Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "The processing process is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

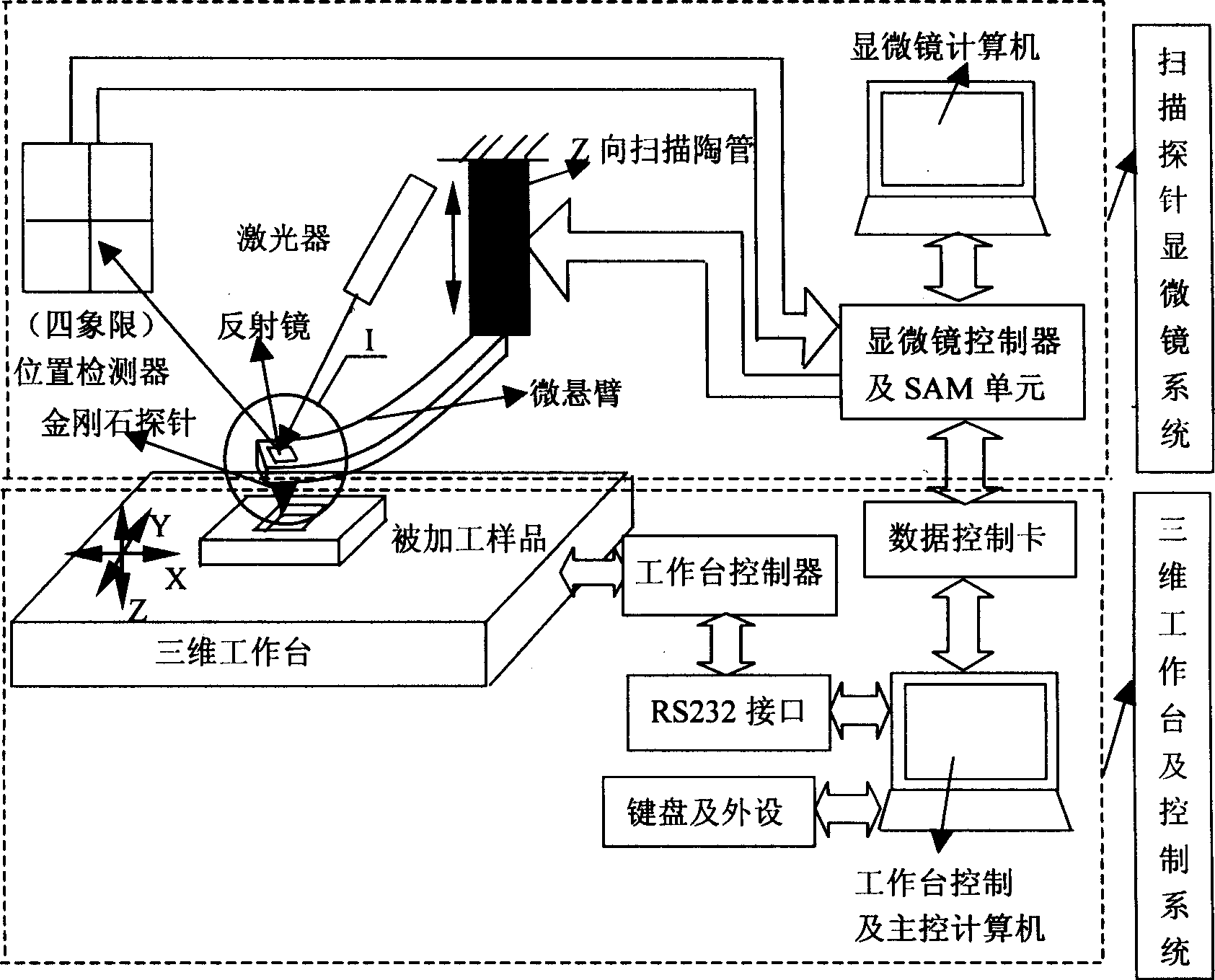

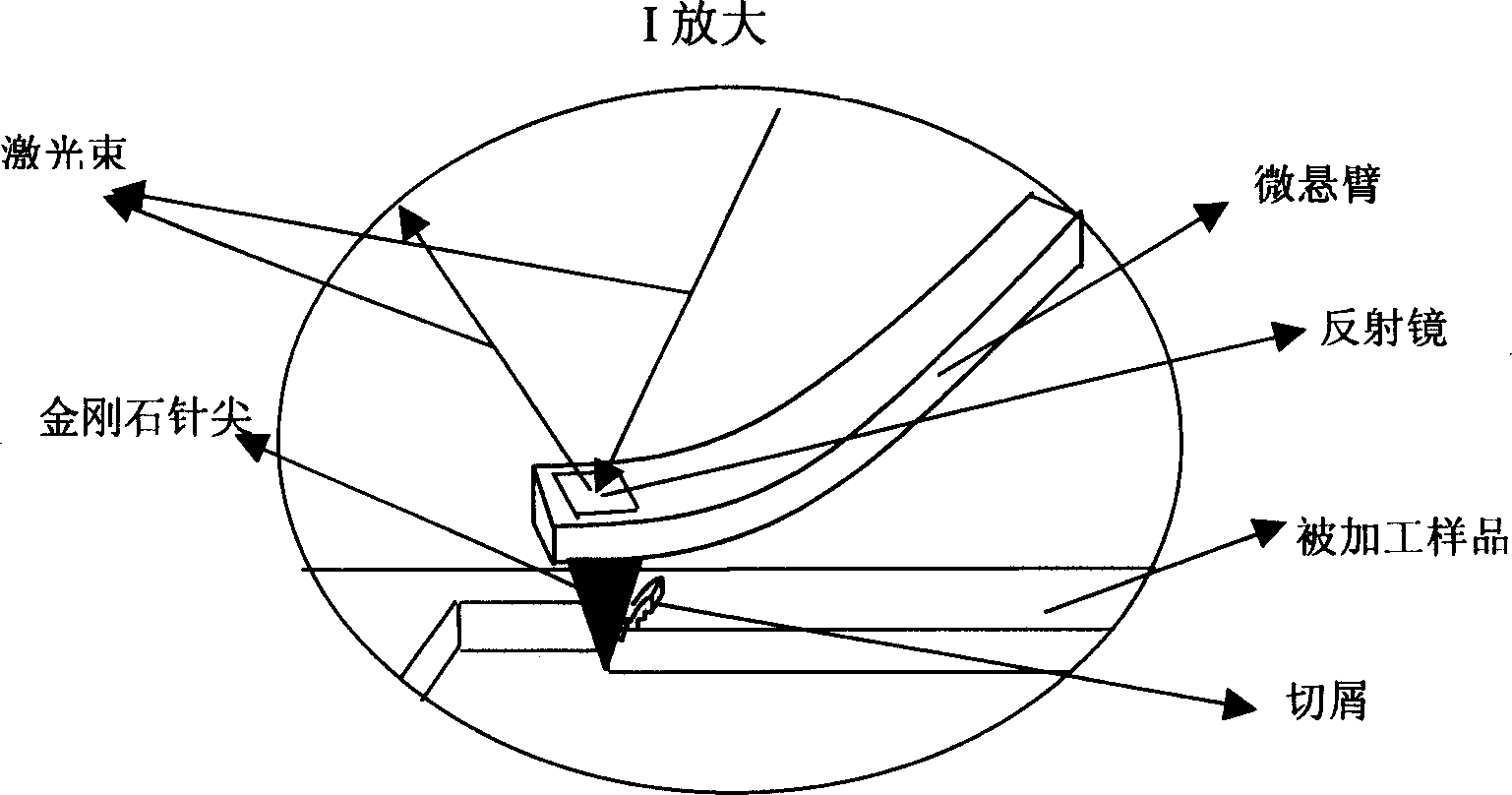

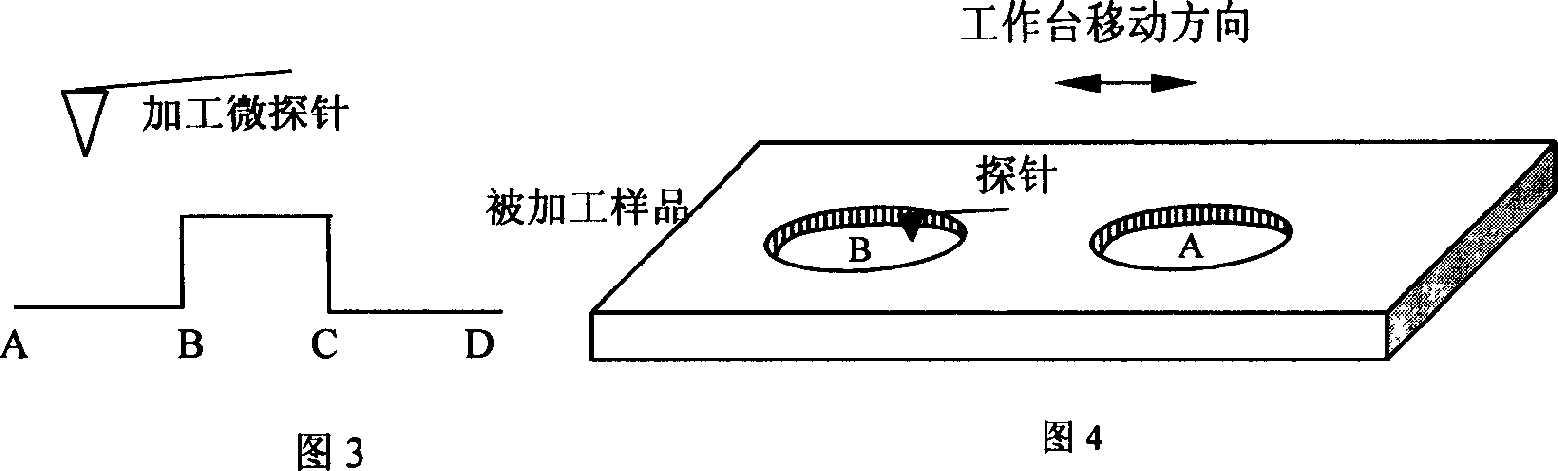

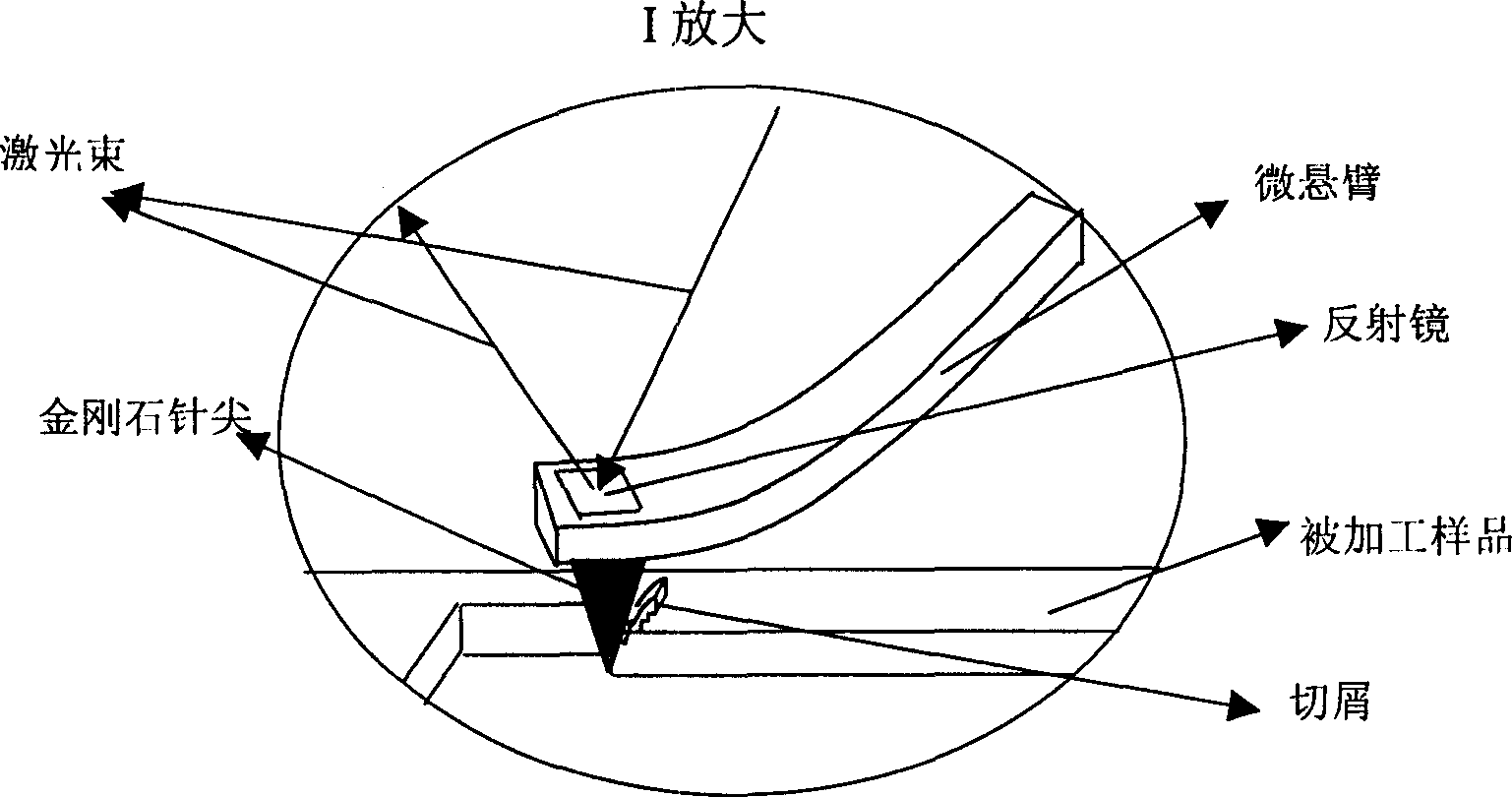

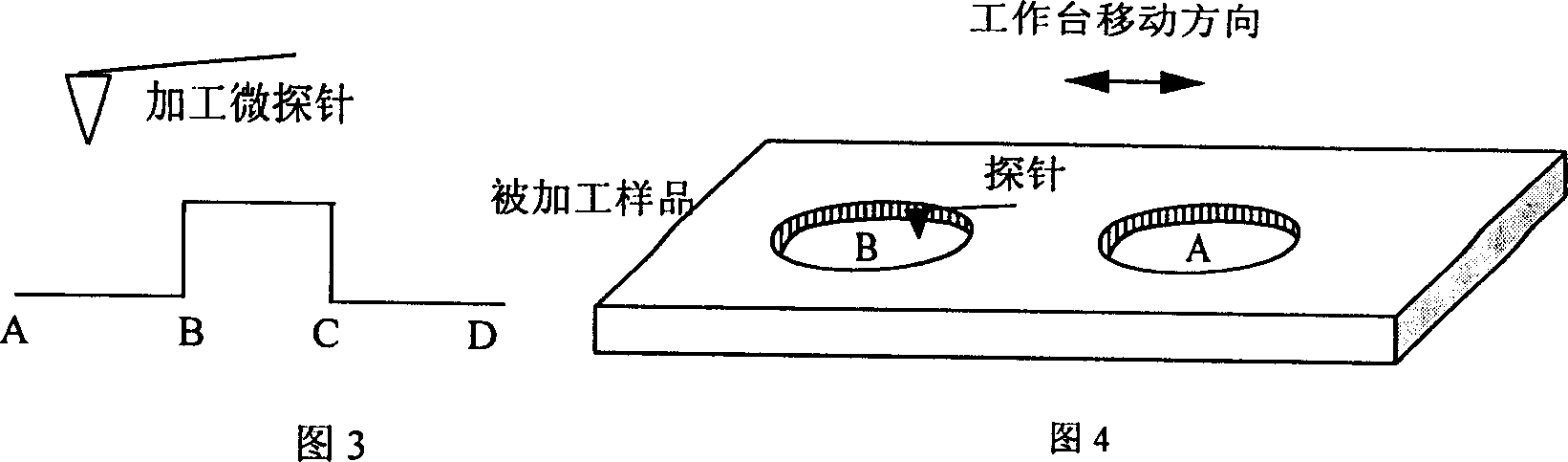

3-D machining method of micromechanical parts

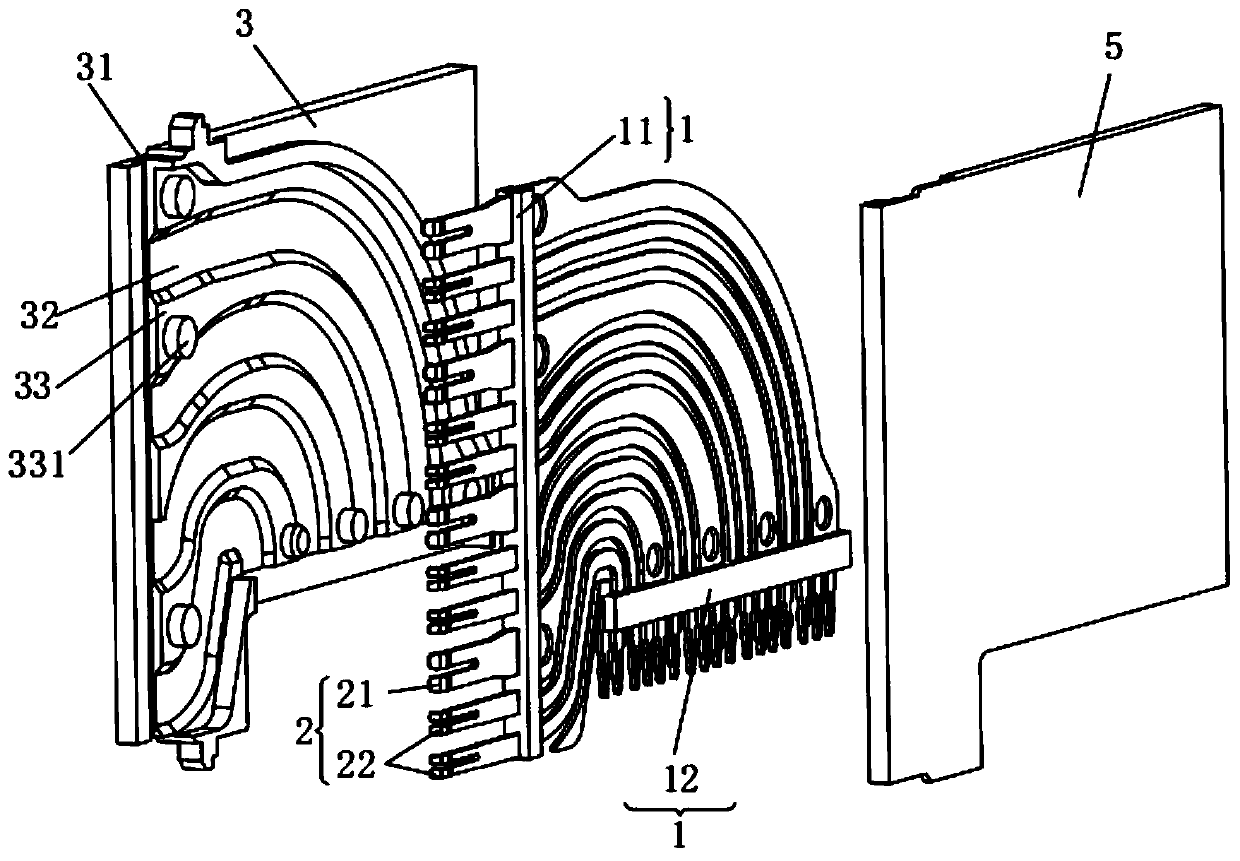

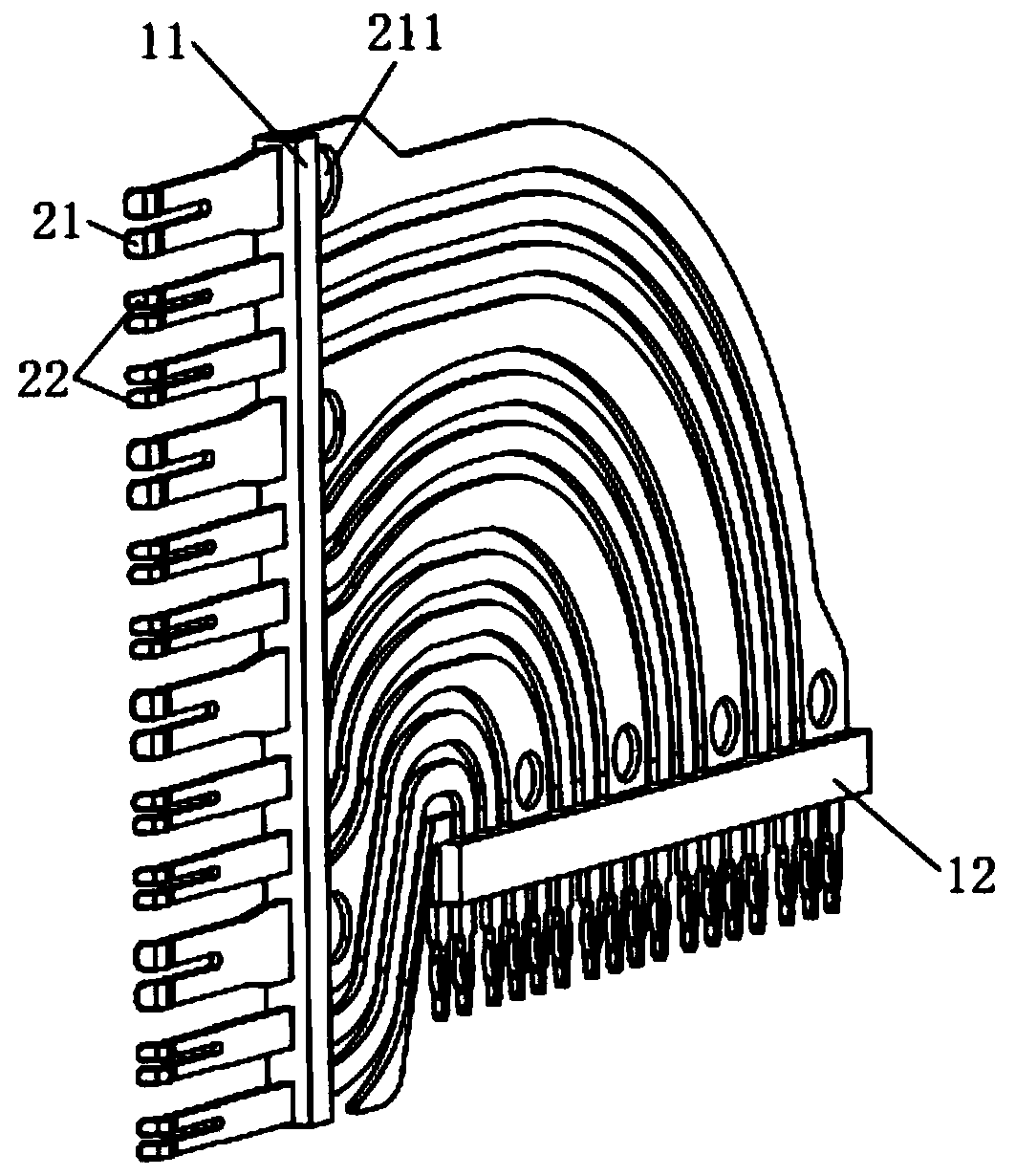

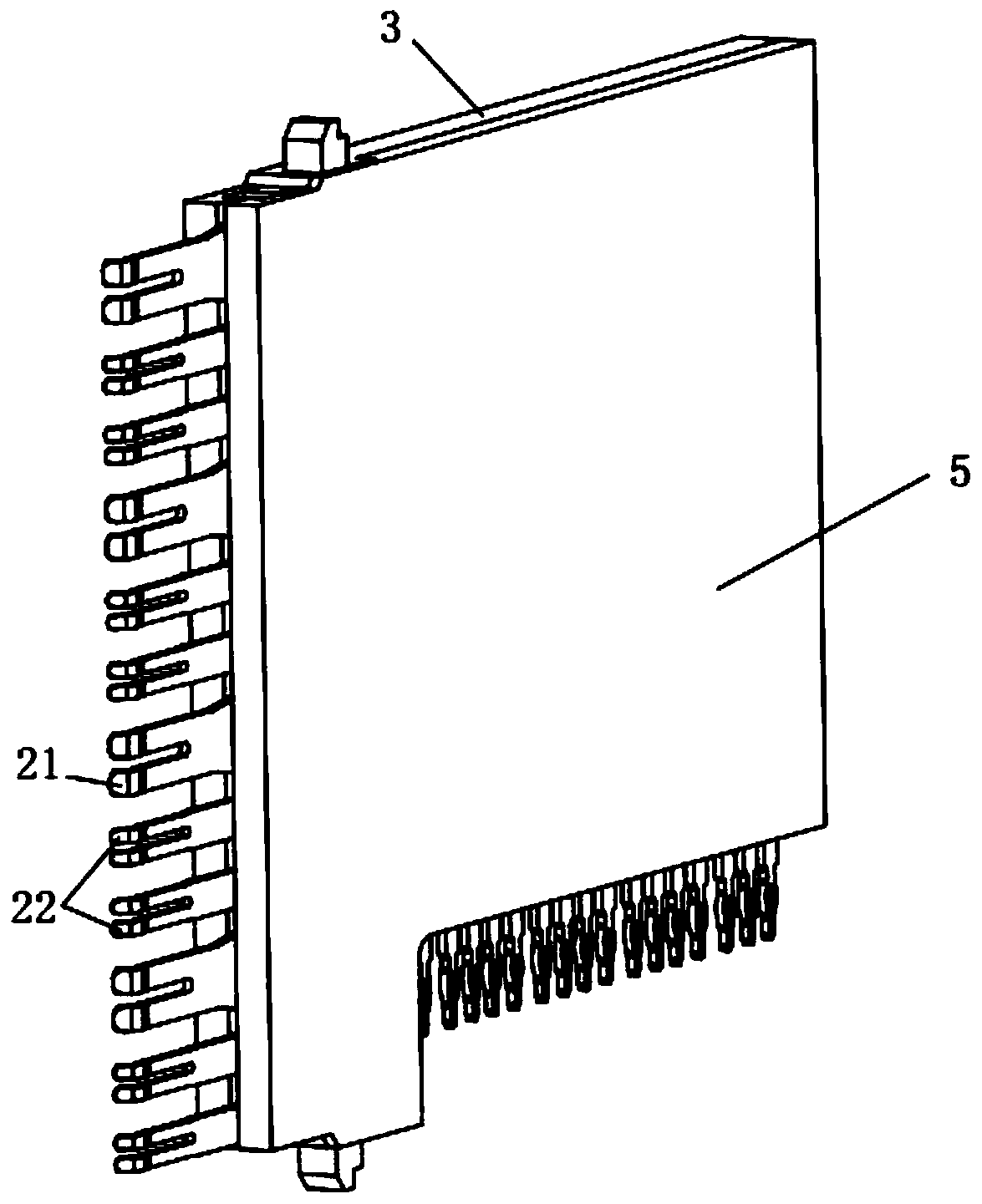

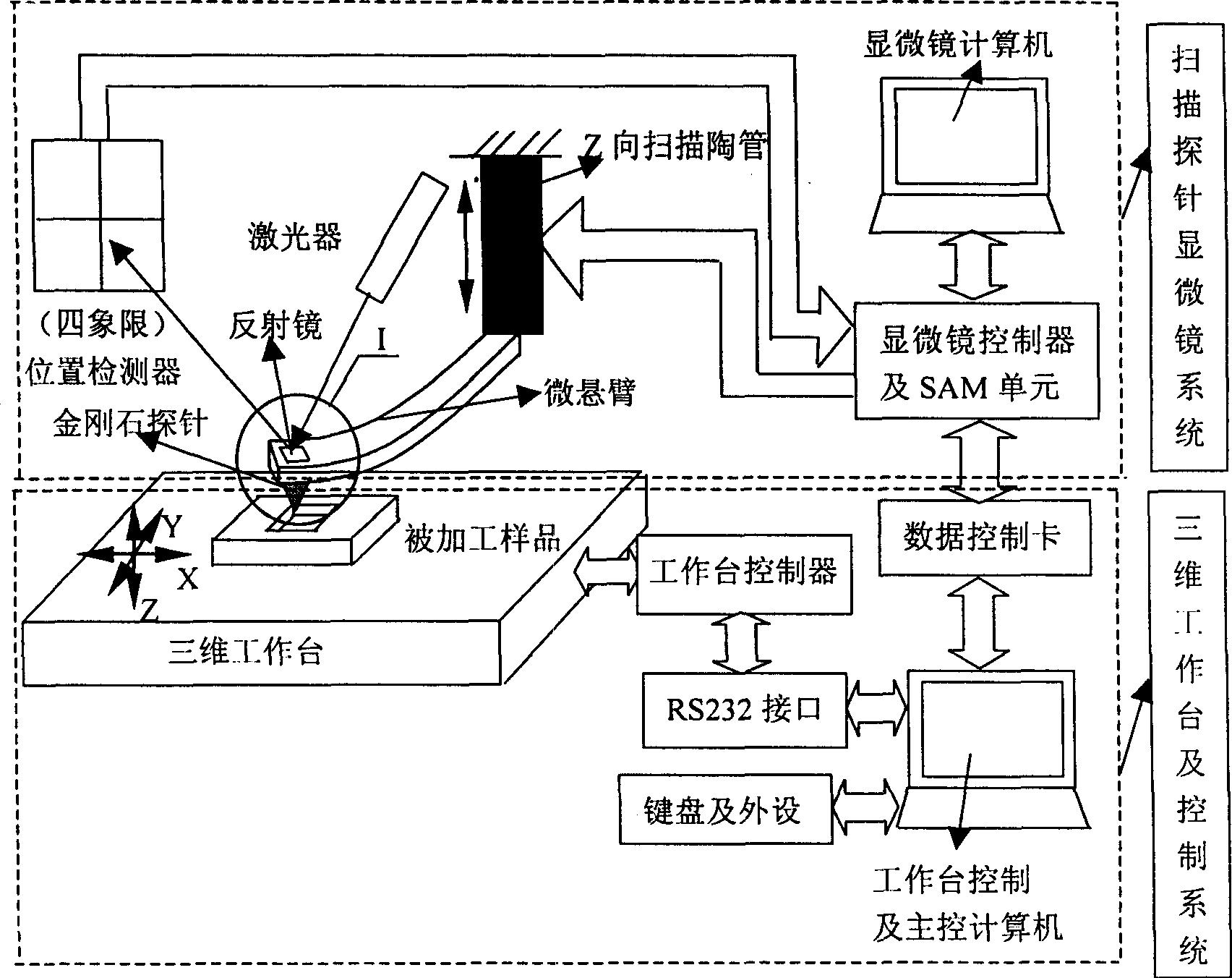

InactiveCN1564094AWide range of choicesAvoid damageComputer controlSimulator controlMachine partsEngineering

The disclosed two methods are realized through combined micro machine parts 3D processing unit: setting up working parameters of sweeping probe microscope; placing workpiece on 3D table, fabricating first graph through XYLEM movement of controlled table, after finishing the first graph, raising probe up; fabricating second graph till completion. Another method includes steps: 3D table is moved in X, Y, Z directions according to presetting values to fabricate all graphs; contracting movement of scanning ceramics tube raises probe up. Comparing prior art, the disclosed method carries our real manufacturing. The method damages surface very little, only nano magnitude of material is removed, applicable to fabricating MEMS parts, masks and microminiature mould.

Owner:HARBIN INST OF TECH

Production method of Pu'er ripe tea

InactiveCN101485369AImprove qualityThe processing process is easy to controlPre-extraction tea treatmentMother cultureCarton

The invention relates to a method for producing cooked pu-erh tea, which belongs to the technical field of pu-erh tea processing. The method is an improvement based on the prior method for processing the pu-erh tea. The improvement comprises the following steps: placing sundried green tea in a carton or a hemp bag, and placing the carton or the hemp bag on a warehouse platform 20 centimeters over the ground with moisture content within 13 percent; using a fermenting case for after-fermentation to realize complete off-ground clean production; evenly inoculating pu-erh tea fermented mother culture produced by a method of CN 2008102333700.X onto the sundried green tea in a spraying mode for pile fermentation; aspersing water on the sundried green tea with aspersion amount of between 30 and 35 percent for foods to make moisture content of the tea to be between 40 and 45 percent; carrying out the pile fermentation in the fermenting case for 35 to 40 days below 60 DEG C; and spreading a tea sample with a thickness of between 10 and 12 centimeters for natural drying after pile fermentation of the pu-erh tea, or drying the tea sample by mechanical equipment at a temperature below 60 DEG C. The method has the advantages of easy control of processing process, clean production environment, non pollution of the product, short time of pile fermentation and stable product quality, and can be widely used for large-scale production of the cooked pu-erh tea.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

