Nano lubricating additive for regulating and controlling interface friction as well as preparation method and application of nano lubricating additive

A lubricating additive and interfacial friction technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of high control efficiency, time-consuming, complex changing conditions, etc., and achieve the goal of increasing reaction rate, stability, and viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

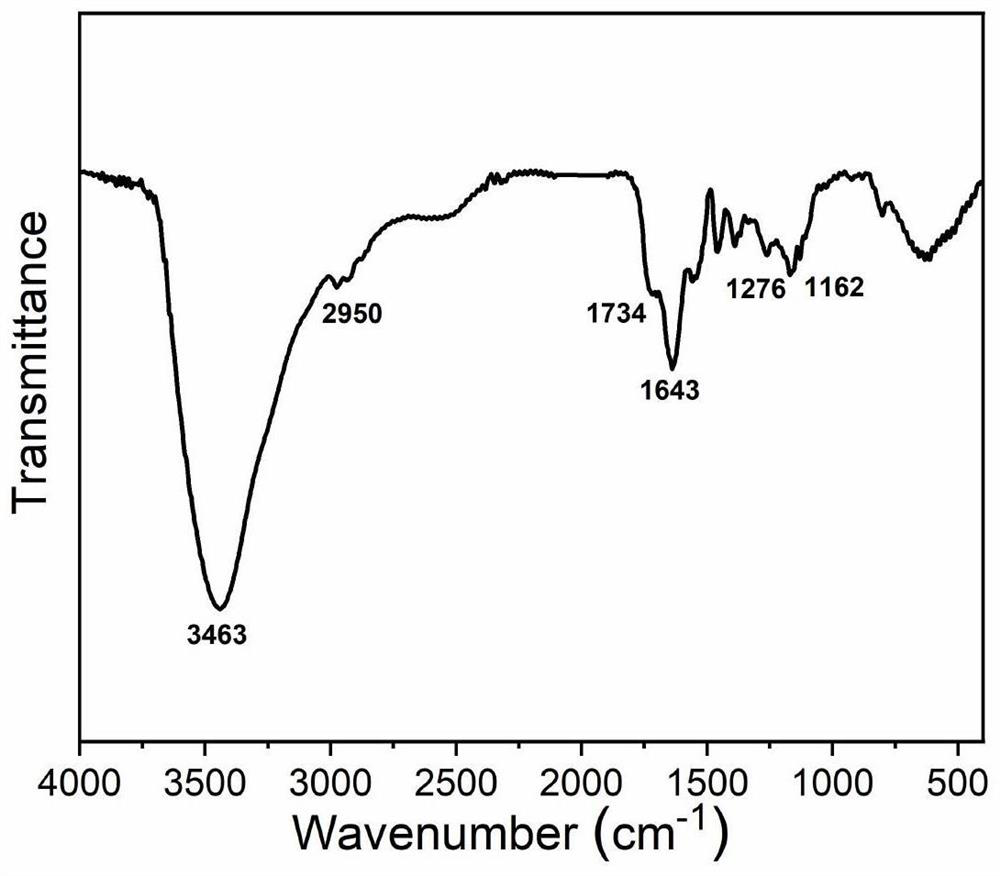

Image

Examples

Embodiment 1

[0032] A nano-lubricating additive for regulating interfacial friction, comprising a core-shell structure nanosphere formed by using gold nanoparticles as the inner core and a temperature-sensitive polymer cross-linked network as the outer shell, and the nanosphere is a composite microgel nanosphere.

[0033] The above-mentioned manufacturing method of the nano-lubricating additive for regulating and controlling interfacial friction comprises the following steps:

[0034] S1. After heating 50mL tetrachloroauric acid solution (0.01wt.%) to boiling, slowly drop into 0.3mL trisodium citrate solution (1.0wt.%), the solution turns from light yellow to dark blue, and then becomes dark blue. Red, at this time the gold nanoparticles are reduced. After 15min, the reaction was completely finished, and 50mL of a solution containing gold nanoparticles was obtained, and its mass fraction was calculated to be 1.0wt.%.

[0035] S2. Synthesize composite microgel spheres (referred to as PTMGs) ...

Embodiment 2

[0038] The preparation method is the same as in Example 1, the difference is that: add the same volume of deionized water to the nano-lubricating additive, fully ultrasonically disperse, dilute the mass fraction of the microgel suspension to 0.5wt.%, and obtain a mass fraction of 1.0wt%. Nano lubricant additive.

Embodiment 3

[0040] The preparation method is the same as in Example 1, the difference is that: take out part of the synthesized microgel dispersion, evaporate half of the deionized water, concentrate the mass fraction of the microgel suspension to 2.0wt.%, and obtain a mass fraction of 2.0 wt% nano-lubricating additives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com