Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122results about How to "Stable reaction conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

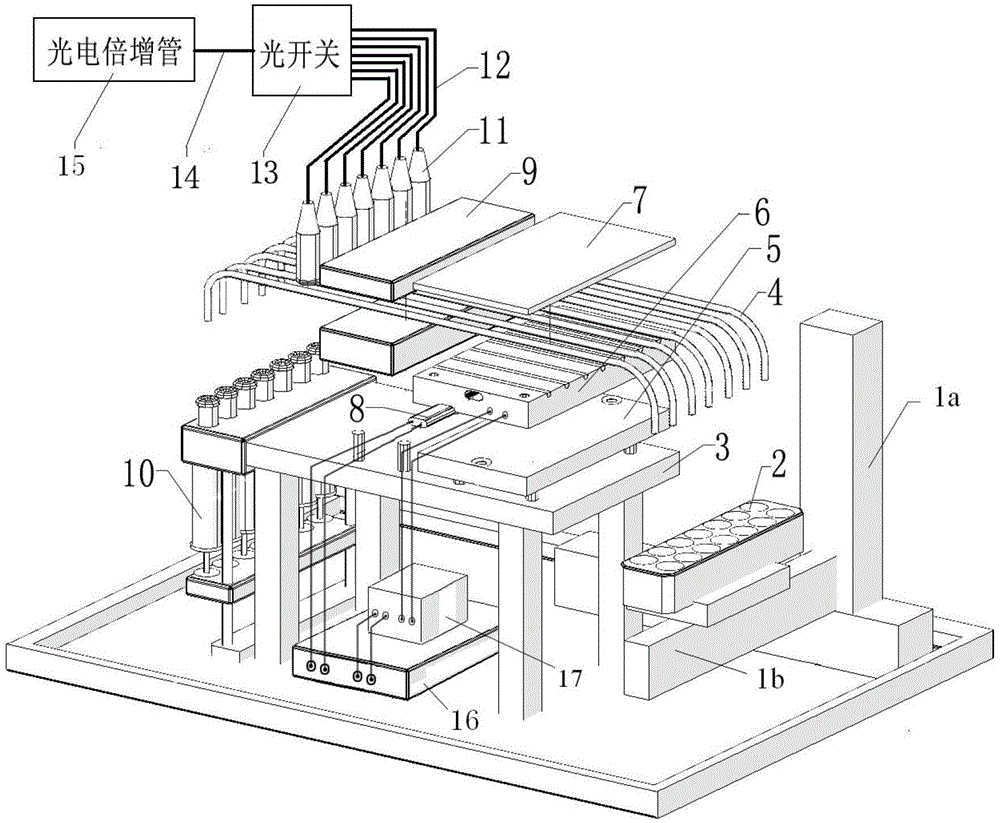

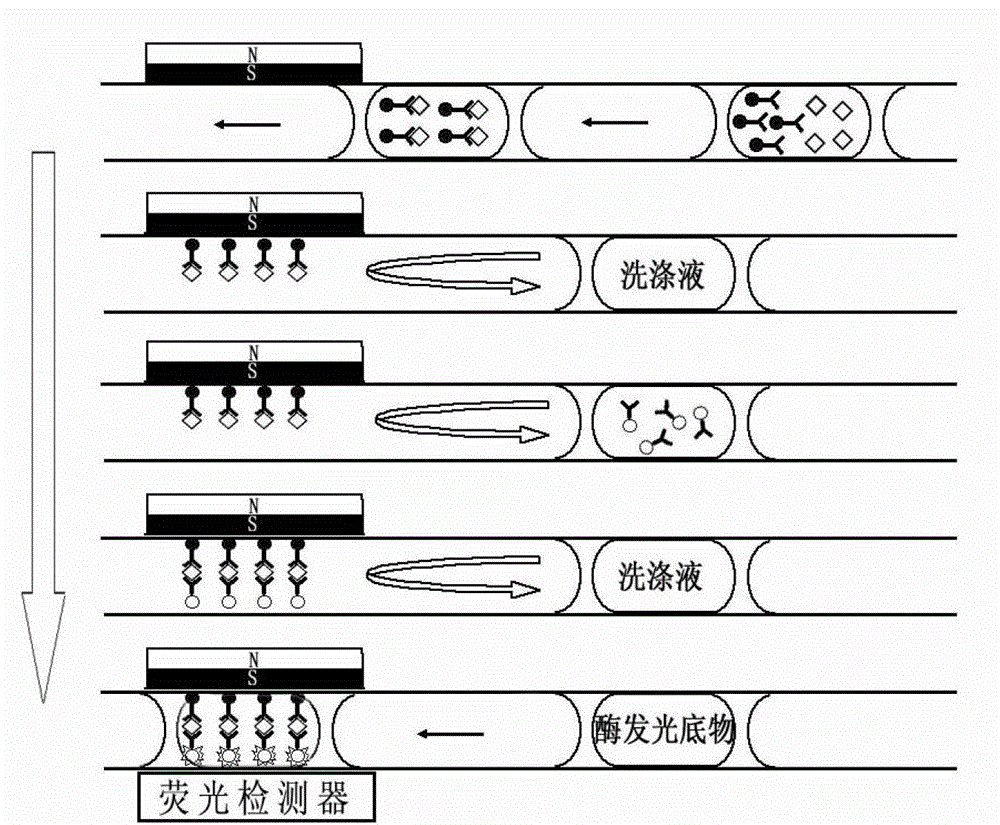

Chemiluminescence immunoassay system, as well as method and application thereof

ActiveCN102980996AReduce volumeFast analysisChemiluminescene/bioluminescenceFluid controlEngineering