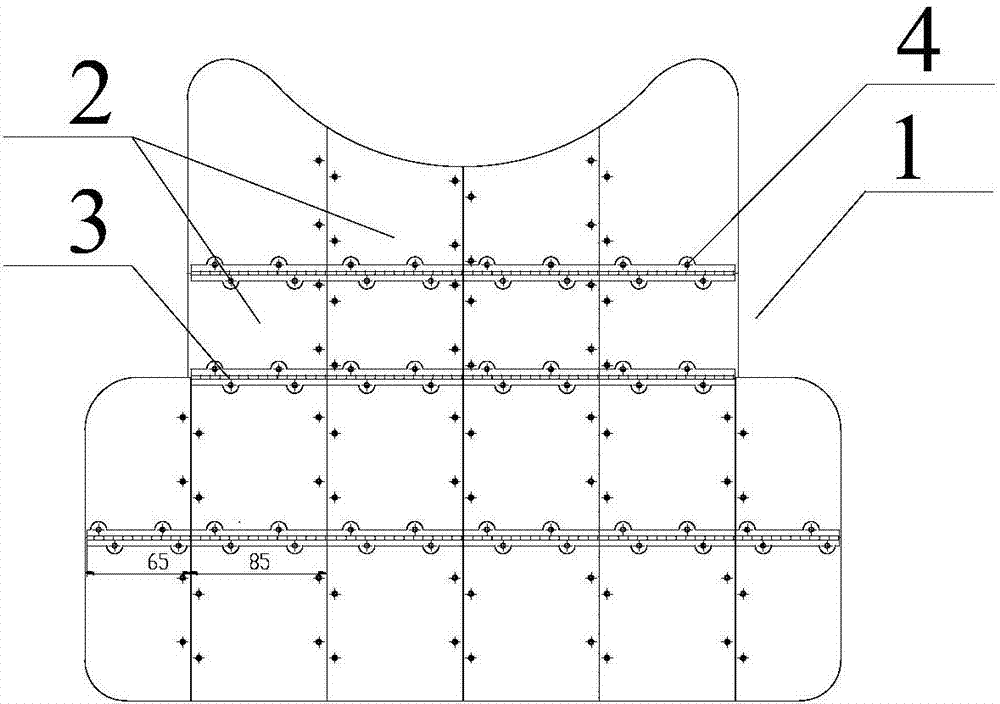

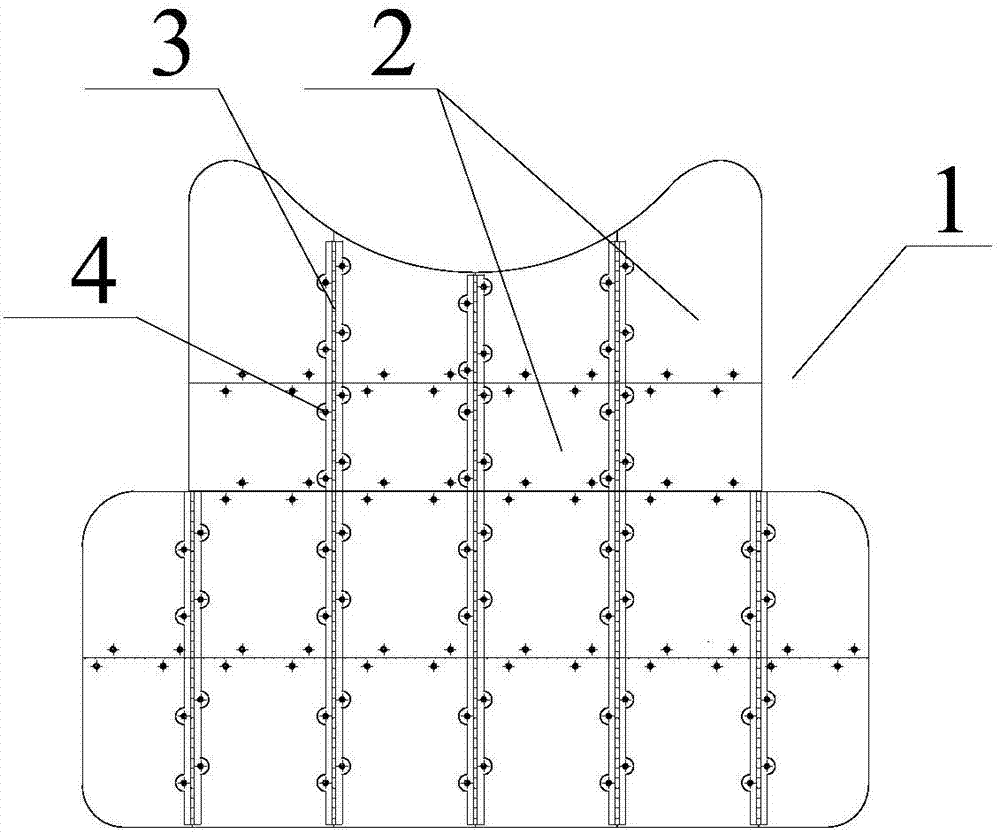

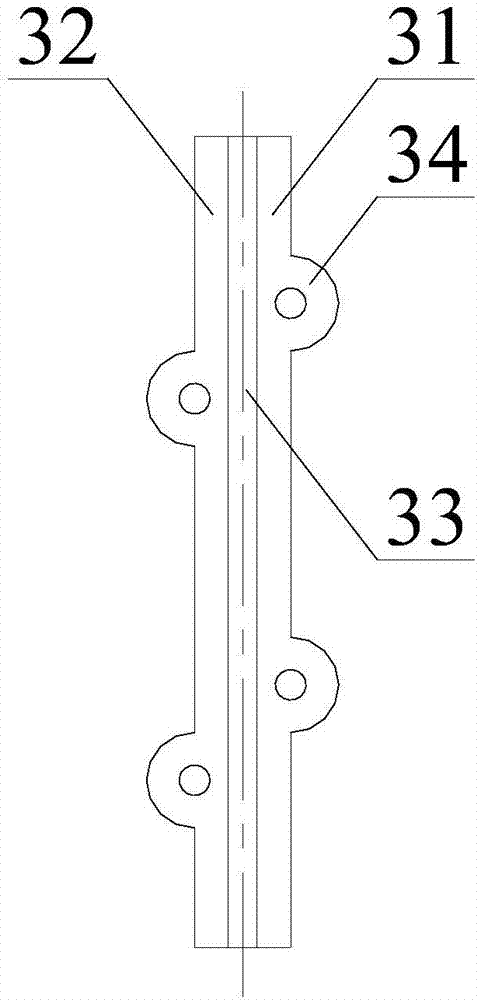

Stab-resistant body armor based on carbon fiber plate splicing block

InactiveCN106858769AAnti-stab effect is goodReduce weightProtective garmentSpecial outerwear garmentsEngineeringBody armor

The invention discloses a stab-resistant body armor based on carbon fiber plate splicing blocks. The stab-resistant body armor at least comprises two stab-resistant layers. The stab-resistant layer respectively comprises a plurality of stab-resistant sheets which are made of carbon fiber plates and are formed through CNC processing. Adjacent stab-resistant sheets are fixedly connected through hinges and set screws. Compared with an existing stab-resistant body armor, the stab-resistant body armor is advantaged by good stab-resistant effect and light weight. Raw materials are easy to obtain, a processing process is simple and controllable, and the stab-resistant body armor has good comfort and flexibility, and good damp and hot transmitting performance. The stab-resistant body armor would not bring about physiological fatigue, and market prospect is wide.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Production process of precise seamless steel tube for hydraulic cylinder

InactiveCN104307876AIdeal production processNo crackMetal rolling arrangementsHydraulic cylinderPunching

The invention discloses a production process of a precise seamless steel tube for a hydraulic cylinder. The production process comprises the following steps of selecting a tube blank, cutting off the tube blank, peeling, performing blank surface treatment, heating the tube blank, discharging a seamless steel tube blank, cooling, performing micro-oxygenation thermal treatment, lubricating the surface of the steel tube by use of a lubricating agent, punching, chambering, pickling, inspecting, polishing, performing steel tube cold rolling, deoiling, performing secondary thermal treatment, straightening, cutting the tube, pickling a finished product, inspecting the product, packaging and storing. The production process of the precise seamless steel tube for the hydraulic cylinder has the beneficial effects that the effect is ideal, the steel tube does not generate cracks, the obdurability and the corrosion resistance are favorable and the processing process is easy to control.

