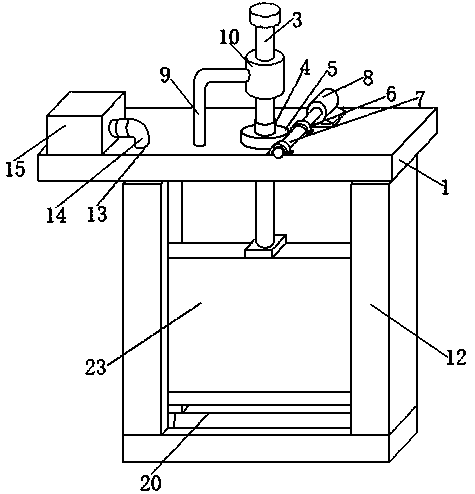

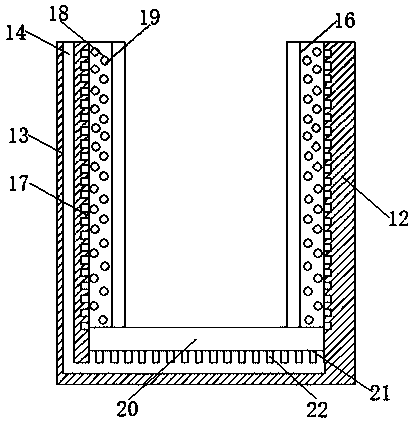

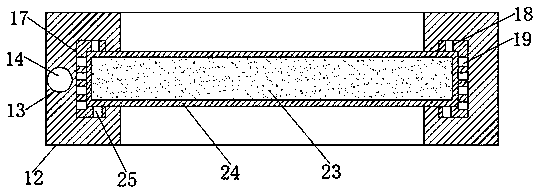

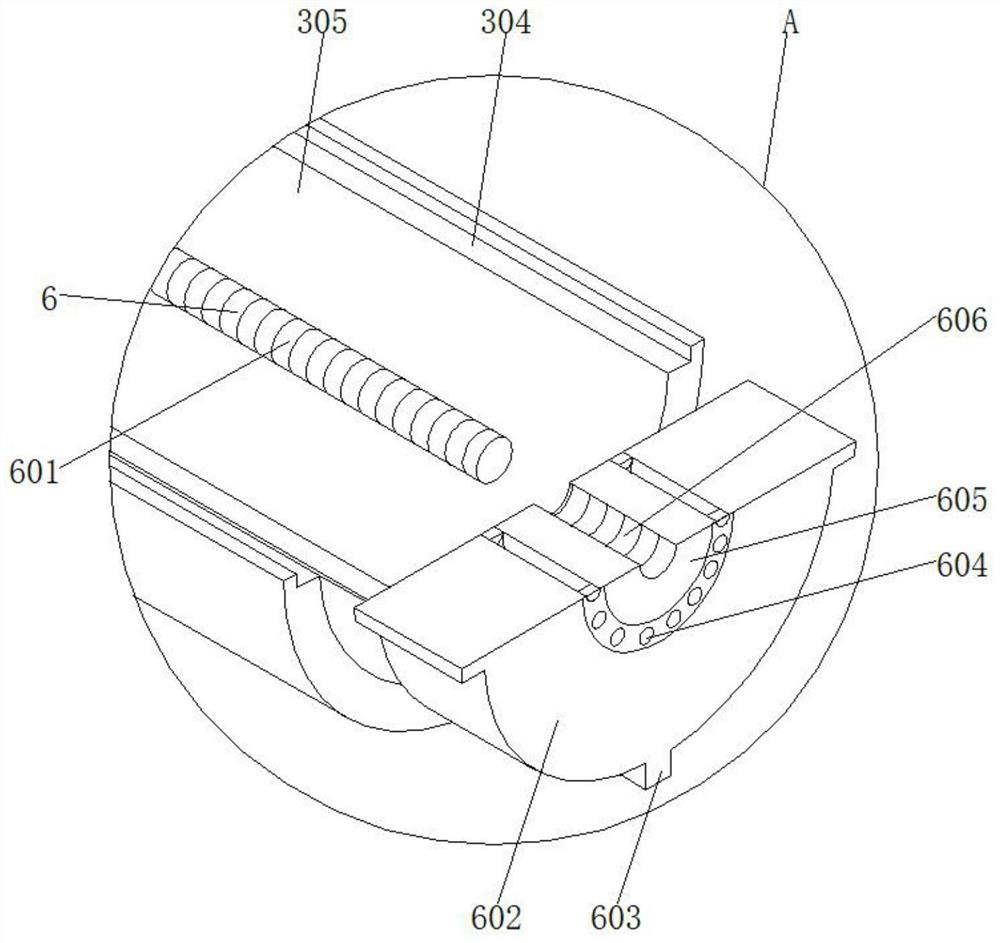

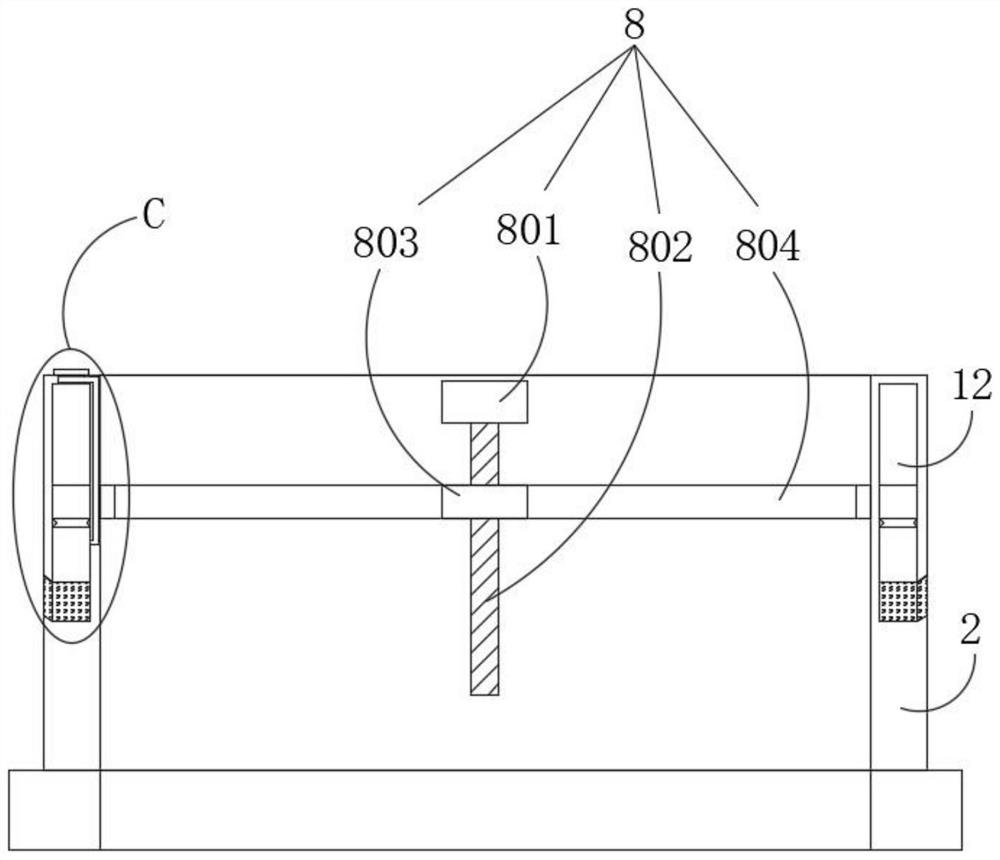

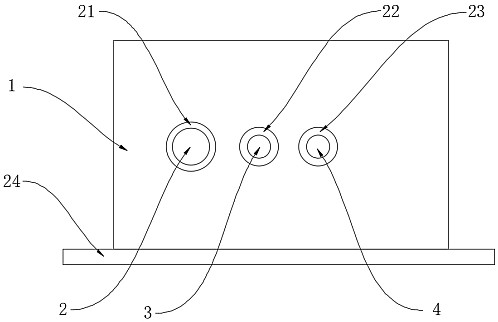

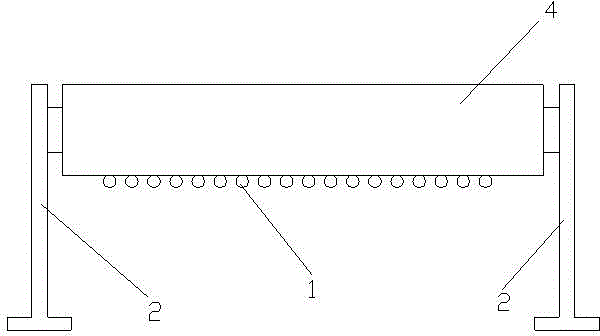

Guide rail lubricating device for maintenance of riveting equipment

InactiveCN106678173AApply evenlyTo achieve the lubrication effectLinear bearingsEngine lubricationEngineering

The invention relates to a lubricating device, in particular to a guide rail lubricating device for maintenance of riveting equipment. To achieve the technical aim, the guide rail lubricating device for maintenance of the riveting equipment can achieve comprehensive lubricating. In order to achieve the above technical aim, the guide rail lubricating device for maintenance of the riveting equipment comprises a frame, supporting rods, a fixed table, a dropping device, a smearing cotton block, a first connecting rod and the like. The supporting rods are connected with the inner bottom of the frame. The tops of the supporting rods are connected with the fixed table. A mounting plate is connected with the inner top of the frame. A moving mechanism is arranged at the bottom of the mounting plate. The bottom of the moving mechanism is connected with a second connecting rod and the first connecting rod. The second connecting rod is located on the left side of the first connecting rod. The bottom of the second connecting rod is connected with the dropping device. According to the guide rail lubricating device, the effect of comprehensive lubricating is achieved; by means of a smearing brush arranged at the bottom of the smearing cotton block, the corner part of a guide rail can be effectively lubricated; and by means of the design of the dropping device, grease can be saved.

