Aluminum alloy material capable of being anodized and suitable for semi-solid forming and preparing method of aluminum alloy material

A technology of semi-solid forming and aluminum alloy materials, applied in the field of aluminum alloy materials, can solve the problems of less than optimal contribution effect of mechanical properties, difficult control of die-casting process, high alloy Si content, etc., to achieve good semi-solid forming performance and excellent processing Ease of control and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

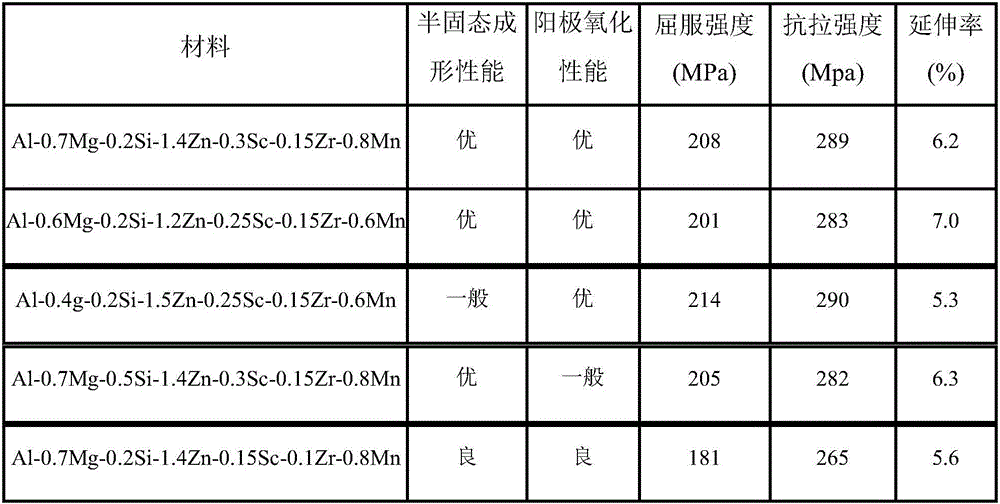

Examples

Embodiment 1

[0036] The composition elements of the aluminum alloy material are: Mg0.7wt%, Si0.2wt%, Zn1.4wt%, Sc0.3wt%, Zr0.15wt%, Mn0.8wt%, and other impurity elements content ≤ 0.1wt% , and the rest is aluminum Al.

[0037] After preparing and drying the materials according to the components, put the aluminum ingots with a purity ≥99.9% in a melting furnace to melt them. The temperature of the molten aluminum is 660°C to 670°C. Add pure Mg ingots, pure Zn ingots, Al- 20% Si master alloy, Al-2% Sc master alloy, Al-5% Zr master alloy, Al-10% Mn master alloy, after the alloy is melted, the temperature is raised to 730°C for full stirring, and then standing for 15 minutes for refining at 720°C Degassing and slag removal. After standing for 20 minutes, cool the melt to 655°C and keep it warm. Take out the required aluminum liquid with a cylindrical spoon with paint on the inner surface and place it in a semi-solid electromagnetic stirring device. After stirring for 15s, make a semi-solid sl...

Embodiment 2

[0039] The composition elements of the aluminum alloy material are: Mg0.6wt%, Si0.2wt%, Zn1.2wt%, Sc0.25wt%, Zr0.15wt%, Mn0.6wt%, other impurity element content ≤ 0.1wt% , and the rest is aluminum Al.

[0040] After preparing and drying the materials according to the components, put the aluminum ingots with a purity ≥99.9% in a melting furnace to melt them. The temperature of the molten aluminum is 660°C to 670°C. Add pure Mg ingots, pure Zn ingots, Al- 20% Si master alloy, Al-2% Sc master alloy, Al-5% Zr master alloy, Al-10% Mn master alloy, after the alloy is melted, the temperature is raised to 730°C for full stirring, and then standing for 15 minutes for refining at 720°C Degassing and slag removal. After standing for 20 minutes, cool the melt to 655°C and keep it warm. Take out the required aluminum liquid with a cylindrical spoon with paint on the inner surface and place it in a semi-solid electromagnetic stirring device. After stirring for 15s, make a semi-solid slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com