Owner:ZHANGJIAGANG RENHE HIGH PRECISION TUBE

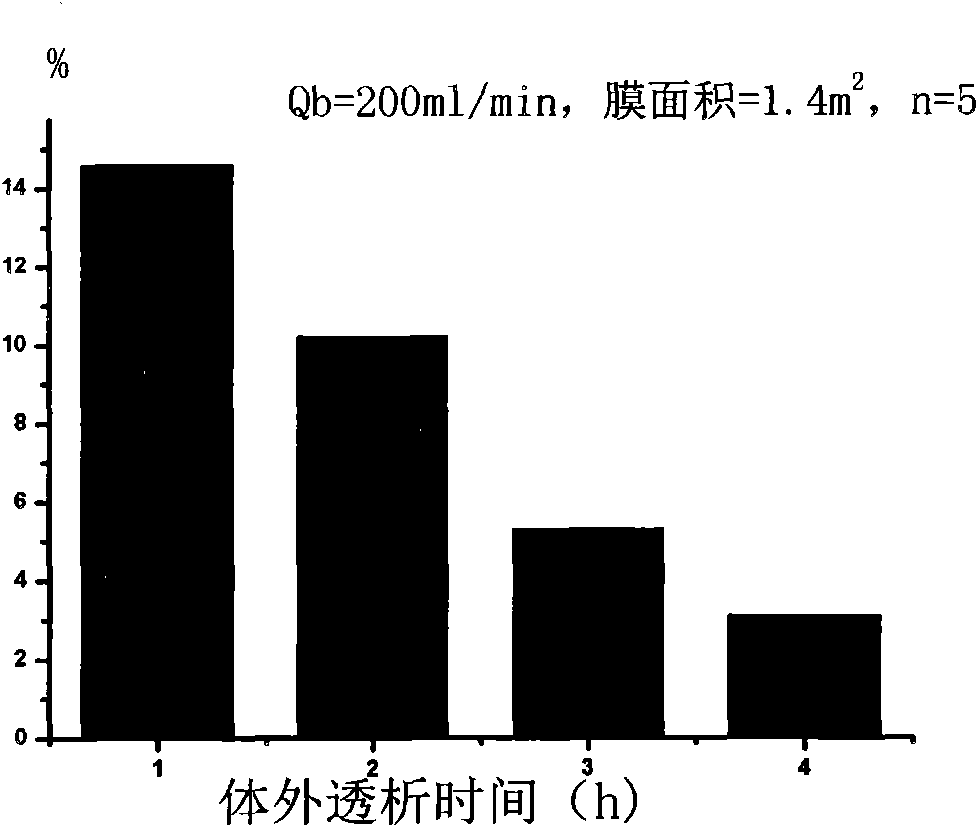

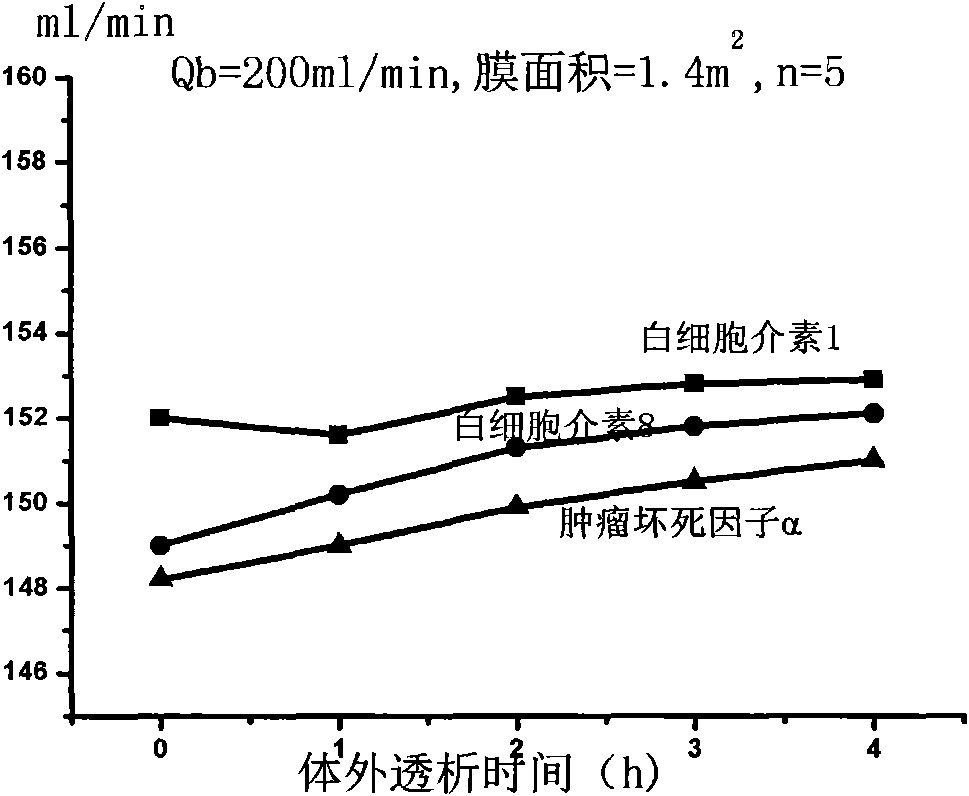

Co-mixing film of ethylene-acetic acid ethylene copolymer and polysulfone and method for preparing same

InactiveCN101844043AImprove clearanceReduce adsorptionSemi-permeable membranesDialysis systemsAcetic acidAbsorption capacity

The invention relates to a co-mixing film of ethylene-acetic acid ethylene copolymer and polysulfone. The co-mixing film comprises: 5 to 10 weight percent of polysulfone, 5 to 10 weight percent of ethylene-acetic acid ethylene copolymer, 5 to 10 weight percent of hole-forming agent and 70 to 75 weight percent of organic solvent. The preparation method comprises the following steps of: 1, mixing the raw materials in part by weight to prepare uniform spinning raw liquid, standing the raw liquid; 2, filtering the spinning raw liquid by a filter core with a hole diameter of 3 to 5 micrometers, and performing vacuumizing and debubbling to obtain film-forming liquid; and 3, coating the film-forming liquid on a support layer by a film scraper to obtain the co-mixing film after the solidification of the film-forming liquid. The co-mixing film prepared by the invention has the advantages of high removing rate, low blood protein and blood platelet absorption capacity, no or fewer heparins, simple preparation process, controlled preparation process, low cost, high application values and wide application fields.

Owner:DONGHUA UNIV

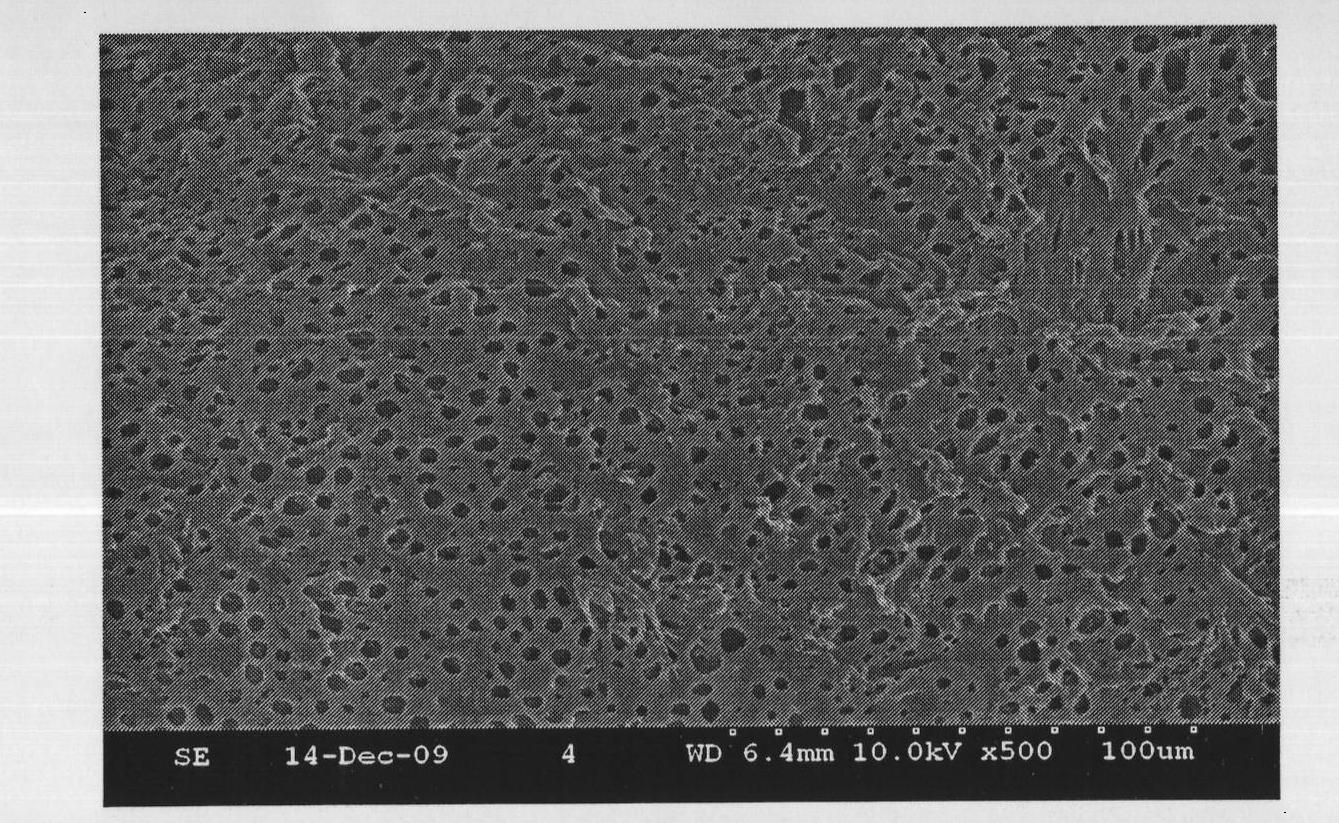

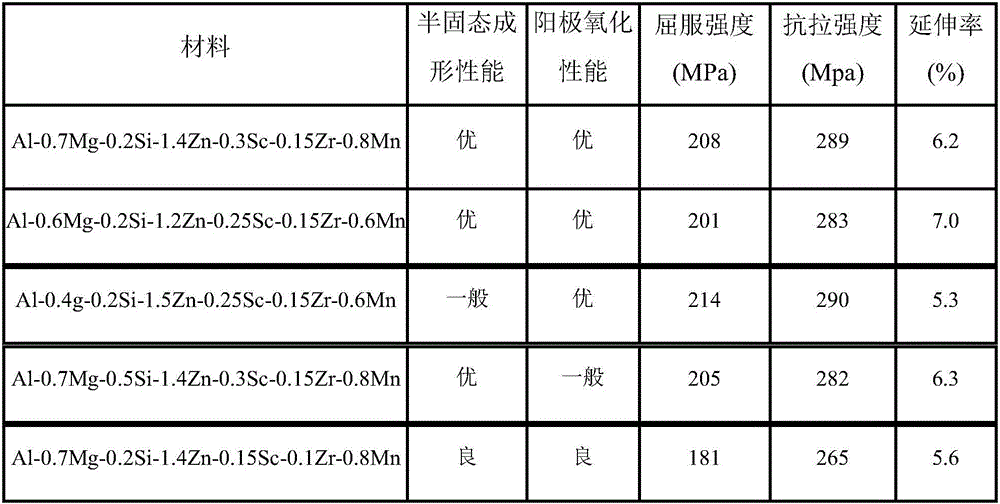

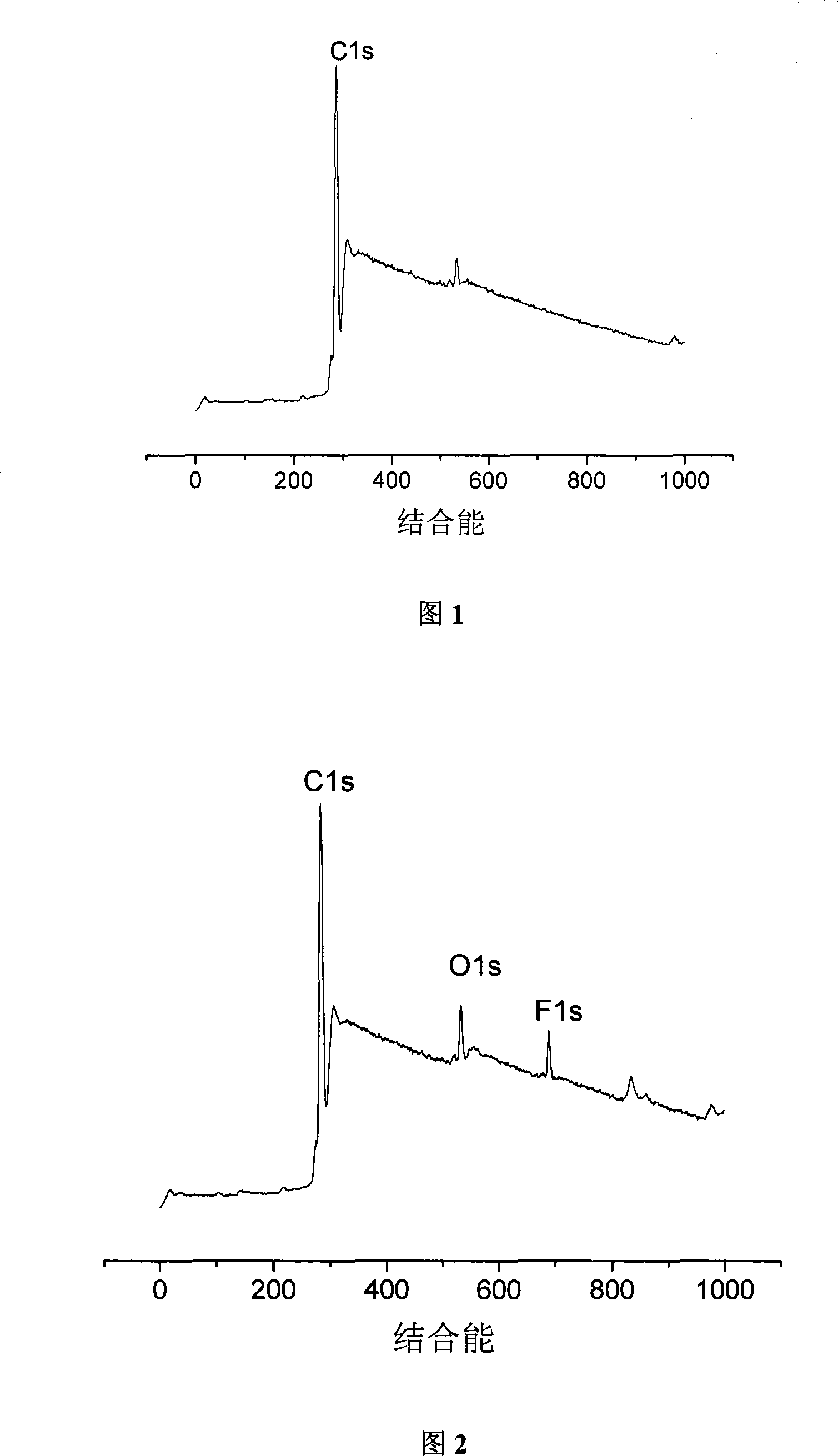

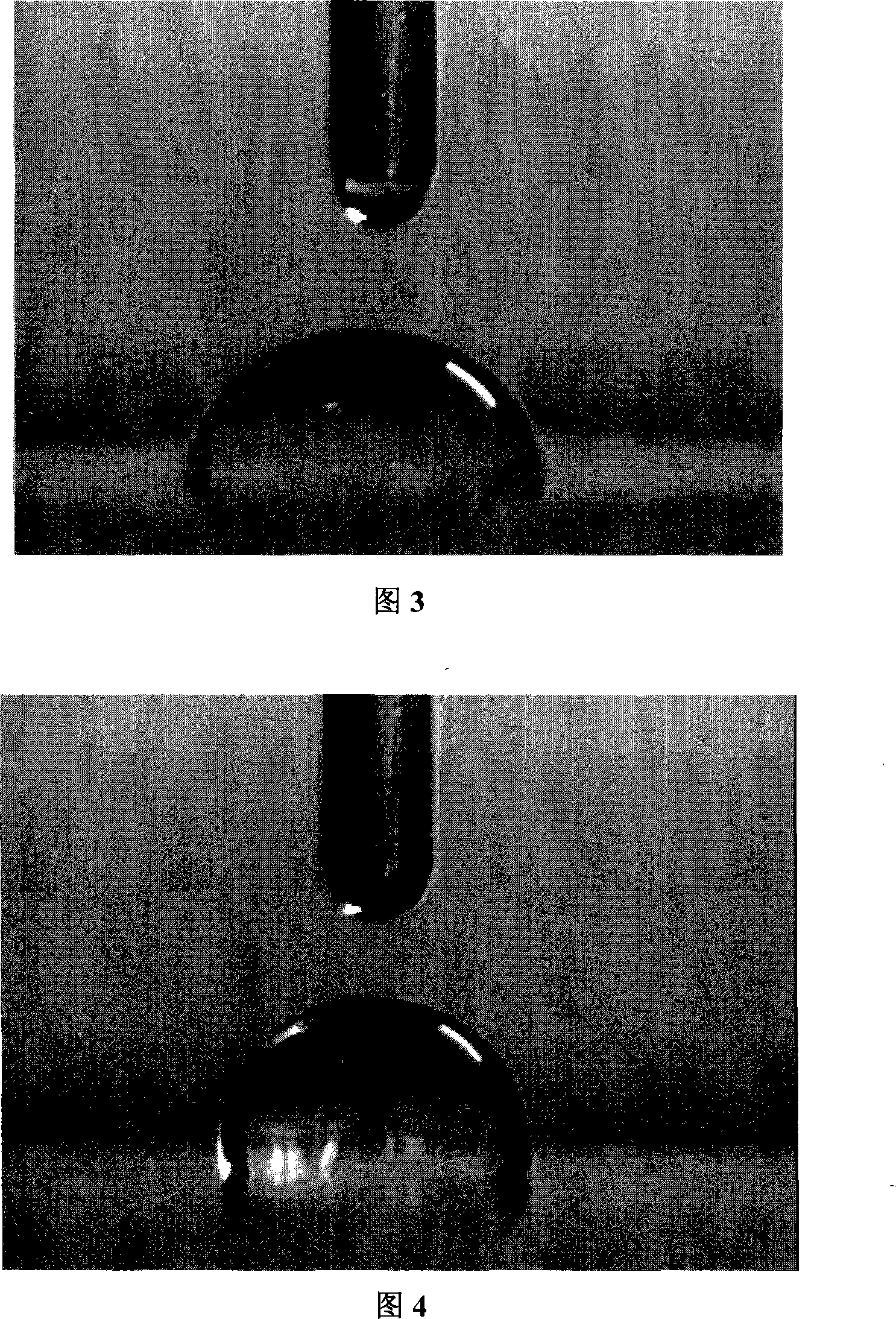

Aluminum alloy material capable of being anodized and suitable for semi-solid forming and preparing method of aluminum alloy material

The invention provides an aluminum alloy material capable of being anodized and suitable for semi-solid forming and a preparing method of the aluminum alloy material. The aluminum alloy is composed of the following elements including Mg, Si, Zn, Sc, Zr, Mn and the balance Al and inevitable impurity elements. The preparing method includes the following steps that an aluminum alloy melt is prepared through the preparing method for the aluminum alloy material; the aluminum alloy melt is stirred under the temperature of 720 DEG C to 730 DEG C and then is subjected to standing, refining gas removing and slag removing are conducted under the temperature of 710 DEG C to 720 DEG C, then heat insulation is conducted under the temperature of 650 DEG C to 670 DEG C after standing is conducted again, and molten aluminum alloy is obtained; the molten aluminum alloy is put into a semi-solid electromagnetic stirring device to be subjected to electromagnetic stirring, and then semi-solid slurry is obtained; and the semi-solid slurry is subjected to pressure casting or extrusion casting forming, and the aluminum alloy material is obtained. The prepared aluminum alloy capable of being anodized and suitable for semi-solid forming is high in thixotropy in a semi-solid state, the processing process is easy to control, the semi-solid forming performance is good, meanwhile, no air holes or cracks or the like exist in formed thin-wall parts, and the yield is high.

Owner:SHANGHAI JIAO TONG UNIV

Machining and producing process of seamless steel pipe

The invention discloses a machining and producing process of a seamless steel pipe. The machining and producing process includes the following steps that a steel pipe raw material is selected; pipe blank cut-off and stripping are conducted on the surface layer of the steel pipe material; the steel pipe material is heated; and high pressure water phosphorous removal, perforation, hole enlarging, hot extrusion, demolding, thermal treatment, steel tube saw cutting, cooling, secondary acid pickling, inspecting, coping, cold rolling, oil removal, secondary straightening and water pressure test crack detection are conducted. The machining and producing process of the seamless steel pipe is reasonable in flow design, high in machining work efficiency, high in workpiece deformation speed and capable of avoiding cracks generated in the inner surface and the outer surface.

Owner:TAICANG DONGHUI MACHINERY PLANT

Polypropylene material with low surface tension and method for preparing the same

The present invention relates to grafting modified polypropylene material and the preparation method, in particular to a recipe of low interfacial tension polypropylene material and the preparation method, pertaining to the art of polymer processing technology. The present invention mixes the polypropylene material with non-saturated double-bond fluorochemical monomer including low interfacial tension and co-grafting monomer, adopts the double-screw fusional grafting method to prepare the low interfacial tension waterproof polypropylene material or extrude the product. The obtained solid surface can be greatly decreased and the waterproof performance can be effectively improved. The present invention adopts the fusional grafting reaction to obtain the fluoric high polymer. Compared with the electric ion and optical radiation method, the present invention facilitates the grafting process, easily controls the process and reduces the process complexity, even avoids the possible radioactive damages caused by these grafting processes, protects the body health of operational staff and eliminates the radioactive pollution to the environment.

