Low-resistance warp yarn lubricating device

A technology of lubricating device and warp yarn is applied in the field of yarn lubricating device in the textile field. The effect of reducing influence, reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

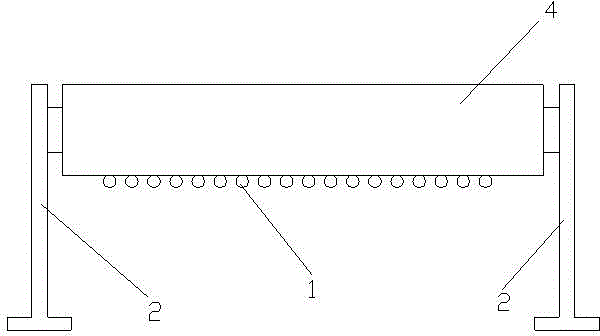

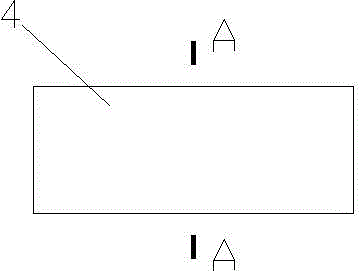

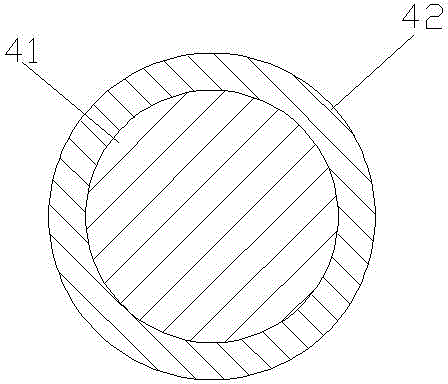

[0020] Example 1: Such as Figure 1-3 As shown, a low-resistance warp lubricating device includes two longitudinally extending brackets 2 on which a cylindrical lubricating body 4 extending laterally is provided. The lubricating body 4 is a rotatable lubricating roller shaft connected to the two supports 2. The lubricating body 4 includes an inner core 41 and a lubricating layer 42 wrapped on the outside of the inner core 41. The lubricating layer 42 is linoleum with a thickness of 5-20 times the diameter of the lubricated warp yarn 1 to ensure that the lubricating oil content in the linoleum is moderate. To ensure the lubrication effect of the warp yarn 1, and avoid the pollution and resistance increase caused by the excessive oil, and prevent the linoleum from being damaged due to the thinning of the linoleum and the warp yarn 1 and the friction for a short time, which can ensure the service life of the linoleum. The way that the linoleum absorbs the lubricating oil can be s...

Embodiment 2

[0021] Embodiment 2: The difference from Embodiment 1 is that the lubricating layer 42 is a solid paraffin layer, which avoids the problem of controlling the amount of oil when using liquid lubricating oil. Compared with liquid lubricating oil, it is easier to keep the warp yarn 1 clean. The outer side of the inner core 41 is provided with a groove 6, and the solid paraffin layer 42 is arranged in the groove 6, which is convenient for replacement. For example, when the warp yarn 1 causes more and deeper scratches and affects normal lubrication, replace it. Replace it later. The thickness of the lubricating layer 42 is 5-10 times the diameter of the warp yarn 1, achieving a balance between the lubricating effect and the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com