Owner:朱梅

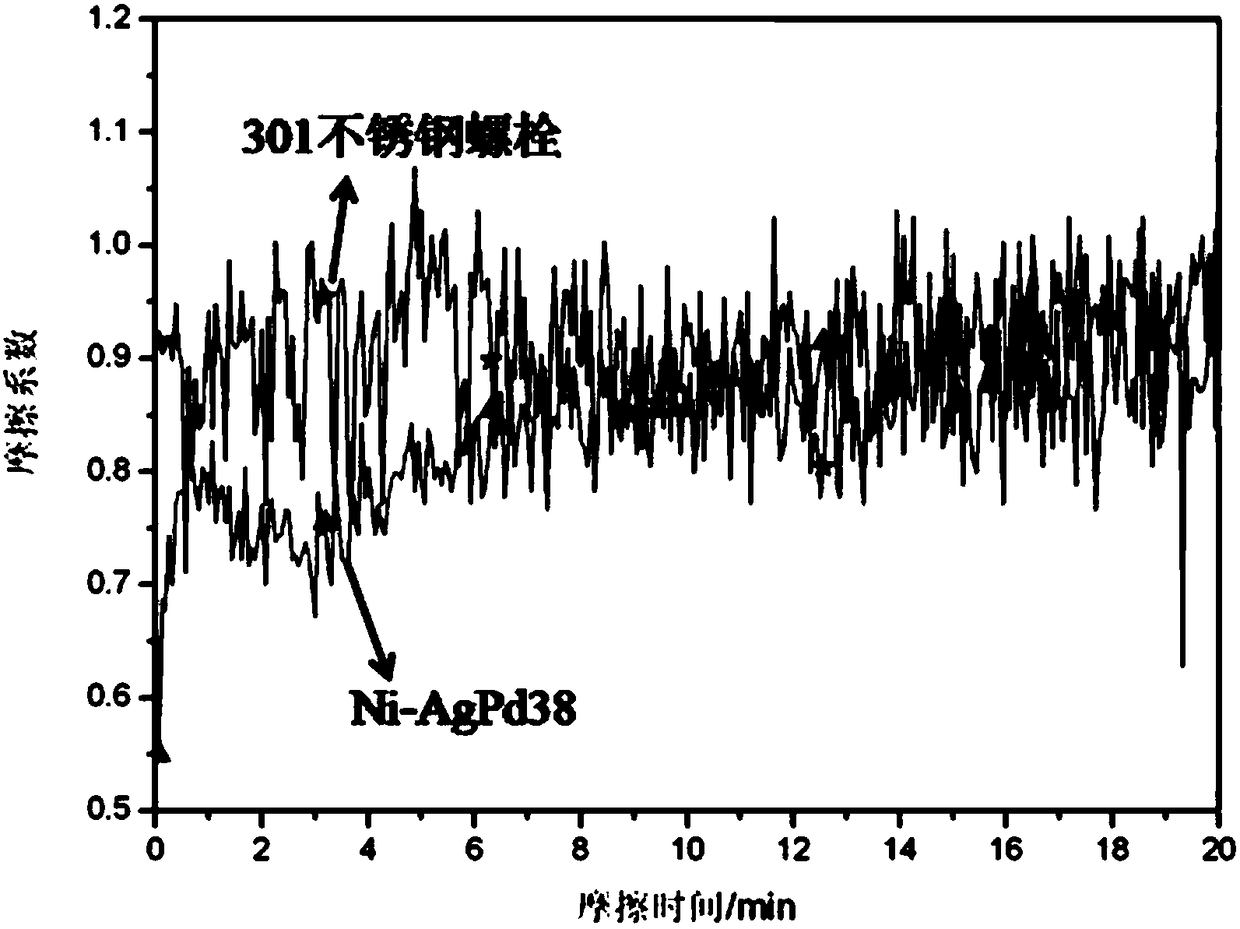

Method for preparing thread anti-seizure coating by adopting unbalanced magnetron sputtering technology

ActiveCN108103469AImprove ductilityImprove the lubrication effectVacuum evaporation coatingSputtering coatingSputteringSurface layer

The invention discloses a method for preparing a thread anti-seizure coating by adopting an unbalanced magnetron sputtering technology. The method comprises the steps of 1, polishing and cleaning bolts; 2,carrying out a sand blasting treatment on the bolts; 3, arranging a Ni target, a Ag target and a Pd target on a plurality of independent targets on an unbalanced magnetron sputtering device, theunbalanced magnetron sputtering technology is adopted on the surface of the bolts to obtain a depositional Ni transition layer; 4, and adopting the unbalanced magnetron sputtering technology to continuously deposit an AgPd coating on the depositional Ni transition layer, and finally the thread anti-seizure coating is formed by the depositional Ni transition layer and the AgPd coating. According to the invention, the problem of seizure failure occurring in the dismounting and locking processes of bolts is solved, and the Ag in the AgPd coating located on the surface layer has good ductility and lubricity, and the heat stability of the coating is improved after the Pd is added, meanwhile, the AgPd composite coating has good oxidation resistance and relatively high hardness, so that the comprehensive performance of the coating is improved.

Owner:西安赛福斯材料防护有限责任公司

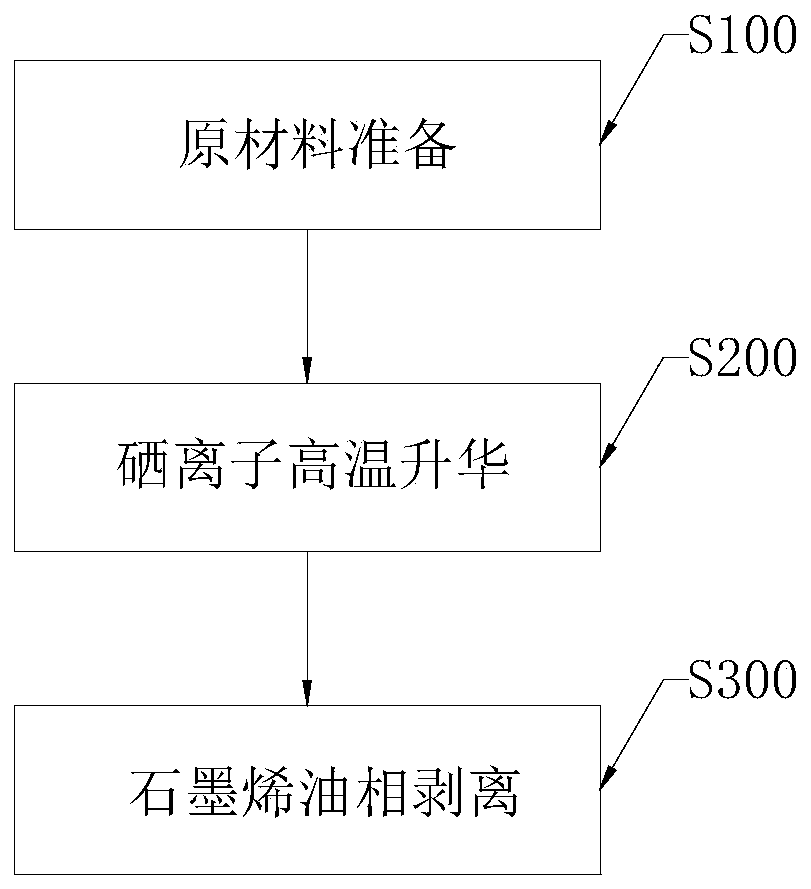

Selenium-ion inlaying method for oil-phase graphene

The invention discloses a selenium-ion inlaying method for oil-phase graphene. The selenium-ion inlaying method comprises the following steps: respectively placing natural flake graphite powder and aselenium material into two different molybdenum boat vessels, placing the vessels into a vacuum reaction kettle, and carrying out vacuumizing; heating the vacuum reaction kettle through a high-frequency heating method, allowing selenium ions in the selenium material to be sublimated onto the natural flake graphite powder so as to form a selenium-ion graphite powder; and after the selenium-ion graphite powder is cooled, adding the selenium-ion graphite powder into base oil for stripping of oil-phase graphene so as to obtain selenium-ion inlaid oil-phase graphene. According to a scheme of the invention, the selenium ions are sublimated onto the natural flake graphite powder as infiltration of a coating film; after completion of infiltration, an oil-phase graphene stripping process is performed, so selenium-ion inlaid graphene is obtained; and the selenium-ion inlaid graphene is added into engine oil, so a lubricating effect can be achieved, and the effects of cooling an engine and savingoil can be achieved.

Owner:陈让珠 +3

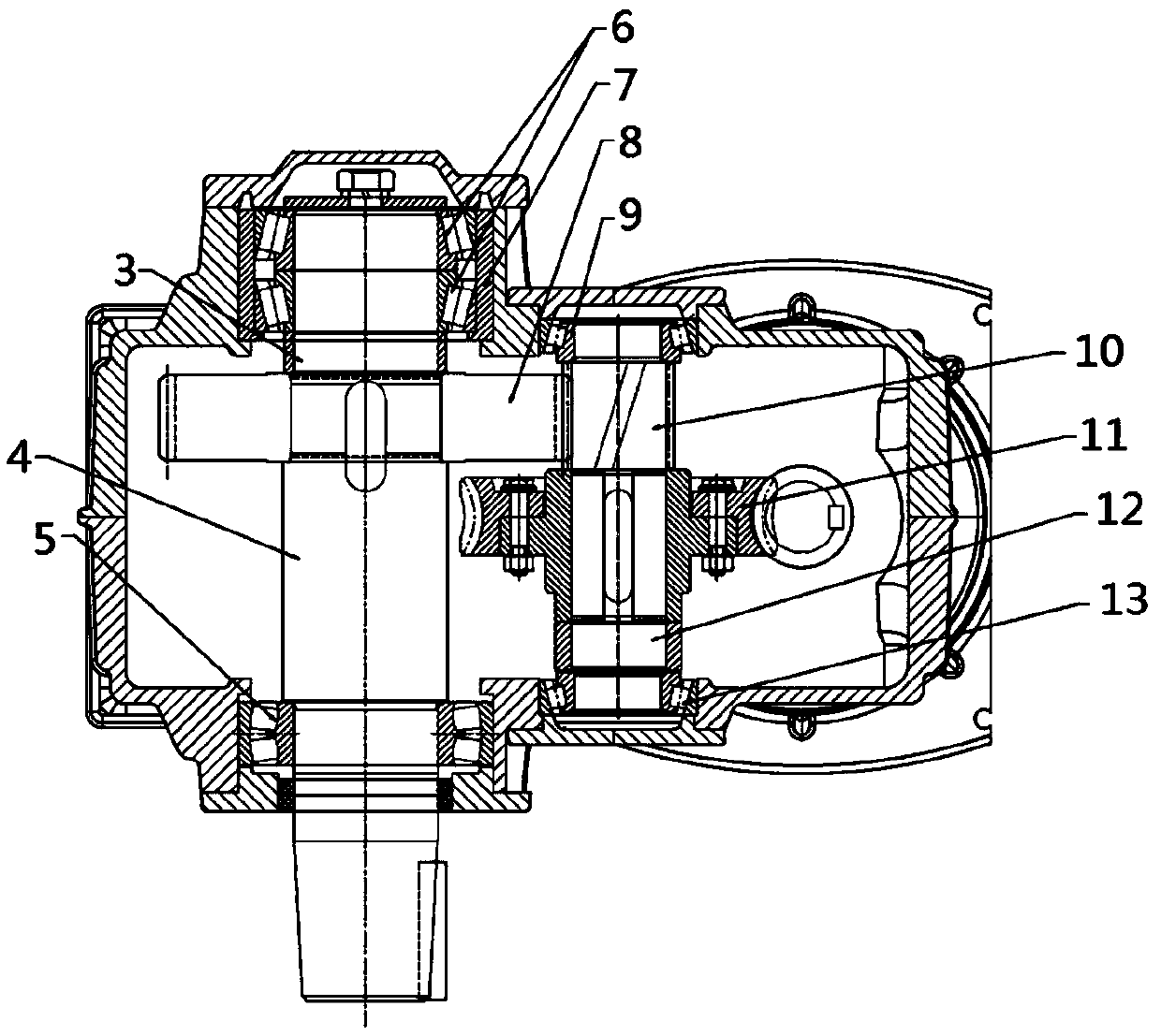

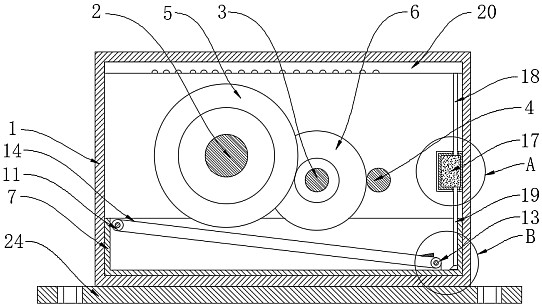

Automatic centering piston connecting rod assembly used for refrigeration compressor