Owner:SUZHOU UNIV

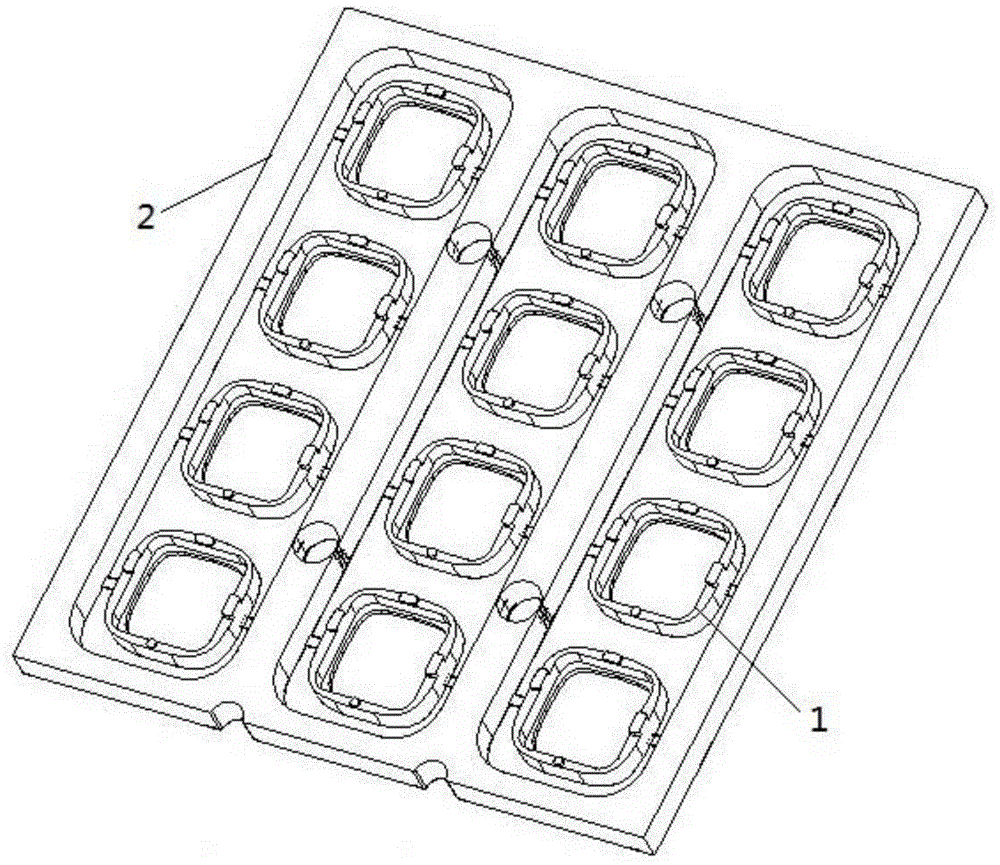

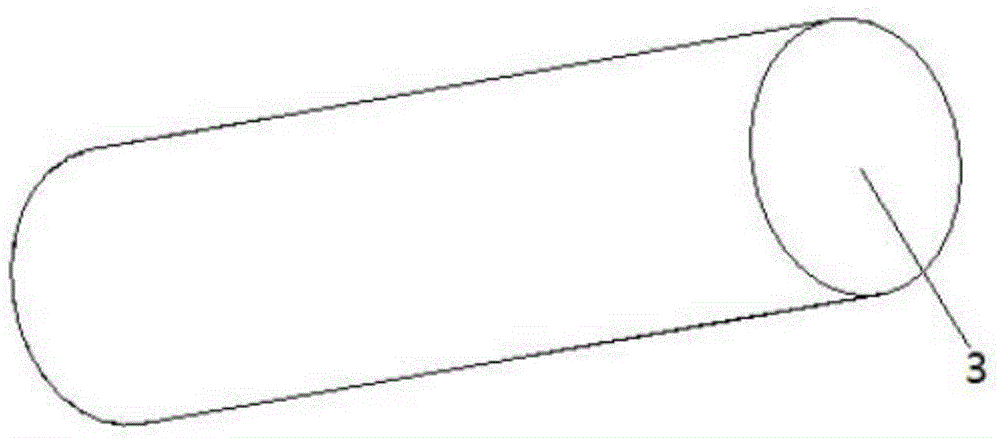

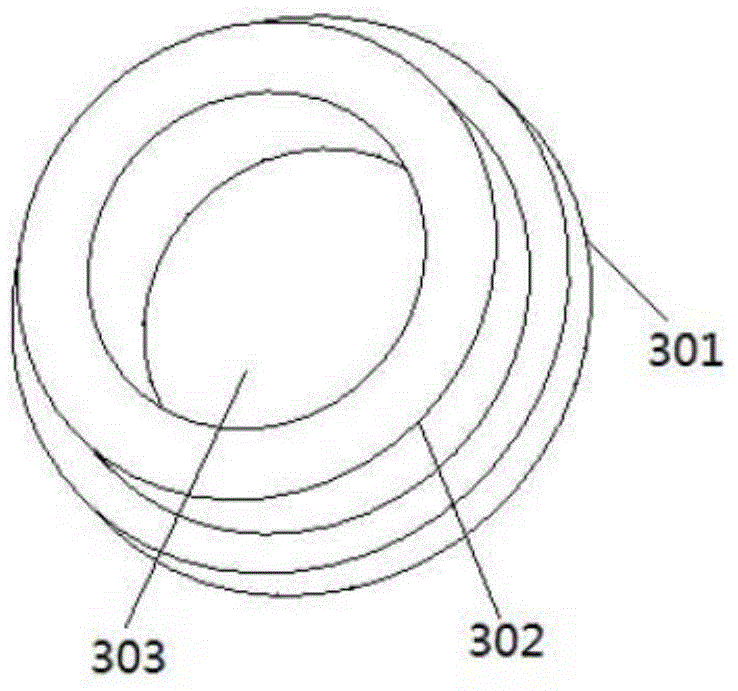

Mobile phone camera frame and manufacturing method thereof

ActiveCN104836946AReduce wasteSave raw materialsTelevision system detailsColor television detailsElectroplatingMachine tool

The invention discloses a mobile phone camera frame and a manufacturing method thereof, which belong to the technical field of manufacturing mobile phone components. The mobile phone camera frame comprises a frame body. A camera window is disposed in the frame body. One end face of the frame body is provided with a chamfer, and the other end face of the frame body is provided with a plurality of buckles. The manufacturing method of the mobile phone camera frame comprises the steps of processing metal bars into a plurality of ring-shaped members through a turning machine tool; processing an inner cavity in the ring-shaped members; processing the shapes of the ring-shaped members and obtaining preliminarily-formed frame members; conducting polishing and electroplating on the preliminarily-formed frame members. The mobile phone camera frame and the manufacturing method thereof are advantageous in that bars with appropriate specification are adopted for processing; processed frames are separated individuals, which are not connected; traditional sheet materials are replaced, the waste of leftover materials is reduced, cost is decreased, and the utilization rate of materials is greatly increased.

Owner:CHINJET PRECISION ELECTRON

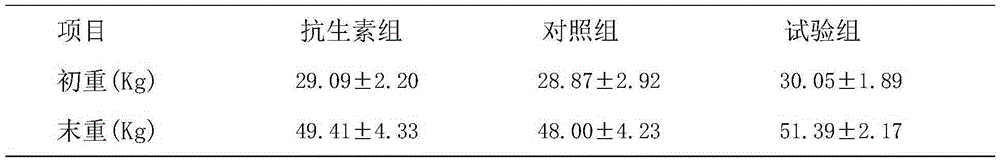

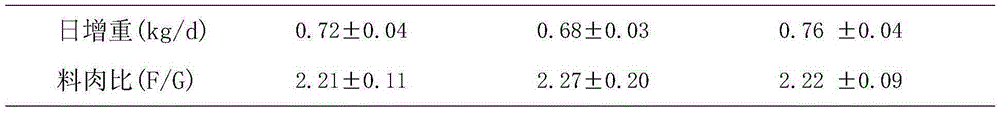

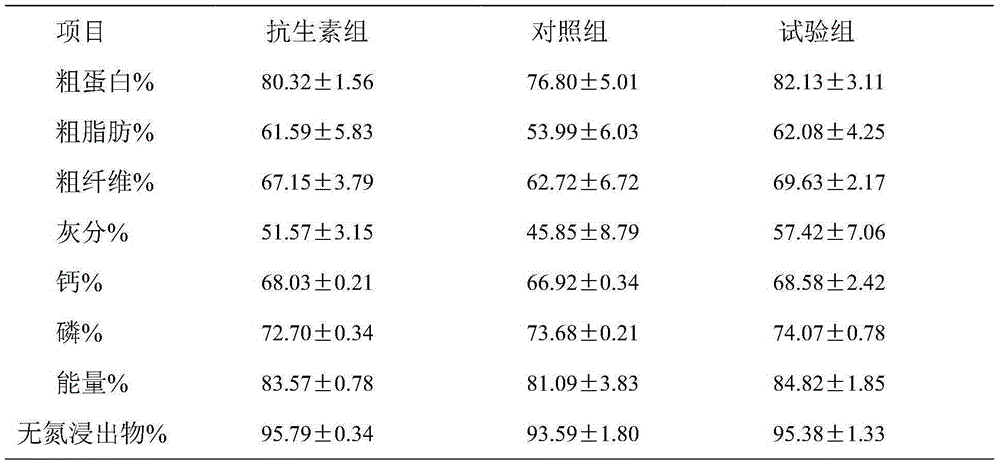

Preparation method of feed micro-ecologic agent produced by using citrus peels

InactiveCN105285326ASolve pollutionSave pollution control costsAnimal feeding stuffYeastBacillus subtilis

The present invention discloses a preparation method of a feed micro-ecologic agent produced by using citrus peels and a product thereof. The preparation method: Lactobacillus delbrueckii (Preservation No., CCTCC M 207096), Bacillus subtilis (Preservation No., CCTCC M 207097), Saccharomyces paradoxus (Preservation No., CCTCC M 207098) are inoculated to the corresponding liquid culture medium and cultured at a constant temperature of 37 DEG C for 18-24 hours, then the prepared bacteria solution is mixed in a certain proportion, the mixture is inoculated into sterilized solid state fermentation medium with the citrus peel as the main raw material and fermented at 30-40 DEG C for 36-48 hours, the fermented mixture is dried at a low temperature of 50-55 DEG C, and the dried mixture is crushed, thereby obtaining the feed micro-ecologic agent. Production technology of the feed micro-ecologic agent has the advantages of low investment, low energy consumption, no waste water pollution, etc., and opens up a new way for the utilization of the citrus peels at the same time.

Owner:HUNAN AGRICULTURAL UNIV

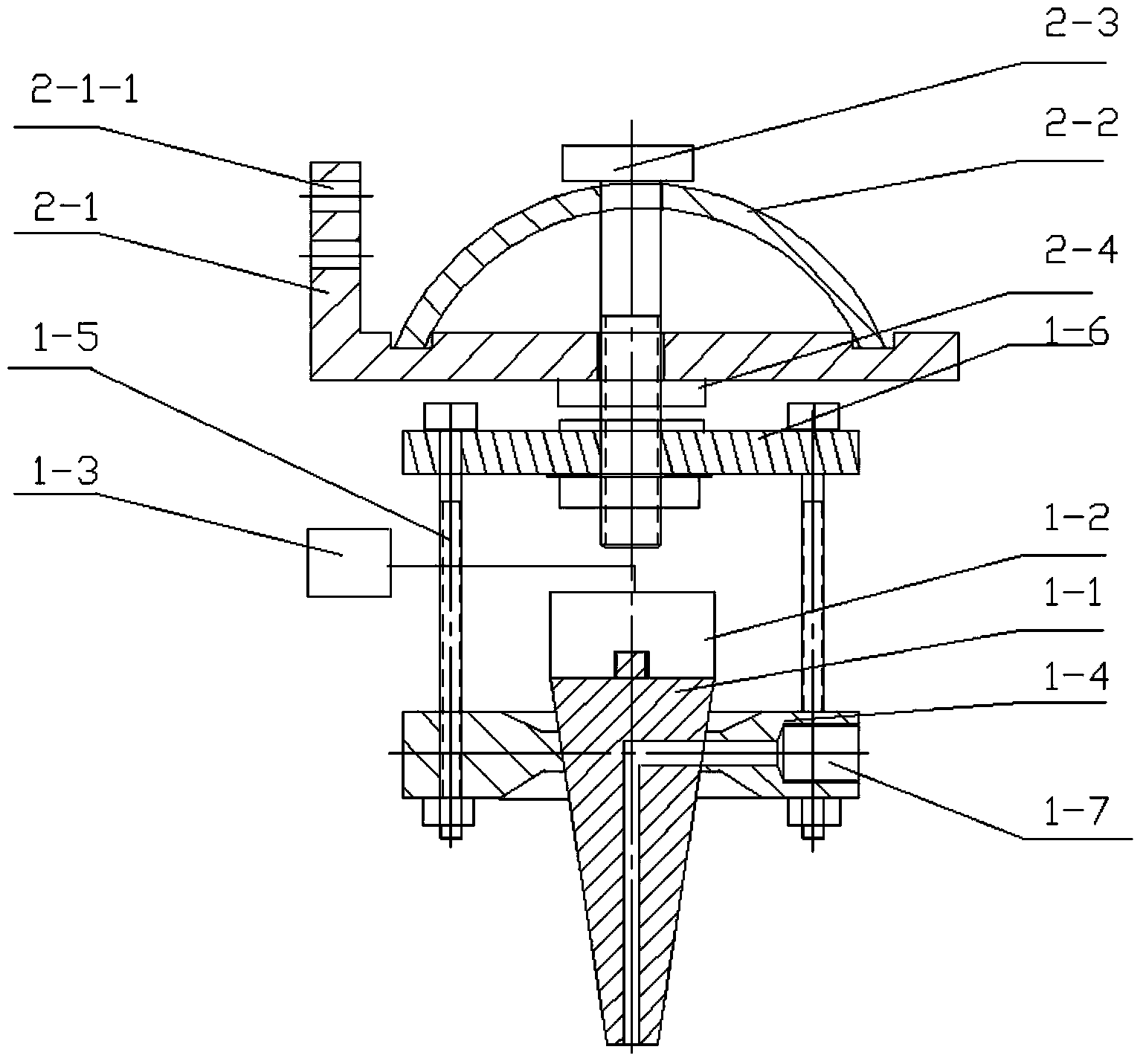

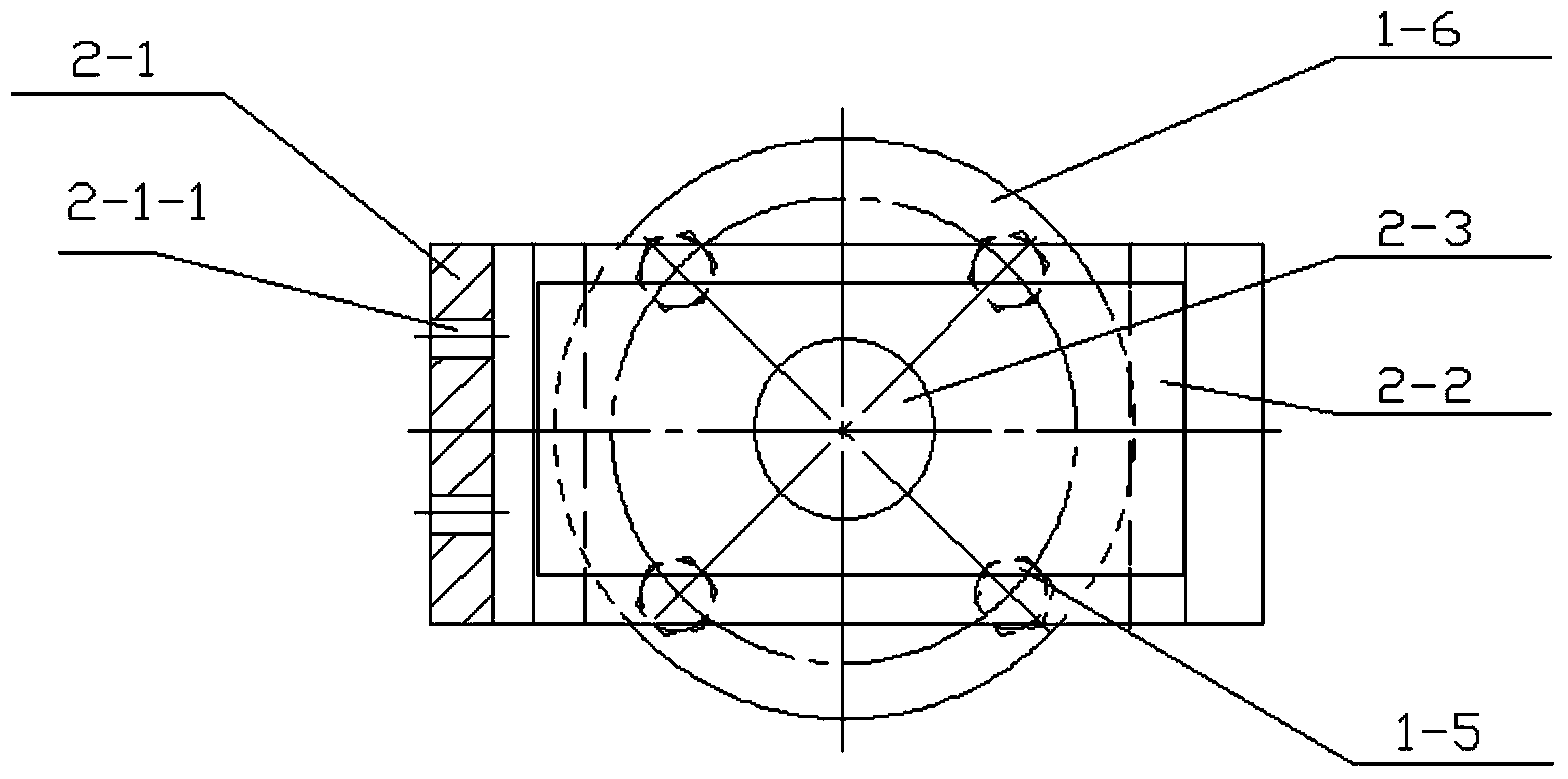

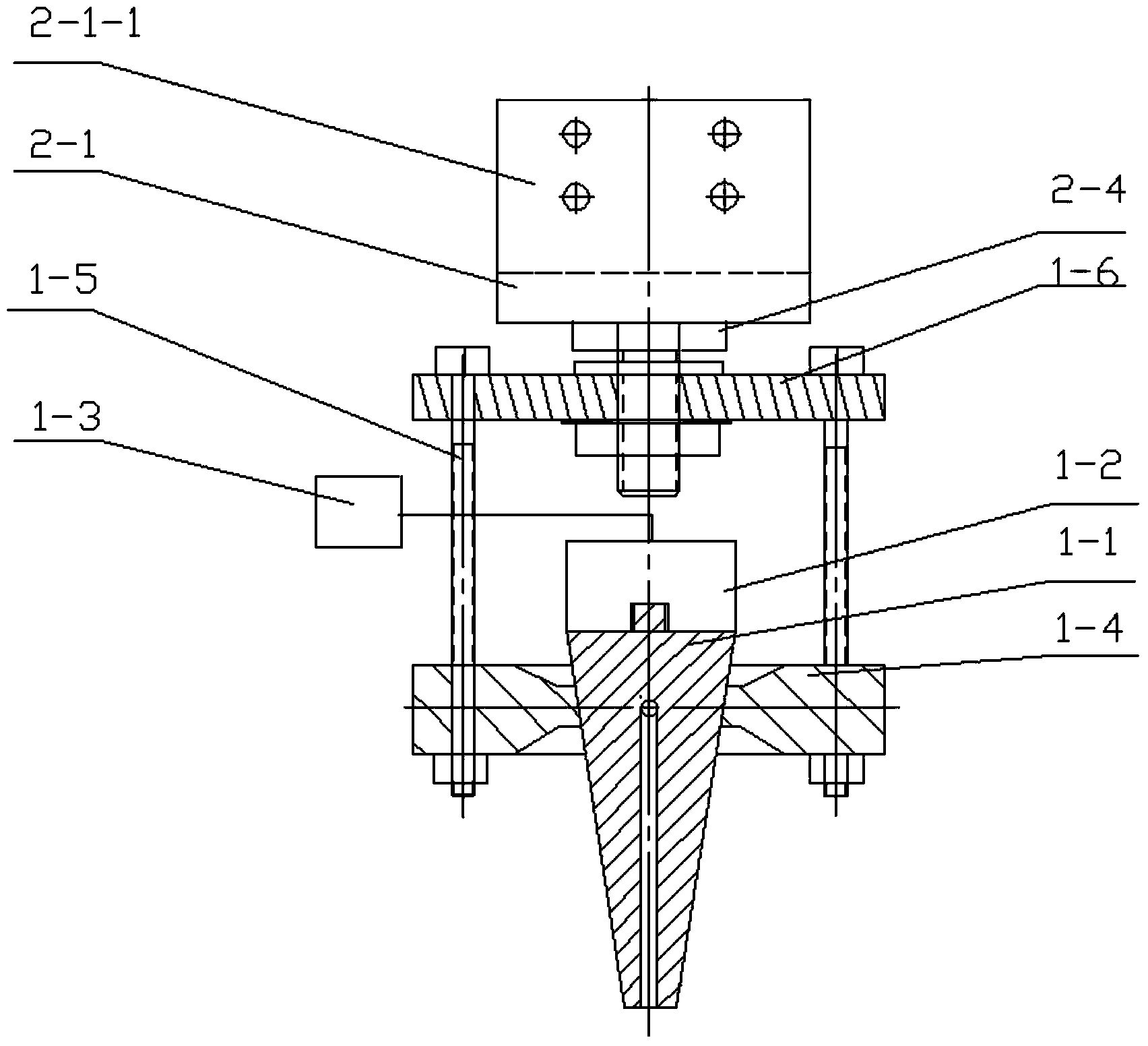

Ultrasonic reinforced abrasive water jet machining device

InactiveCN103753405AEliminate process effectsEliminate the effects ofAbrasive feedersSpray nozzleTransducer

The invention relates to the non-traditional machining technology, in particular to an ultrasonic reinforced abrasive water jet machining device which is applied to an abrasive water jet machining system. The ultrasonic reinforced abrasive water jet machining device consists of a variable-amplitude rod nozzle, a transducer, a pulse power supply, a lower installation tray, a bolt, an upper installation tray, an abrasive water jet pipeline connecting port and a vibrating isolation mechanism, wherein the transducer is installed on the variable-amplitude rod nozzle, the variable-amplitude rod nozzle is fixed on the lower installation tray, the lower installation tray and the upper installation tray are installed together through the bolt, and the upper installation tray is connected with the vibrating isolation mechanism and installed on a motion control part of the abrasive water jet machining system through the vibrating isolation mechanism. The original continuous jet flow is converted into the pulse jet flow, so that the influence on the machining process caused by a water cushion can be eliminated. By adopting the ultrasonic reinforced abrasive water jet machining device, the machining process is controllable, the jet flow machining capacity is enhanced, the removal efficiency of a workpiece material is improved, high efficiency in abrasive water jet machining is realized, and the popularization and application of the precise fine abrasive water jet machining process can be facilitated.

