Aluminium alloy cable

An aluminum alloy and aluminum alloy wire technology, applied in the manufacture of insulated cables, cables, cables/conductors, etc., can solve the problem of lack of halogen-free low-smoke flame retardant and fire-resistant properties, conductor compaction, annealing technology failure, electrical conductivity and resistance Failure to meet the standard and other problems to achieve the effect of avoiding fire accidents, not easy to breakdown, avoiding corrosion and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

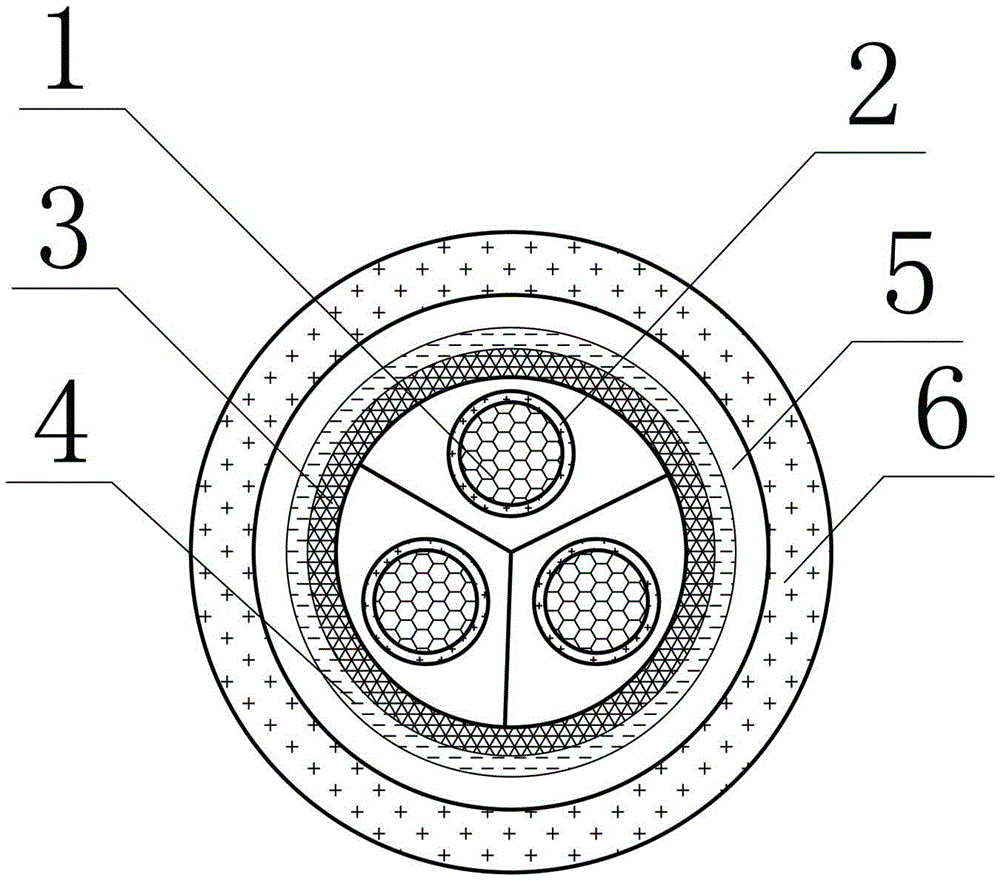

[0017] like figure 1 As shown, an aluminum alloy cable includes an aluminum alloy wire bundle 1 distributed sequentially from the inside to the outside, a cross-linked polyethylene insulating layer 2, a basalt fiber cloth tape heat-insulating and flame-retardant reinforcing layer 3, and a wrinkled aluminum alloy sheath layer 4 , asphalt coating 5, low-smoke halogen-free flame-retardant sheath layer 6, wherein, the cross-linked polyethylene insulating layer 2 is wrapped on the aluminum alloy conductor bundle 1 to form an insulated wire core; the insulated wire core The basalt fiber cloth is wrapped with a heat-insulating and flame-retardant reinforcing layer 3, and the basalt fiber cloth is wrapped with a heat-insulating and flame-retardant reinforcing layer 3, and the wrinkled aluminum alloy sheath layer coated with the asphalt coating 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com