ActiveCN106640599AGuaranteed contact accuracyTo achieve the lubrication effectPositive displacement pump componentsPlungersRefrigeration compressorEngineering

An automatic centering piston connecting rod assembly used for a refrigeration compressor comprises a connecting rod and a piston skirt body. One end of the connecting rod is connected with the piston skirt body, and the other end of the connecting rod is connected with a crankshaft. A sphere base of which the bottom end abuts against the upper wall of the piston skirt body is installed in the piston skirt body. The sphere base comprises a sphere base body and a positioning ring integrated with the sphere base body. The outer diameter of the positioning ring is 0.05-0.1 mm smaller than the inner diameter of the piston skirt body. A sphere is installed above the sphere base body. The middle of the piston skirt body is provided with a clamping opening. A buckle plate inwards and downwards extends out of the position, located on the upper wall of the clamping opening, of the piston skirt body. A sphere upper cover is connected between the sphere and the buckle plate in a clamped mode. The wall sticking surface of the sphere base body and the sphere is provided with an oil groove. The connecting rod is provided with a vertical oil hole. The sphere is riveted to the connecting rod. The automatic centering piston connecting rod assembly used for the refrigeration compressor is convenient to install and maintain, good in lubrication effect and long in service life.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

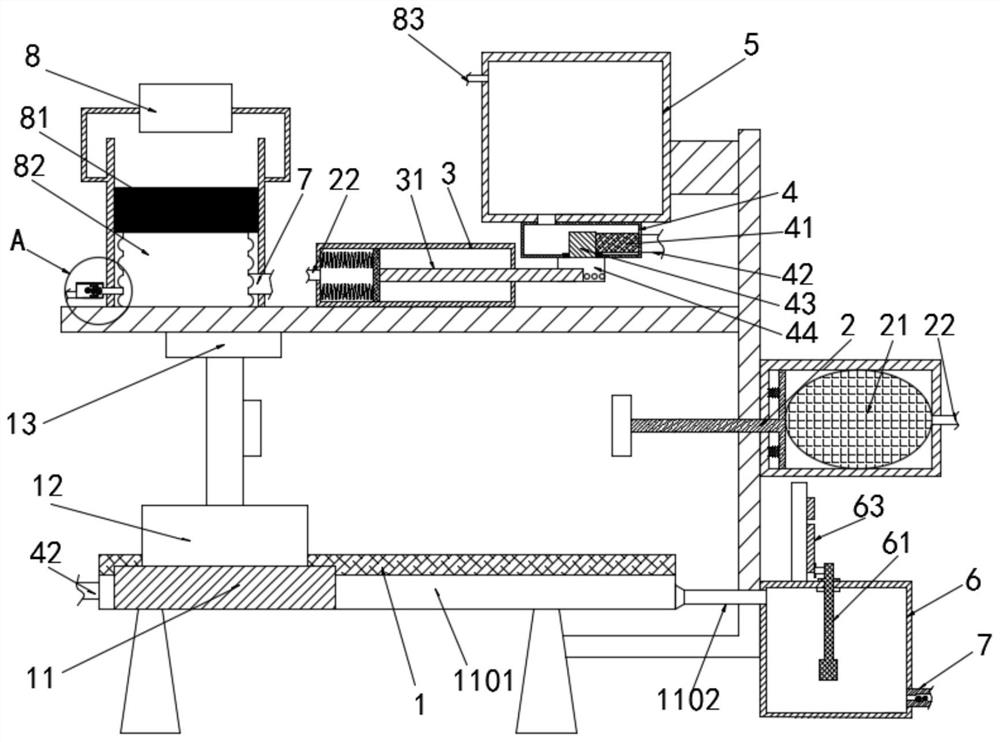

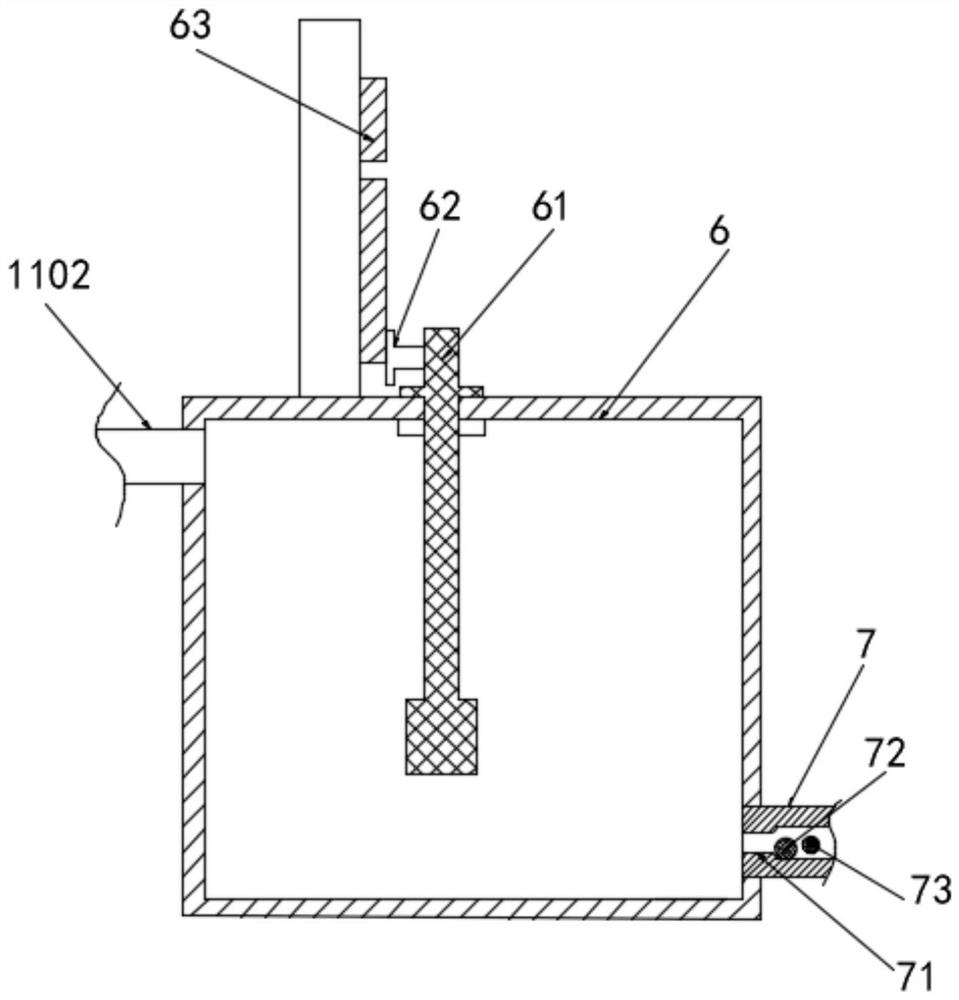

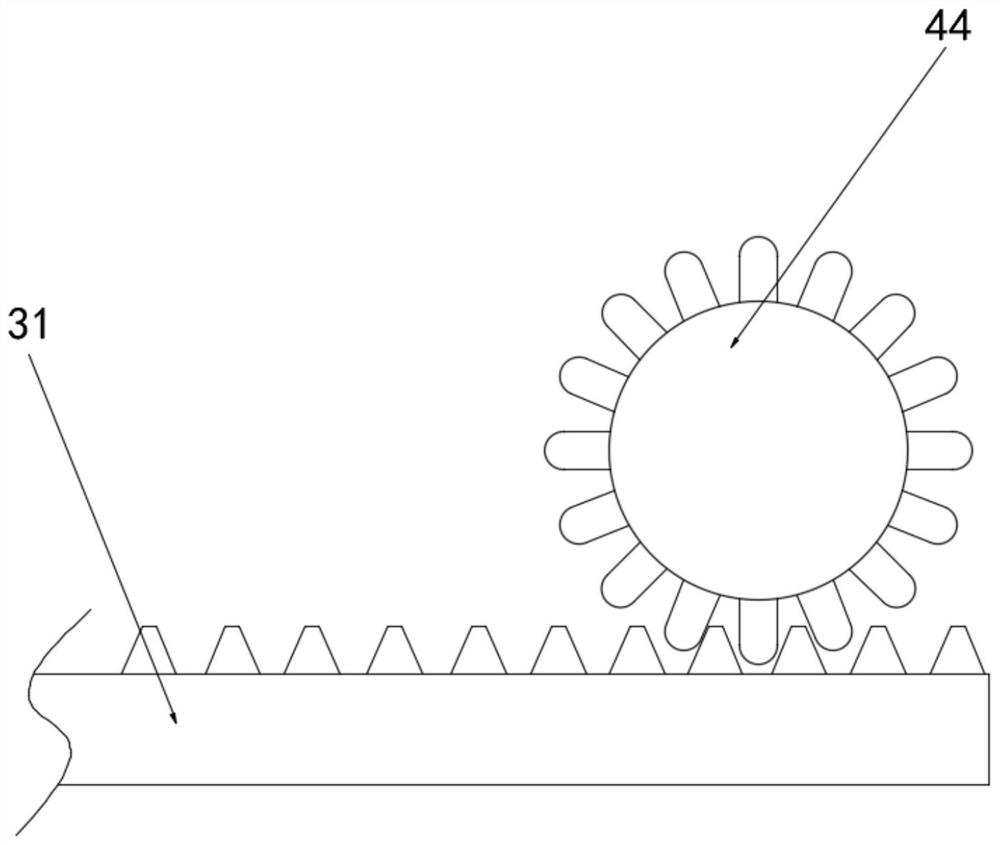

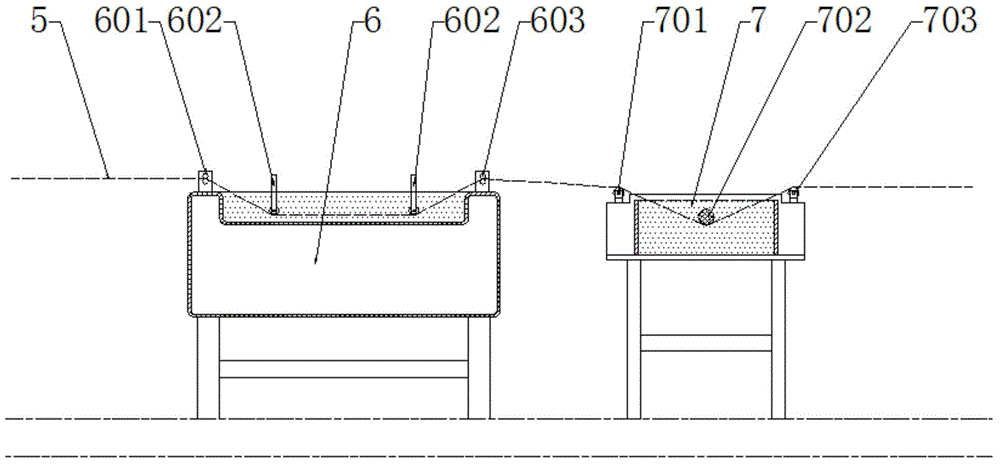

Device for automatically adding lubricating oil according to processing speed of processing machine tool

InactiveCN112303460AProcessing speed synchronizationReduce friction lossLubrication elementsMaintainance and safety accessoriesOil canFriction loss

The invention relates to the technical field of maintenance of lubrication of machine tools, and discloses a device for automatically adding lubricating oil according to processing speed of a processing machine tool. The device comprises a machine tool main body and an oil filling box, wherein the machine tool main body comprises a processing device and a driving device; a sliding slot is formed in the lower part of a sliding plate; the oil filling box comprises a rotary stop block, an oil filling pipe, a connecting shaft and a rotary column; the lubricating oil is added in a rotation processof the rotary stop block; when the rotary stop block rotates at an initial position, addition of the lubricating oil is stopped; in a circulation motion that the processing device is moved at a time leftwards and rightwards, the lubricating oil is added into the sliding slot at a time; the addition times of the lubricating oil are automatically increased along with the processing speed of the processing device, so that synchronization of addition of the lubricating oil and the processing speed of the processing device can be realized, and thus, a lubrication effect can be achieved to the maximum extent, friction loss of the sliding plate during sliding can be reduced, and the service life of the device is prolonged. Through adoption of a lubricating oil recycling device of the device, recycling of the lubricating oil can be realized.

Owner:张金华

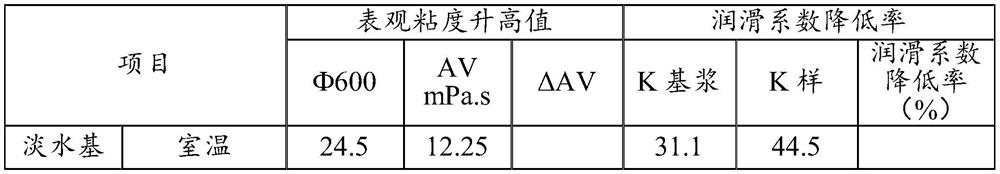

Temperature-resistant and salt-resistant lubricating drag reducer for drilling fluid and preparation method thereof

PendingCN111704897AImprove high temperature resistanceImprove low intensityDrilling compositionDrag reducing agentTriethanolamine

The invention provides a temperature-resistant and salt-resistant lubricating drag reducer for drilling fluid and a preparation method of the temperature-resistant and salt-resistant lubricating dragreducer. The composition comprises the following components in parts by mass: 60-80 parts of base oil, 20-40 parts of fatty acid amide, 3-5 parts of oleic acid monoglyceride, 1-3 parts of fatty acid alcohol amine, 1-3 parts of triethanolamine and 1-3 parts of triethanolamine. The base oil comprises any one or a mixture of more of biodiesel, white oil, vegetable oil, animal oil and mineral oil, thefatty acid alcohol amine comprises any one or a mixture of more of C4-8 alcohol amine, triethanolamine and a C10-18 fatty acid mixture, and the preparation method comprises the following steps: weighing the base oil, and putting the base oil into a reactor; adding fatty acid amide into the base oil, and uniformly stirring; adding oleic acid monoglyceride, and uniformly stirring; adding fatty acidalcohol amine, and uniformly stirring; and performing continuous stirring reaction for 30 min. The friction resistance between a drill stem and rock can be greatly reduced, abrasion of a drilling tool and other metal parts is reduced, rotation resistance is reduced, and the oil-gas drill bit has the advantages of temperature resistance, salt resistance, friction resistance reduction, adhesion coefficient reduction and the like, and can meet the requirement for smooth development of oil-gas drills.

Owner:SINOPEC SSC +1

High-temperature alloy end mill