Owner:SHANDONG UNIV

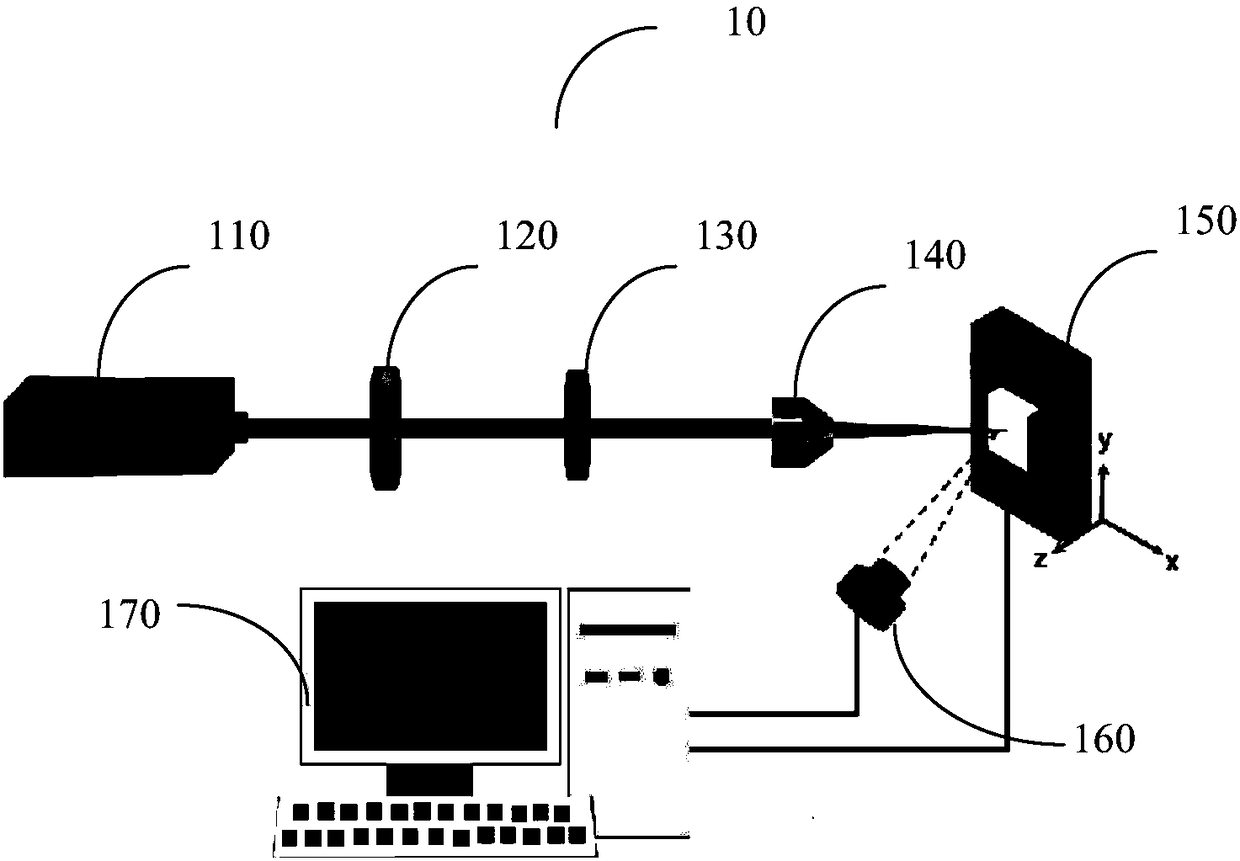

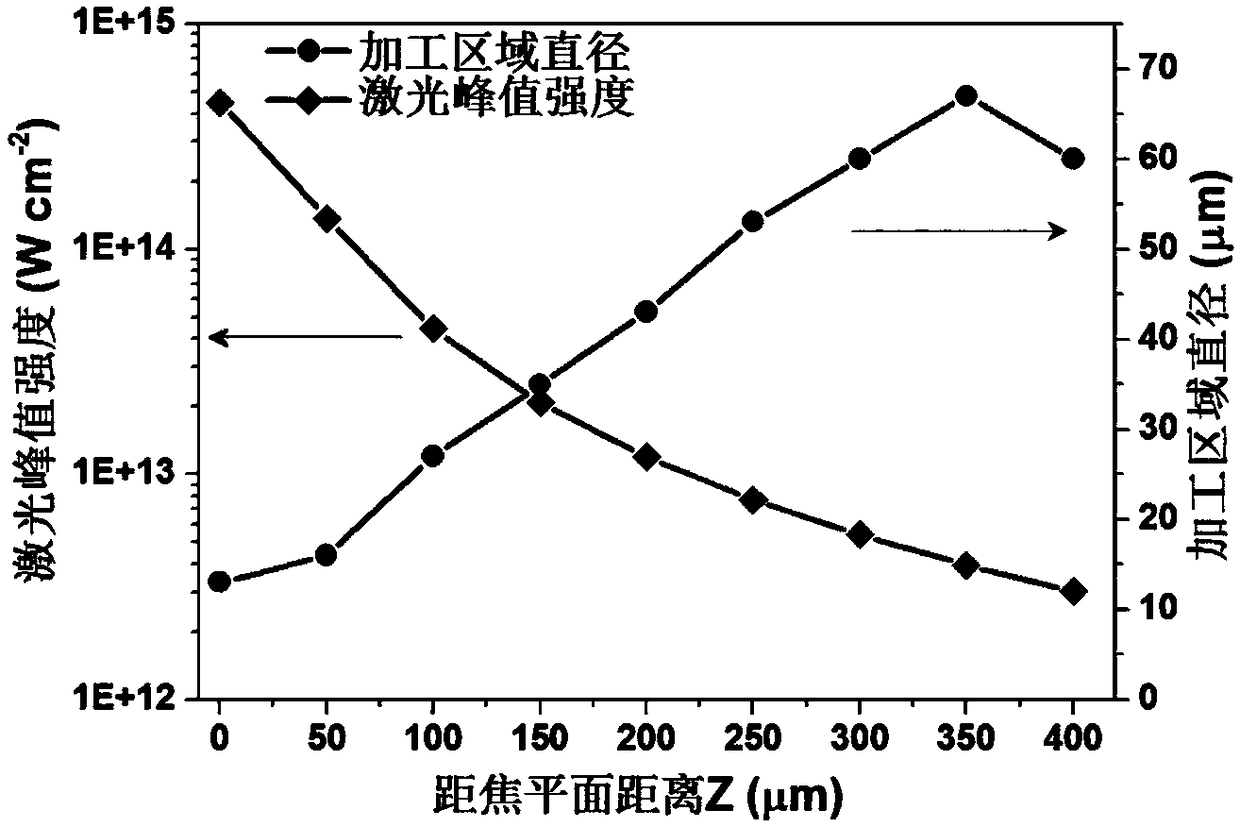

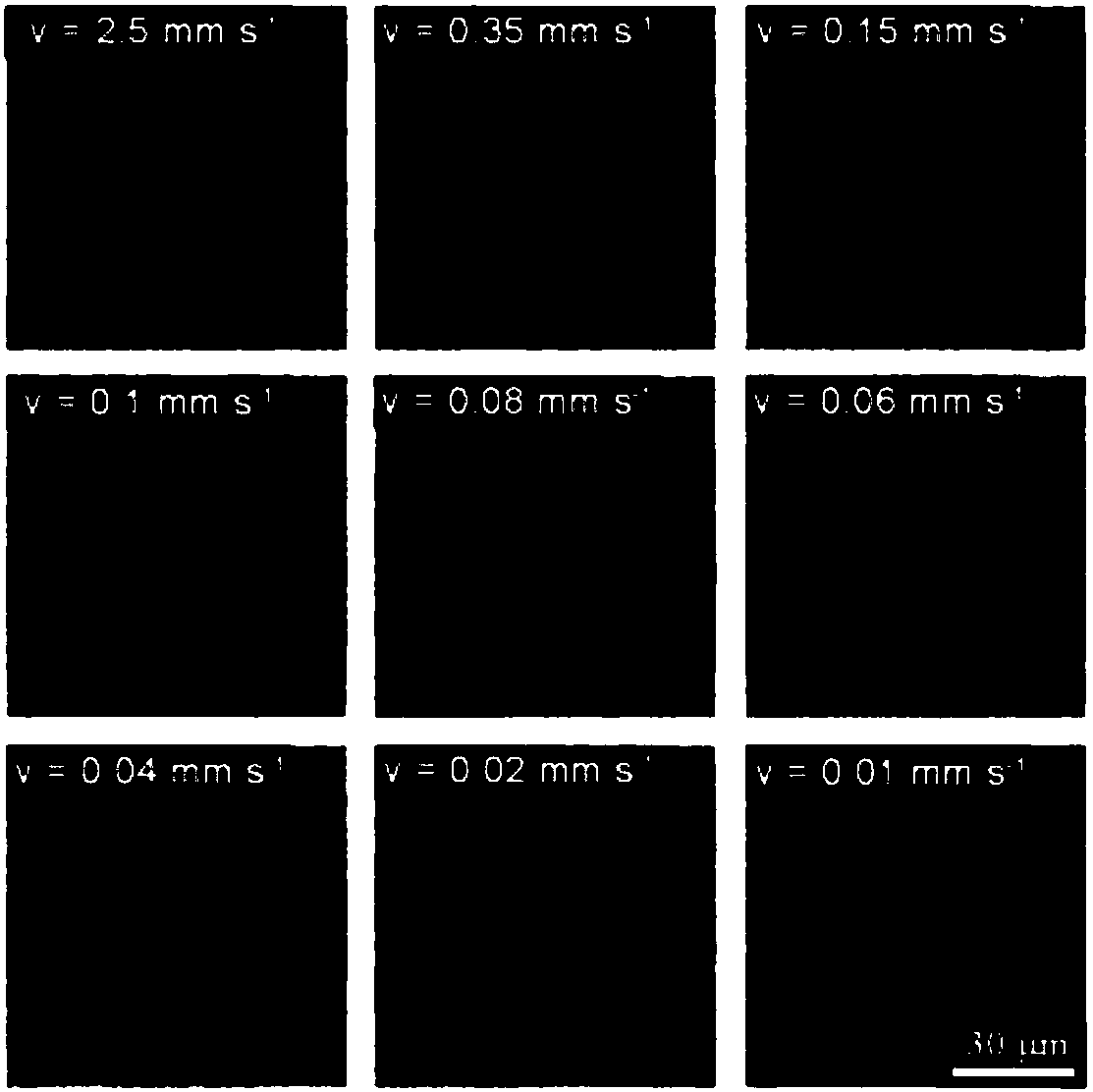

Optical processing system of perovskite single crystal and application of perovskite single crystal with remarkably enhanced fluorescence

InactiveCN108526699AWide range of usesAvoid destructionLaser beam welding apparatusPhysicsSurface trap

The invention discloses an optical processing system of perovskite single crystal. The system comprises a laser light source, a numerical aperture, an attenuator, an objective lens, a three-dimensional translation table, a charge coupling device and a computer; a femtosecond laser light beam emitted by a femtosecond laser light source sequentially passes through the numerical aperture, the attenuator and the objective lens and then is focused on the surface of the perovskite single crystal on a three-dimensional translation table, and micro-machining on the surface of the perovskite single crystal is carried out to obtain the perovskite single crystal with remarkably enhanced fluorescence; and a charge coupling device can transmit the micro-machining process to a computer. According to thesystem, the optical processing system of the perovskite single crystal is used for realizing induction etching of various morphologies of the surface of the perovskite single crystal by controlling relevant laser processing parameters; and based on that the surface trap density of the perovskite single crystal is reduced and the principle of changing the surface state of the perovskite single crystal, the remarkable enhancement of the fluorescence property is realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

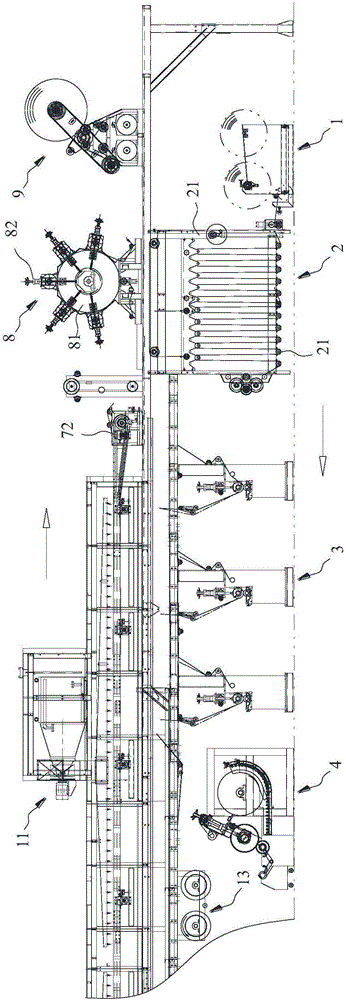

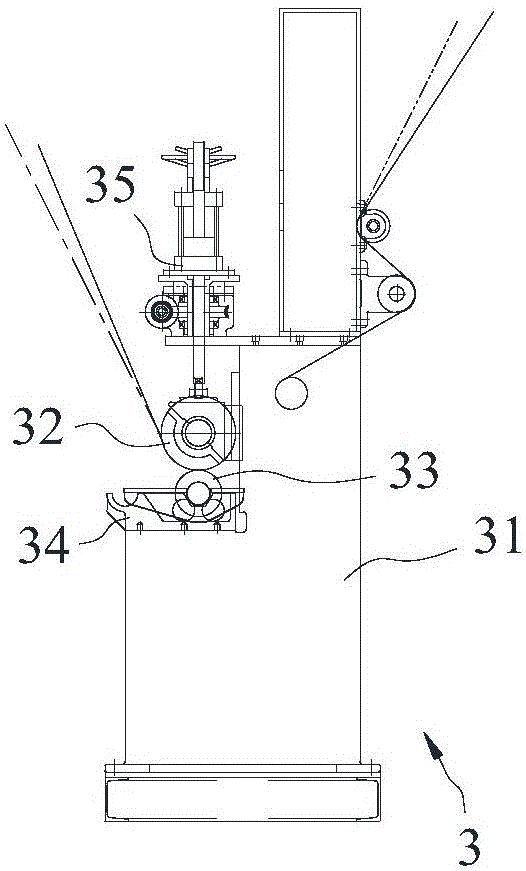

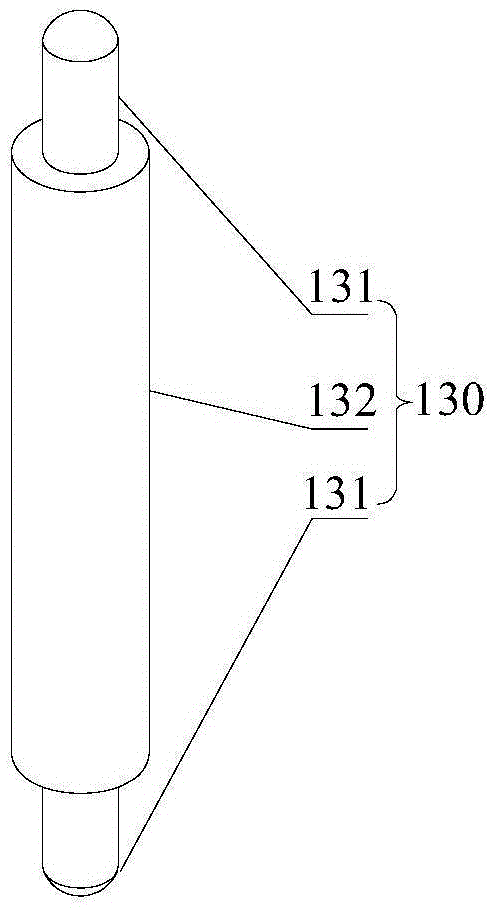

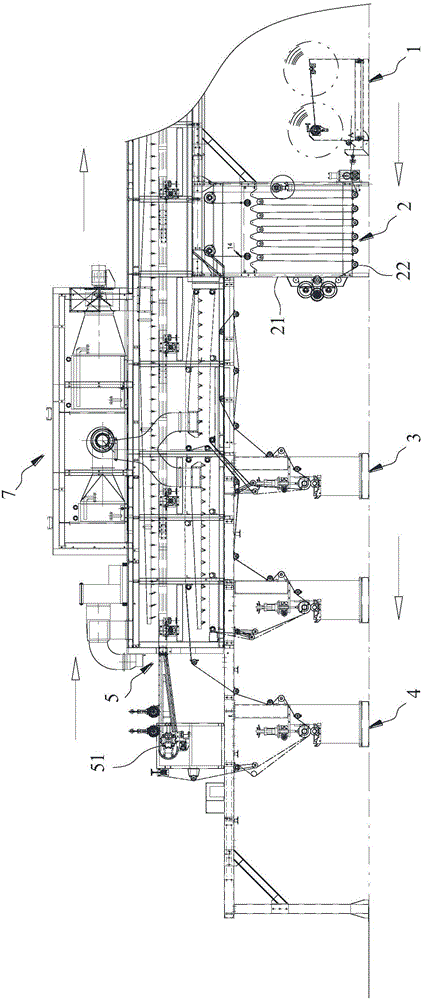

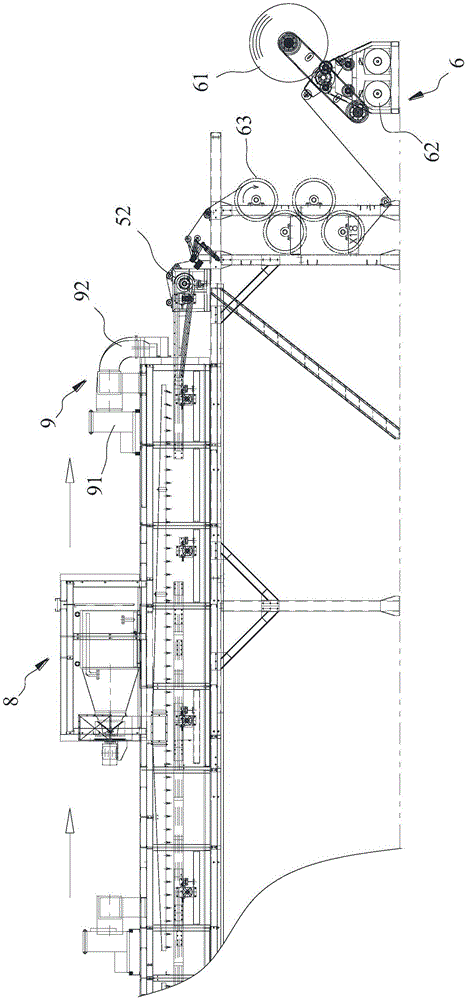

Integrated synthetic leather processing device

ActiveCN106521977AIncrease productivityThe processing process is easy to controlTextiles and paperEngineeringWork in process

The invention discloses an integrated synthetic leather processing device. The integrated synthetic leather processing device comprises an unwinding mechanism, a cloth storage rack, a first printing component, an embossing machine, a storage tank, a second printing component, a widening mechanism, a polishing mechanism and a winding mechanism which are sequentially connected along the conveying direction of cloth, wherein the unwinding mechanism is used for delivering to-be-processed cloth, the cloth storage rack is used for carding and temporarily storing the to-be-processed cloth, the first printing component is used for dyeing printing, the embossing machine is used for printing patterns, the storage tank is used for stretching and extending cloth, the second printing component is used for sizing material printing, the widening mechanism is used for widening the cloth, the polishing mechanism is used for polishing semi-product synthetic leather, and the winding mechanism is used for winding the finished-product synthetic leather. The integrated synthetic leather processing device further comprises a gravure dryer and a widening forming dryer which are located above the widening mechanism. The integrated synthetic leather processing device has the advantages that integrated synthetic leather processing is achieved, and processing and production efficiency are increased.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

Lithium battery laminating machine double-battery-cell processing and production method

ActiveCN110534814AThe processing process is easy to controlAccurate locationMeasurement devicesFinal product manufacturePole pieceMachining process

The invention belongs to the battery cell processing field and especially relates to a lithium battery laminating machine double-battery-cell processing and production method. Aiming at current problems of low machining precision and a high defective rate, the invention provides the following method. The method comprises the following steps of S1, inputting sizes of positive and negative pole pieces which need to be machined into a computer, and modeling on the computer; S2, simulating lamination of the positive and negative pole pieces, and recording simulated data; S3, connecting the pole pieces on two sides through tabs, placing a diaphragm, placing diaphragm volumes on the left, right, positive and negative sides, and adding the two diaphragm volumes on the front, back, left and rightsides; and S4, inputting the data in the S2 into a lamination machine through input equipment, conveying the pole pieces by the lamination machine through a lamination clamping and conveying device according to the received data, and carrying out lamination. According to the invention, a processing process of a battery cell can be accurately controlled, the defective rate can be effectively reduced, production efficiency is improved, and a reliable basis is provided for subsequent production.

