Method for preparing thread anti-seizure coating by adopting unbalanced magnetron sputtering technology

A magnetron sputtering and unbalanced technology, which is applied in the direction of coating, sputtering plating, metal material coating technology, etc., to achieve the effect of improving anti-sulfurization, good wear resistance and anti-seizure, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method of the present embodiment comprises the following steps:

[0026] Step 1. Bolt polishing and cleaning: Use a vibration polishing machine to vibrate and polish the bolts for 25 minutes, then use industrial degreaser, deionized water, absolute ethanol and deionized water for ultrasonic cleaning, each time The time of cleaning is all 12min; Add diamond polishing fluid and diameter to be the white corundum ball of 3mm in described vibration polishing machine, white corundum ball is as abrasive material, and the mass ratio of described white corundum ball and aluminum oxide polishing liquid is 10:1; the material of the bolt is 304 stainless steel;

[0027] Step 2, thread sandblasting: sandblasting the bolts after ultrasonic cleaning in step 1; the sandblasting gun head used in the sandblasting treatment is a siphon nozzle, and the process conditions for using a siphon nozzle for sandblasting are: The sand is made of quartz sand with a diameter of 300 mesh, the pr...

Embodiment 2

[0038] The method of the present embodiment comprises the following steps:

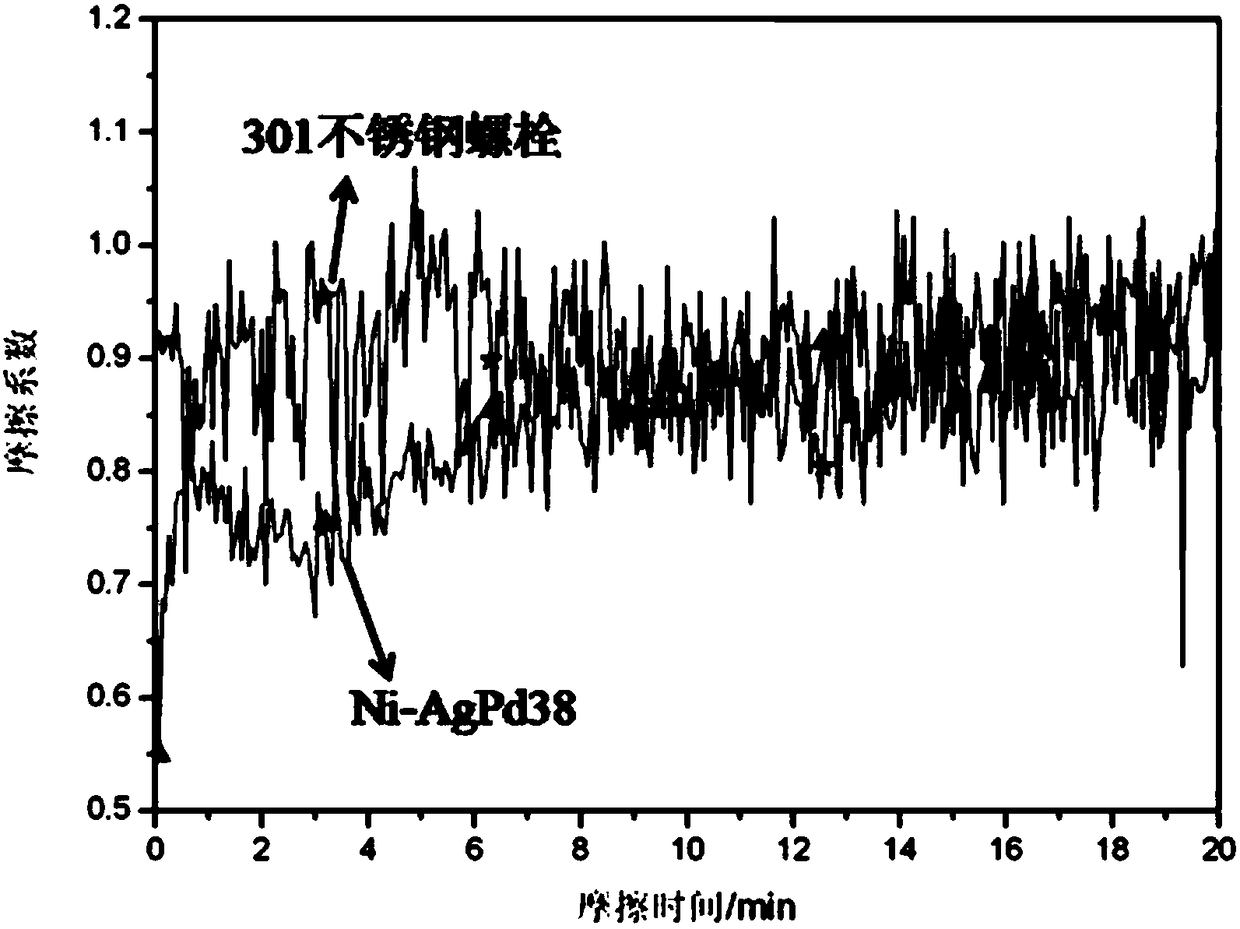

[0039] Step 1. Bolt polishing and cleaning: use a vibration polishing machine to vibrate and polish the bolts for 15 minutes, then use industrial degreaser, deionized water, absolute ethanol and deionized water for ultrasonic cleaning, each time The cleaning time is 8 minutes; when vibrating polishing, add diamond polishing liquid and white corundum balls with a diameter of 0.5mm in the vibrating polishing machine, and the white corundum balls are used as abrasives. The mass ratio of the white corundum balls to the alumina polishing liquid is is 10:1; the material of the bolt is 301 stainless steel;

[0040] Step 2, thread sandblasting: sandblasting the bolts after ultrasonic cleaning in step 1; the sandblasting gun head used in the sandblasting treatment is a siphon nozzle, and the process conditions for using a siphon nozzle for sandblasting are: The sand is made of quartz sand with a diameter of 4...

Embodiment 3

[0045] The method of the present embodiment comprises the following steps:

[0046] Step 1. Bolt polishing and cleaning: Use a vibration polishing machine to vibrate and polish the bolts for 30 minutes, then use industrial degreasing agent, deionized water, absolute ethanol and deionized water for ultrasonic cleaning, each time The time of cleaning is all 15min; Add diamond polishing liquid and the white corundum ball that diameter is 5mm in described vibration polishing machine during vibration polishing, white corundum ball is as abrasive material, and the mass ratio of described white corundum ball and aluminum oxide polishing liquid is 10:1; the material of the bolt is 316 stainless steel;

[0047] Step 2, thread sandblasting: sandblasting the bolts after ultrasonic cleaning in step 1; the sandblasting gun head used in the sandblasting treatment is a siphon nozzle, and the process conditions for using a siphon nozzle for sandblasting are: The sand is made of quartz sand w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com