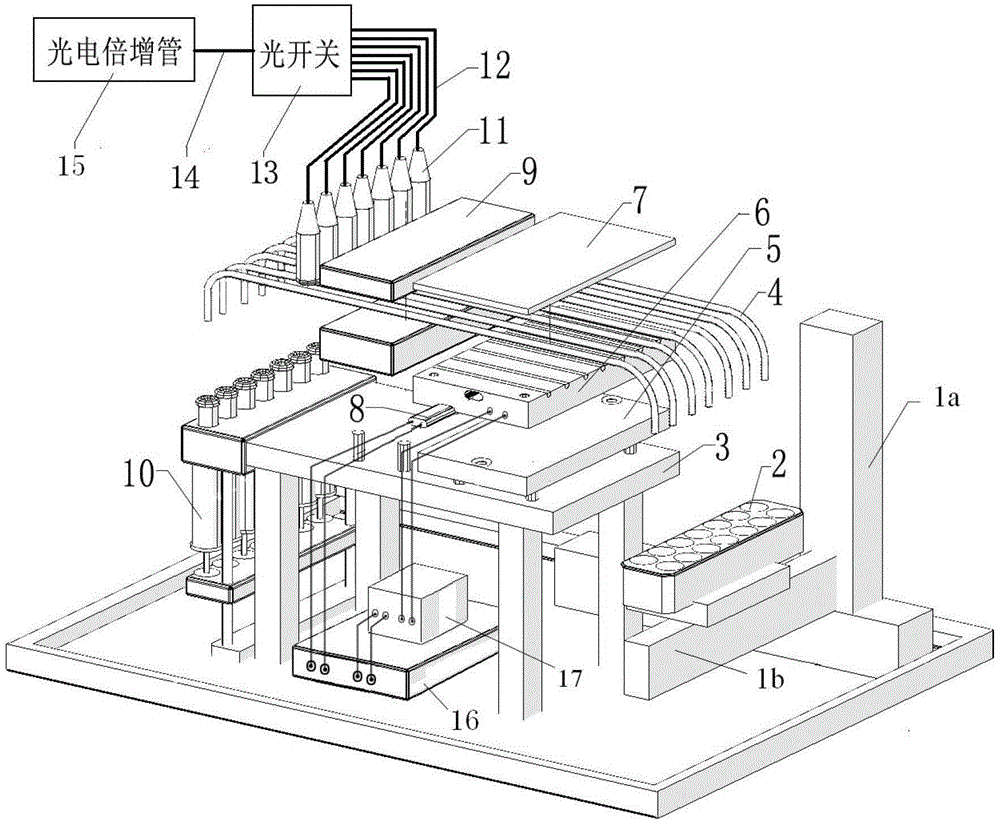

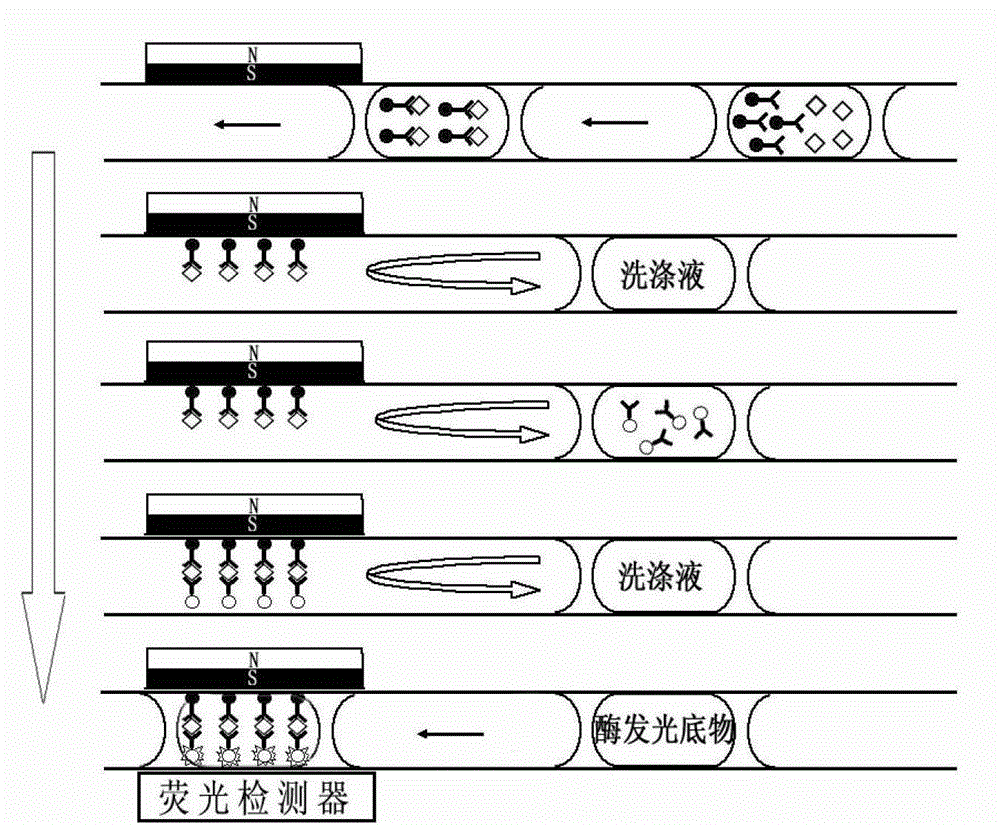

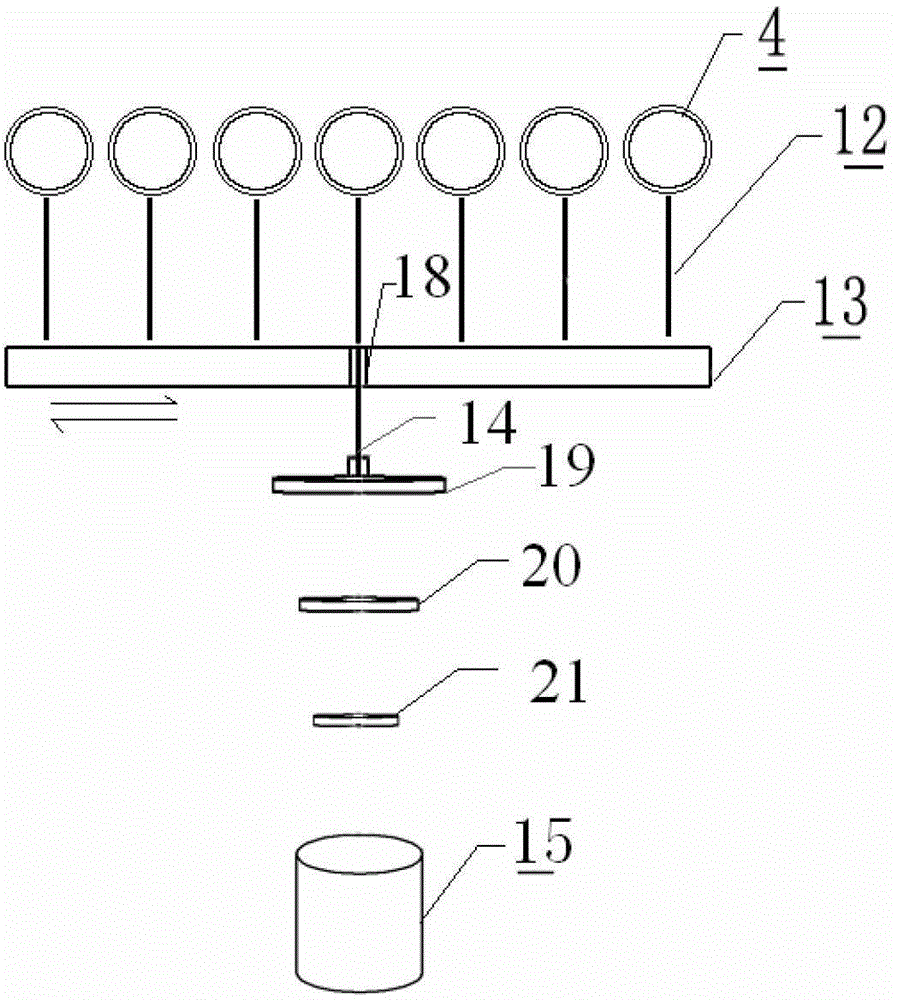

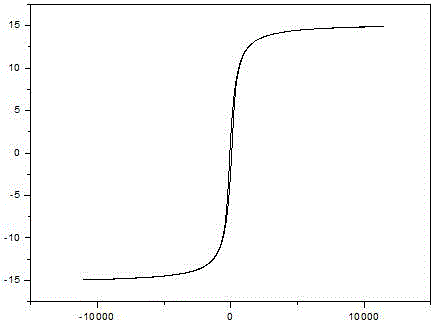

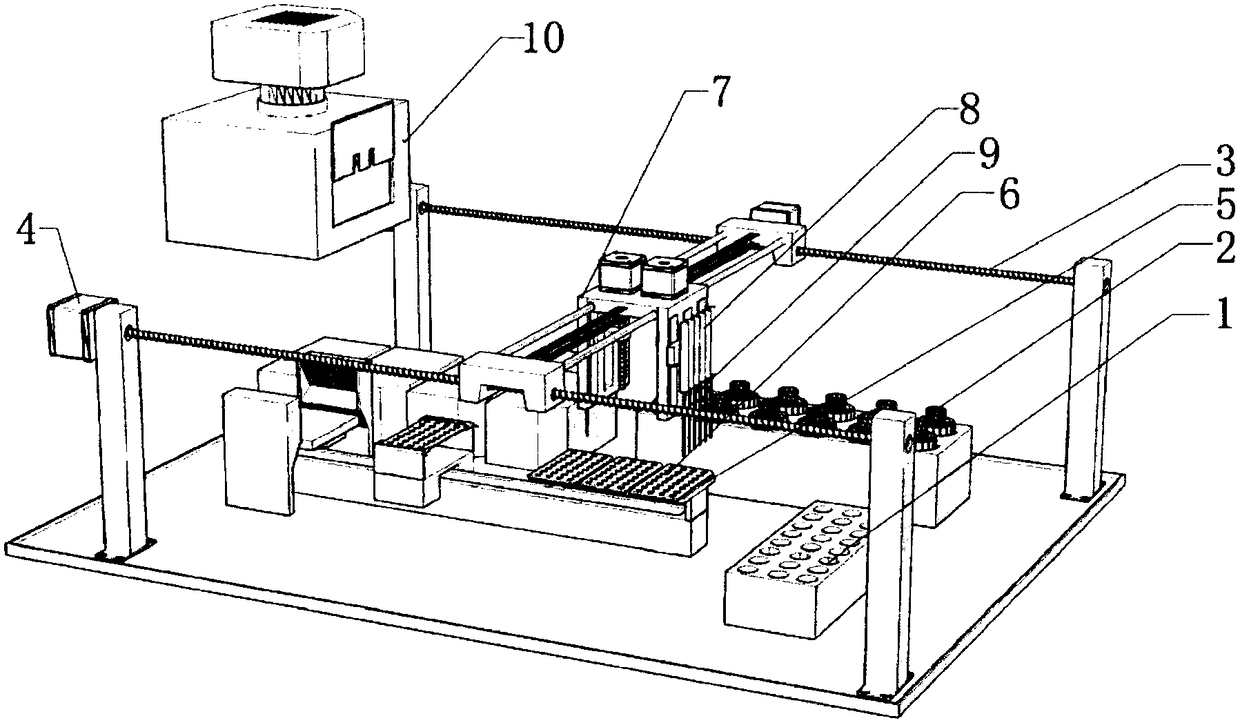

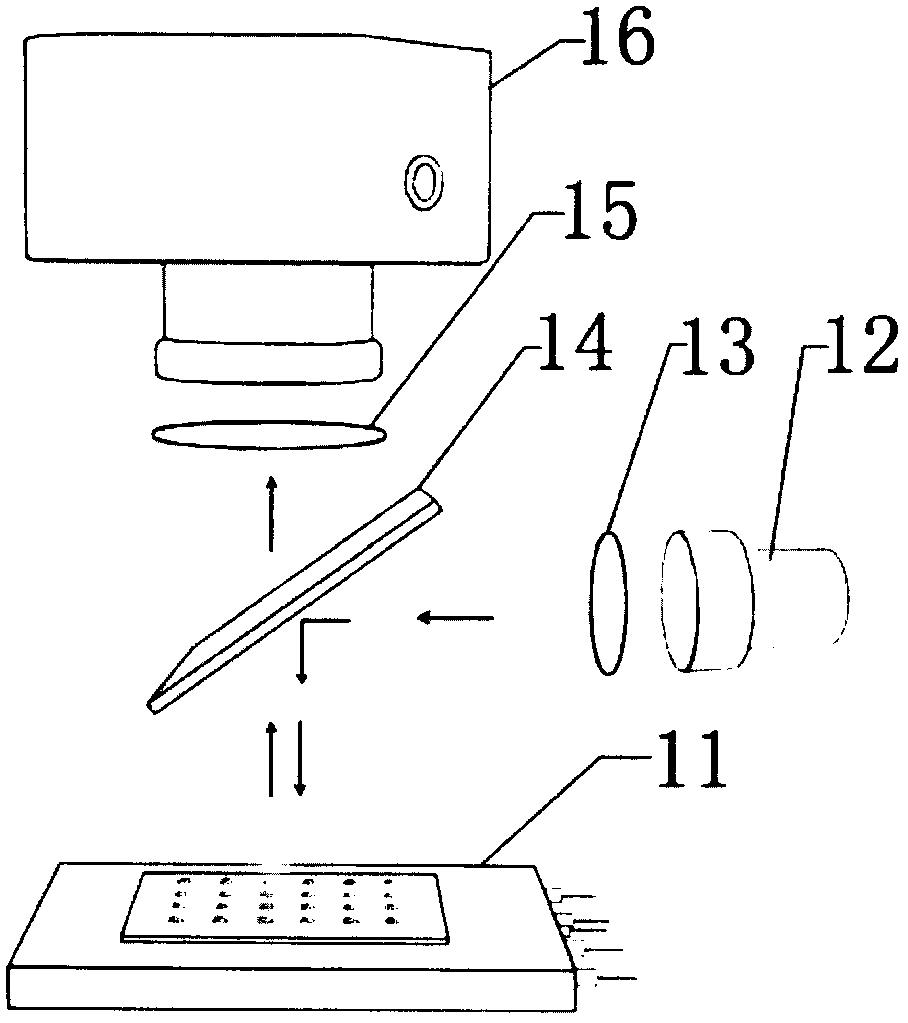

The invention discloses a chemiluminescence immunoassay system, as well as a method and an application thereof. The chemiluminescence immunoassay system comprises a fluid control unit as well as a three-dimensional motion sample feeding platform, a temperature control unit, a magnetic field control module and an optical detecting module, wherein the three-dimensional motion sample feeding platform, the temperature control unit, the magnetic field control module and the optical detecting module are connected with each other in sequence; and the fluid control unit is connected with the temperature control unit. The chemiluminescence immunoassay system disclosed by the invention has the advantages as follows: with a capillary tube as a reactor, reagent transportation and reaction are both carried out in a water-in-oil type liquid drop by using a capillary tube liquid drop technology, so that a stable reaction condition is kept, and crossed pollution between samples and reaction suppression caused by surface adsorption are effectively avoided. The chemiluminescence immunoassay system disclosed by the invention has the advantages of small size, high assay speed, high testing flux, automatic operation and flexibility in application and is suitable for analyzing single sample, batch samples and field rapid assay; medical demands of the masses can be preferably satisfied; meanwhile, the purchasing and operation cost of equipment is obviously reduced, and excellent social and economic benefits are obtained.

Owner:GUANGDONG HEXIN BIOTECH

Capillary bioanalysis system, and analytical method and applications thereof

ActiveCN103409317AReduce volumeFast analysisBioreactor/fermenter combinationsBiological substance pretreatmentsFluid controlMedical equipment

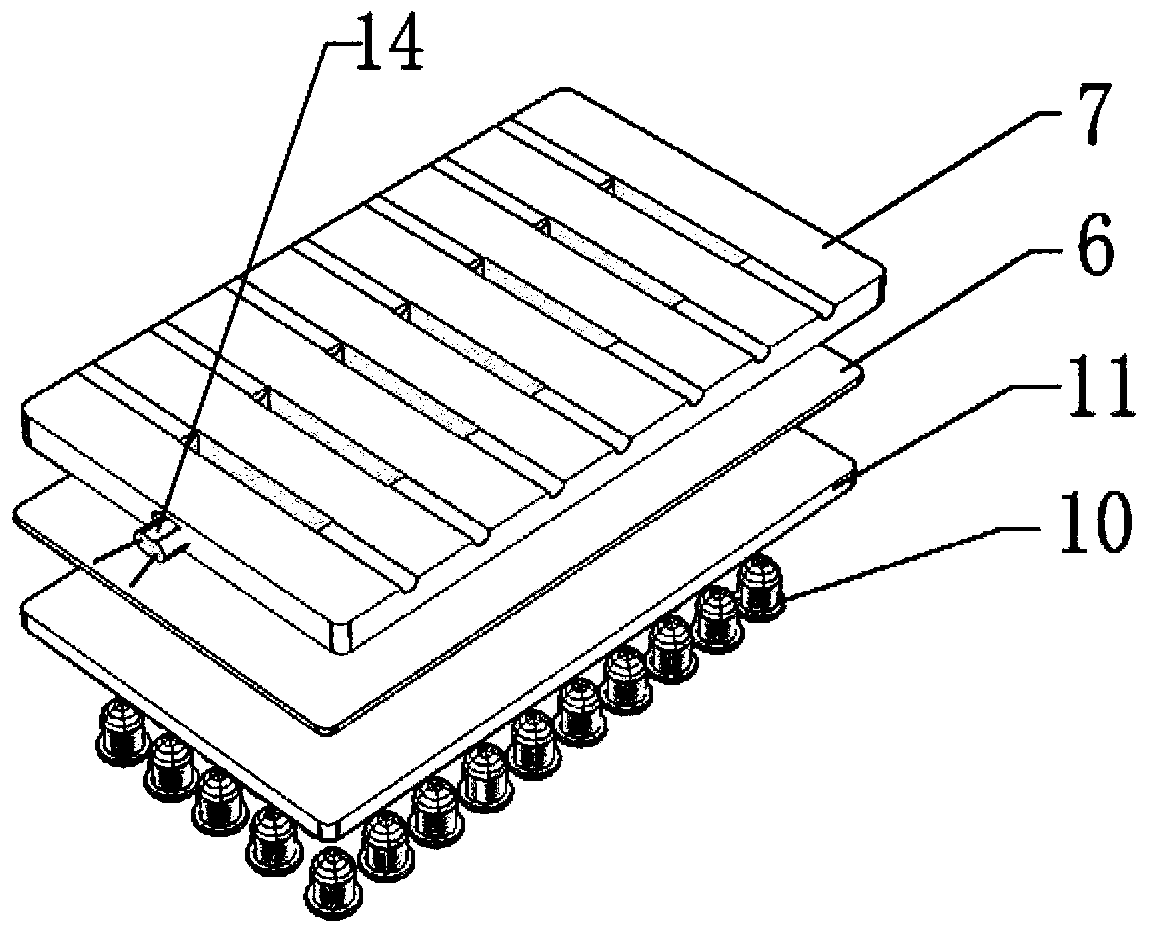

The invention discloses a capillary bioanalysis system, and an analytical method and applications thereof, and belongs to the field of medical equipment and biological detection technologies. The capillary bioanalysis system comprises a three-dimensional movement sample injecting platform, a temperature control-optical detection module, a magnetic field control module, a fluid control unit and a capillary array. The three-dimensional movement sample injecting platform and the fluid control unit are arranged on the two sides of the capillary array, and the capillary array is provided with the temperature control-optical detection module and the magnetic field control module. According to the capillary bioanalysis system, the droplet technology and the magnetic bead technology are combined, and bioanalysis processes such as loop-mediated isothermal amplification, fluorescence quantitative PCR analysis and immunochemiluminometry are integrated in capillaries. Advantages of the capillary bioanalysis system are that: volume is small, analysis speed is fast, detecting flux is large, and automation degree of operation is high. The capillary bioanalysis system is flexible in application, is suitable for analysis of single sample, batches of samples and on-site rapid detection, is capable of reducing acquisition cost and operation cost of equipment significantly, and possesses excellent economic benefits.

Owner:广州市第一人民医院

Preparation method and application of mild reaction type aldehyde ketone resin

ActiveCN103333302AReduce volatilityOvercoming the disadvantage of being prone to bumpingBuilding insulationsEpoxyKetone

The invention discloses a preparation method of mild reaction type aldehyde ketone resin. The mild reaction type aldehyde ketone resin is prepared by adding a quantitative superbase catalyst into mixed liquid of aldehyde and ketone compounds under the condition of stirring at normal temperature, wherein the reaction process is mild and stable, so the defect that the traditional furfuraldehyde acetone system is easy to implode is overcome. The invention also discloses an application of the mild reaction type aldehyde ketone resin to preparation of an aldehyde ketone resin modified epoxy grouting material. The prepared grouting material can completely exert the flexibility of the aldehyde ketone resin, solves the problem that epoxy resin has high brittleness, can further improve excellent mechanical properties, adhesive property, ageing resistance and corrosion resistance of the epoxy resin, and also has the characteristics of low toxicity, environmental friendliness and the like. In addition, according to the preparation method, the aldehyde ketone resin is prepared in advance and has higher viscosity and thixotropism when being used together with fillers, so the construction process is simple and the aldehyde ketone resin can be applied to concrete surface corrosion of basic facilities such as bridges and ports, restoration of cultural relic, water and seepage prevention, reinforcement and strengthening of buildings and the like.