The invention discloses a high-temperature alloy end mill. The high-temperature alloy end mill comprises a mill bar and a mill head; a mill blade is fixedly connected to the left side surface of the mill bar; a notch is formed in the middle of the left end of the mill blade; a first drainage channel is formed in the middle of the mill blade; the notch communicates with the first drainage channel; a dustproof net is fixedly connected to the inner part of the left end of the first drainage channel; and a circular groove is formed in the outer side surface of the right end of the mill bar. According to the high-temperature alloy end mill, in the working state, lubricating fluid can flow out of the notch, and therefore the lubricating effect can be achieved, too fast abrasion of the end mill can be effectively avoided, the certain cooling performance can be achieved, the deformation of the end mill can be effectively avoided, the anti-wear effect can be good, the high-temperature-resistant performance can be high, impurities can be effectively blocked, blockage of the first drainage channel can be avoided, the leakage of liquid in a liquid storage cavity ican be avoided, the use can be more convenient, and the normal use of the end mill can be effectively guaranteed.

Owner:江苏扬碟钻石工具有限公司

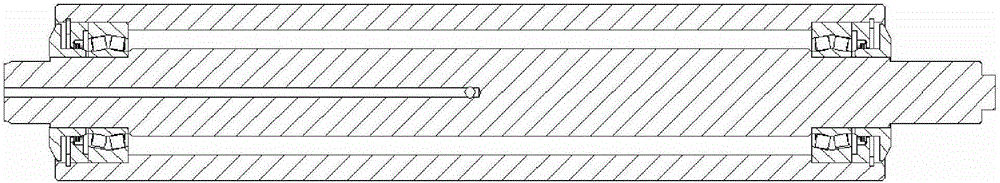

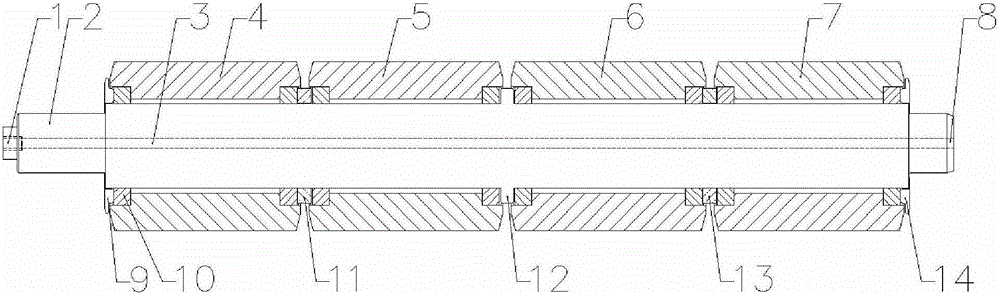

Anti-deformation foot roll combination device for sector section of large square blank and application method of anti-deformation foot roll combination device

The invention discloses an anti-deformation foot roll combination device for a sector section of a large square blank. A through hole penetrates the two ends of a whole center shaft with the center line of the center shaft as the center. The through hole comprises a water inlet and a water outlet. The end, close to the water inlet, of the center shaft is provided with a first end cover board. The end, close to the water outlet, of the center shaft is provided with a second end cover board. A first foot roll, a second foot roll, a third foot roll and a fourth foot roll are sequentially arranged between the first end cover board and the second end cover board in a sleeved manner. A first locating ring is installed at the joint of the first foot roll and the second foot roll. A shaft ring is arranged at the joint of the second foot roll and the third foot roll. A second locating ring is installed at the joint of the third foot roll and the fourth foot roll. The invention further discloses an application method of the anti-deformation foot roll combination device for the sector section of the large square blank. When just delivered out of a crystallizer, a casting blank is guided. The combination device can guarantee that the casting blank can be smoothly guided into the sector section in the continuous casting process and the casting blank cannot be scratched or indented.

Owner:NANJING IRON & STEEL CO LTD

Continuous casting crystallizer covering slag for hot-working die steel slab and application of continuous casting crystallizer covering slag

The invention discloses continuous casting crystallizer casting powder for a hot-working die steel slab and application of the continuous casting crystallizer covering powder, and belongs to the technical field of steelmaking auxiliary materials. The covering slag comprises the following chemical components of, in percentage by weight, 22-27% of CaO, 25-30% of SiO2, 4-6% of MgO, 0.2-2% of Al2O3, 0.2-2% of Fe2O3, 12-15% of Na2O, 4-7% of F, 2.5-3.7% of BaO, 6.5-9.5% of C and the balance of inevitable impurities. The covering slag has the characteristics of small slag denaturation and stable and uniform slag consumption after absorbing heavy metal oxides in molten steel, so that the hot-working die steel has good lubrication and heat transfer effects in the throwing process, the surface quality of a casting slab is good, the accident risk of producing the hot-working die steel by continuous casting slabs can be remarkably reduced, and the production cost is reduced; and the covering slag is especially suitable for continuous casting production of hot-working die steel with the pulling rate of 0.7-2.0 m / min.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Device capable of rapidly cleaning air cylinder and beneficial to high-temperature drying and rapid lubricating

InactiveCN111504045AQuick lubricationQuick washDrying gas arrangementsCleaning using liquidsEnvironmental engineeringMechanical engineering

The invention relates to the technical field of power cylinder lubricating, and discloses a device capable of rapidly cleaning an air cylinder and beneficial to high-temperature drying and rapid lubricating. The device comprises a power cylinder. The lower portion of the power cylinder is movably connected with an air inlet pipe. Moving rails are movably connected in the power cylinder. A pushingrod is movably connected between the two moving rails. A cleaning pipe is movably connected to the right upper portion of the power cylinder. The lower portion of the cleaning pipe is movably connected with a feeding valve. A control rail is movably connected in the feeding valve, and a control sliding block is movably connected in the control rail. The interiors o f the moving rails are started to be filled with cleaning liquid, the air inlet pipe at the bottom of the power cylinder continues to carry out air inflation on the power cylinder, furthermore, cleaning liquid in the moving rails isextruded into a pollution discharge bin movably connected in a pollution discharge box through moving of moving sliding blocks, and therefore the effect of rapidly cleaning away oil contamination infront of the power cylinder is achieved, and cleanliness in the moving rails of the power cylinder is guaranteed.

