Two-stage worm and gear bevel wheel transmission speed reducer

A technology of worm gears and helical gears, which is applied in the field of deceleration and torque-increasing transmission devices to achieve the effects of improved load-carrying capacity, stable transmission, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

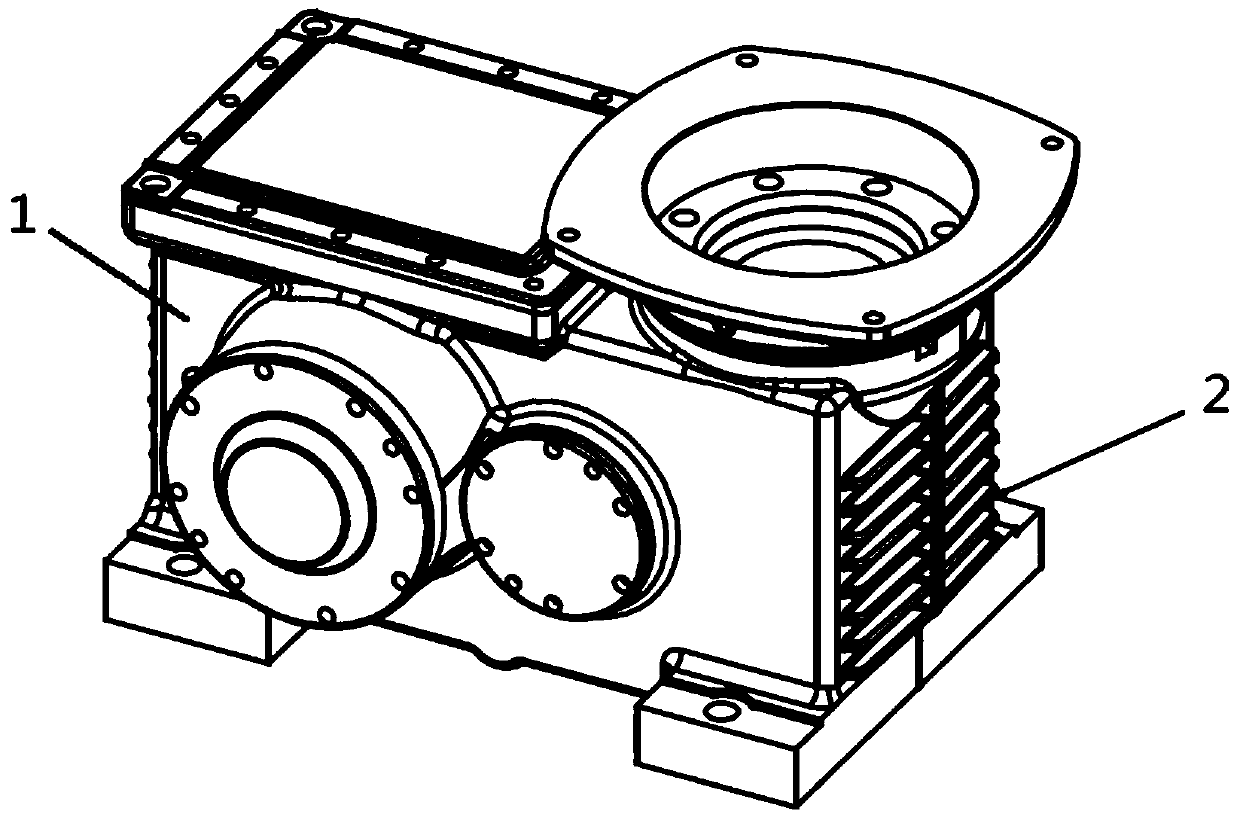

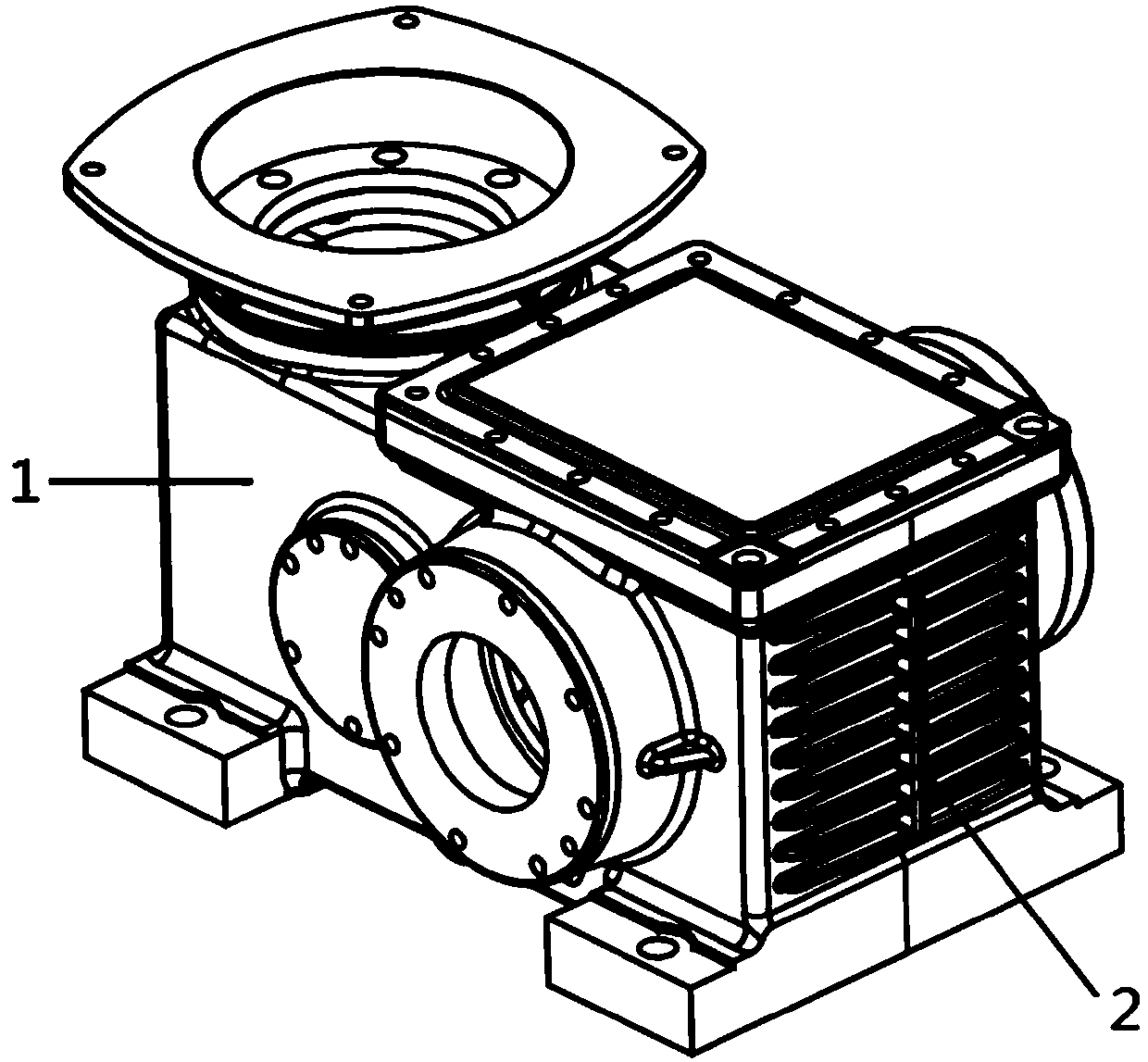

[0034] A two-stage worm gear helical gear transmission reducer, its structure is as follows Figure 1-4 As shown, including the box body 1, heat dissipation ribs 2 are arranged on both sides of the box body 1, and are arranged parallel to each other and evenly arranged on both sides of the box body, as shown in Figure 1-2 As shown, the rib structure can be adopted similarly to this embodiment, the fin structure can also be adopted, or the arc-shaped wave structure can be used, which can have a good heat dissipation effect and has a delicate and beautiful appearance.