Owner:东莞微积分新材料科技有限公司

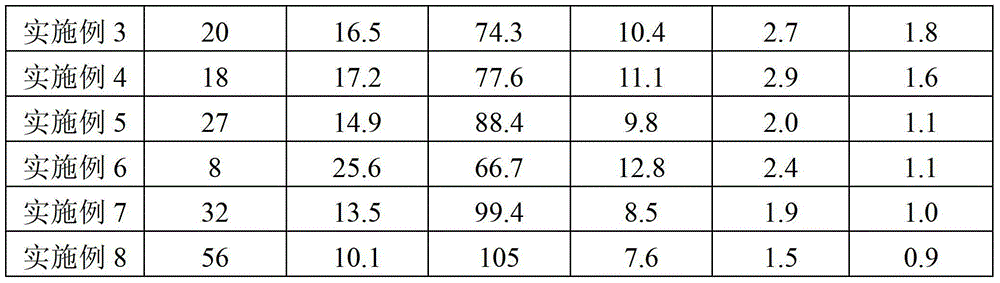

Polyacrylonitrile copolymer spinning solution and preparation method thereof

ActiveCN103421141AImprove the forceEnhanced mass transferFibre chemical featuresSpinning solutions preparationPolymer scienceAcrylonitrile

The invention relates to a polyacrylonitrile copolymer spinning solution and a preparation method thereof. In the invention, copolymerization reaction is performed on acrylonitrile in a tubular reactor containing a static mixer component; the tubular reactor, which contains the static mixer component and has the characteristics of mass transfer, efficient heat transfer, continuous and stable reaction and no mechanical stirring, is adopted to prepare the polyacrylonitrile copolymer spinning solution with high molecular weight and narrow molecular weight distribution. The polyacrylonitrile copolymer spinning solution is obtained after copolymerization reaction is performed on reaction liquid composed of monomers, a radical initiator and a solvent, wherein the percent concentration by weight of the monomers in the reaction liquid is 15% to 20%; the weight of the radical initiator is 0.4% to 1% of that of the monomers; the solvent is in balancing amount; the monomers are an acrylonitrile monomer and a comonomer. The dynamic viscosity of the polyacrylonitrile copolymer spinning solution provided by the invention is 200 to 800 Pa.S, and the molecular weight distribution is 1.5 to 2.6.

Owner:INST OF CHEM CHINESE ACAD OF SCI

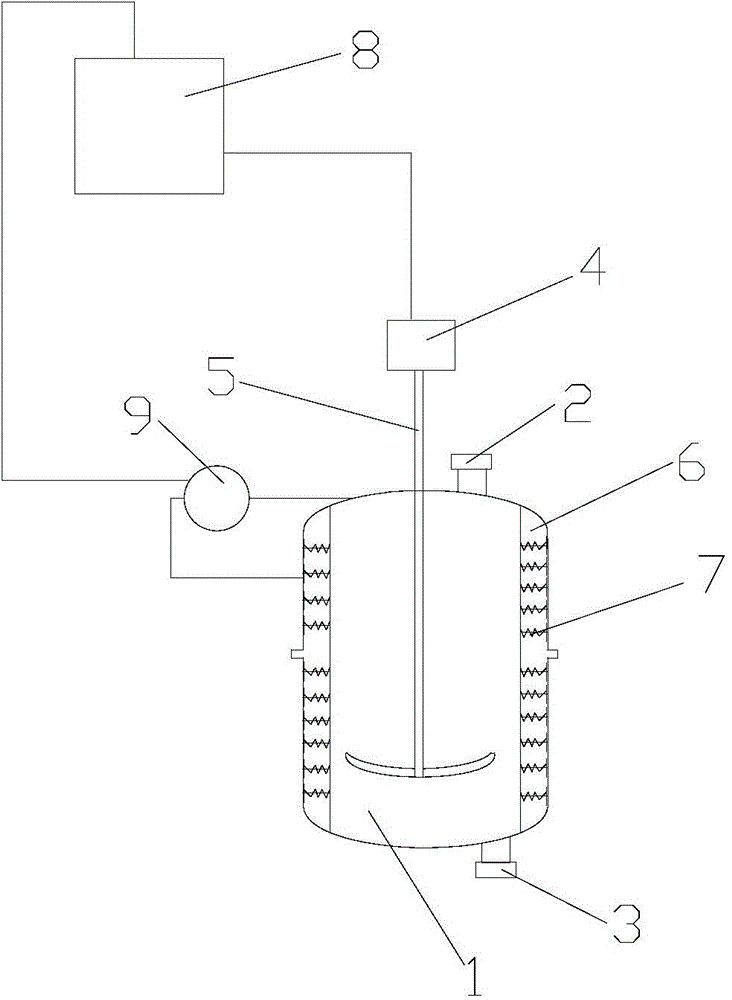

Variable frequency control reactor

InactiveCN104368298AGood effectStable reaction conditionsProcess control/regulationMixer accessoriesVariable frequency controlElectricity

The invention discloses a variable frequency control reactor comprising a reactor body comprising an upper portion and a lower portion. The top of the upper portion is provided with a feed opening; the bottom of the lower portion is provided with a discharge opening. The variable frequency control reactor further comprises a mixing motor and a mixing device; the mixing motor is disposed over the reactor body; the mixing device is connected with the mixing motor; the mixing motor is electrically connected with the output end of a variable frequency controller. The reactor body is further provided with a pipeline provided with a pressure sensor; the output end of the pressure sensor is electrically connected with the input end of the variable frequency controller. In the case that interior pressure of the reactor is too high, the pressure sensor generates semiconductor deforming pressure on the surface of a sheet; the sheet is deformed by the external force (pressure) to generate piezoelectric impedance, thus changes in the impedance are converted into electrical signals transmitted to the variable frequency controller. The variable frequency controller controls the speed of the motor according to a set pressure output frequency; the motor controls the mixing speed, stabilizing reaction conditions.

Owner:JIANGSU NEW MATERIALS SCI & TECH

Method for preparing natural vanillin by utilizing eugenol

InactiveCN103641698ASmooth responseStable reaction conditionsOrganic compound preparationCarbonyl compound preparation by oxidationFlavorIsoeugenol

The invention discloses a method for preparing natural vanillin by utilizing eugenol. The method comprises the following steps of preparing isoeugenol sylvine, preparing an intermediate product vanillin sylvine, and preparing and purifying the target product vanillin. The reaction is stable, the condition is more moderate compared with the traditional process, the yield is higher, the product quality is better, edible spice is widely used for the strong milky fragrance of the target product, the mass production is easy to realize, and the pollution is little in the production process.