Owner:王洋

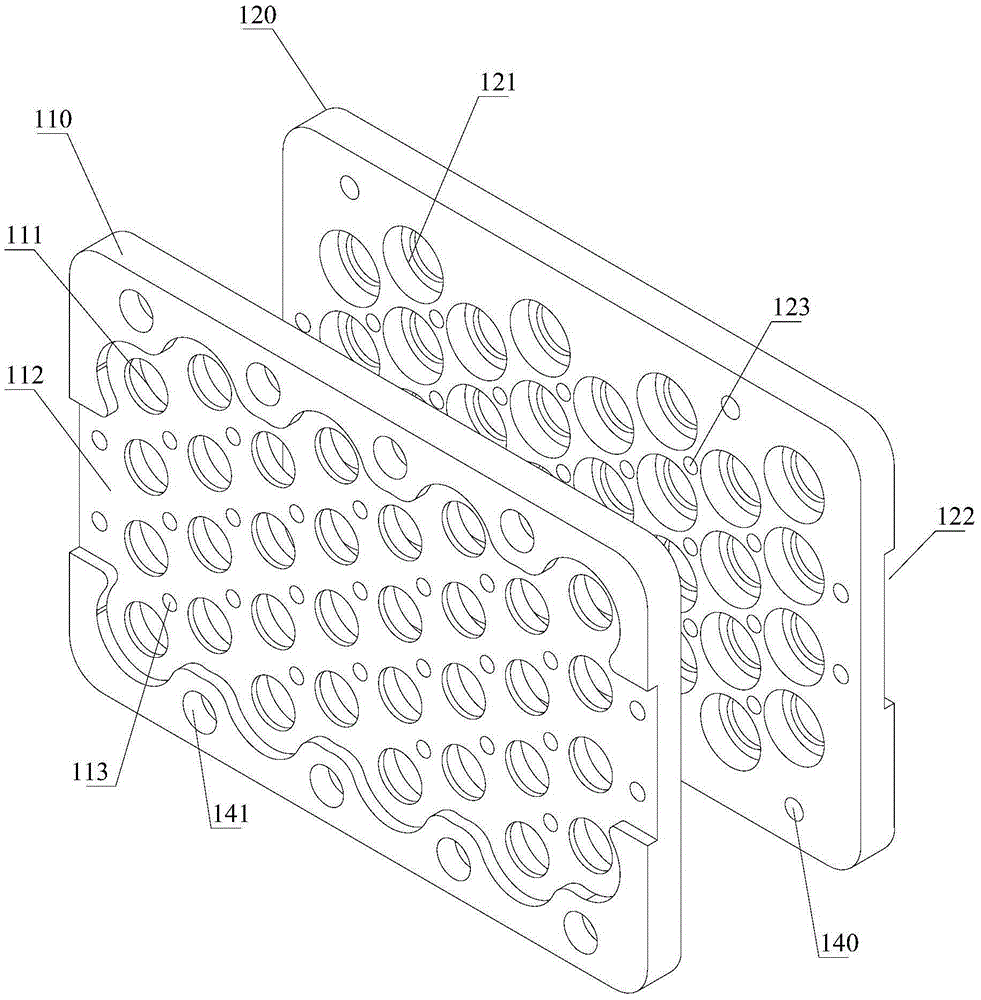

Battery pack support

InactiveCN105576170AFirmly connectedAvoid relative motionCell component detailsControl systemElectronic control system

The invention discloses a battery pack support, wherein support columns are connected with a first fixing plate and a second fixing plate in a hot melting way not by bolts; by hot melting connection, the connection between the support columns and the first fixing plate and the second plate is more steady and firm, the relative moving between the first fixing plate and the second fixing plate, which is caused by bolt looseness, can be eradicated effectively, such problems as the power output is stable during th running process of a vehicle, an electronic control system works abnormally and accessory equipment works abnormally can be solved.

Owner:华霆(常州)动力技术有限公司

Method for preparing underwear from antibacterial fiber

InactiveCN103882687AHas antibacterial effectImprove antibacterial propertiesVegetal fibresUndergarmentsFiberDiethylenetriamine

The invention discloses a method for preparing underwear from an antibacterial fiber. The method comprises the following concrete steps: mixing a bamboo fiber with an antibacterial aqueous solution according to a ratio of 1 g: 200 ml, adding diethylenetriamine at the same time, carrying out heating to a temperature of 80 DEG C after uniform mixing with stirring, maintaining the temperature for 30 min, taking out the bamboo fiber, washing the bamboo fiber with clear water until a pH value is 5.0 to 6.0 and drying the bamboo fiber on a dryer. The method is simple, can be easily understood and has easily controllable processing process; the prepared underwear has an antibacterial function, a good antibacterial effect and long antibacterial duration and can meet demands of people.

Owner:赵建英

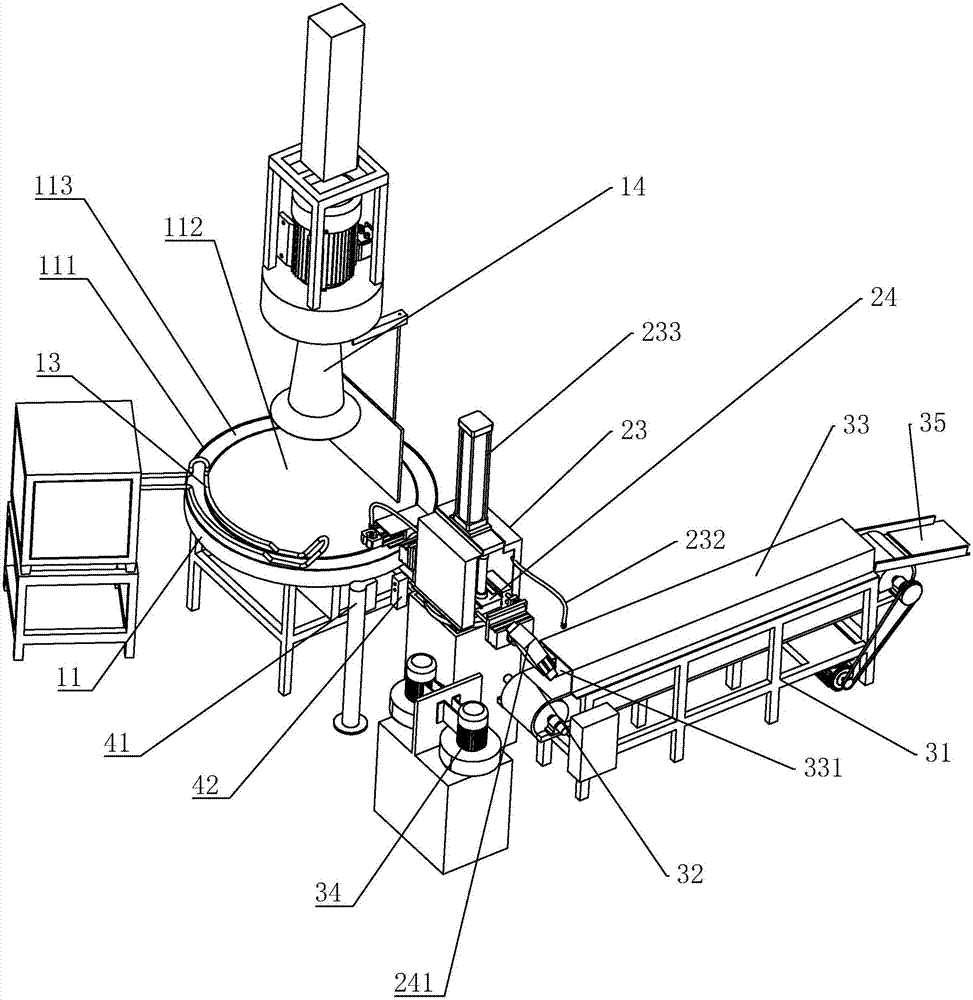

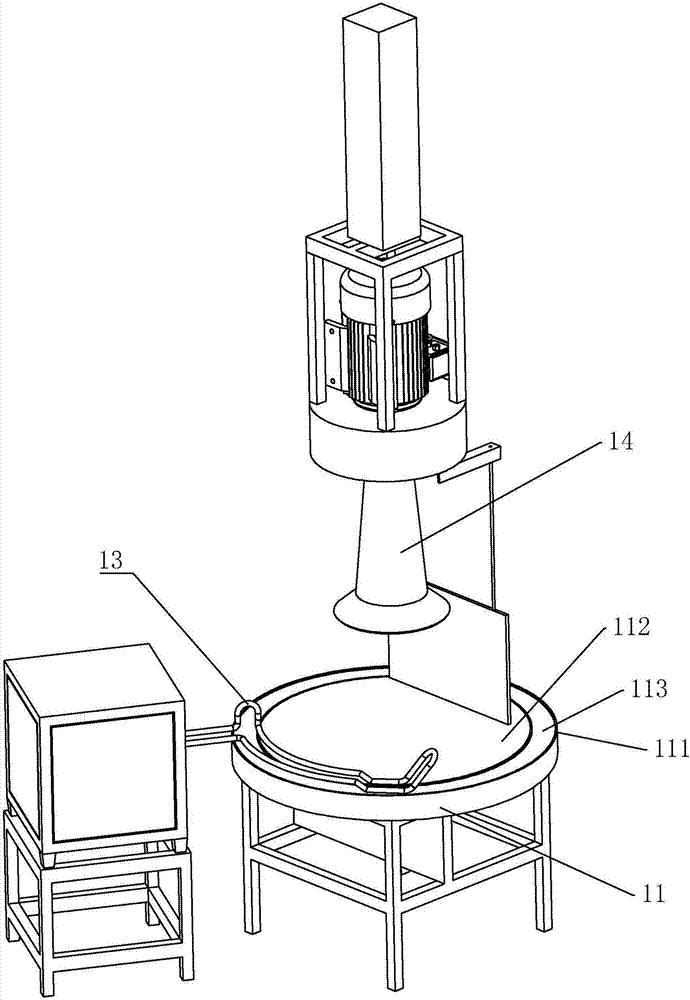

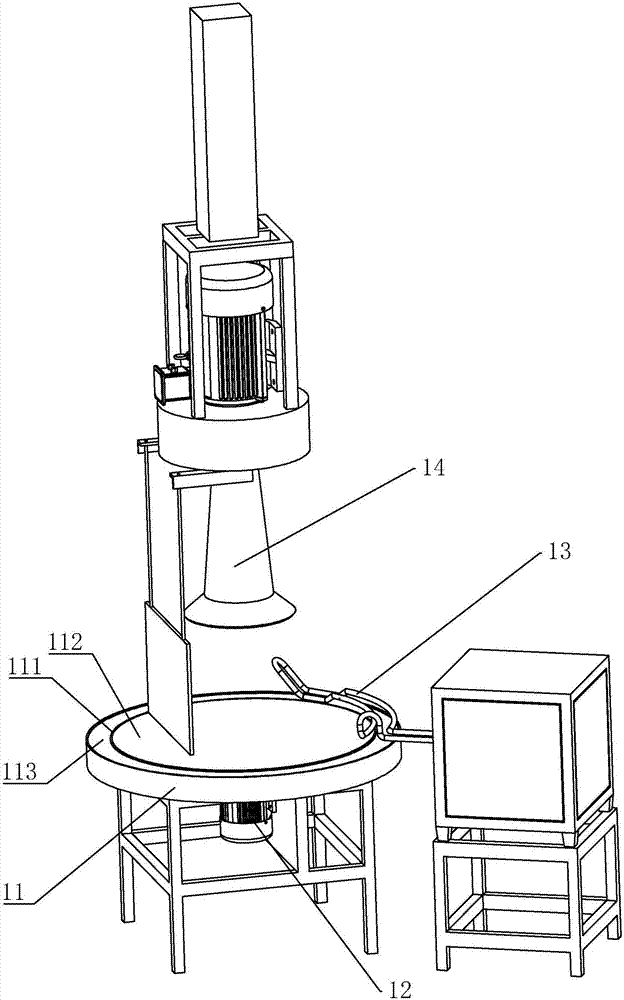

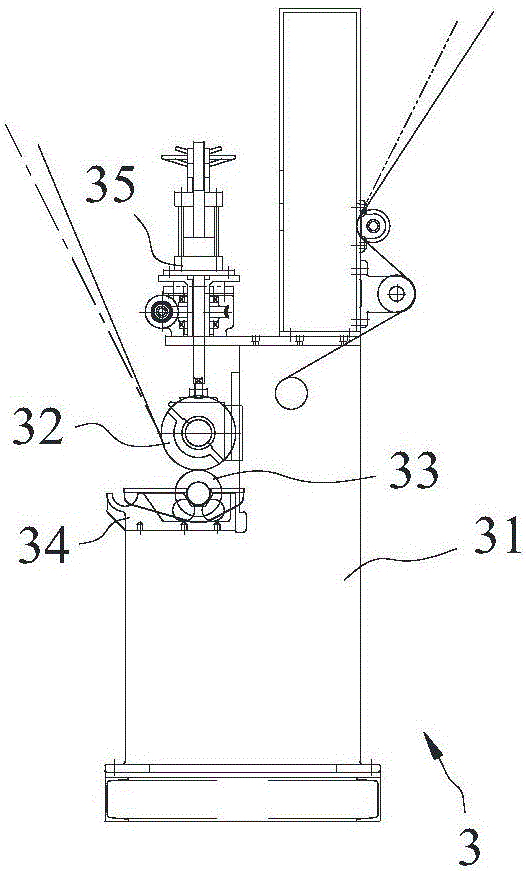

Automatic device for drill tool welding

ActiveCN107303629AReduce labor intensityEfficient processingWelding/cutting auxillary devicesAuxillary welding devicesFree coolingEngineering

The invention discloses an automatic device for drill tool welding. According to the technical scheme of the automatic device, the automatic device is characterized in that the automatic device comprises a heating mechanism used for a drill tool, a cooling mechanism used for natural cooling, and a detection head, a mechanical arm used for grabbing the drill tool from the heating mechanism and transferring the drill tool to the cooling mechanism from the heating mechanism is arranged between the heating mechanism and the cooling mechanism, the detection head is in signal connection with the mechanical arm, and after the drill tool completely heated by the heating mechanism enters a detection area of the detection head, the detection head drives the mechanical arm to transfer the completely-heated drill tool to the cooling mechanism. The heating mechanism can conduct heating processing on the drill tool; and by arranging the detection head, the mechanical arm can be operated to effectively grab the completely-heated drill tool, and therefore the drill tool is transferred to the cooling mechanism and then cooled on the cooling mechanism, people only need to place completely-assembled products on the heating mechanism, the tedious and complex product transfer labor of people is avoided, and meanwhile the production efficiency is also ensured.

