Selenium-ion inlaying method for oil-phase graphene

A graphene, oil phase technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as overall cost increase, cost increase, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

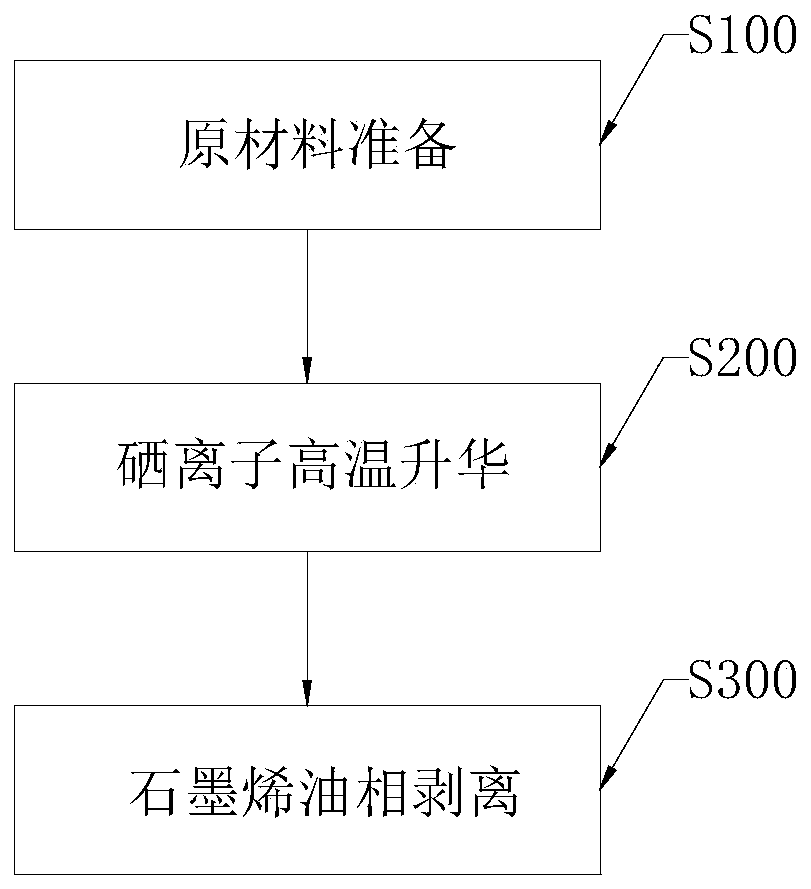

[0057] A kind of selenium ion embedding method of oil phase graphene of the present invention, comprises the steps:

[0058] 1. Put 100g of natural flake graphite powder and 10g of selenium material into two different molybdenum boat vessels respectively, and put them into a vacuum reactor to evacuate to a pressure of negative two atmospheres to negative five atmospheres;

[0059] 2. Using a high-frequency heating method to heat the temperature in the vacuum reactor to 900 degrees Celsius-1100 degrees Celsius, so that the selenium ions in the selenium material are sublimated to the natural flake graphite powder to form selenium ion graphite powder;

[0060] 3. After the selenium ion graphite powder is cooled, add the selenium ion graphite powder into the base oil to peel off the oil-phase graphene to obtain the oil-phase graphene embedded with selenium ions.

[0061] Applying the product in this embodiment to the actual automobile lubrication process, in the emission detection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com