Owner:EAST CHINA UNIV OF TECH +1

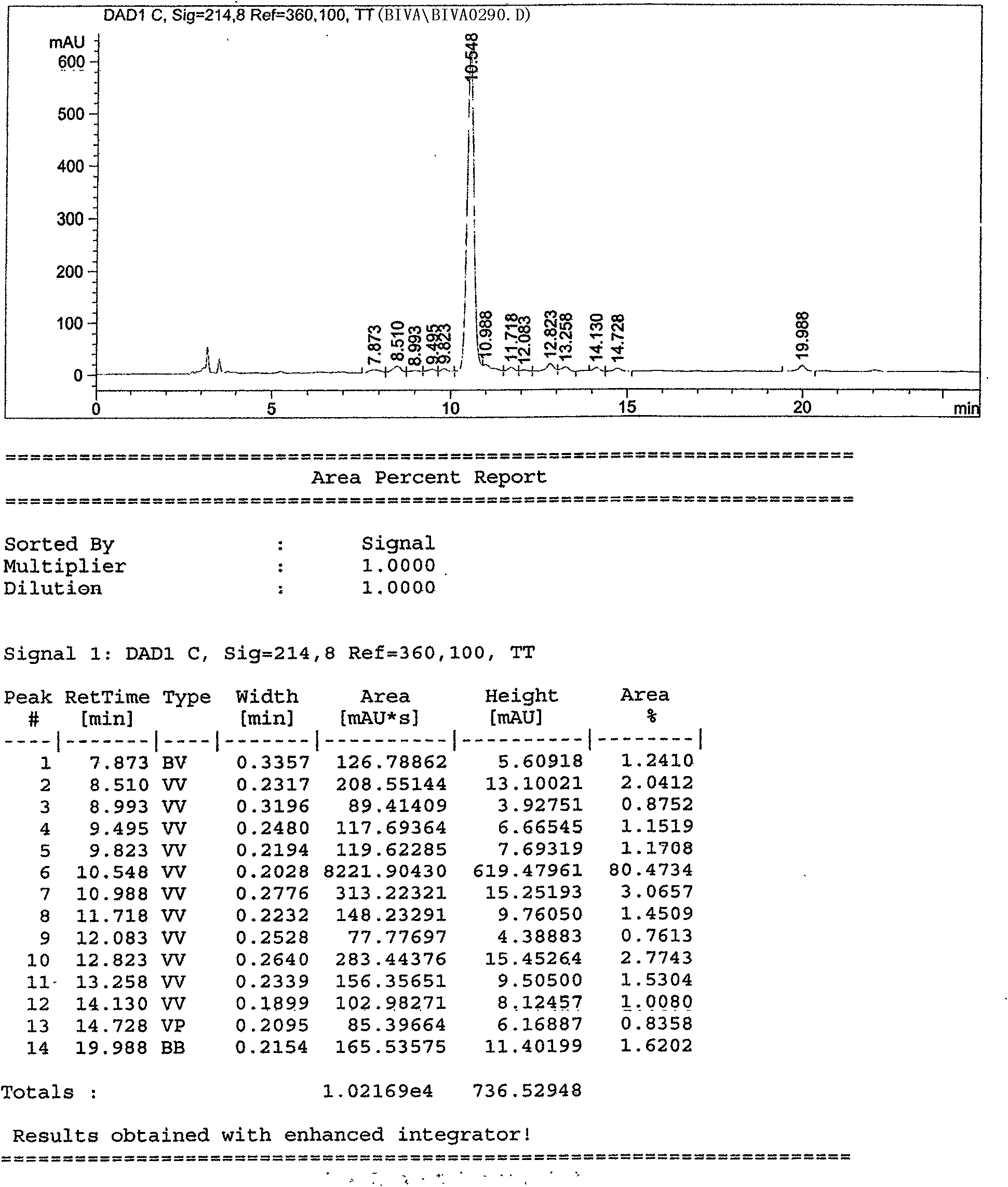

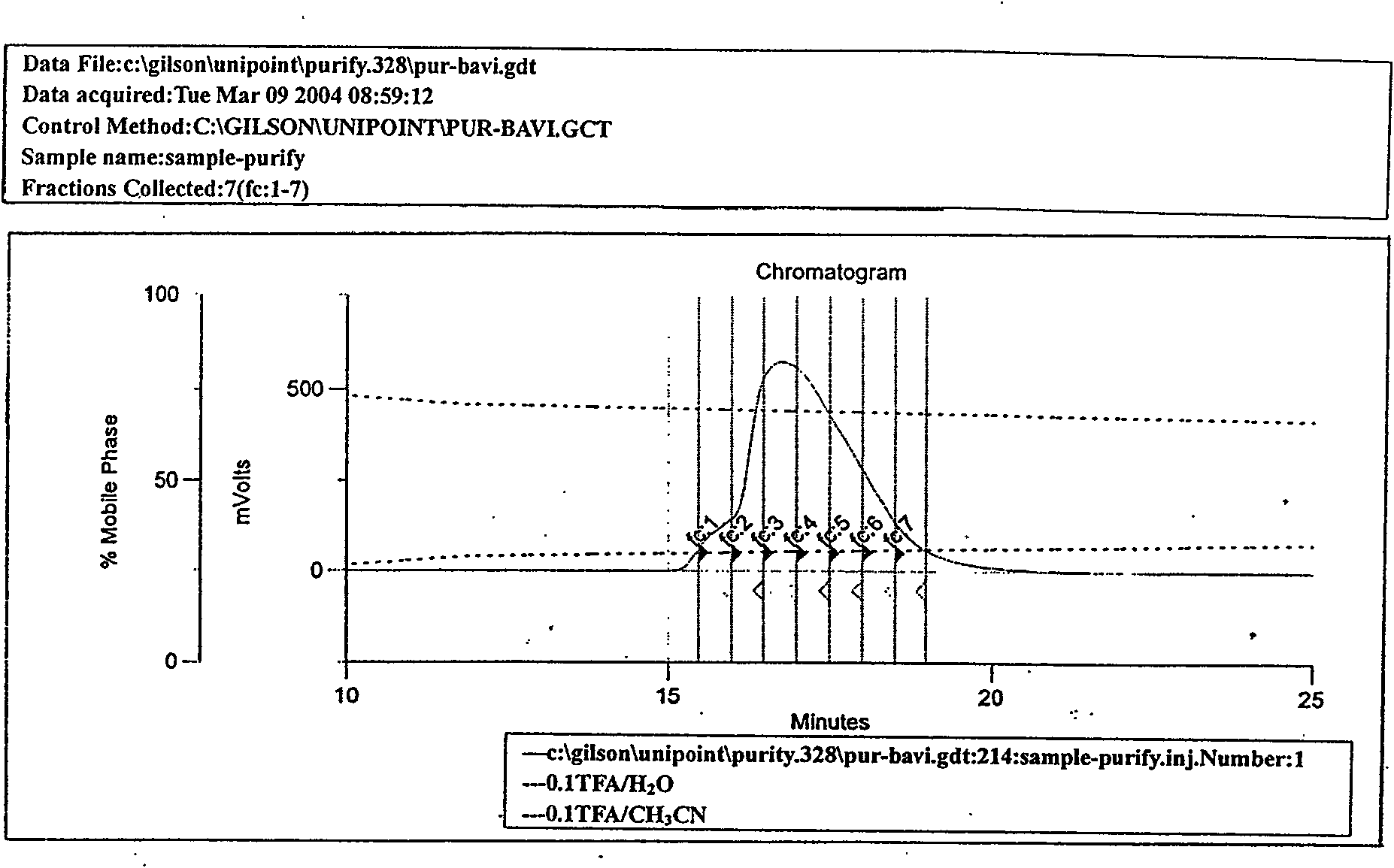

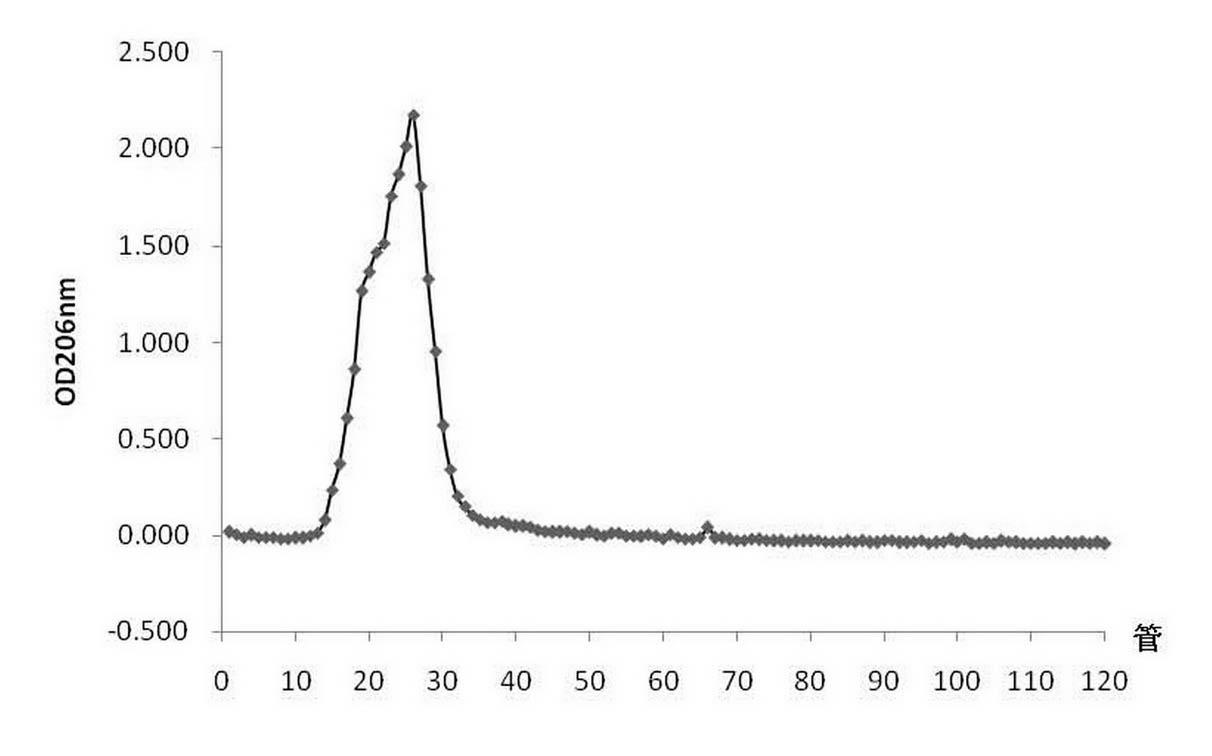

Polypeptide hydrous salt of direct thrombin inhibitor and synthesis method thereof

The invention relates to the field of medicaments, in particular to a polypeptide hydrous salt of a direct thrombin inhibitor and a synthesis method thereof. The invention solves the problems of the prior art including lack of direct thrombin inhibitor polypeptide hydrous salts, difficult synthesis methods and post treatment of compounds of related types, heavy environmental pollution and great harm to human body, and provides a convenient-to-operate and effective polypeptide hydrous salt of a direct thrombin inhibitor and a synthesis method thereof, wherein the general formula of the polypeptide hydrous salt is C98h138N24O33.mXnH2O. The synthesis method adopts coupling single amino acids or peptide fragments. The details of the synthesis method details are described in the description. The method of the invention is simple in operation process, stable in reaction conditions and good in repeatability, allows for automatic synthesis in a synthesizer and allows a whole reaction process to be carried out in one reactor, thereby avoiding product loss caused by the transfer of intermediates and greatly saving labor and materials; and reagents used in the reaction process cause little pollution to environment and little harm to the health of operators.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

Acapsular type staphylococcus aureus extracellular polysaccharide-protein conjugate and preparation method thereof

InactiveCN102120761AEasy to purifyQuality improvementDepsipeptidesPeptide preparation methodsStaphylococcus cohniiADAMTS Proteins

The invention relates to an acapsular type staphylococcus aureus extracellular polysaccharide-protein conjugate and a preparation method thereof. The acapsular type staphylococcus aureus extracellular polysaccharide-protein conjugate is prepared by performing covalent coupling on extracellular polysaccharide of acapsular type staphylococcus aureus and protein under the action of a coupling reagent. The preparation method is an antidiuretic hormone (ADH) bridge method or an l-ethyl-3(3-diaminopropyol)-carbodiimide (EDAC) zero-distance crosslinking method. The preparation of the acapsular type staphylococcus aureus extracellular polysaccharide-protein conjugate provides a strong technical support for development of a vaccine for preventing staphylococcus aureus.

Owner:新疆维吾尔自治区畜牧科学院兽医研究所

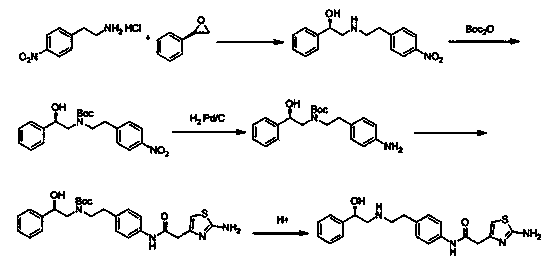

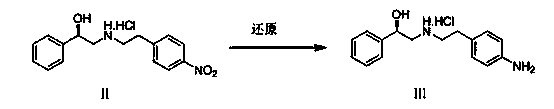

Synthesis method of mirabegron

The invention provides a synthesis method of mirabegron. The synthesis method comprises the following steps: (1) in a tetrahydrofuran solvent and a nitrogen atmosphere, reducing a compound I into a compound II by adopting a reducing agent; (2) in an alcohol solvent and a hydrogen environment, reducing the compound II into a compound III by adopting palladium-on-carbon catalytic hydrogenation; and (3) in a water solvent and under an acidic condition, mixing the compound III with 2-amino-4-thiazole acetic acid, and performing condensation reaction under the action of a condensing agent, to obtain mirabegron. The method has the advantages of being mild in reaction conditions, high in yield and low in cost, and the provided mirabegron is low in the content of impurities, therefore, the synthesis method is suitable for large-scale industrial production.

Owner:安徽联创生物医药股份有限公司

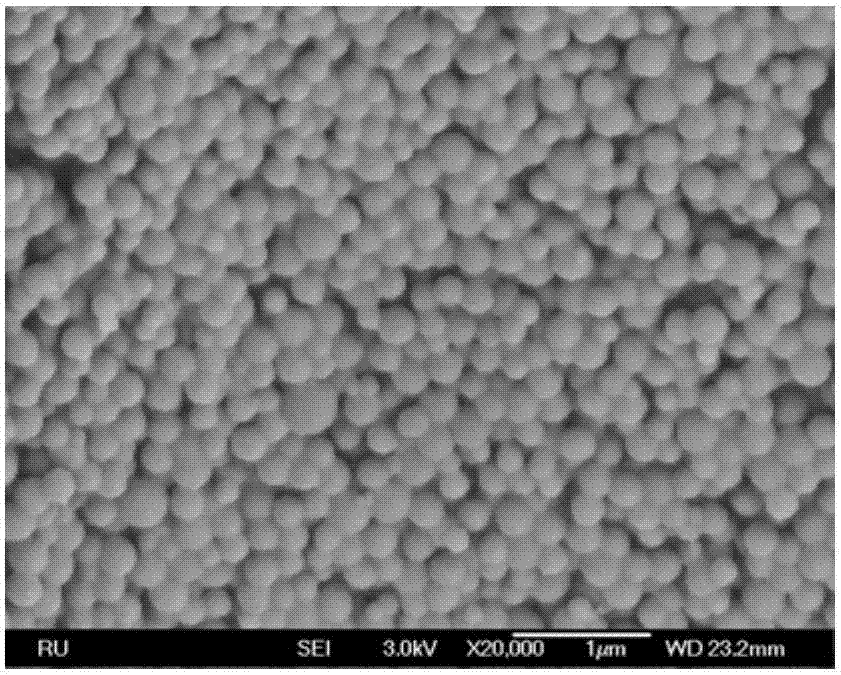

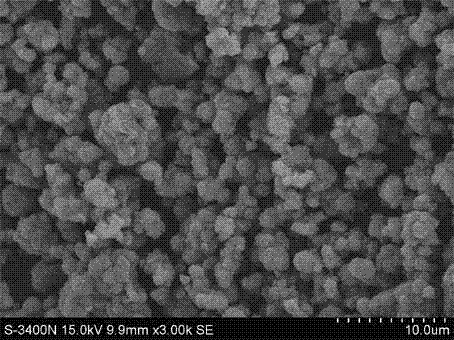

Preparation method of calcium phosphate/gelatin compound material nano particles and application thereof

ActiveCN107412877ARealize one-step preparationBiocompatiblePharmaceutical delivery mechanismTissue regenerationCross-linkCalcium biphosphate

The invention provides a preparation method of calcium phosphate / gelatin compound material nano particles and application thereof. The preparation method comprises, adding phosphate into gelatin aqueous solution to obtain phosphate-gelatin aqueous solution; dissolving calcium salt into polar organic solvent, dropwise adding the solution into the phosphate-gelatin aqueous solution to obtain calcium phosphate / gelatin compound material nano particle suspension liquid; keeping the temperature below 20-90 DEG C, adding cross-linking agent into the suspension liquid for cross-linking, performing repeated centrifugal treatment and resuspension in deionized water on the reaction mixture to obtain the calcium phosphate / gelatin compound material nano particles. The invention first provides the coprecipitation preparation method of the calcium phosphate / gelatin compound material nano particles, achieves one-step preparation of the calcium phosphate / gelatin compound material nano particles and lays foundation for industrial scale production.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

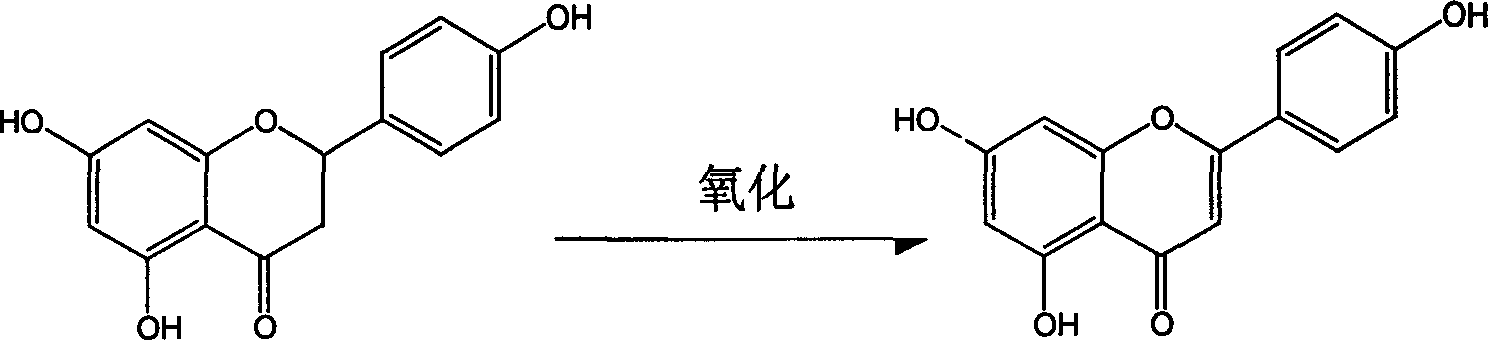

Process for semi-synthesizing of apiolin

The invention discloses a semi compounding method for apium celery element that uses natural extract as basic raw material. It uses pomelo peel element as raw material, 1, 4-dioxy cyclohexane as reaction solvent, taking oxidative dehydrogenation reaction with iodine to form raw apium celery element. Taking multi-steps recrystallizing, the refined apium celery element would be gained. The invention is easy to operate, stable reacting condition, easy to control. The yield would be 60-70% and the purity could be over 97%. And it is low cost, no harmful to the environment.

Owner:ZHEJIANG TIANCAO BIOTECHNOLOGY CO LTD

Continuous preparation method of polyester polyol

The invention relates to a continuous preparation method of polyester polyol. The method comprises three reaction stages including esterification, flash evaporation and polycondensation. The esterification reaction is performed at 130-260 DEG C, preferably, 180-240 DEG C and more preferably, 200-230 DEG C, the esterification rate is about 50%-95%, and the loss of raw material polyhydric alcohols can be reduced when the esterification reaction is performed at the higher temperature. Small molecules such as water and the like can be removed efficiently and quickly through flash evaporation, thereaction speed can be increased, the production time can be saved, and energy consumption can be reduced. A mixture of a catalyst and polyester polyol is fed, catalyst hydrolysis can be effectively reduced in thermodynamics and kinetics in a ligand change manner, and the dosage of the catalyst can be reduced. The polyester polyol produced with the technology has the advantages of low catalyst residues, low color number and stable product quality.