Owner:姜勇军

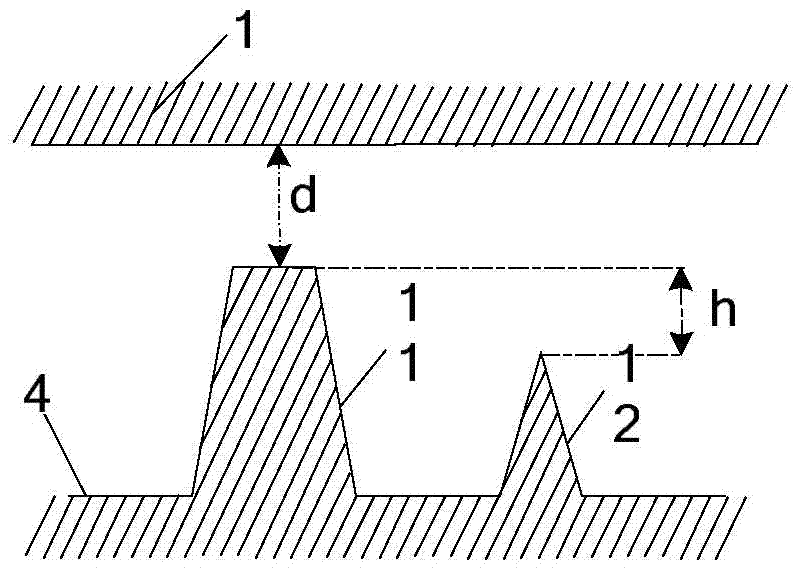

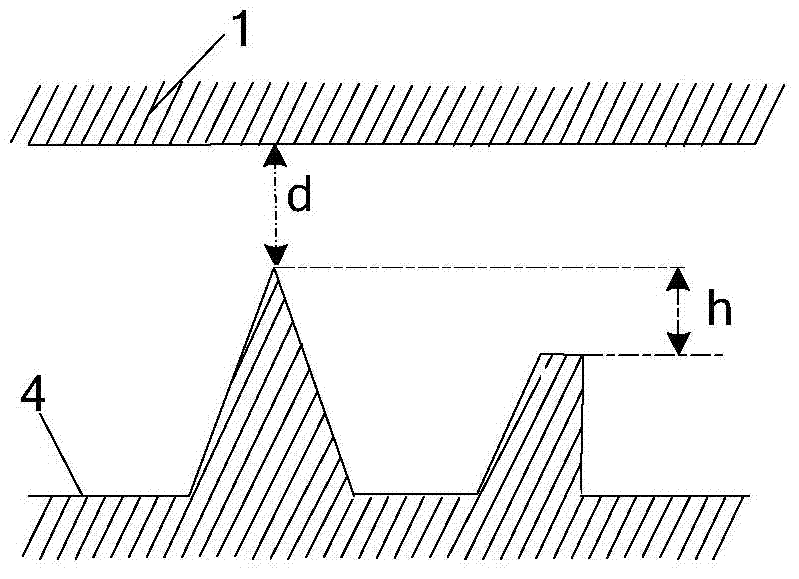

Gas-assisted extrusion equipment with stirring and pushing functions

InactiveCN103496135AReduced rotational torque requirementsReduce frictional resistanceInput controlScrew thread

The invention discloses gas-assisted extrusion equipment with stirring and pushing functions. The gas-assisted extrusion equipment comprises an extruding machine, an extruding machine head which is matched and connected with the extruding machine, and a charging barrel, wherein the feeding end of the charging barrel is provided with a feeding hole, the charging barrel is internally provided with a screw rod, the screw rod can rotate in the charging barrel and is provided with a thread structure, the thread structure comprises a first thread region and a second thread region connected with the first thread region, the first thread region is close to the feeding hole of the charging barrel, and the tooth heights of threads of the first thread region are greater than those of threads of the second thread region; the extruding machine head comprises a gas input control device as well as an extruding opening mould with a gas inlet hole, the gas inlet hole is connected with the gas input control device, gas in the gas input control device enters the extruding opening mould through the gas inlet hole, and a gas layer is formed between the inner wall of the extruding opening mould and a fusion plastic body. The gas-assisted extrusion equipment provided by the invention has good effects of stirring and pushing the fusion plastic body, and the requirement on rotating twisting force of the screw rod is lowered.

Owner:昆山市华浦塑业有限公司

Wear-resistant lubricating water conservancy gate equipment

InactiveCN111321707ATo achieve the lubrication effectSolve the rustBarrages/weirsElectric machineryScrew thread

The invention belongs to the technical field of water conservancy equipment, and particularly relates to wear-resistant lubricating water conservancy gate equipment which comprises a gate beam. A threaded hole is formed in the upper surface of the gate beam, a screw is in threaded connection with the inner wall of the threaded hole, a threaded sleeve is in threaded connection with the surface of the screw, and a worm gear fixedly sleeves the outer surface of the threaded sleeve in a connected mode; and the upper surface of the gate beam is fixedly connected with bearing seats, the inner wallsof the two bearing seats are fixedly connected with bearings, the inner rings of the bearings are movably connected with worms in a sleeving mode, and the outer surface of the worm gear is meshed withthe outer surfaces of the worms. According to the wear-resistant lubricating water conservancy gate equipment, the effect of lubricating between the two sides of a gate plate and sliding grooves is achieved, when the wear-resistant lubricating water conservancy gate equipment is used, a motor is started, the worm gear and the worms are in meshing transmission, the screw is made to ascend and descend, the screw drives the gate plate to ascend and descend, and the gate plate is inserted connection with the sliding grooves in a sliding mode in the ascending and descending process; and when the gate plate ascends and descends, a lubrication core in a placing hole lubricates the gate plate, and therefore the problem about abrasion of the gate plate and the sliding grooves is solved.

Owner:陕西沃斯工业科技有限公司

Preparation method of water-based lubricant for metal stamping

InactiveCN104560353AImprove wettabilityImprove adsorption capacityLubricant compositionStampingPolyethylene glycol

The invention discloses a preparation method of a water-based lubricant for metal stamping, and belongs to the technical field of lubricants for metal stamping. The preparation method comprises the following steps: (1) preparing a mixture A: mixing components such as polyethylene glycol and sodium polyacrylate; (2) preparing a mixture B: heating the mixture A; (3) preparing a mixture C: adding components such as silica sol and polyacrylamide in the mixture B; (4) preparing the water-based lubricant: adding naphthalenesulfonate in the mixture C to prepare the lubricant. Through the creative component ratio, the lubricant has favorable anti-corrosion performance while ensuring the favorable lubricating property, and in addition, the lubricant is convenient to clean, and not only greatly reduces the cleaning labor intensity, but also endows a workpiece with a favorable degree of finish.