Owner:ZHEJIANG PULANKA ROCK TOOLS CO LTD

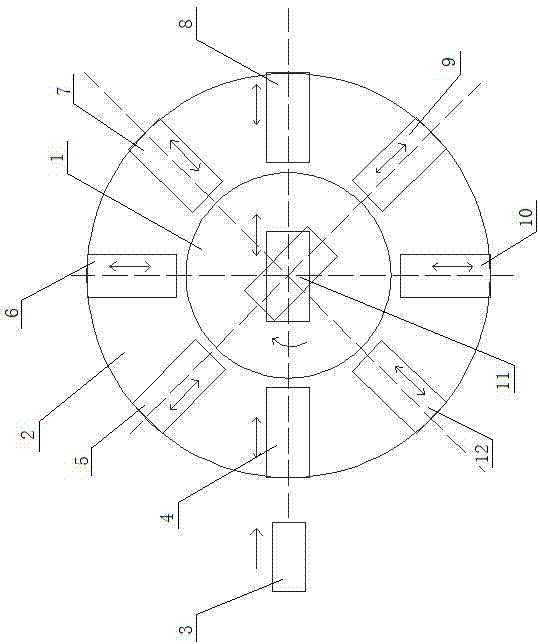

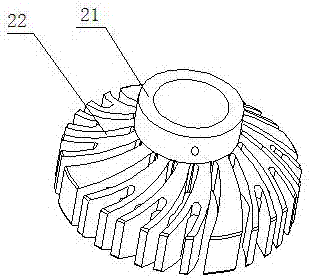

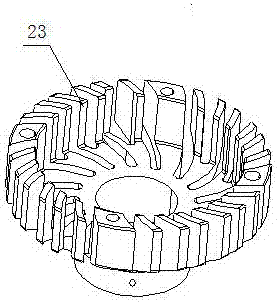

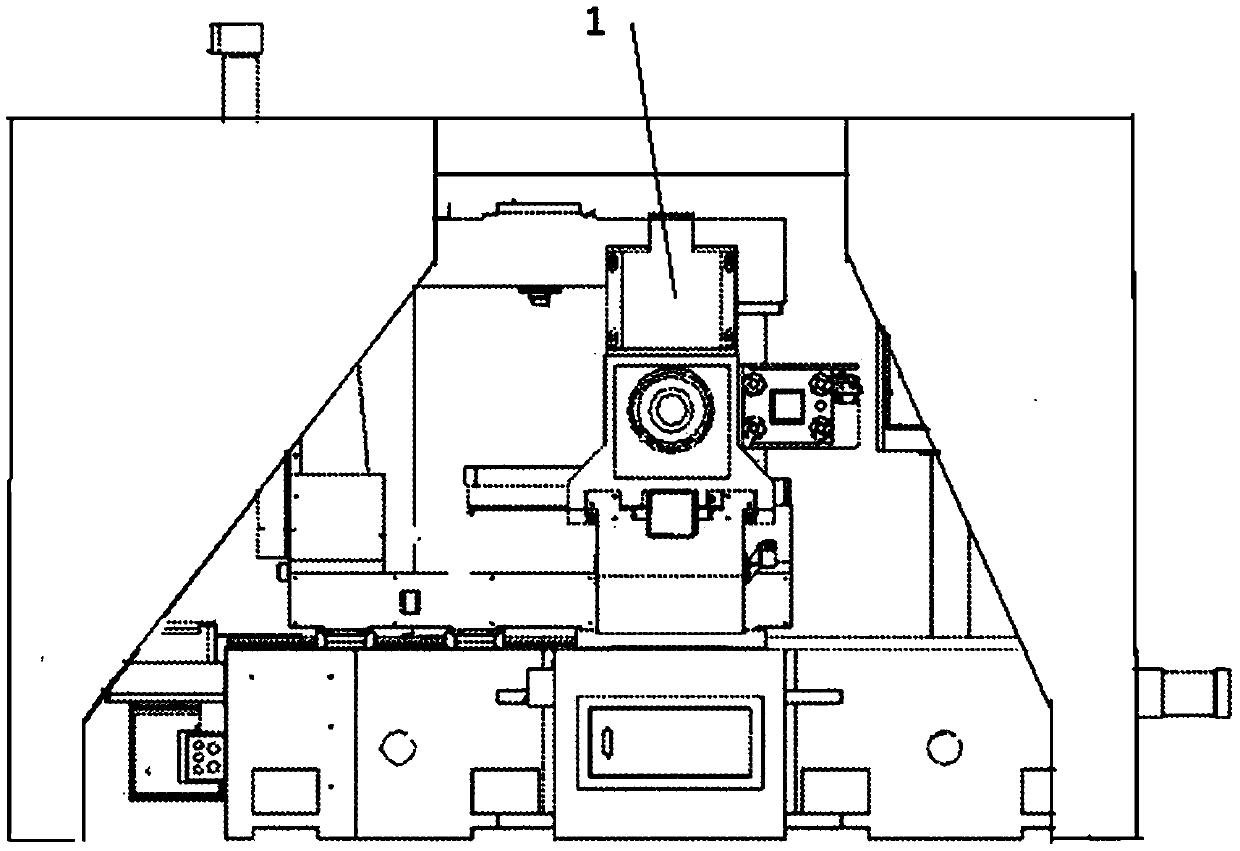

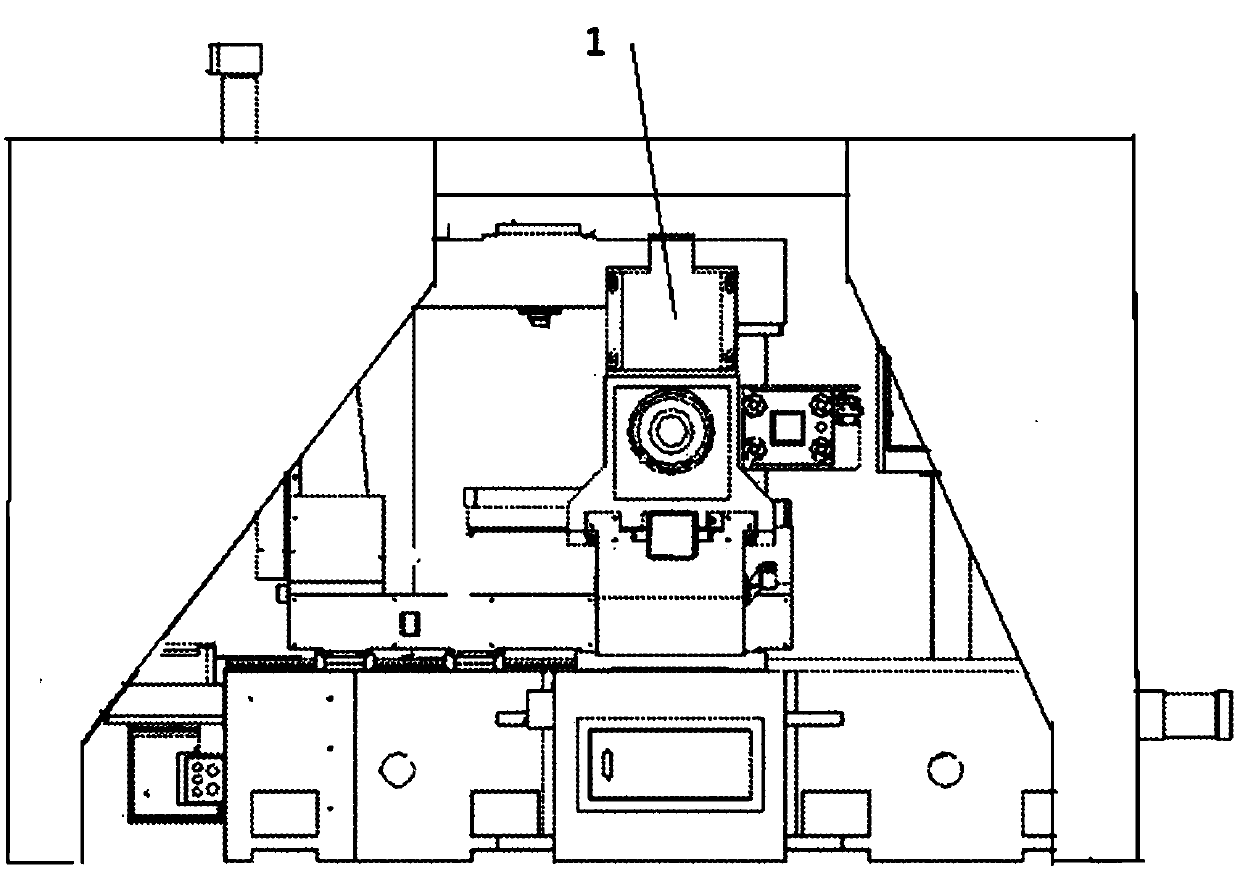

Eight-axis turning-milling compound numerical control equipment

InactiveCN107378492AReasonable structural designImprove automated processingOther manufacturing equipments/toolsNumerical controlEngineering

The invention discloses an eight-axis turn-milling compound numerical control equipment, which comprises an inner guide rail and an outer guide rail arranged coaxially, a milling mechanism is arranged at the center of the inner guide rail, the inner guide rail and the milling hole mechanism rotate freely, and the outer guide rail The guide rail is fixedly installed on the outer side of the inner guide rail, and a plurality of turning and milling mechanisms arranged at equal intervals are fixedly connected to the outer guide rail. The platform sinking mechanism, the side hole drilling mechanism, the car end face circular arc mechanism and the cutting mechanism are provided with an automatic feeding mechanism at the position facing the feeding guide mechanism. The invention has a reasonable structural design, integrates the processing tools of each process of the turning and milling radiator, improves the automatic processing and greatly improves the processing efficiency, and the processing process is controllable and the product quality is improved.

Owner:NANTONG SUHE LAMP PARTS

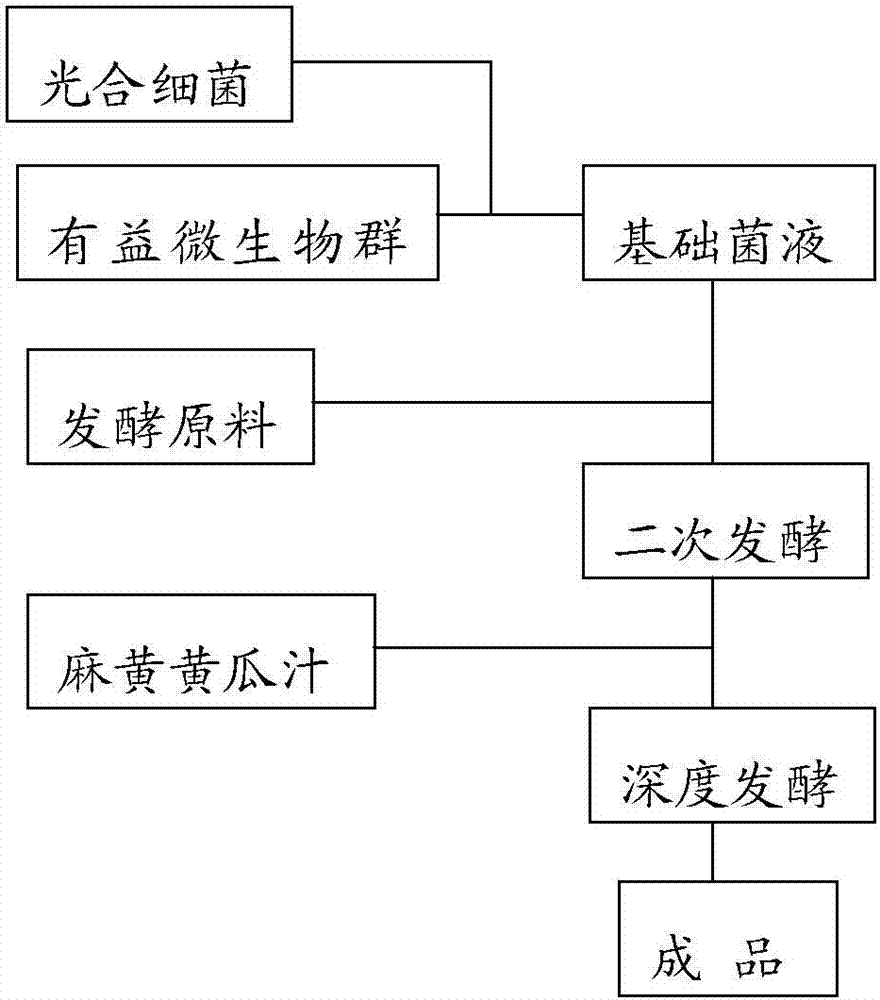

Preparation method of functional beverage having functions of invigorating spleen and nourishing stomach

ActiveCN107232459AHigh nutritional valueReasonable fermentation processBacteriaFood ingredient functionsMicroorganismEphedra herb

The invention relates to a preparation method of a functional beverage having functions of invigorating the spleen and nourishing the stomach, and belongs to the field of biological fermentation engineering. According to the adopted method, firstly basic bacterial liquid is prepared, then effective raw materials are added, and biological fermentation is performed. The bioactivity of beneficial microorganisms is utilized, so that effective components in the raw materials are transformed, and the functions of the beverage for invigorating the spleen and nourishing the stomach are sufficiently exerted. The method comprises the following specific steps of firstly culturing photosynthetic bacteria and other beneficial microorganisms, then performing mixed fermentation on the photosynthetic bacteria and the other beneficial microorganisms in proportion so as to obtain the basic bacterial liquid, adding the effective components based on the basic bacterial liquid, performing secondary fermentation, finally adding Chinese ephedra herb and cucumber juice, and performing deep fermentation. According to the preparation method disclosed by the invention, based on maintaining certain beneficial microorganism flora, traditional Chinese medicine raw materials are added, so that the value of the functional beverage is increased, and effective components in traditional Chinese medicines are not destroyed by a biotechnology means.

Owner:SHENYANG NORMAL UNIV

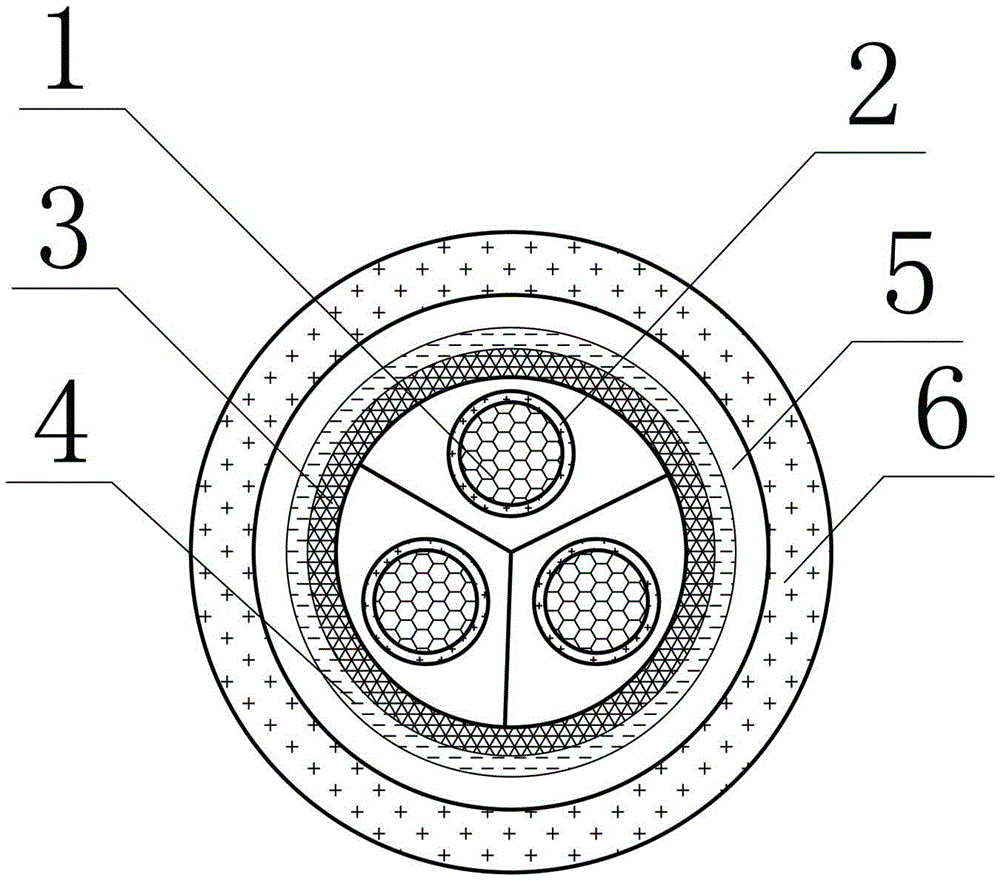

Aluminium alloy cable

InactiveCN105244084AImprove flame retardant performanceImprove securityInsulated cablesCable/conductor manufactureElectrical conductorCross-linked polyethylene

The invention provides an aluminium alloy cable which comprises an insulated cable core and a heat-insulation flame-retarding reinforcement layer, a metal jacket layer, a bituminous coating layer and a sheath layer, which are arranged on the insulated cable core from the inside out in sequence. The insulated cable core is formed by a plurality of aluminium alloy wires and a cross-linked polyethylene insulating layer wrapped on the surfaces of the aluminium alloy wires. The Aluminium alloy cable overcomes the defects in the aspects of conductor processing, halogen-free low-smoke flame retardation, fire-resistant performance and anticorrosion and the like, and thus comprehensive protection performance of the cable is improved.

Owner:HENAN KAIQI POWER IND

A kind of processing and production method of lithium battery lamination machine double cell

ActiveCN110534814BThe processing process is easy to controlAccurate locationMeasurement devicesFinal product manufactureThermodynamicsCell processing

The present invention belongs to the field of cell processing, in particular to a method for processing double cells of a lithium battery lamination machine. Aiming at the existing problems of low processing accuracy and high defective rate, the following scheme is proposed, which includes the following steps: S1 : Enter the size of the positive and negative electrodes to be processed into the computer, and model on the computer; S2: Simulate the lamination of the positive and negative electrodes, and record the simulated data; S3: Connect the two sides through the tabs Place the diaphragm on the pole piece, place a diaphragm roll on the left and right sides, and add two diaphragm rolls on the front, back, and left and right sides; S4: Input the data in S2 into the lamination machine through the input device, and the lamination machine passes through the received data. The lamination pinch device transports the pole pieces and performs lamination. The invention can precisely control the processing process of the battery cells, effectively reduce the defective rate, improve production efficiency, and provide a reliable basis for subsequent production.

Owner:王洋

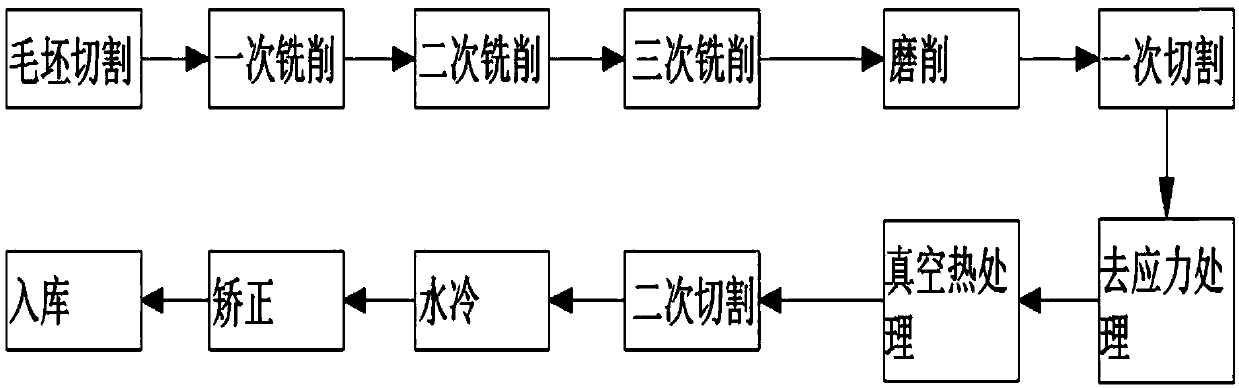

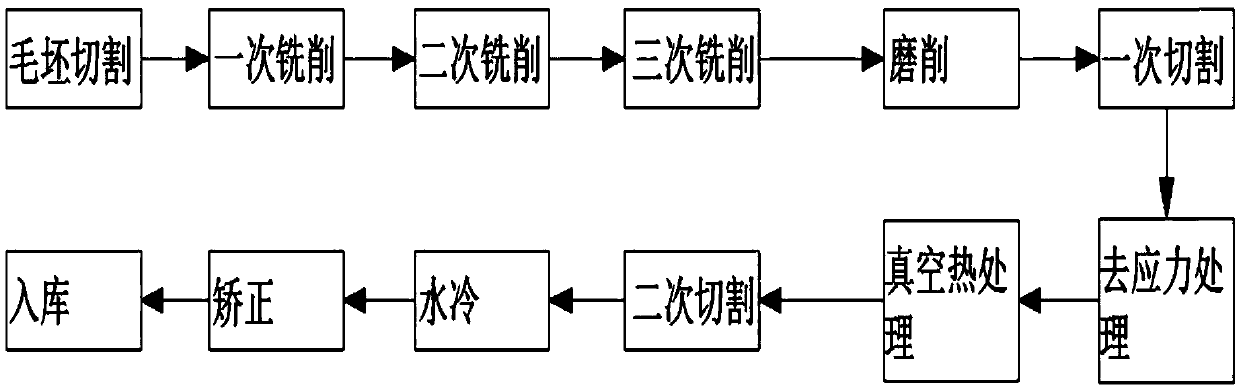

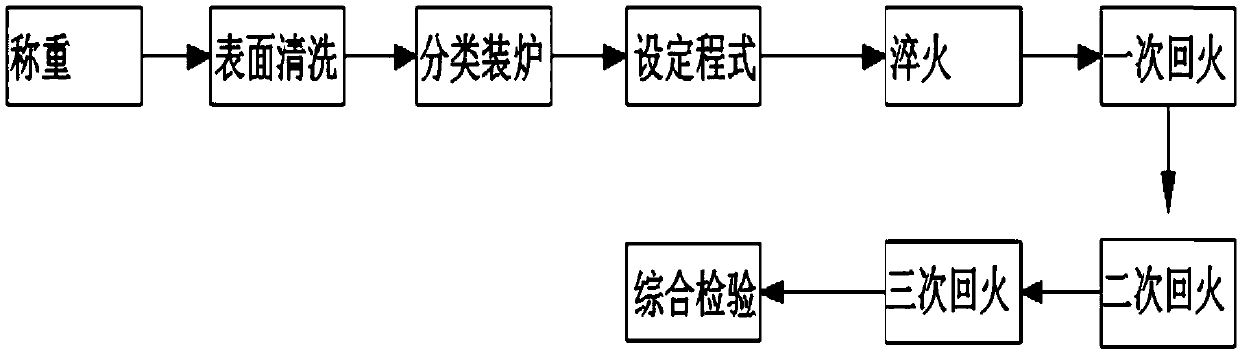

Die production technology

InactiveCN109628706AExtended service lifeNot easy to damageFurnace typesHeat treatment furnacesSurface cleaningCost Controls

The invention discloses a die production technology. The die production technology comprises the specific steps of blank cutting, milling, grinding, cutting, vacuum heat treatment, cutting, water cooling, straightening and storage. Milling is carried out in a milling machine. Grinding is carried out in a grinding machine. Cutting is carried out in a sawing machine. Straightening is carried out ina straightening machine. Vacuum heat treatment is carried out in a vacuum nitriding furnace, and comprises the specific steps of weighing, surface cleaning, classified furnace charging, program setting, quenching, tempering and comprehensive inspection. The die production technology is reasonable in production process, appropriate in cost control and high in percent of pass of products.

Owner:宁波久生模具科技有限公司

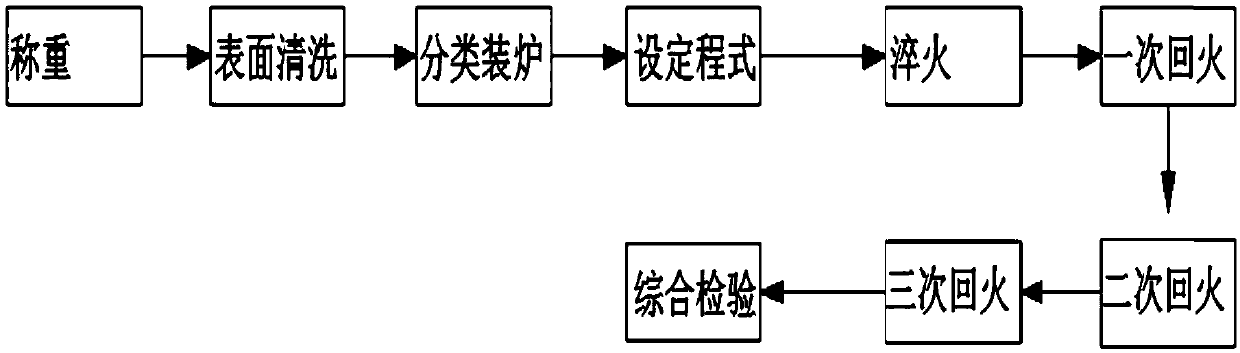

Novel mold manufacturing technology

InactiveCN109576452AExtended service lifeNot easy to damageFurnace typesHeat treatment furnacesManufacturing technologySurface cleaning

The invention discloses a novel mold manufacturing technology. The novel mold manufacturing technology comprises the steps of blank cutting, milling, grinding, cutting, stress relief treatment, vacuumheat treatment, cutting, water cooling, straightening and warehousing; according to the stress relief treatment step, specific steps of weighing, surface cleaning, inspecting and furnace charging tempering are included; milling is conducted through a milling machine, grinding is conducted through a grinding machine, cutting is conducted through a sawing machine, and straightening is conducted through a straightening machine; vacuum heat treatment is conducted through a vacuum nitriding furnace, and specific steps of weighing, surface cleaning, classification furnace charging, formula setting,quenching and tempering are included; after quenching, the hardness, deformation and appearance need to be checked; and after tempering, deformation and appearance are subjected to spot check. According to the novel mold manufacturing technology, the production process is reasonable, the cost is controlled properly, and the product percent of pass is high.