Owner:WANHUA CHEM GRP CO LTD

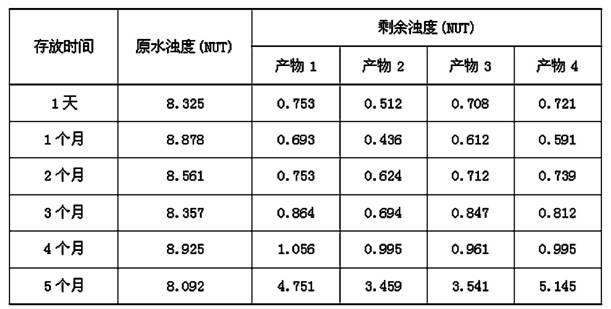

High-effective composite flocculant for treating low-turbidity water and preparation method of high-effective composite flocculant

ActiveCN102502932AGood stabilityReduce dosageWater/sewage treatment by flocculation/precipitationSodium silicateAluminium salts

The invention discloses a high-effective composite flocculant for treating low-turbidity water and a preparation method of the high-effective composite flocculant. The raw materials of the high-effective composite flocculant comprise sodium aluminate, a sodium silicate solution, an aluminum sulfate solution and the like. The preparation method comprises three steps including preparation of a stable sodium aluminate solution, preparation of a polysilicate solution with a low polymerization degree and a polymeric reaction. According to the preparation method disclosed by the invention, when silicic acid is activated, due to the combination of weak acid with strong acid ammonium salt, the polymerization speed of self polymerization of the silictic acid is effectively controlled and stable polysilicate with the low polymerization degree is prepared; and in the subsequent polymeric reaction, the bonding of aluminum with silicon is facilitated, the effective smooth operation of the polymeric reaction is ensured and the obtained inorganic polymer composite flocculant is favorable in stability and low in consumption; and flocculating constituent particles are quick in settling and favorable in reaction effect.

Owner:江门市志升环保科技有限公司

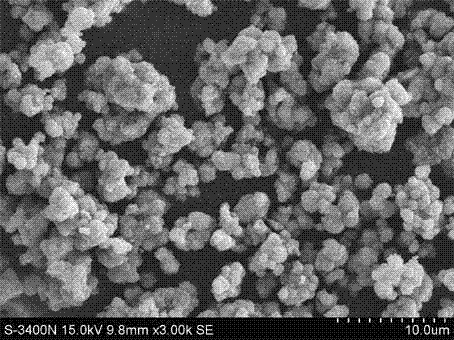

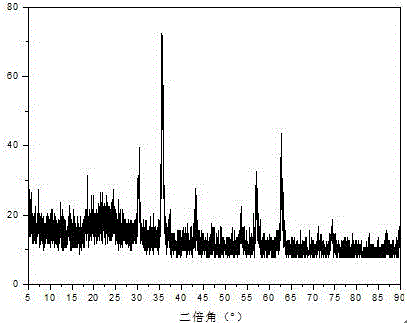

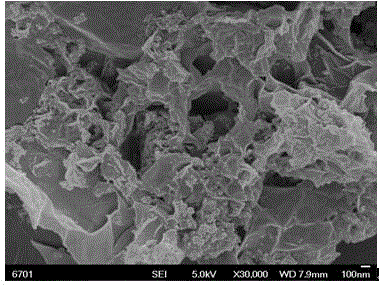

Manganese oxide adsorbent and preparation method thereof

InactiveCN102921371AExtended service lifeFast adsorption rateOther chemical processesProcess efficiency improvementSorbentRoom temperature

The invention discloses a manganese oxide adsorbent and a preparation method thereof. The manganese oxide adsorbent comprises the following components in parts by weight; 100-150 parts of powder containing manganese oxide and 25-30 parts of binding agent, wherein the powder containing manganese oxide is composed of a manganese-containing compound and a lithium-containing compound in a weight ratio of (1:1)-(1:3). The preparation method comprises the steps of: 1, uniformly mixing the manganese-containing compound with the lithium-containing compound, heating to 100-200 DEG C and carrying out temperature preservation for 24-48 hours; 2, cooling the mixture to the room temperature, drying at the temperature of 60-100 DEG C, and then carrying out the temperature preservation for 5-8 hours at the temperature of 400-600 DEG C so as to obtain the powder containing manganese oxide; 3, uniformly mixing 100-150 parts of powder containing manganese oxide in the step 2 with 25-30 parts of binding agent; 4, carrying out extrusion forming or centrifugal forming on the obtained uniform mixture; and 5, dripping the formed material in ethanol or a solution of the ethanol and deionized water to obtain the manganese oxide adsorbent. The manganese oxide adsorbent disclosed by the invention is high in extraction efficiency and long in service life; and the preparation method is easy to implement, convenient, safe and low in energy consumption.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

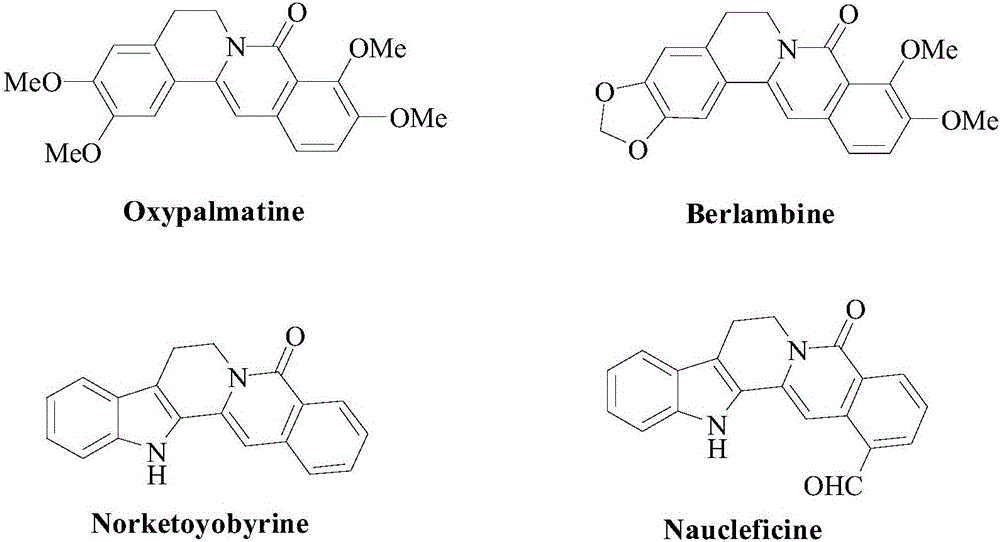

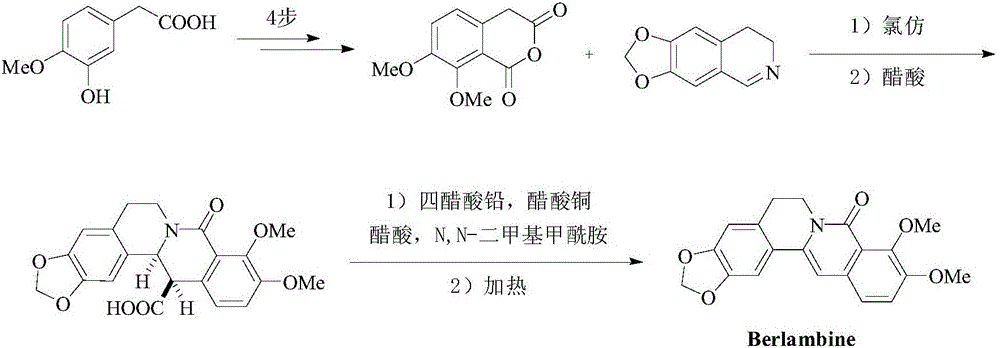

Method for synthesizing 6-6 fused ring structure in berberine and ebony natural product

InactiveCN105801573AEasy to operateReduce manufacturing costOrganic chemistryBulk chemical productionArylBerberine

The invention discloses a method for synthesizing a 6-6 fused ring structure in berberine and ebony natural products. The method comprises the step of carrying out intramolecular tandem cyclization reaction on conjugated enyne ester with a structure shown in a formula II in a solvent, so that the 6-6 fused ring structure shown in a formula I is obtained, a specific reaction formula is described in the specification, wherein R1 and R2 are respectively independently selected from hydrogen, alkyl, naphthenic base, aryl and heterocyclic radical; or R1 and R2 form a saturated or unsaturated carboatomic ring or heterocyclic ring together; R3 and R4 are respectively independently selected from hydrogen, alkyl, naphthenic base, aryl and heterocyclic radical; or R3 and R4 form a saturated or unsaturated carboatomic ring or heterocyclic ring together; R is selected from C1-C4 alkyl; P is an amino-protecting group. The method disclosed by the invention has the advantages of simple operation, safety, environmental friendliness, low production cost, high yield and adaptability to large scale production and has important value in promotion of extensive use of the compound in the filed of medicines.

Owner:EAST CHINA NORMAL UNIV

Process for continuously preparing methyl silicone resin

ActiveCN105111441AAverage molecular weight distributionIncrease the degree of prolapseSolventSilicone resin

The invention relates to a process for manufacturing silicone resin, in particular to a process for continuously preparing methyl silicone resin. The process includes steps of hydrolyzing methyl trichlorosilane, dimethyl dichlorosilane and benzene solvents, to be more specific, mixing the methyl trichlorosilane, the dimethyl dichlorosilane and the benzene solvents with one another according to mass ratios to obtain mixtures, feeding the mixtures into a tubular hydrolysis reactor, filling the reactor with alkyl alcohol and washing water with diluted acid according to mass ratios and enabling the methyl trichlorosilane, the dimethyl dichlorosilane, the benzene solvents, the washing water with the diluted acid and the alkyl alcohol to jointly react to one another so as to obtain hydrolysate; washing the hydrolysate by the aid of water by three or more stages until the hydrolysate is neutral; continuously concentrating the hydrolysate in a vacuum state; carrying out condensation polymerization, to be more specific, adding catalysts into the hydrolysate when the effective content of siloxane reaches 50%-60% of kettle volumes, blowing inert gas into the hydrolysate and carrying out condensation polymerization reaction. The process has the advantages that wastewater discharge can be prevented, difficult problems of high discharge of the traditional washing water with acid, high contents of organic matters and difficulty in treating wastewater can be solved, and the product yield can be increased; the inert gas is blown into the hydrolysate in condensation polymerization procedures, accordingly, the low-molecular-weight removal time can be shortened, and yellowing of products can be prevented; system reaction conditions are stable, and the products are excellent in performance.

Owner:TANGSHAN SANYOU SILICON IND

Method for producing sodium periodate

The invention discloses a method for producing sodium periodate. The method comprises the steps of preparation of trisodium dihydrogen periodate, preparation of sodium periodate, crystallization and separation, centrifugal dehydration and drying, wherein the preparation step of the trisodium dihydrogen periodate sequentially comprises the steps of preparation of sodium hydrogen iodate, preparation of sodium iodate and oxidation with sodium persulfate. The trisodium dihydrogen periodate is obtained by reacting sodium chlorate and iodine in an aqueous solution to produce the sodium hydrogen iodate, neutralizing the sodium hydrogen iodate by using sodium hydroxide to obtain the sodium iodate and oxidizing the sodium iodate in the sodium hydroxide solution by using the sodium persulfate, so that the method for preparing the trisodium dihydrogen periodate by using chlorine, iodine and sodium hydroxide in the prior art is abandoned, and the production method is stable in reaction, easy to control and high in production safety degree. Compared with a chlorine oxidation method, the method has the advantages of low consumption of raw materials, small amount of discharged waste liquor and environment friendliness.

Owner:自贡市金典化工有限公司

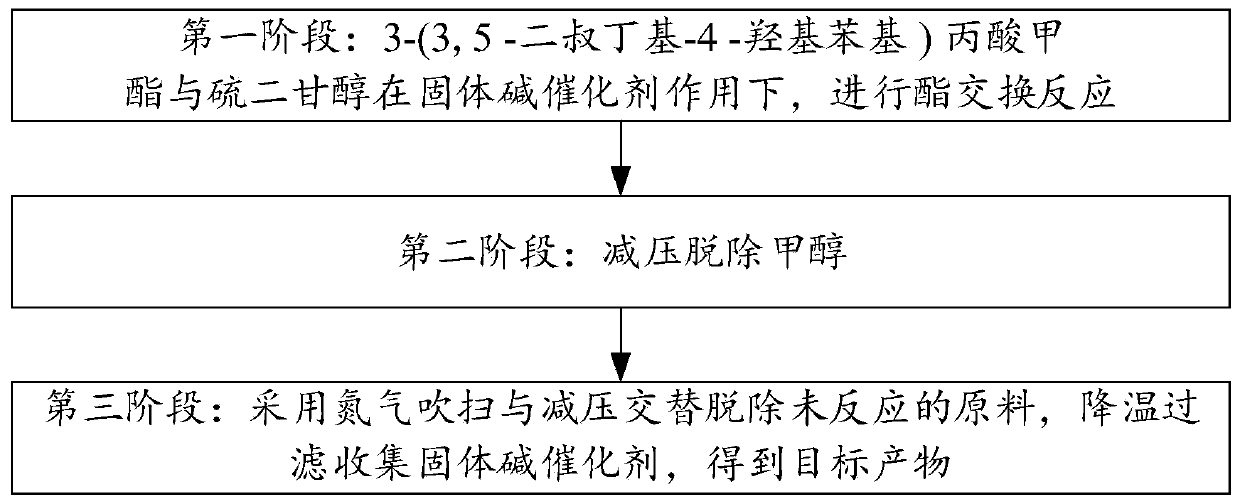

Preparation method of thioether sterically hindered phenol antioxidant

ActiveCN111484432AReduce processingThe synthesis process is simpleOrganic compound preparationSulfide preparationPropanoic acidPtru catalyst