Owner:芜湖华金冲压加工件厂

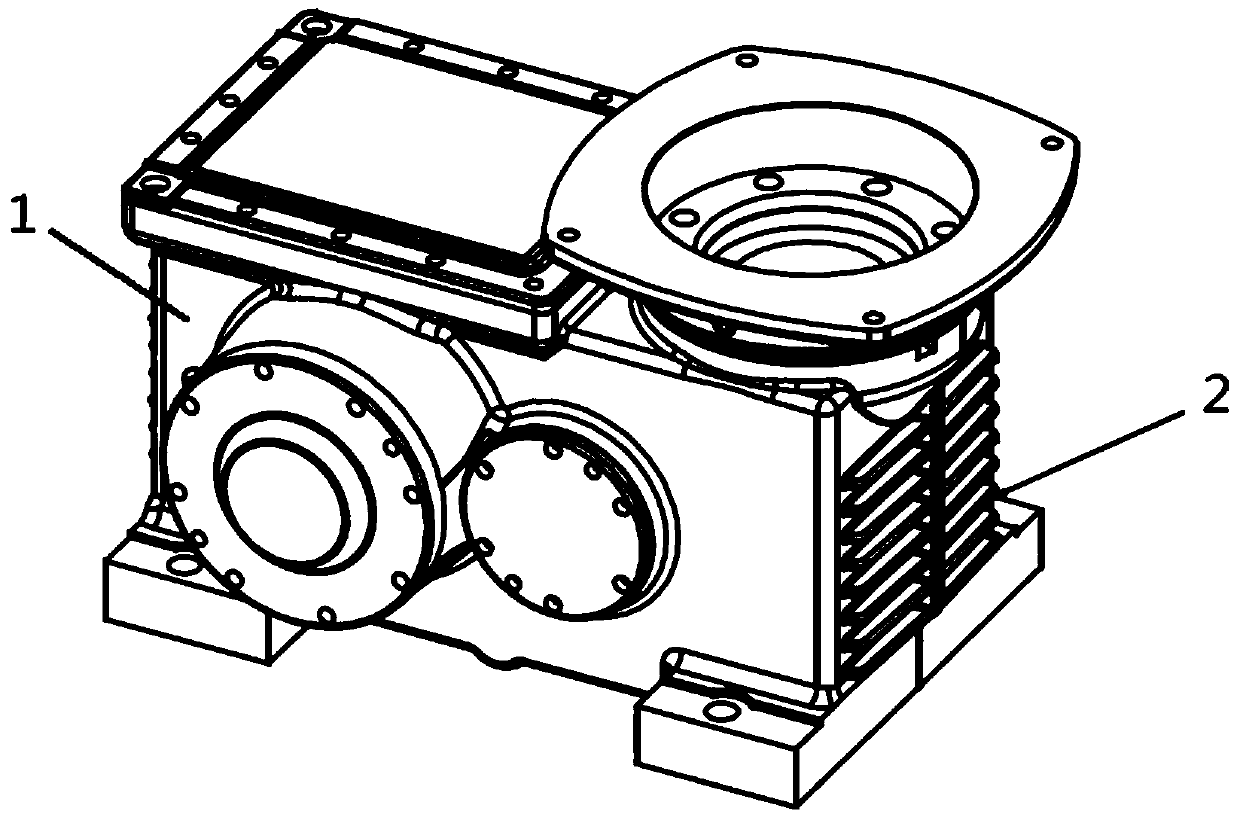

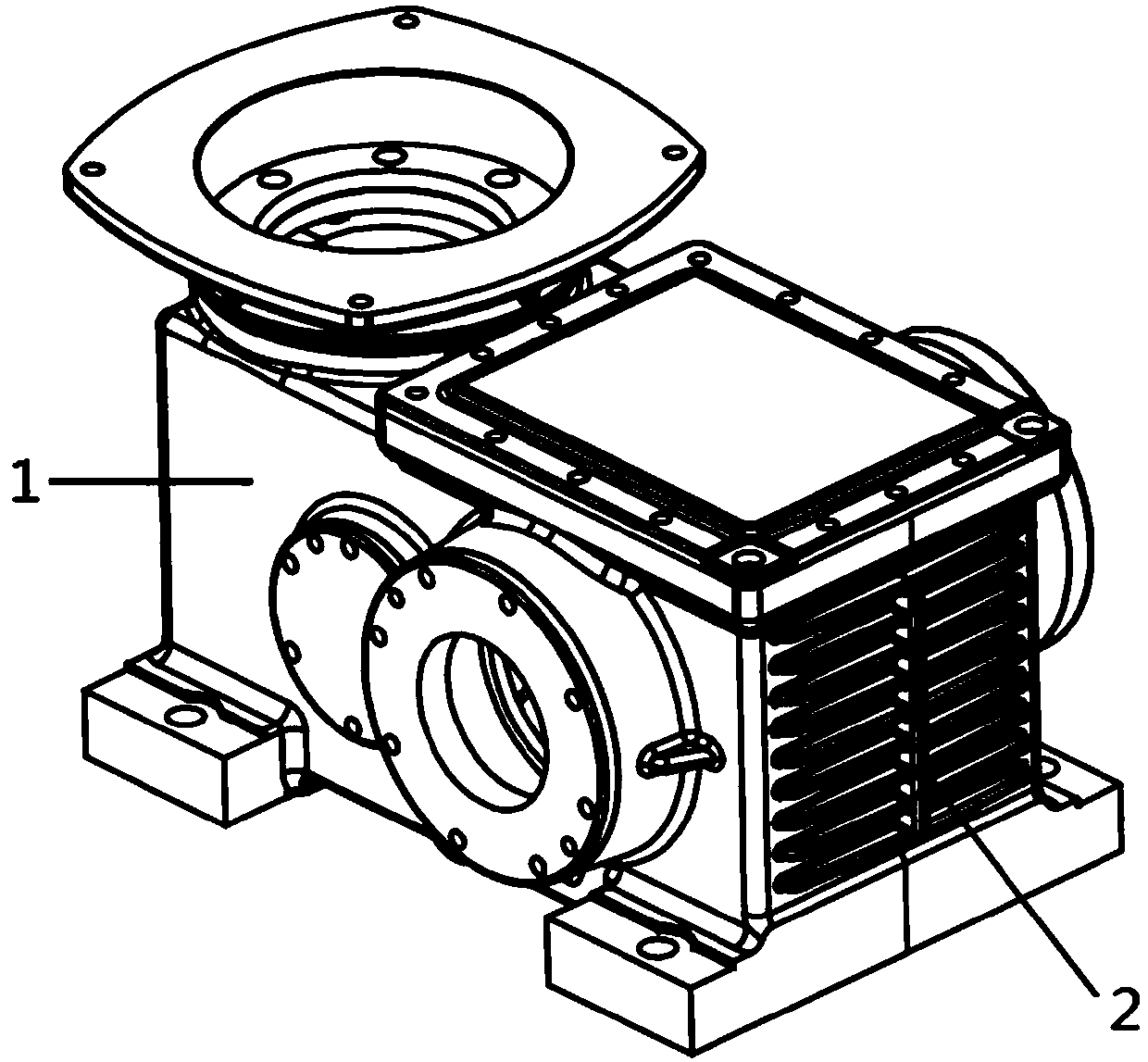

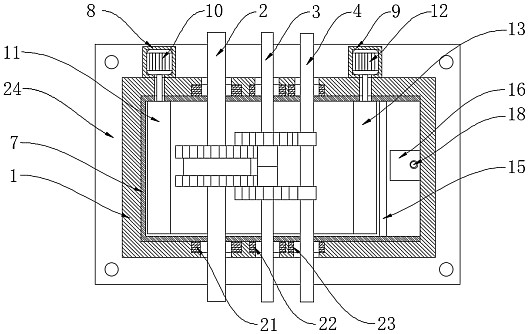

Two-stage worm and gear bevel wheel transmission speed reducer

PendingCN111434954AHigh transmission efficiencyImprove carrying capacityGearboxesToothed gearingsAutomotive engineeringGear drive

The invention relates to a two-stage worm gear and worm bevel wheel transmission speed reducer. The speed reducer adopts a two-stage transmission manner, a worm and gear is located on the high-speed stage, a bevel wheel is located on the low-speed stage, the two-stage worm and gear bevel wheel transmission speed reducer comprises a box body, an output shaft, a worm gear and a worm, the output shaft, the worm gear and the worm are mounted in the box body, a worm gear shaft is mounted in the middle of the worm gear, a spindle and the worm gear shaft are sleeved with gears and are connected, thegears are connected, and the worm is in a ZC tooth shape. Compared with the prior art, the transmission efficiency is improved, meanwhile, the need of outputting large torque is met, the whole bearingcapacity of the speed reducer is greatly improved, and the speed reducer can be mainly used for main drive of heavy escalators (public ladders).

Owner:SHANGHAI LONGYU ELEVATOR ACCESSORIES

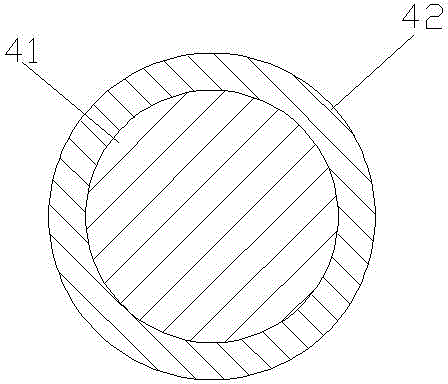

Anti-jam wheel of agricultural sowing machine

The invention discloses an anti-jam wheel of an agricultural sowing machine. The anti-jam wheel includes a rotation shaft and a wheel body; the rotation shaft is movably connected to the wheel body through a bearing; the bearing includes a bearing inner ring and a bearing outer ring; steel balls are evenly arranged between the bearing inner ring and the bearing outer ring; oil inlet holes are formed in the steel balls; second sponge blocks are added in inner cavities of the steel balls; the oil inlet holes communicate with the second sponge blocks; second oil injection holes are formed in the bearing inner ring; the second oil injection holes are connected to one end of an oil injection pipe, and the other end of the oil injection pipe communicates with a gap between the bearing outer ring and the bearing inner ring; a first protection cover is arranged on the left side of the bearing; a first oil injection hole is formed in the left side of the first protection cover; a first sponge block is added in an inner cavity of the first protection cover; and a second protection cover is arranged on the right side of the bearing. The anti-jam wheel is simple in structure, can effectively prevent the wheel from jam, and can ensure normal working.

Owner:重庆市潼南区晨兴铸造厂

Gas assisted extrusion device with feed inlet stirring function

The invention discloses a gas assisted extrusion device with a feed inlet stirring function. The gas assisted extrusion device with the feed inlet stirring function comprises an extruder and an extruder head which is connected with the extruder in a matched mode, wherein the extruder comprises a charging barrel; the charging barrel is internally provided with a screw capable of rotating in the charging barrel; a feed inlet is provided with an impellor structure which is driven to rotate by a motor; the screw is provided with a first threaded zone and a second threaded zone connected with the first threaded zone; the first threaded zone is close to the feed inlet of the charging barrel; the second threaded zone is far away from the feed inlet of the charging barrel; the thread height of the first threaded zone is greater than the thread height of the second threaded zone; the extruder head comprises a gas input control device and an extrusion opening die provided with a gas inlet; gas in the gas input control device enters the extrusion opening die through the gas inlet; a gas layer is formed between the inner wall surface of the extrusion opening die and a fusion plastic body. The gas assisted extrusion device with the feed inlet stirring function, which is provided by the invention, has good stirring and pushing effects on the fusion plastic body, is beneficial to preventing the charging barrel from being blocked, lowers the requirement on rotation torsion of the screw, and charges rapidly.

Owner:昆山市华浦塑业有限公司

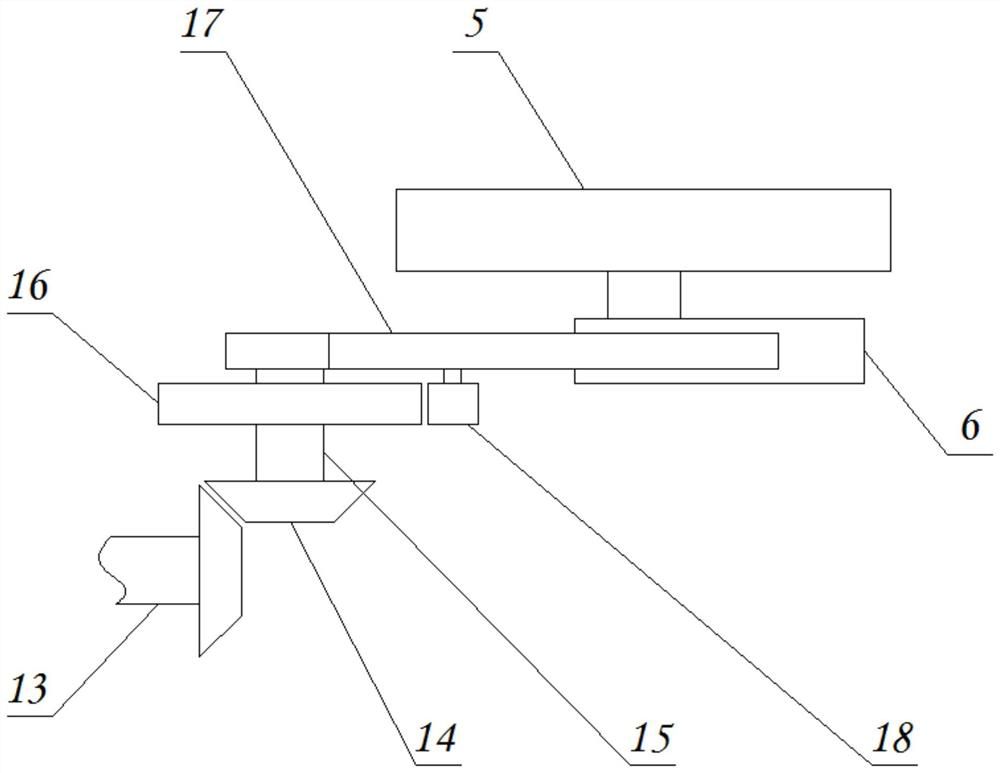

A manipulator telescopic device for a welding robot used in the manufacture of RV trailers