Owner:宁波久生模具科技有限公司

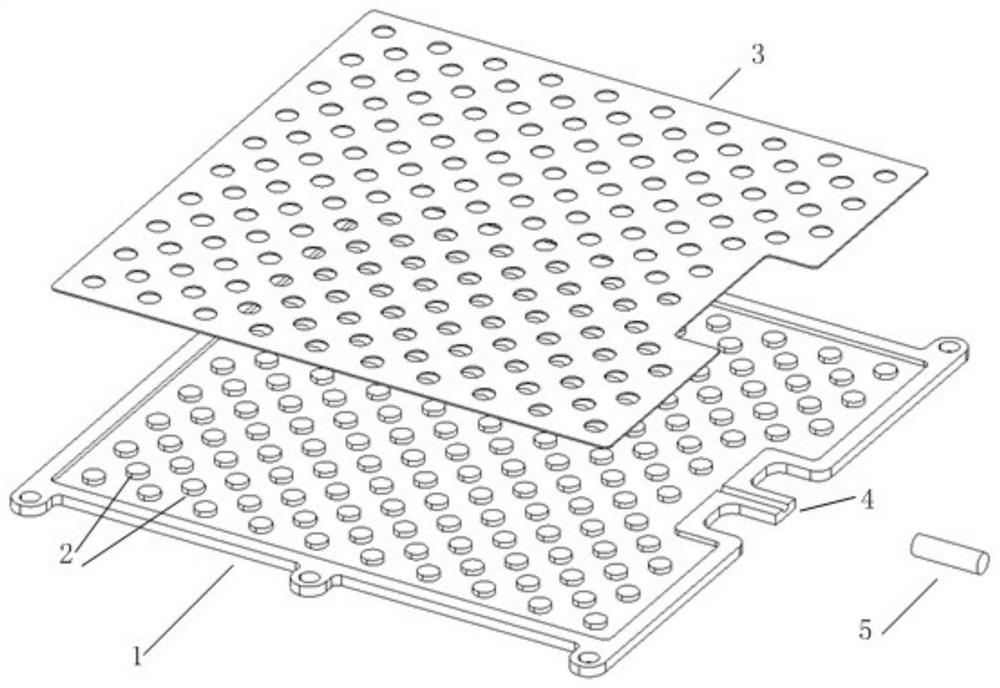

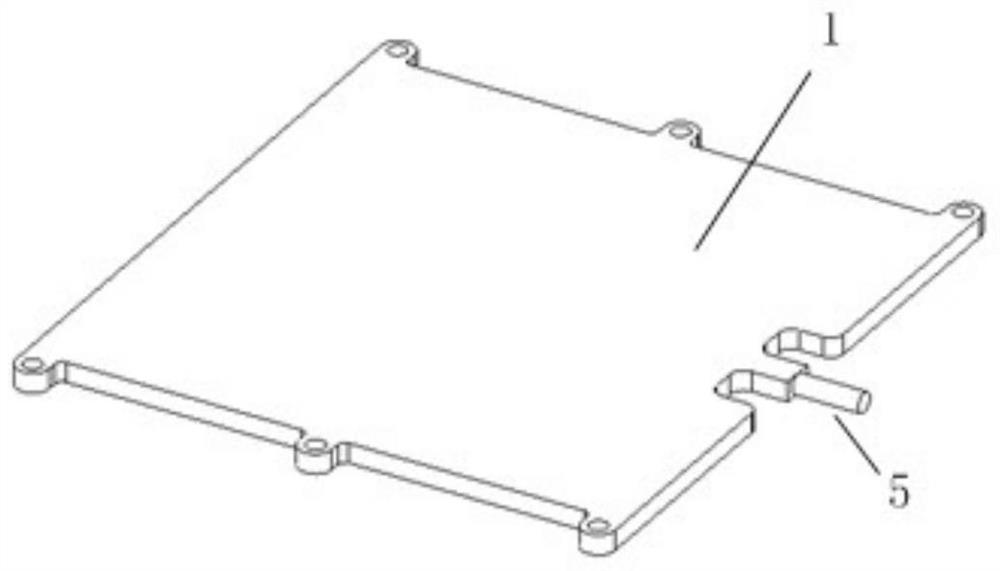

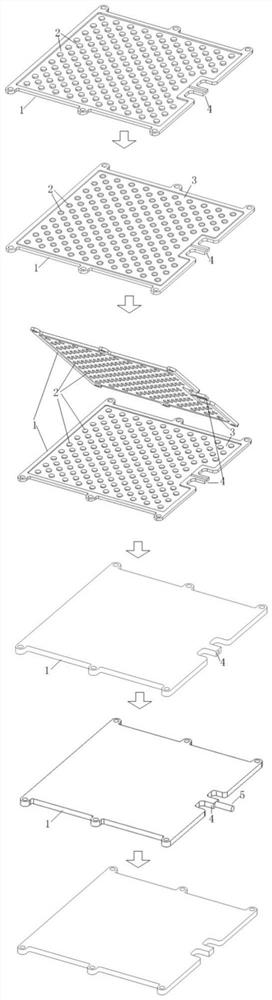

Flat heat pipe based on liquid absorbing core of composite structure, assembling method and electronic component

InactiveCN111928706AImprove heat transfer performanceReduce backflow resistanceIndirect heat exchangersHeat exchanger casingsEngineeringElectronic component

The invention provides a flat heat pipe based on a liquid absorbing core of a composite structure. The flat heat pipe comprises baseplates, the liquid absorbing core and a liquid filling pipe, whereinthe liquid absorbing core is arranged between the baseplates, and comprises supporting columns and foamed nickel components; the baseplates comprise an upper baseplate and a lower baseplate; the supporting columns are arranged on the upper baseplate and the lower baseplate; the foamed nickel components are matched with the inner wall surface structures of the baseplates; the liquid filling pipe is arranged between the upper baseplate and the lower baseplate; the interior of the flat heat pipe is filled with a working medium through the liquid filling pipe; and a channel where the working medium inside the flat heat pipe flows is jointly defined by the supporting columns and foamed nickel on the foamed nickel components. Through the adoption of the channel where the working medium inside the flat heat pipe flows and which is jointly defined by the supporting columns arranged in an array and the foamed nickel, the resistance to the backflow of the liquid working medium can be reduced when the capillary force is good, the flat heat pipe can achieve the better heat transfer property, and the reliability can be improved during the use of the flat heat pipe.

Owner:SHANGHAI SATELLITE ENG INST

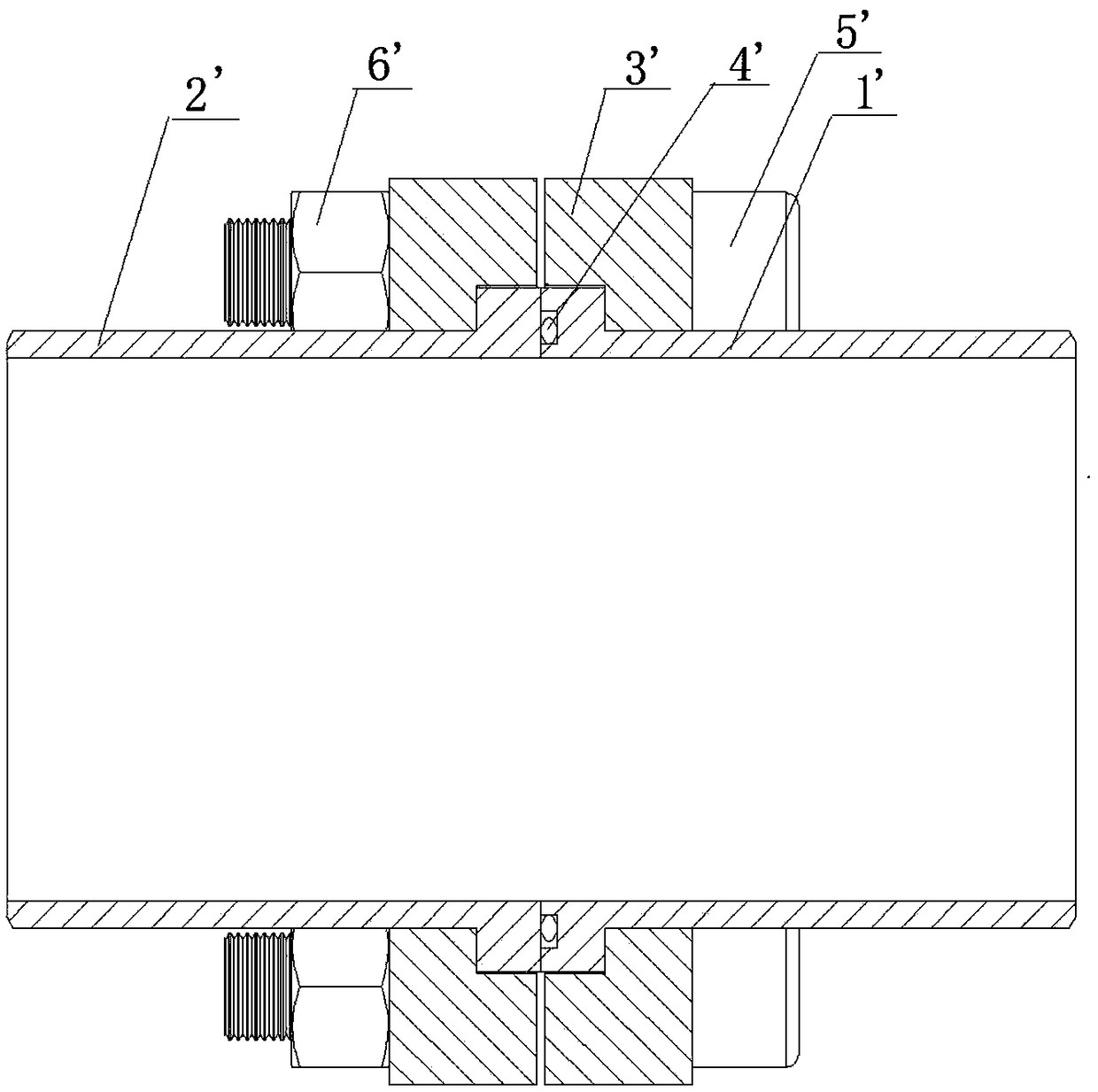

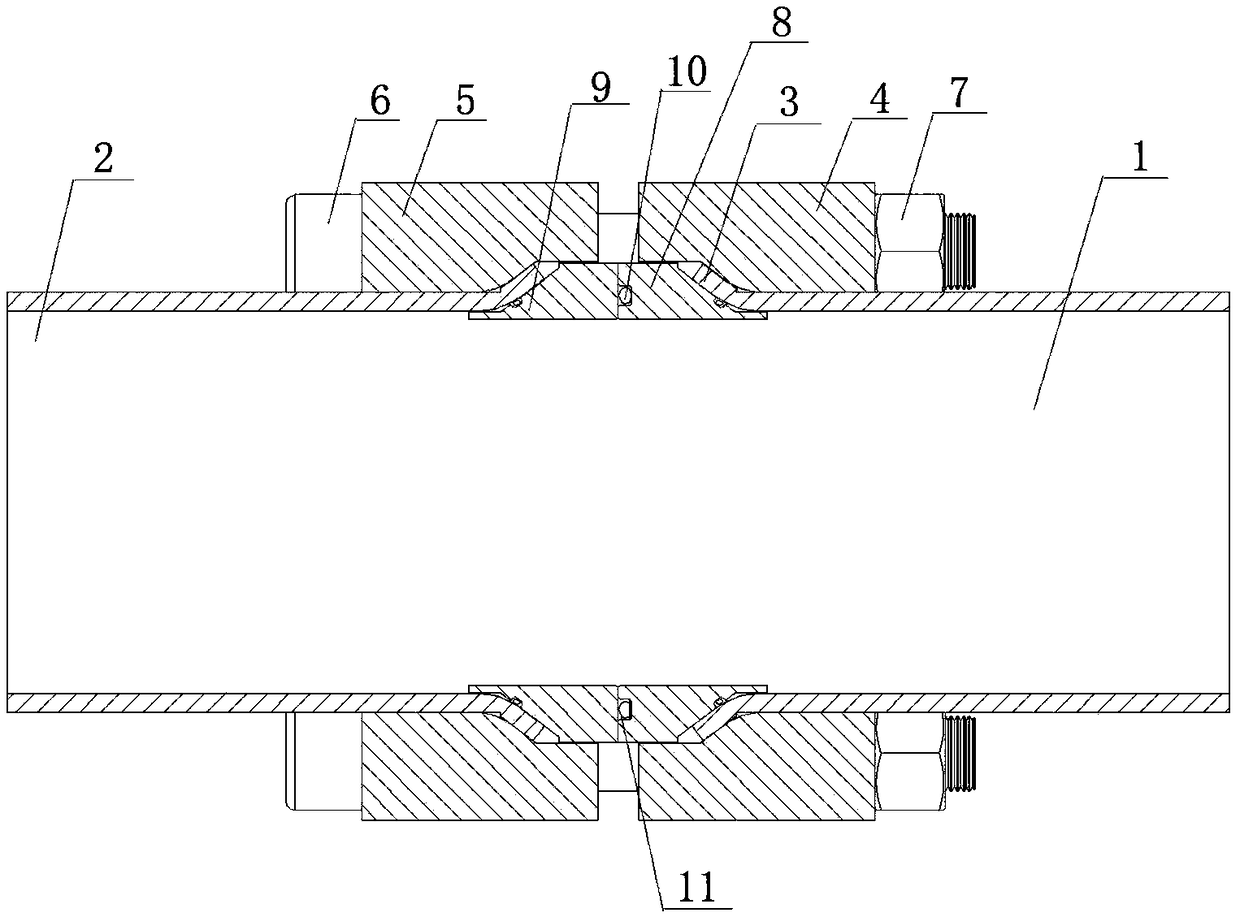

Flared flange pipe connecting system

The invention discloses a flared flange pipe connecting system. The flared flange pipe connecting system comprises two or more branch pipes. A conical flared opening is outwards formed in the end of each branch pipe. Every two adjacent branch pipes are connected through a connecting mechanism. Each connecting mechanism comprises a first flange, a second flange, a first seal conical body and a second seal conical body. The first seal conical bodies and the second seal conical bodies each comprise a conical section and a cylindrical section. The first flanges and the second flanges are arrangedon the different branch pipes. Each first flange is connected with the corresponding second flange through bolts and nuts. According to the flared flange pipe connecting system, spinning flaring is conducted on the end of each pipe through a flaring machine, so that the conical flared openings are formed; and by means of close matching of the first flanges, the second flanges, the first seal conical bodies, the second seal conical bodies, bolts and nuts, a safe and zero-leakage pipe system can be formed.

Owner:弗通流体科技(上海)有限公司

Silk screen aided laser soldering method for heterogeneous multi-layer structure

InactiveCN1159130CGuaranteed requirements for fatigue strengthEnsure proper heatingSoldering apparatusLaser beam welding apparatusMetallic materialsOptoelectronics

A wire screen aided laser soldering technology for making multi-layer heterogeneous composite side electrode of element includes coating soldering material on the side of element, putting metallic wire screen in the soldering material, heating by laser beams to fuse them, and cooling to form the side electrode of element. Its advantages include good connection between layers, local heating, no damage to element, high electrode strength, and high machining efficiency.

Owner:TSINGHUA UNIV

Differential connector with special-shaped conductive structure and manufacturing method of differential connector

PendingCN110247223AEasy to processReduce processing costsLine/current collector detailsCoupling contact membersDifferential signalingConductive coating

The invention discloses a differential connector with a special-shaped conductive structure and a manufacturing method of the differential connector. The differential connector comprises a mounting mechanism, a plurality of groups of differential conductive parts are installed in the mounting mechanism, and each differential conductive part comprises grounding sheets and differential signal sheets. A protection structure is mounted outside the mounting mechanism. The inner wall of the protection structure is provided with continuous and compact conductive coatings. The differential signal sheets and the conductive coatings are arranged at intervals, the grounding sheets are electrically connected with the conductive coatings, and the conductive coatings are used for forming a continuous anti-crosstalk structure outside the differential signal sheets. The outer protective layer of the differential connector is manufactured by adopting a mode of spraying the conductive coatings, and the differential connector can be processed into any shape and size, so that the processing cost of the differential connector is lower, and the processing is more convenient.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

3-D machining method of micromechanical parts

InactiveCN1279414CWide range of choicesRealize processingComputer controlSimulator controlGraphicsEngineering

The invention relates to a three-dimensional processing method of a micromechanical part, which belongs to an ultra-precision processing method. Many existing processing methods of micro-mechanical parts have the disadvantages of only processing quasi-three-dimensional structures. Both methods of the present invention need to be realized in combination with the existing three-dimensional processing device for micromechanical parts: set the working parameters of the scanning probe microscope in sequence, place the sample on the three-dimensional workbench, and start by controlling the X and Y direction movement of the workbench Process the first graphic; when the first graphic is processed, the probe is raised, and the workbench moves two-dimensionally to process the next graphic until all the graphics are processed. Another method is that the three-dimensional workbench moves in the X, Y, and Z directions according to the preset value. After processing all the graphics at one time, the probe is lifted by scanning the pottery tube for contraction movement, and the processing is completed. The method of the invention can carry out real three-dimensional processing, the removal amount is at the nanometer level, and the damage to the surface is very small, and it can be applied to the manufacture of MEMS devices, masks and tiny molds.

Owner:HARBIN INST OF TECH

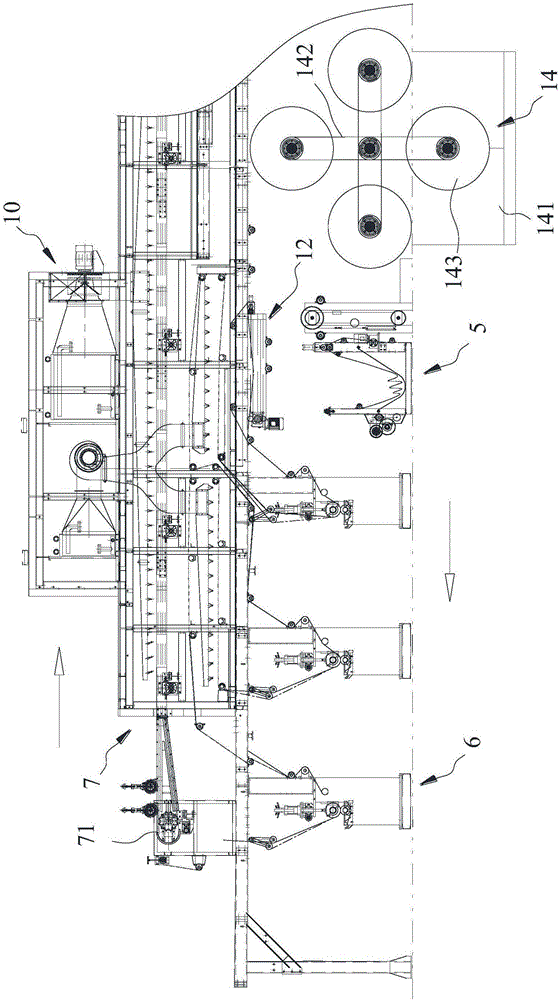

Integrated processing device of synthetic leather

InactiveCN106521979AIncrease productivityFast processingTextiles and paperEngineeringIntegrated processing

The invention discloses an integrated processing device of synthetic leather. The device comprises an unwinding mechanism, a cloth storage rack, a first printing component, a second printing component, a widening mechanism, a cooling mechanism and a winding mechanism sequentially connected along the cloth conveying direction, wherein the unwinding mechanism is used for delivering the to-be-processed cloth; the cloth storage rack is used for carding and temporarily storing the to-be-processed cloth; the first printing component is used for dyeing printing; the second printing component is used for sizing material printing; the widening mechanism is used for widening the cloth; the cooling mechanism is used for cooling the synthetic leather; the winding mechanism is used for winding a finished product of synthetic leather; and the integrated processing device of synthetic leather also comprises an inter-plate dryer and a widening setting dryer arranged above the widening mechanism. In the invention, the processing speed of synthetic leather can be increased, and the transfer loss is reduced.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

Processing method of ginkgo puffing powder

ActiveCN109674009AImprove stabilityEnhance efficacy valueGaseous food ingredientsFood shapingQuality performancePre treatment

The invention discloses a processing method of ginkgo puffing powder. Fruit nuts are used as main raw materials to be sequentially subjected to pretreatment, drying crushing, ammonium bicarbonate addition, ginkgo leaf ethanol extract and citric acid proportioning, water preparation, extrusion puffing, hot air drying and crushing and cooling operation. The stability of active substances in a product can be effectively improved; the ginkgolic acid is degraded to a great degree; the quality performance and the safety level of the obtained product are greatly improved; the nutrition value of the product is high; the powder particles are uniform; the product has luster; the special fragrance of ginkgo fruit is realized; the brewing and eating are convenient; the taste is pure, fine and smooth;the digestive absorption is easy; in addition, the production efficiency of the method is high; the cost is low; the waste is little; no waste materials exist.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com