The invention discloses a preparation method of a thioether sterically hindered phenol antioxidant, which comprises the following steps: a first stage: carrying out transesterification on 3-(3, 5-di-tert-butyl-4-hydroxyphenyl) methyl propionate and thiodiglycol under the action of a solid base catalyst; a second stage: removing by-product methanol under reduced pressure; and a third stage, alternately removing unreacted raw materials by nitrogen purging and pressure reduction, cooling, filtering, and collecting the solid base catalyst to obtain the target product. The synthesis process is simple, solvent crystallization purification, drying and other operations do not need to be conducted on a reaction mixture, and the product can be obtained through direct cooling; the production period is short, the later solvent waste liquid treatment is reduced, and the production cost is obviously reduced.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

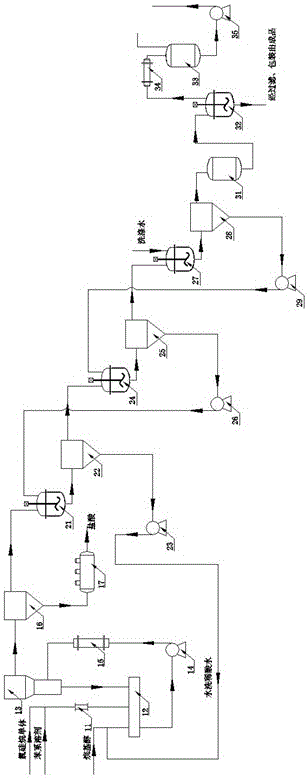

Production process of medicinal phloroglucinol

ActiveCN103012069ARaw materials are easy to getStable reaction conditionsOrganic chemistryOrganic compound preparationHollow fibreChemical industry

The invention discloses a production process of medicinal phloroglucinol, and belongs to the field of medicine chemical industry. The production process comprises the following steps of: uniformly mixing 1,3,5-trimethoxy benzene with concentrated hydrochloric acid, adding phosphoric acid, and adding a catalyst; stirring for 2-4 hours at room temperature; adding in an ice bath, adding Na2CO3 in different batches while stirring; regulating the pH value to 2-3; filtering; extracting a filtrate for three times by methyl tert-butyl ether; combining the extracting liquids; recovering the methyl tert-butyl ether to obtain a yellow solid, namely coarse phloroglucinol; adding proper amount of pure water into the coarse product to dissolve the coarse product; heating to 80 DEG C, stirring to dissolve the coarse product; adding 0.50% of active carbon, preserving the heat for 45minutes; filtering by a filter membrane of 0.45 microns, and filtering a filtrate by a hollow fiber; and cooling the obtained filtrate to room temperature, crystallizing for 4hours, centrifuging, reserving a white crystal substance, and drying the white crystal substance under a vacuum environment to obtain the product. The production process disclosed by the invention is simple in process, low in cost, high in yield being greater than 85% and high in product purity being greater than 99.8%.

Owner:HUNAN ER KANG PHARMA

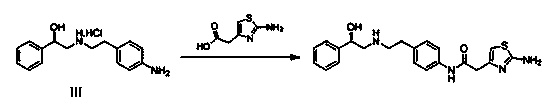

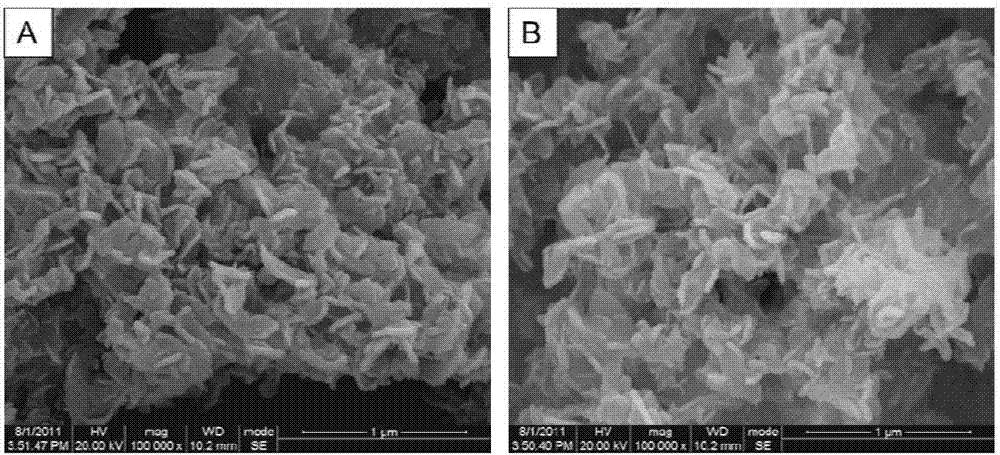

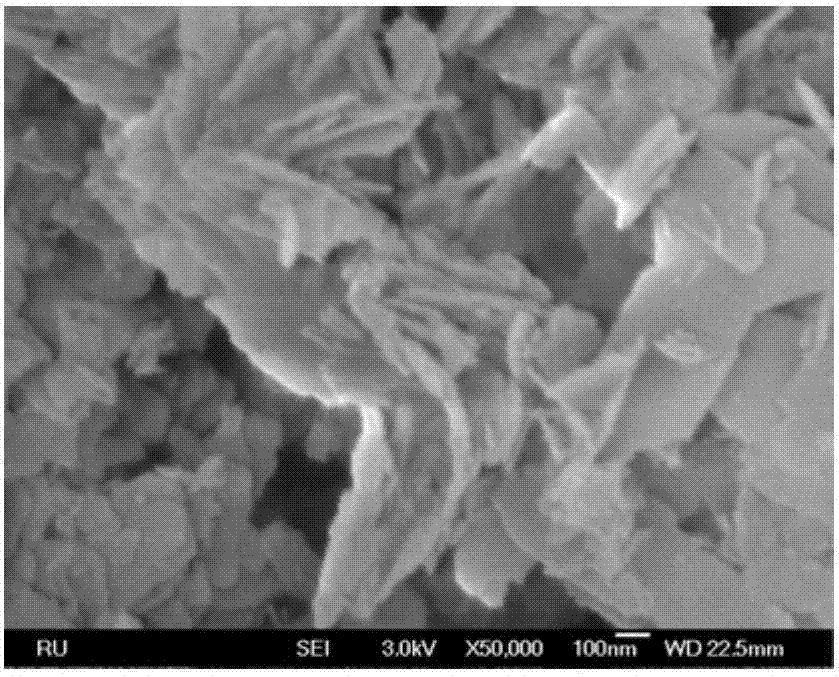

Preparation of magnetic ferroferric oxide/graphene composite material and application thereof in preparing magnetic paint

The invention discloses a preparation method of a magnetic ferroferric oxide / graphene composite material. The method comprises the following steps: ultrasonically dispersing graphite oxide into water to form graphite oxide dispersion liquid, adding ferroferric oxide into the graphite oxide dispersion liquid, and ultrasonically dispersing and uniformly mixing; dropwise adding ammonia water into a mixed system, so that pH of the mixed system is equal to 12 to 13, then adding a hydrazine hydrate solution, and ultrasonically treating for 1 to 2 min; and transferring the system into a reaction kettle, reacting for 10 to 12 h at 160 to 180 DEG C, cooling to the room temperature, washing, and drying to obtain the ferroferric oxide / graphene composite material. By virtue of test, the composite material has good dispersity, so that the composite material can be used for preparing magnetic paint, and further preparing an electromagnetic shielding layer.

Owner:NORTHWEST NORMAL UNIVERSITY

Acylation reaction method for preparing 2-4-(chlorophenyl)-3-methylbutyryl chloride

InactiveCN103193621AStable reaction conditionsHigh yieldOrganic compound preparationCarboxylic compound preparationActivated carbonAcetic acid

The invention discloses an acylation reaction method for preparing 2-4-(chlorophenyl)-3-methylbutyryl chloride. The acylation reaction method comprises the following steps: adding 900-950 parts by weight of 2-4-(chlorophenyl)-3-methylbutyric acid, 10-12 parts by weight of acetic acid and 20-25 parts by weight of activated carbon into a reaction kettle, dripping 510-520 parts by weight of thionyl chloride into the reaction kettle at normal temperature, performing heat release reaction, increasing the temperature to 80 DEG C, then opening the reaction kettle, stirring, performing heat preservation for 6hours after the end of dripping of the thionyl chloride, and press-filtering out the activated carbon and other impurities to obtain a crude product 2-4-(chlorophenyl)-3-methylbutyryl chloride. According to the acylation reaction method, the activated carbon is adopted for heat absorption, so that the smooth reaction conditions can be ensured, the yield is greatly improved, the acetic acid is increased and the stable reaction conditions are ensured so as to be conductive to performing the reaction.