ActiveCN112139714BReduce wearTo achieve the lubrication effectWelding/cutting auxillary devicesAuxillary welding devicesOil canRobot hand

Owner:湖南文辉汽车制造有限公司

Tin-plating production line

InactiveCN104451501AIncrease the lengthIncrease tinning timeHot-dipping/immersion processesProduction lineCopper wire

The invention provides a tin-plating production line. The tin-plating production line comprises a tin-plating device, a tin bath guide wheel guider, a tin bath pressing wheel set, a tin bath asbestos guider, a tin-plating cooling tank, a cooling tank asbestos guider, a cooling tank pressing wheel and a cooling tank guide wheel guider, wherein the tin-plating device is provided with a tin bath guide wheel guider at an incoming end, a pressing wheel set is arranged in a tin bath of the tin-plating device, an asbestos guider is arranged at the outgoing end of the tin-plating device, the tin-plating cooling tank is arranged behind the tin-plating device, the asbestos guider is arranged at the incoming end of the tin-plating cooling tank, a pressing wheel is arranged in the cooling tank, and the cooling tank guide wheel guider is arranged at the outgoing end of the tin-plating cooling tank. The tin-plating production line has the beneficial effects that the tin plating time of a copper wire can be prolonged due to the pressing wheel set in the tin bath, the asbestos guider can effectively prevent the drifting phenomenon after wire breakage while protecting the coated tin, and the tin-plated copper wire can be cooled and the lubricating effect is improved due to use of oxygen protection liquid.

Owner:TIANJIN DEXIANGPENG METAL PROD

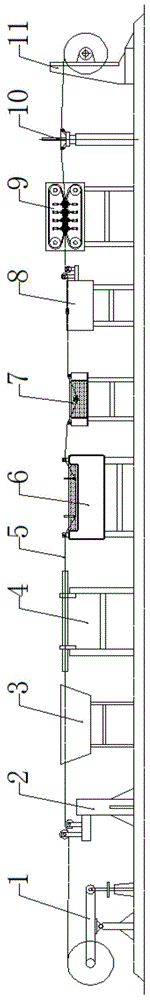

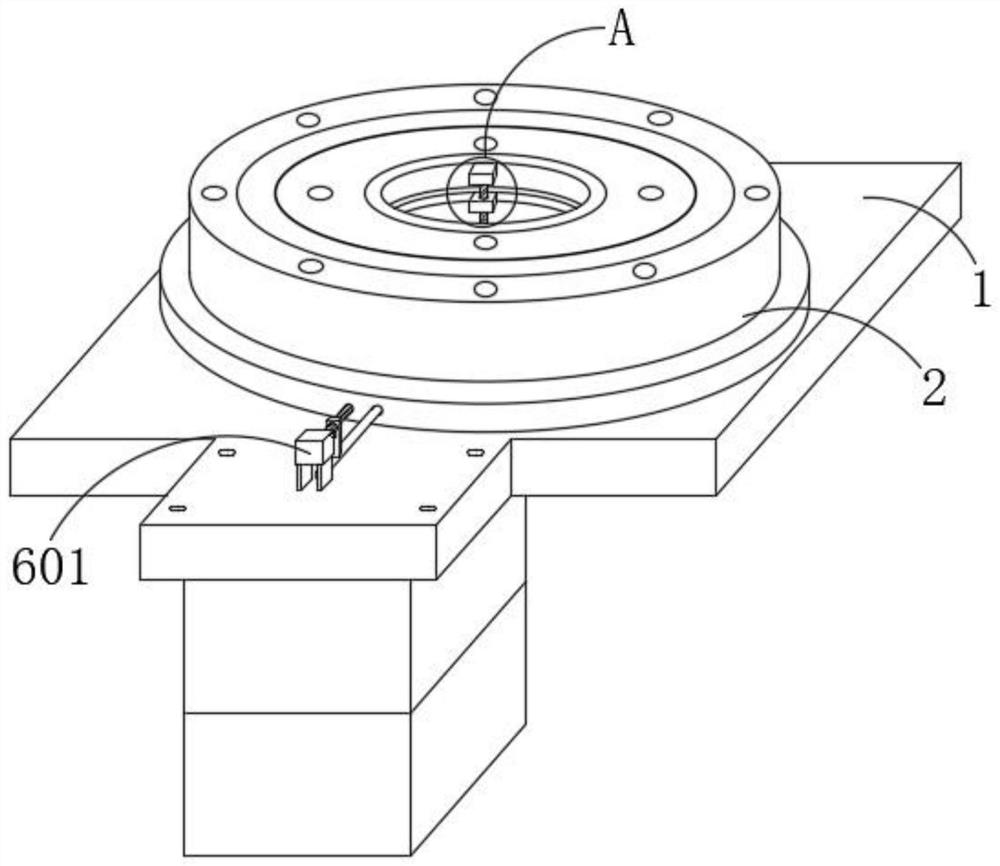

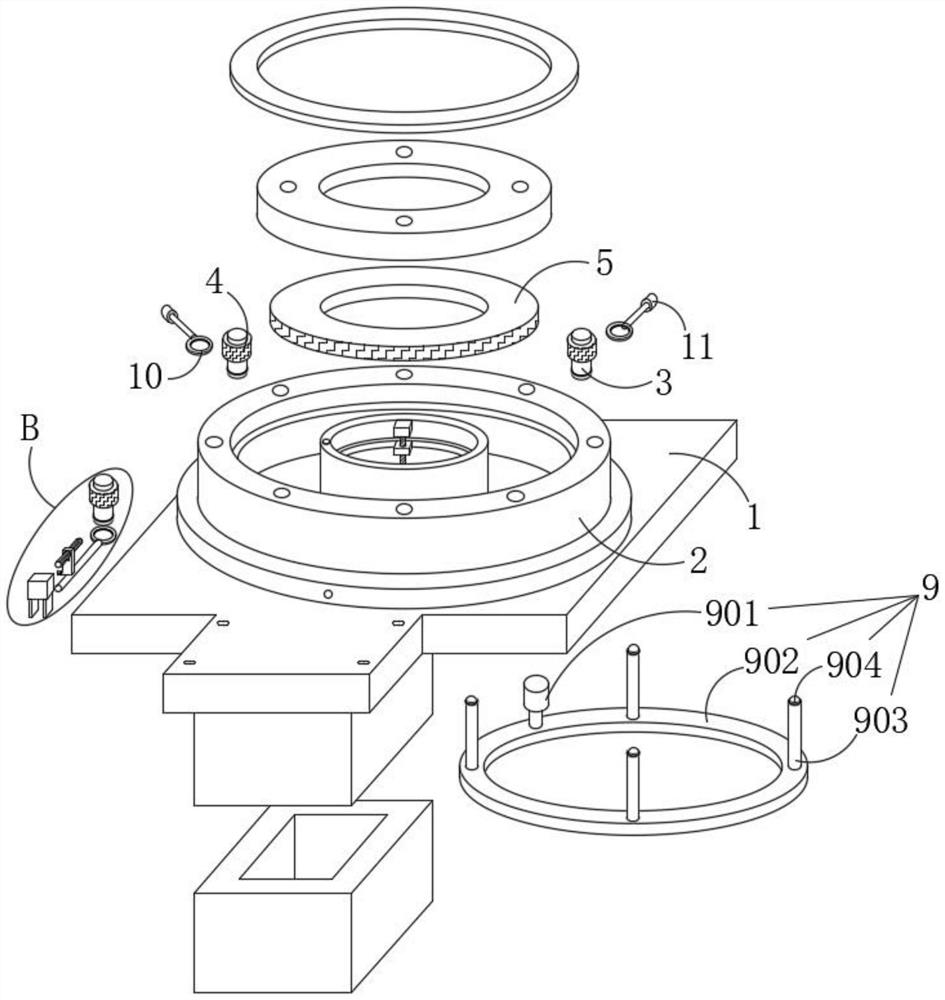

Adjustable hollow rotating platform

InactiveCN114542896AChange distanceEasy meshGear lubrication/coolingToothed gearingsGear wheelClassical mechanics

The invention discloses an adjustable hollow rotating platform which comprises a bottom plate, a mounting seat is mounted at the top of the bottom plate, a group of rotating shafts, a group of gears and a gear ring are mounted in the mounting seat, the gears are mounted in the middles of the rotating shafts, and the outer sides of the gears are meshed with the outer side of the gear ring. The middle of the rotating shaft is sleeved with a lantern ring rotationally connected with the rotating shaft. The distance between the gear ring and the gear is convenient to adjust, the clamping distance between the gear ring and the gear is appropriate, the gear ring mounting base can be suitable for gear rings with different outer diameters and different gear ring numbers, the contact area between the gear ring and the mounting base can be reduced in the using process, noise and abrasion are reduced, and the service life of the gear ring is guaranteed; and meanwhile, continuous oil injection can be automatically carried out, lubrication between the gear ring and the mounting base is conveniently guaranteed, the transmission effect is guaranteed, and a user can conveniently supplement lubricating oil in the later period.

Owner:擎川智能科技(苏州)有限公司

Oil receiving method for reducer of pumping unit in oil field

ActiveCN111457079BQuick diversionAdequate drainageGear lubrication/coolingTiming beltReduction drive

The invention discloses an oil receiving method for a reducer of an oil pumping unit in an oil field. The oil receiving device includes a device box, an oil storage tank is fixedly installed on the inner bottom wall of the device box, and an oil guiding device is arranged inside the oil storage tank. The oil guiding device includes a first fixed box and a second fixed box respectively fixedly installed on the back of the device box; the present invention also proposes a method for receiving oil for the reducer of an oil field pumping unit, comprising the following steps: S1, the second When the first rotating shaft, the second rotating shaft and the third rotating shaft rotate synchronously, the lubricating oil in the reducer will drop into the oil storage tank. The oil receiving device used for the oil pumping unit reducer in the oil field, by setting the first fixed box, the second fixed box, the first drive motor, the second drive motor, the synchronous belt and the triangular guide plate, the pumping unit reducer The oil receiving device can quickly guide the lubricating oil infiltrated by the reducer into the oil storage tank, so that the oil receiving device can fully guide the lubricating oil infiltrated by the reducer, and at the same time improve the working efficiency.