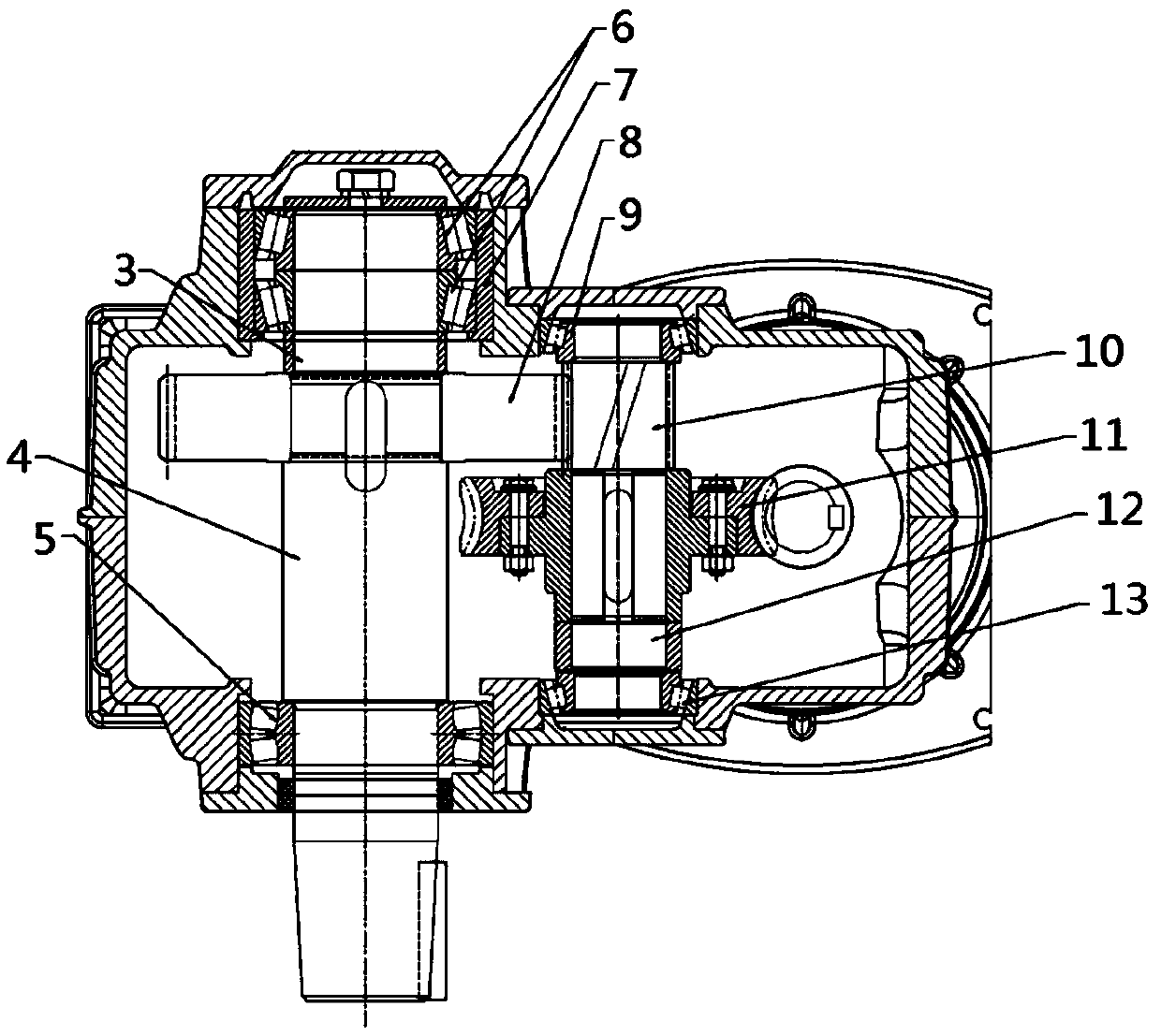

[0035] Main shaft 4, worm wheel 11, and worm screw 16 are arranged in box body 1, and the middle part of worm wheel 11 is provided with worm gear shaft, and large helical gear 8 is set on main shaft 4, and small helical gear 10 is set on worm wheel shaft, two helical gears The gears are meshed with each other. The worm gear transmission is placed in the high-speed stage, and the high-speed stage adopts 4 or 5-h...

Embodiment 2

[0040] A two-stage worm gear helical gear transmission reducer, its structure mainly includes a box body, an output shaft, a worm wheel, a worm, and a helical gear arranged in the box body, a worm wheel shaft is arranged in the middle of the worm wheel, and gears are sleeved on the main shaft and the worm wheel shaft And connected to each other, the worm used adopts ZC tooth shape. The high-speed stage of the two-stage worm gear helical gear transmission reducer adopts worm gear transmission, and the high speed stage adopts 4-head worm, and the transmission ratio is 4:1. The low-speed stage adopts helical gear transmission, a large helical gear is set on the main shaft, and a small helical gear is set on the worm gear shaft, and the two helical gears are installed on parallel shafts and meshed with each other. The low-speed stage in this embodiment adopts a helical gear with straight tooth structure, and the transmission ratio is 3.5:1.

[0041] Bearings are sheathed at posit...

Embodiment 3

[0044] A two-stage worm gear helical gear transmission reducer, its structure mainly includes a box body, an output shaft, a worm wheel, a worm, and a helical gear arranged in the box body, a worm wheel shaft is arranged in the middle of the worm wheel, and gears are sleeved on the main shaft and the worm wheel shaft And connected to each other, the worm used adopts ZC tooth shape. The high-speed stage of the two-stage worm and worm helical gear transmission reducer adopts worm gear and worm transmission, and the high-speed stage adopts 5-head worm, and the transmission ratio is 8:1. The low-speed stage adopts helical gear transmission, a large helical gear is set on the main shaft, and a small helical gear is set on the worm gear shaft, and the two helical gears are installed on parallel shafts and meshed with each other. The low speed stage in this embodiment adopts a helical gear with a curved tooth structure, and the transmission ratio is 5.5:1.

[0045] Bearings are shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com