Owner:安徽海顺化工有限公司

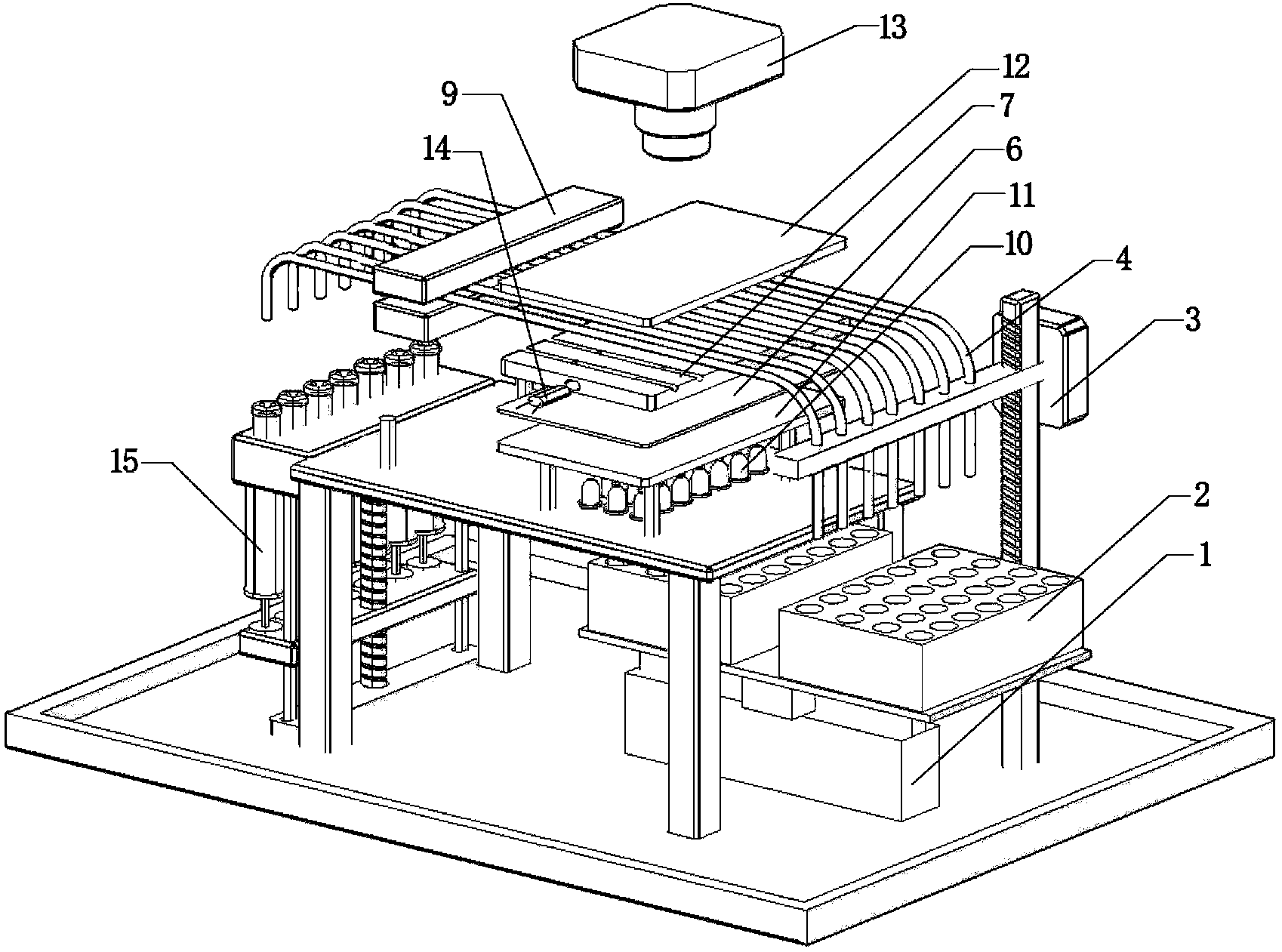

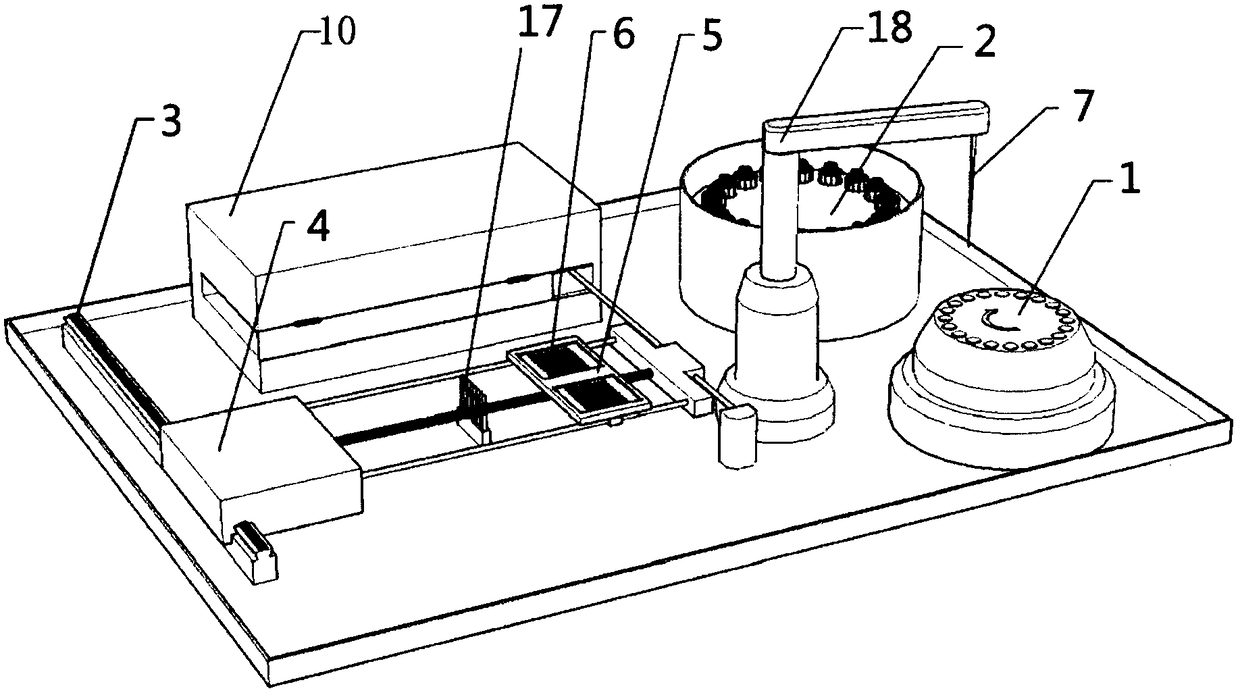

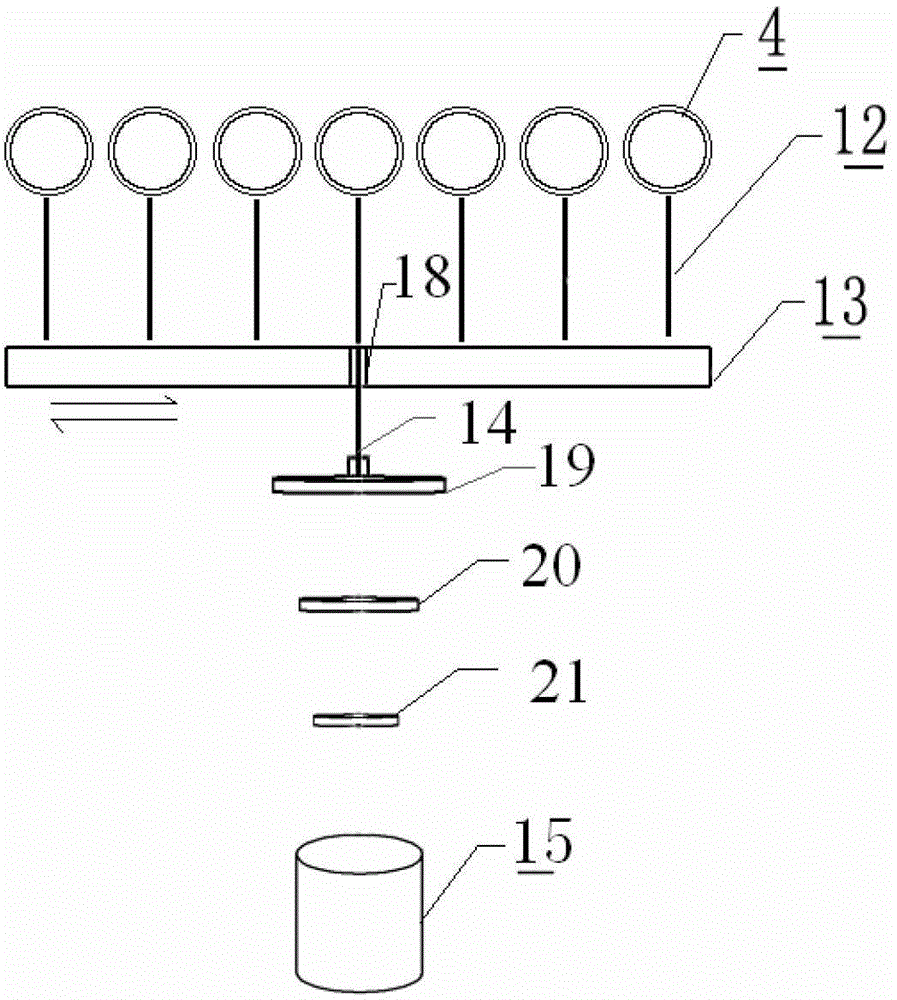

Droplet chip nucleic acid analysis system and analysis method thereof

ActiveCN108823092AFlexible applicationLess reagent consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsBioinformaticsSignal acquisition

The invention relates to a droplet chip nucleic acid analysis system. The droplet chip nucleic acid analysis system comprises a mounting platform as a base mounting plane, a sample carrying bench forcarrying a nucleic acid analysis sample, a reagent carrying bench for carrying a nucleic acid analysis reagent, chip carrier carrying benches for carrying an open chip, a sampling needle that translates between the chip carrying benches, a temperature control module that controls the temperature of a chip, a magnetic control module that performs magnetic bead transferring on the contents of the chip, an optical detection module for performing nucleic acid analysis on the contents in the chip, and a signal acquisition module for performing signal acquisition on the optical detection module, Theoptical detection module is used to detect optical signals in the droplets of the nucleic acid analysis chip. The invention also relates to an analysis method of the droplet chip nucleic acid analysis system. The system has the advantages of small volume, low reagent consumption, flexible operation and fast analysis speed, and belongs to a medical device for biological detection.

Owner:广州市第一人民医院

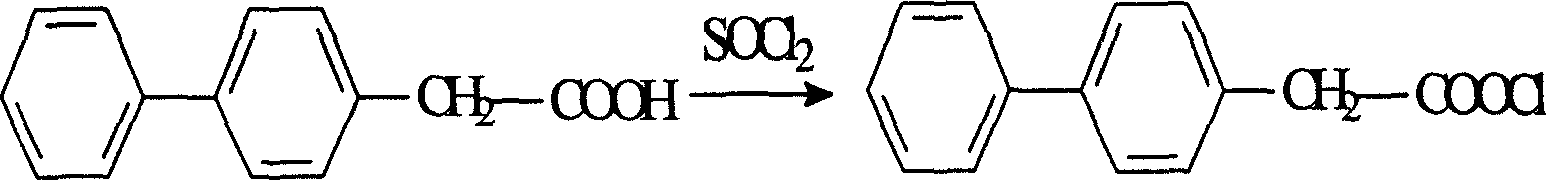

Felbinac acetaminopher ester and its preparation method

InactiveCN1962614ALess irritating to the gastrointestinal tractLess irritatingOrganic active ingredientsAntipyreticAcetyl chlorideActive component

The invention discloses a biphenyl acetate n-acetamido-phenolic ester compound and preparing method with active component as drug composition, which comprises the following steps: adopting biphenyl acetate and thionyl chloride as raw material to prepare biphenyl acetyl chloride; reacting biphenyl acetyl chloride and n-acetamido-phenolic ester to produce rough crystal of product; recrystallizing to obtain the product.

Owner:GUANGDONG ZHONGKE DRUG R&D

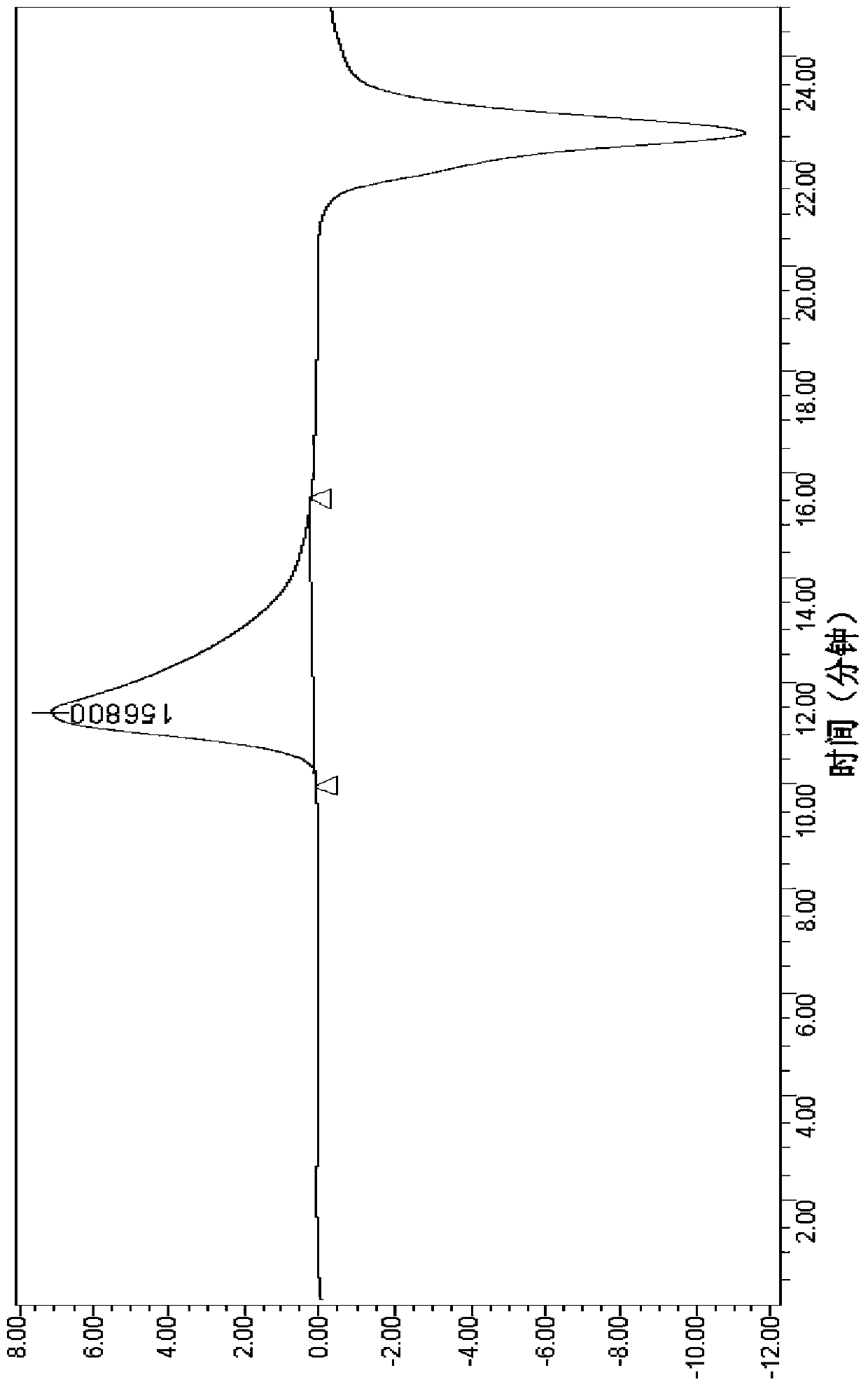

Production process of medicinal potassium citrate

ActiveCN103012115AGood effectRaw materials are easy to getCarboxylic acid salt preparationFiltrationCrystallization

The invention discloses a production process of potassium citrate and belongs to the field of medicine chemical. The preparation method essentially consists of dissolving, column separation, ion substitution, decolorization, filtration and crystallization. The method has the characteristics that raw materials are available, reaction condition is mild, operation is convenient, pollution is little, and the like, and is favorable for the industrial production. Purity of the medicinal potassium citrate produced by the process disclosed by the invention can reach greater than 99% (high performance liquid chromatography (HPLC) method).

Owner:HUNAN ER KANG PHARMA

Polyacrylonitrile copolymer spinning liquid and preparation method thereof

ActiveCN103435747AHigh isotacticityStable Composition Sequence DistributionFibre chemical featuresSpinning solutions preparationItaconic acidAcrylonitrile

The invention relates to a polyacrylonitrile copolymer spinning liquid and a preparation method thereof, wherein the polyacrylonitrile copolymer spinning liquid is high in isotacticity, and the distribution of copolymer units is uniform. According to the preparation method, bifunctional monomer itaconic acid monoester or itaconic acid monoamide is selected, wherein the reactivity ratio of bifunctional monomer itaconic acid monoester or itaconic acid monoamide is close to the reactivity ratio of acrylonitrile; and binary copolymerization is completed in a tubular reactor provided with a static mixer component, so that the isotacticity of acrylonitrile units in the polyacrylonitrile copolymer spinning liquid is increased effectively, formation sequence distribution of the copolymer units in the polyacrylonitrile copolymer spinning liquid is stabilized, and the process of polymerization is controlled smoothly. The isotacticity of the acrylonitrile units in the polyacrylonitrile copolymer spinning liquid is 28 to 35%, dynmaic viscosity is 200 to 800Pa.S, and molecular weight distribution is 1.5 to 2.2.

Owner:中科金绮新材料科技有限公司

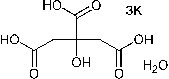

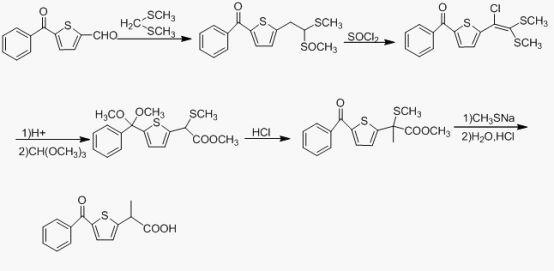

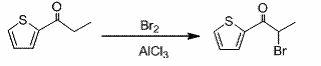

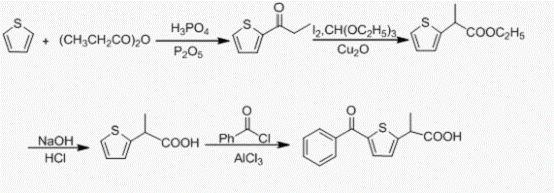

Preparation method of tiaprofenic acid

InactiveCN102659754AStable reaction conditionsHigh yieldOrganic chemistryTiaprofenic acidGlycol synthesis

The invention provides a preparation method of tiaprofenic acid. The method comprises the following steps of: reacting thiofuran serving as a starting raw material with propionic andydride to obtain 2-propionyl thiofuran; reacting the 2-propionyl thiofuran with bromine to obtain alpha bromo on a thiophene ring branch chain; refluxing the obtained bromo compound and ethylene glycol to obtain a bromo-ketal product; rearranging the bromo-ketal product under the action of cuprous oxide serving as a catalyst; performing a Friedel-Crafts reaction on a rearrangement product and benzoyl chloride; and hydrolyzing and acidifying to obtain tiaprofenic acid serving as a target product. The method has stable reaction conditions and high yield; a crude product obtained after reacting has high purity, is easy for purifying and operating, and is low in cost; and used reagents are conventional reagents, so that post-treatment is easy, and convenience is brought to industrial production.