Owner:苏海燕

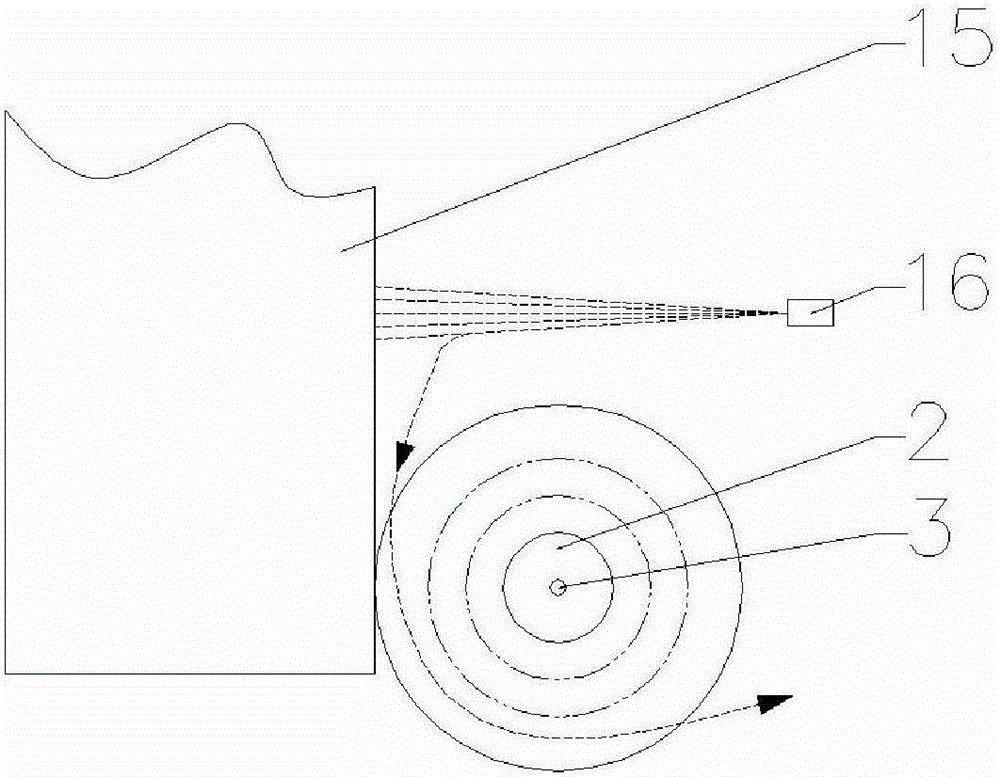

Low-resistance warp yarn lubricating device

The invention relates to a low-resistance warp yarn lubricating device, which includes two vertically extending brackets, and is characterized in that a transversely extending cylindric lubricating body is arranged on the two brackets. The low-resistance warp yarn lubricating device adopts the cylindric lubricating body to be contacted with warp yarn, so as to be used for lubrication; as the lubricating body is contacted with each warp yarn at one point, the friction is greatly reduced, excessive resistance adding to the motion of warp yarns caused by mounting of the lubricating device is avoided to reduce influence on normal weaving; and further, a rotary lubricating roller serves as the lubricating body to replace sliding friction with rolling friction, as a result, more resistance is reduced, and the lateral surface of the entire lubricating body serves as an oil feeding surface or grease feeding surface to enlarge the oil feeding area and the grease feeding area and prolong the usage duration of oil grease one-time stored in the lubricating body.

Owner:WUJIANG KESHIDA TEXTILE

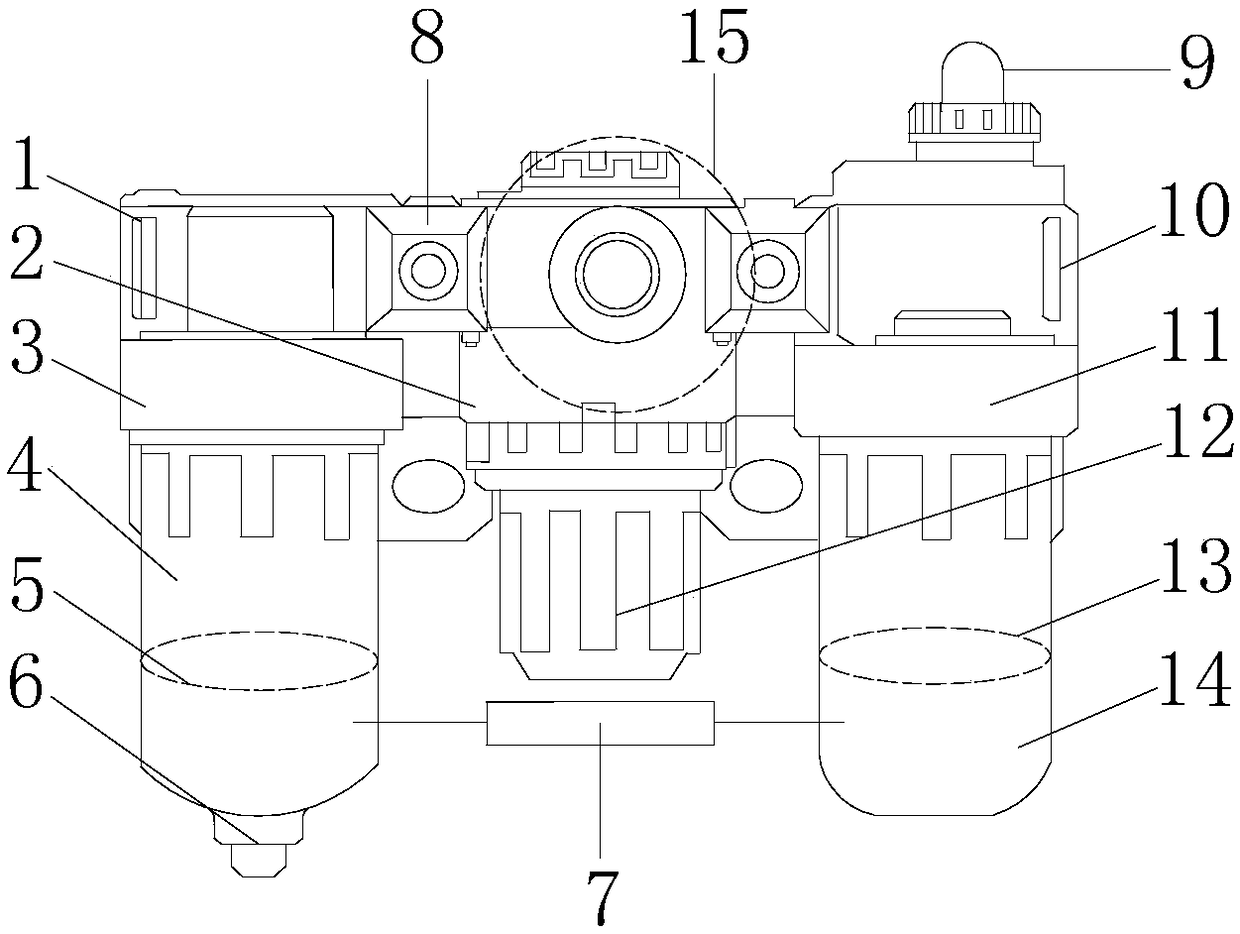

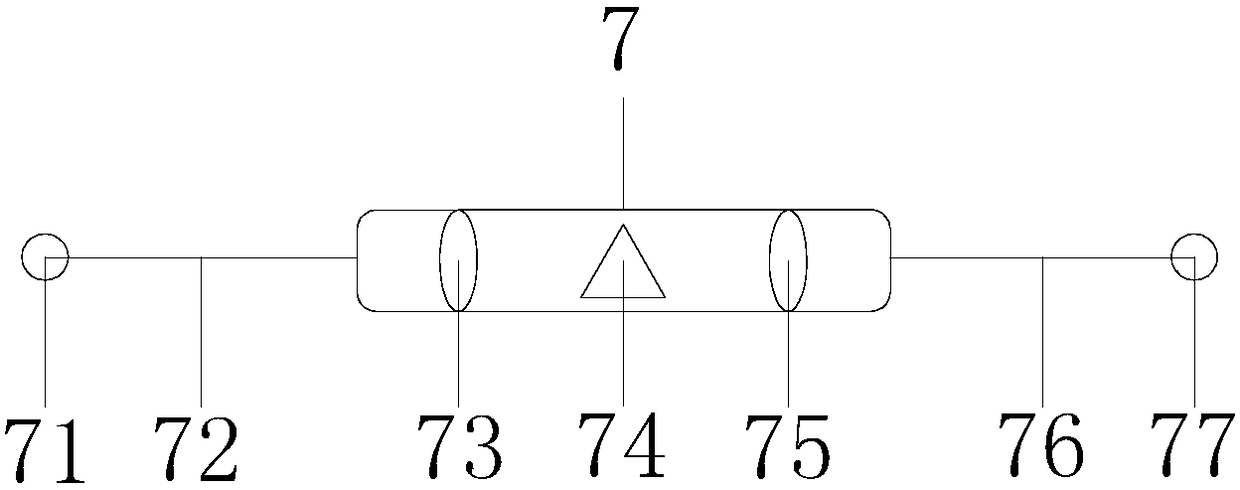

Air source threet capable of automatically detecting water level and oil level

InactiveCN108224054ATo achieve the lubrication effectTimely detectionValve arrangementsEngine levelsSignal processingEquipment state

The invention discloses an air source threet capable of automatically detecting a water level and an oil level. The air source threet comprises a filter valve, an oil mist valve, a pressure regulatingvalve and a water level and oil level detection device; and a water level limiting sensor, a first connecting line, a water level abnormity alarm, a signal processor, an oil level abnormity alarm, asecond connecting line and an oil level limiting sensor are arranged on the water level and oil level detection device. According to the air source threet capable of automatically detecting the waterlevel and the oil level, through mutual action of pneumatic components such as the filter valve, the pressure regulating valve, the oil mist valve, a gas pressure regulator and an oil mist regulator,a gas and water separating effect is achieved, and the effect of lubricating the pneumatic components with a mixture of oil mist and gas are achieved. Through detection action of the water level and oil level detection device, the signal processor can allow the oil level abnormity alarm and the water level abnormity alarm to give alarm information according to signal abnormal states, so that the effect of reminding an equipment user of timely detecting an equipment state is achieved.

Owner:上海多木实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com