Owner:SOUTHEAST UNIV

Chemiluminescence immunoassay system, as well as method and application thereof

ActiveCN102980996BReduce volumeFast analysisChemiluminescene/bioluminescenceFluid controlEngineering

The invention discloses a chemiluminescence immunoassay system, as well as a method and an application thereof. The chemiluminescence immunoassay system comprises a fluid control unit as well as a three-dimensional motion sample feeding platform, a temperature control unit, a magnetic field control module and an optical detecting module, wherein the three-dimensional motion sample feeding platform, the temperature control unit, the magnetic field control module and the optical detecting module are connected with each other in sequence; and the fluid control unit is connected with the temperature control unit. The chemiluminescence immunoassay system disclosed by the invention has the advantages as follows: with a capillary tube as a reactor, reagent transportation and reaction are both carried out in a water-in-oil type liquid drop by using a capillary tube liquid drop technology, so that a stable reaction condition is kept, and crossed pollution between samples and reaction suppression caused by surface adsorption are effectively avoided. The chemiluminescence immunoassay system disclosed by the invention has the advantages of small size, high assay speed, high testing flux, automatic operation and flexibility in application and is suitable for analyzing single sample, batch samples and field rapid assay; medical demands of the masses can be preferably satisfied; meanwhile, the purchasing and operation cost of equipment is obviously reduced, and excellent social and economic benefits are obtained.

Owner:GUANGDONG HEXIN BIOTECH

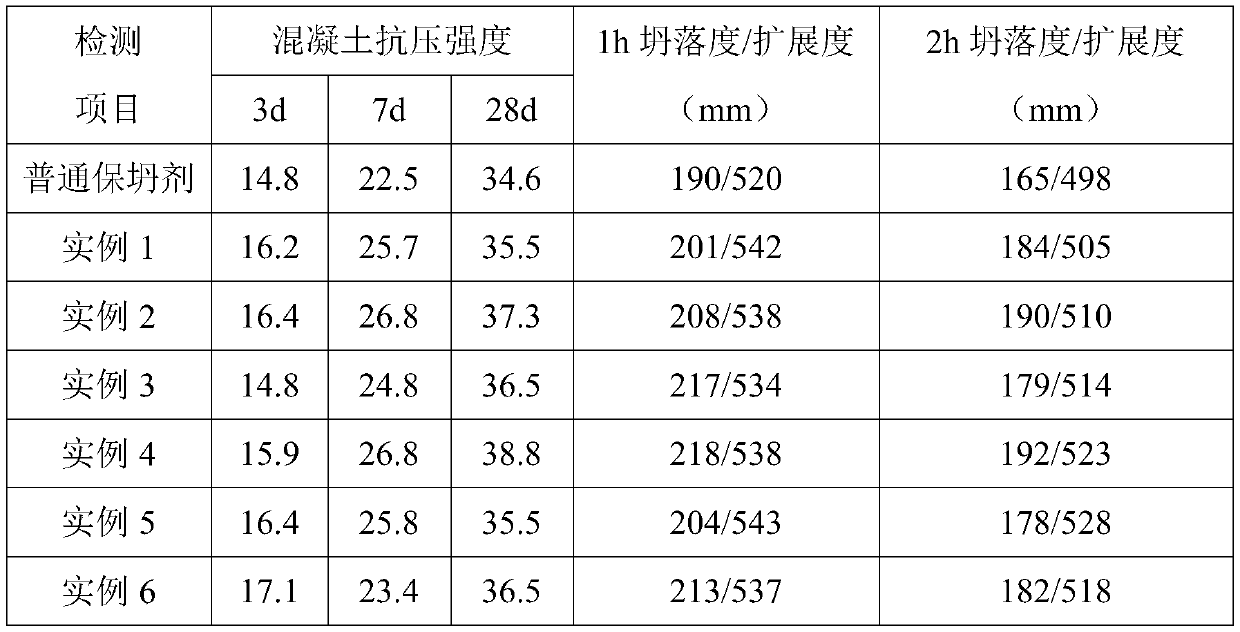

ATRP preparation method for polycarboxylate slump retaining agent based on phenyl-hydroxyl halogenation polymerization

InactiveCN110938183AThe main chain is flexibleImprove water reducing performancePolymer sciencePtru catalyst

The invention discloses an ATRP preparation method for polycarboxylate slump retaining agent based on phenyl-hydroxyl halogenation polymerization. The polycarboxylate water reducing agent is preparedfrom: 345-355 parts of a polyether macromonomer, 20-28 parts of alkyl acrylate, 5-10 parts of a phenyl monomer, 12-18 parts of a hydroxyl monomer, 0.8-1.5 parts of an initiator, 0.6-0.9 parts of a chain transfer agent, 0.8-1.5 parts of a ligand, 0.02-0.1 parts of a catalyst, and the balance being water. The preparation method comprises: performing free radical polymerization on the phenyl monomer,the hydroxyl monomer, the initiator and the chain transfer agent at 60-70 DEG C, then performing heat preservation for 1 h after the reaction is finished and feeding nitrogen gas for 5 min, then feeding chlorine gas for halogenation under light to obtain a halogenated polymer (I); then placing the polyether macromonomer, the alkyl acrylate, 0.8-1.5 parts of the ligand and 0.02-0.1 parts of the catalyst on the bottom of the 2# reaction kettle, dropwise adding the halogenated polymer (I) into the 2# reaction kettle with temperature controlled at 40-50 DEG C, and performing heat preservation for1 h after the dropwise addition is finished, thus obtaining the polycarboxylate slump retaining agent after the reaction is completed. The molecular mass distribution of the polycarboxylate slump retaining agent is narrow, effective component content is high and slump retaining capability is excellent.

Owner:HUBEI UNIV OF TECH

Composite flocculant for treating low-temperature and low-turbidity water and preparation method thereof

ActiveCN104591410ALow costLess aluminum residueWater treatment compoundsBiological water/sewage treatmentChemistryCalcium hydroxide

The invention provides a composite flocculant for treating low-temperature and low-turbidity water. The composite flocculant consists of the following components in percentage by mass: 1.10-7.89 percent of biological flocculant dry powder, 15.87-60.61 percent of polyaluminum ferric chloride and 36.76-81.97 percent of calcium hydroxide. The flocculant provided by the invention is good in product stability, stable in reaction conditions and easy in control, is stabilized for at least more than 12 mouths and is suitable for industrial production and practical water plant application. The flocculant provided by the invention has the characteristics of good product stability, less consumption, reduced cost, good flocculation effect, high treatment efficiency, small sludge output and the like and can be widely suitable for the field of feed water treatment and other water treatment fields.

Owner:北京长兴泰华科技发展有限公司

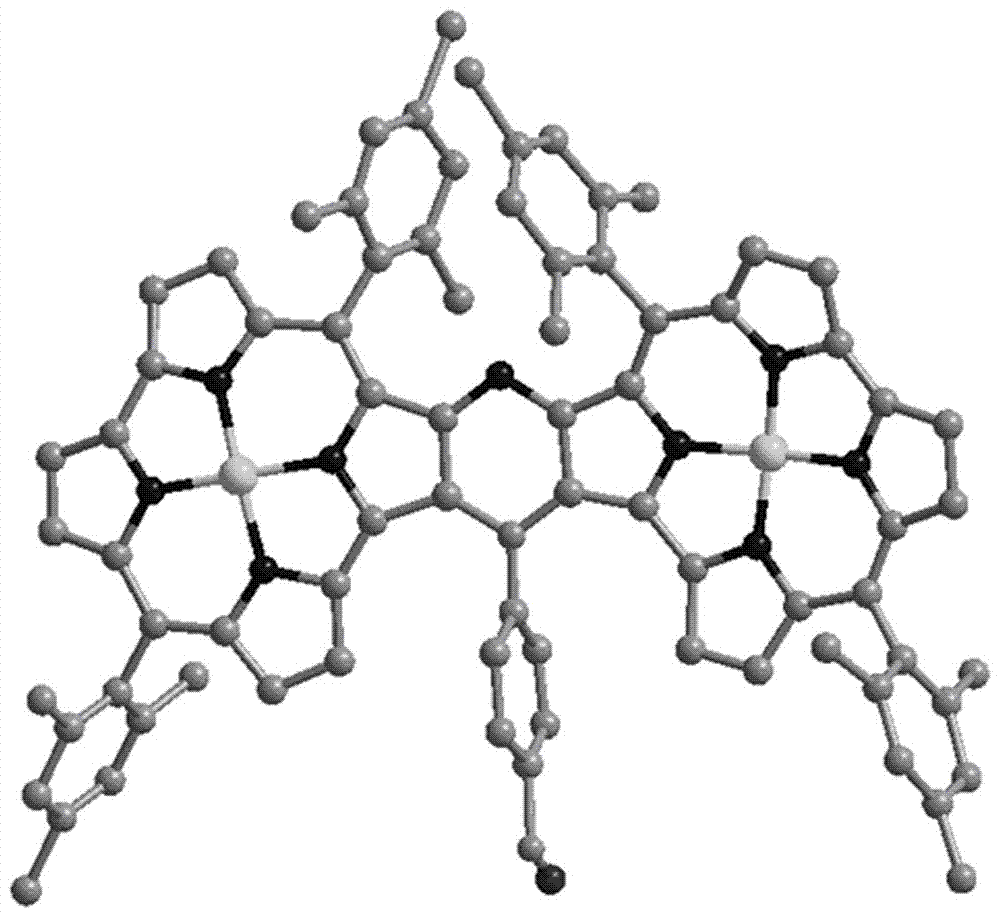

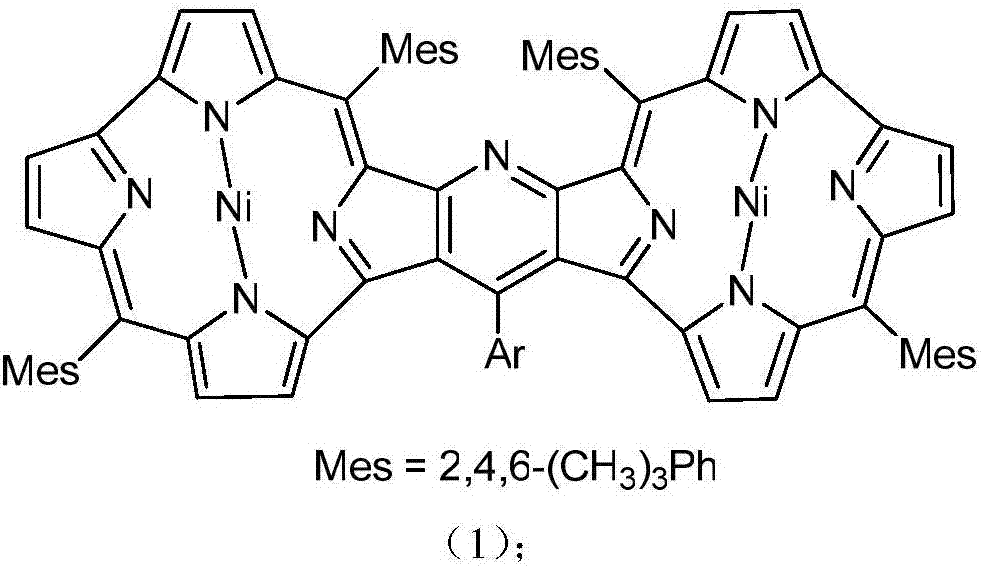

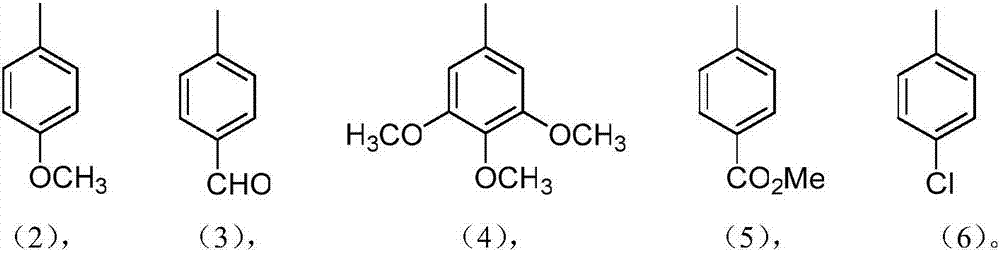

Pyridine fused norcorrole compound and preparation method thereof

The invention discloses a pyridine fused norcorrole compound and a preparation method thereof. The pyridine fused norcorrole compound has a structural formula as shown in formula (1). The preparation method mainly comprises the following steps: weighing a certain amount of amido norcorrole and aromatic aldehyde, putting into a reactor, adding newly steamed toluene solution to the reactor, stirring at 110 DEG C for 5-8 h, and tracking the reaction by a chromatographic method; cooling to room temperature after the reaction is completed, separating directly with a chromatography column, eluting with methylene chloride and normal hexane as eluents, collecting second brown color product as a crude product, and concentrating and drying the crude product to obtain the compound. The pyridine fused norcorrole compound and the preparation method thereof have the following advantages: the reaction conditions are stable, the yield is high, the operation is simple and safe, and batch production can be realized.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com